Modern

ART

explored

...p3

Tackling

TDR

theory

...p4 - 5

Power

problems?

Try mice!

p8

Published by Megger

April 2014

ELECTRICAL

TESTER

Moisture measurement

The industry’s recognised information tool

analysis will produce an exaggerated error in

the moisture-in-insulation result.

else. Note that, without the temperature, no

calculations can be done to determine the

moisture in paper or relative saturation. The

only information you will have is that the oil

has moisture in it!

Tom Dalton - Business unit manager:

power transformers, Martec, South Africa

Introduction

It is well documented that moisture in a

mineral oil cooled and insulated power

transformer has detrimental effects. In fact,

it is said that doubling the moisture content

in the transformer will have the effect of

approximately halving the life of the unit.

Thus the transformer will deliver only half the

expected return on investment and its reliability

will be impacted earlier in its life. This article

looks at some of the methods of determining

the amount of moisture that will affect the

operation of the unit and the subsequent

management of the oil and paper systems.

Moisture effects in an operating

transformer

When a transformer is delivered to a client the

insulation should be dried to around 0.5% (by dry

weight). During the operation of a transformer

there are a number of factors that will influence

the gradual production and contamination of

the system. Moisture has a profound effect on

mineral oil, and will cause the dielectric strength

of the fluid to drop considerably.

First, atmospheric moisture will have an impact,

especially in units that are open breathing

(breathe to atmosphere via a breather filled

with a desiccant). If the desiccant is not

maintained correctly, the oil will absorb

moisture from the atmosphere as the

transformer temperature cycles. The hotter the

oil, the more moisture it will absorb.

Second, whether transformers are open

breathers or sealed units (sealed meaning

that the unit does not breathe to atmosphere

directly), paper degradation by-products and

natural gassing of transformer oil will produce

moisture in small quantities (approximately

0.5 – 1 ppm per year). Note that transformers

that do not use paper-based insulating material

are less susceptible to this phenomenon, but

the natural gassing of the oil will still produce

small amounts of moisture. Coming back to

the breakdown by-products of paper, an OH

molecule is given off when the cellulose chain

www.megger.com

is severed by heat and electrical stress. With

most insulating fluids some hydrogen is given

off during normal operation and even greater

quantities are produced under overload and

fault conditions.

From an insulating fluid perspective: as most

insulating fluids are hydrocarbon based, small

amounts of hydrogen are given off during

operation. This combines with the ever-present

oxygen (a natural marriage) to form H2O –

moisture.

With more moisture in the system, temperature

cycling brings further destruction and thus

the deterioration increases over time. Without

intervention, the life of the transformer will be

severely impacted.

Monitoring

As a transformer operates, moisture will

move from the insulation body (thin and thick

insulation) into the oil as it heats and will move

back to the insulation from the oil as it cools.

This phenomenon is called equilibrium. If the

transformer loading and ambient temperature

were to remain constant for a long period of

time, eventually moisture movement would

cease and a state of equilibrium would be

reached. The insulation system will always

seek to obtain an equilibrium state, but

with constant load changes and ambient

temperature fluctuations, this hardly ever

occurs in real life. This is also very difficult

to predict as different parts of the system

(both oil and solid insulation) are at different

temperatures. Thus equilibrium is merely an

assumption of where the moisture may be at a

specific point in time or temperature.

To add to the dilemma, thin and thick insulation

will give off moisture at different rates (diffusion

rates). With thin insulation (mainly paper)

the transfer is quick, but with thick insulation

(blocking) it is much slower (diffusion rate is

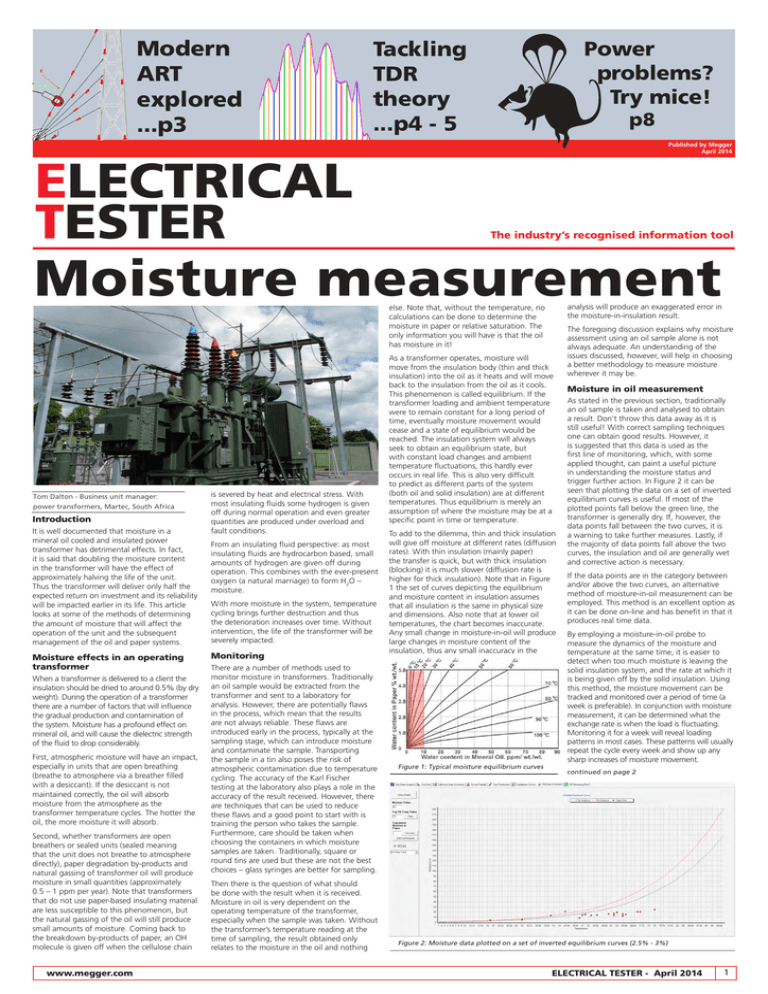

higher for thick insulation). Note that in Figure

1 the set of curves depicting the equilibrium

and moisture content in insulation assumes

that all insulation is the same in physical size

and dimensions. Also note that at lower oil

temperatures, the chart becomes inaccurate.

Any small change in moisture-in-oil will produce

large changes in moisture content of the

insulation, thus any small inaccuracy in the

There are a number of methods used to

monitor moisture in transformers. Traditionally

an oil sample would be extracted from the

transformer and sent to a laboratory for

analysis. However, there are potentially flaws

in the process, which mean that the results

are not always reliable. These flaws are

introduced early in the process, typically at the

sampling stage, which can introduce moisture

and contaminate the sample. Transporting

the sample in a tin also poses the risk of

atmospheric contamination due to temperature

cycling. The accuracy of the Karl Fischer

testing at the laboratory also plays a role in the

accuracy of the result received. However, there

are techniques that can be used to reduce

these flaws and a good point to start with is

training the person who takes the sample.

Furthermore, care should be taken when

choosing the containers in which moisture

samples are taken. Traditionally, square or

round tins are used but these are not the best

choices – glass syringes are better for sampling.

Then there is the question of what should

be done with the result when it is received.

Moisture in oil is very dependent on the

operating temperature of the transformer,

especially when the sample was taken. Without

the transformer’s temperature reading at the

time of sampling, the result obtained only

relates to the moisture in the oil and nothing

Figure 1: Typical moisture equilibrium curves

The foregoing discussion explains why moisture

assessment using an oil sample alone is not

always adequate. An understanding of the

issues discussed, however, will help in choosing

a better methodology to measure moisture

wherever it may be.

Moisture in oil measurement

As stated in the previous section, traditionally

an oil sample is taken and analysed to obtain

a result. Don’t throw this data away as it is

still useful! With correct sampling techniques

one can obtain good results. However, it

is suggested that this data is used as the

first line of monitoring, which, with some

applied thought, can paint a useful picture

in understanding the moisture status and

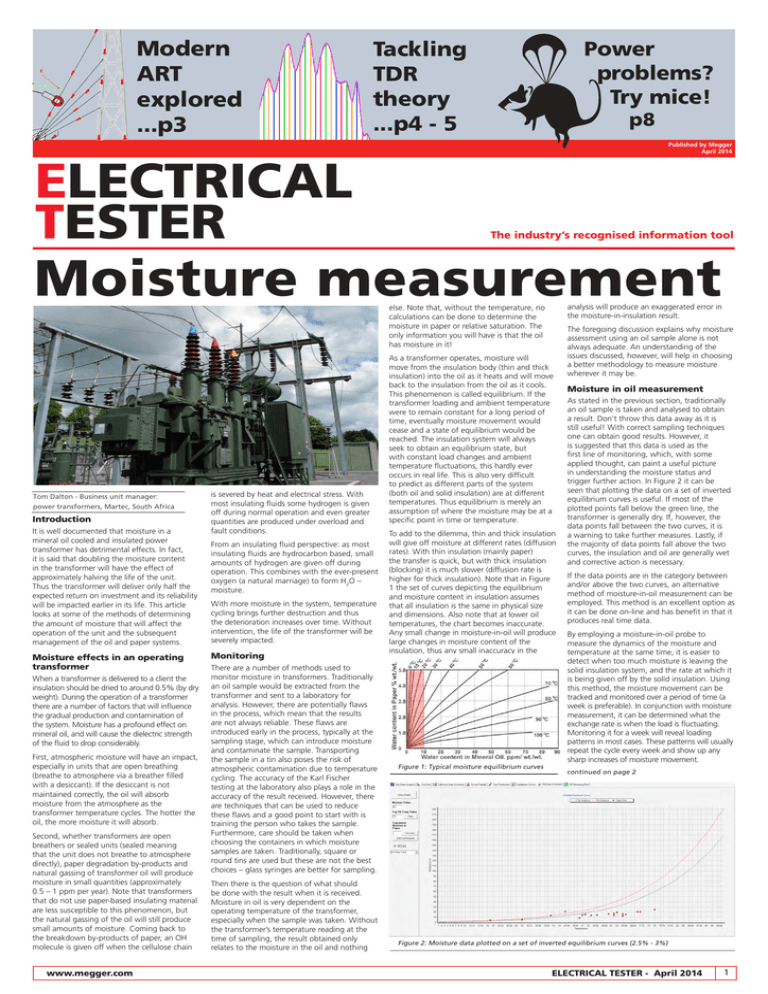

trigger further action. In Figure 2 it can be

seen that plotting the data on a set of inverted

equilibrium curves is useful. If most of the

plotted points fall below the green line, the

transformer is generally dry. If, however, the

data points fall between the two curves, it is

a warning to take further measures. Lastly, if

the majority of data points fall above the two

curves, the insulation and oil are generally wet

and corrective action is necessary.

If the data points are in the category between

and/or above the two curves, an alternative

method of moisture-in-oil measurement can be

employed. This method is an excellent option as

it can be done on-line and has benefit in that it

produces real time data.

By employing a moisture-in-oil probe to

measure the dynamics of the moisture and

temperature at the same time, it is easier to

detect when too much moisture is leaving the

solid insulation system, and the rate at which it

is being given off by the solid insulation. Using

this method, the moisture movement can be

tracked and monitored over a period of time (a

week is preferable). In conjunction with moisture

measurement, it can be determined what the

exchange rate is when the load is fluctuating.

Monitoring it for a week will reveal loading

patterns in most cases. These patterns will usually

repeat the cycle every week and show up any

sharp increases of moisture movement.

continued on page 2

Figure 2: Moisture data plotted on a set of inverted equilibrium curves (2.5% - 3%)

ELECTRICAL TESTER - April 2014

1

ELECTRICAL

TESTER

The industry’s recognised information tool

Contents

Moisture measurement.......................... P1-3

Tom Dalton - Business unit manager: power

transformers, Martec, South Africa

ART - Attached Rod Techniques .............P3

Paul Swinerd - Product portfolio

manager - Power

Time Domain Reflectometers

- the physical basics....................................P4

Peter Herpertz - Product manager - power,

SebaKMT

TDR fault finding: cable fault basics....P5

Peter Dennis - Product manager communications

When reflection isn’t the answer............P6

Peter Herpertz - Product manager,

power, SebaKMT

University at Buffalo

collaboration brings benefits for all.....P6

Casey Henry, marketing program manager

Putting cables to the test...... ...................P7

Clive Pink - Product manager

Timely testing helps restore

power to 200,000 .......................................P7

Erik Blichfeld - Produktchef, SebaKMT A/S

Q&A...................................................................P8

The stability factor......................................P8

Damon Mount - power sales manager

Power problems? Bring on the mice!....P8

Ted Kim, Regional sales manager, North Asia

continued from page 1

Note that the probe’s location and oil flow are

extremely important. The probe must be placed

in a location that has rapid oil flow or at least

a steady flow over the probe tip. Normally it

would be placed in the cooling system (inlet to

or outlet from the cooler bank) or in pumped oil

flow. Another location is in the flow of the online gas-in-oil monitor. The bottom main tank

sampling point is not always the best location

as there is little movement over the tip of the

probe and in this case the measurement would

merely measure the oil close to the probe tip.

One of the outstanding benefits of this method

is the rate of change. This is an important

factor and especially important if rapid changes

in load and/or temperature are occurring. Too

much moisture in the system with rapid load

changes can cause detrimental conditions

leading to disastrous results. With rapid load

growth and wet insulation, there is a dynamic

that leads to insulation failure very quickly.

The transformer is cold and the oil is cold, with

the moisture predominantly embedded in the

solid insulation. Sudden high loading will drive

moisture out of the solid insulation rapidly and

the oil, not being able to absorb the now free

moisture, will have a low dielectric strength

zone where the moisture cannot be moved

away (high saturation zone). A characteristic of

oil is that at low temperature it is not capable

of absorbing the quantity of moisture being

driven out of the paper and will only be able

to do so once a higher temperature is reached.

In an operating transformer, the volume of oil

takes time to reach higher temperature. (Like

a kettle put on to boil, there will be aggressive

heating of the moisture near the element but

water has not yet boiled – it takes time.) This

creates a very low dielectric strength in areas

where there is insufficient oil flow (see Figure

3). To add to the problem, when oil is cold

the viscosity is higher (thicker) and the oil is

then sluggish and does not flush the moisture

away. This set of conditions can often lead to

insulation system break down and flashover.

When you have finished with

this magazine please recycle it.

The rights of the individuals attributed in Electrical Tester to

be identified as authors of their respective articles has been

asserted by them in accordance with the Copyright, Designs

and Patents Act 1988. © Copyright Megger. All rights reserved.

No part of Electrical Tester may be reproduced in a retrieval

system, or transmitted in any form or by any means, electronic,

mechanical, photo-copying, recording or otherwise without the

Figure 3: Moisture in highly loaded transformers

prior written permission of Megger.

To request a licence to use an article in Electrical Tester, please

email electricaltester@Megger.com, with a brief outline of the

reasons for your request.

All trademarks used herein are the property of their respective

owners. The use of any trademark in this text does not imply

trademark ownership rights in such trademarks, nor does use

of such trademarks imply any affiliation with or endorsement of

Electrical Tester by such owners.

A printed newsletter is not as interactive as its email equivalent

so to help you find items quickly on www.megger.com, we have

underlined key search words in blue.

Note from the Editor - Time for your say.

We have introduced a ‘Questions and Answers’ section and

would like your input. If you have any questions or stories that

you think we could use, then please email

electricaltester@megger.com

‘Views expressed in Electrical Tester are not necessarily

the views of Megger.’

The word ‘Megger’ is a registered trademark

Editor Nick Hilditch.

T +44 (0)1304 502232

E nick.hilditch@megger.com

Megger Limited

Archcliffe Road Dover Kent CT17 9EN

T +44 (0)1304 502100

E electricaltester@megger.com

www.megger.com

2

Most on-line dissolved gas analysers have

moisture detection built in and will measure

moisture along with the gases, however it is

important that a temperature-in-oil probe is fitted

and the temperature monitored along with the

moisture. From this data a very good idea of the

relative saturation can be calculated and this

parameter will be most useful in determining the

state of the transformer in terms of moisture.

Using moisture in oil measurement to determine

moisture in cellulose is a tricky business as the

equilibrium plays a major role and because

different parts of the transformer are at

different temperatures and states of equilibrium.

In most cases a set of equilibrium curves are

used to determine the amount of moisture in

paper. There are a few technical papers that

attempt to evaluate the mechanism, but there is

still much doubt as to their accuracy.

Moisture in paper measurement

Moisture in cellulose is a difficult parameter to

measure. There are two main methods to determine

this and the results are not always reliable.

First, taking a paper sample means that the

unit must be out of service. Either a hatch on

the transformer has to be opened and some

paper (or board) removed from the unit, or

the unit must be transferred to a workshop

environment where it is easier to access

paper and board. However, in both cases it

is necessary to contend with atmospheric

ELECTRICAL TESTER - April 2014

lumped together by connecting all the HV

terminals (all phases), together, all the LV

terminals (all phases) together and all the

tertiary terminals (all phases) together, to

produce three entities. Typically three tests

conditions that will influence the outcome

of the analysis. It takes a skilled technician to

perform this type of test, and he/she needs to

ensure that the location where the insulation

was removed is restored. Furthermore, the

sample has to be handled extremely carefully.

Any outside influences, such as atmospheric

conditions and poor handling will contaminate

the sample and render it useless, giving

incorrect results. Temperature and relative

humidity at the time of taking the sample will

have a significant impact.

The insulation’s diffusion rate plays a key role

in the transfer of moisture between insulation

and oil. Larger blocking or thick insulation is

not as badly affected and good results can be

obtained if it is handled correctly. Larger blocks

of insulation are normally affected by surface

moisture, e.g. between 1 – 1.5 mm deep.

Deeper moisture is locked in and will take

much effort to release, ie longer periods of

high temperature and vacuum.

Using this method of moisture determination

outside of a controlled environment is

challenging at the best of times. There are too

many obstacles to make this a cost-effective

way of measuring moisture.

Figure 4: Data obtained from a FDS test showing

how the different parameters affect the curve

– CHL, CL and CH – are performed on the

transformer. The CHL measurement is preferred

for moisture and oil assessment.

Moisture in air measurement

In this method of measurement there are

again some questions as to the accuracy of

the results. This method can only be used to

determine the moisture in air, and to some

degree moisture in insulation. Here again, there

is the question of equilibrium state and, as

mentioned above, there is still some doubt as

to when all the components in a transformer

are in equilibrium.

To perform this measurement the transformer

must have all the oil drained out, so the

measurement cannot be performed online.

This technique is normally used during

manufacture and repair either in a workshop

or on site. The unit is filled with extremely

dry air and left to stand for at least 48 hours

with as little temperature variation as possible.

It is important to ask if the insulation is “oil

impregnated” or “dry” as these parameters

will have a significant effect on the results. Dry

paper has the ability to transfer moisture far

quicker than oil impregnated paper.

A dew point probe of high accuracy is needed

and it must be installed in such a way that it

has air flowing over the tip. The transformer

tank must be pressurised with dry air (dew

point temperature below -50° C) to greater

than atmospheric air pressure (typically 25

kpa) and left to stand for a least 48 hours.

The duration of the measurement should

be between 10 – 15 minutes and the data

logged over that time period. Note that if the

technician performing the test touches the

probe with his/her fingers the initial reading

will be significantly higher until that moisture

has dissipated. If this happens the test duration

should be lengthened. Once the data has been

captured, the initial data should be discarded

and ideally the flatter section of the data taken

and averaged. The averaged data must then be

applied to the “Pipers” chart and the moisture

in paper read off the chart.

Figure 5: Typical measurement connection

Depending on the instrument, the test will

vary the frequency between 1000 Hz down to

about 0.001 Hz (the preferred frequency range

depends on the insulation temperature and

can be set by the test technician). Once the

tests are completed the data set measured is

modelled against a predefined set of curves and

the closest curve is matched to the data. From

the modelling performed, the instrument will

give an accurate determination of not only the

moisture in insulation but also moisture in oil ie

system moisture. Figure 6 shows typical curves

measured and the various observations made.

Figure 6: Typical traces for varying conditions

FDS can be used in dry air (no oil in the

transformer tank) and with oil filled

transformers, making it a very useful tool in

both field and workshop applications.

This method gives an indication of surface

moisture, but there is still doubt about its accuracy

for determining the total amount of moisture in

the transformer insulation and there are better

means of determining moisture in paper.

System approach

The system approach is far more refined

and uses an electrical means to measure

the “system” rather than trying to measure

one of the components (either oil or air)

and calculating the resultant moisture. This

method is finding greater acceptance and is

improving as the technology matures and gains

momentum. Frequency Domain Spectroscopy

(FDS) or variable frequency dissipation factor

measurement (tan delta) takes both oil and solid

insulation into consideration. The instrument

uses the data measured (dielectric dissipation

factor or tan Δ) and models this to a known

curve, which then equates to moisture in oil and

moisture in insulation. That is, it takes the whole

insulating system into consideration.

This measurement cannot be done on line and

the transformer will need to be disconnected

from the network. The windings are normally

Figure 7: Typical moisture analysis performed

with modelling

Management

Many people ask how much moisture should

be allowed or is good practice. To answer this

question three categories of transformer need

to be considered:

New

In repair process

In service

www.megger.com

ELECTRICAL

TESTER

The industry’s recognised information tool

A new transformer should be dried to a value of

0.5% or below.

A point to remember is that there is a tradeoff, because to dry the unit to very low values

takes a number of cycles to dry the windings.

Depending on the methods and technique,

these drying cycles have a tendency to lower

the degree of polymerisation (the shortening

of fibres in the insulation material) and thus

shorten the life of the unit’s insulation. Also

some manufacturers oil impregnate the

windings early in the process and thus it is more

difficult to remove moisture in the drying cycle,

but this works both ways as the insulation will

not absorb moisture as readily. However, left

un-impregnated the insulation will get wetter

quicker and it will take longer to remove the

moisture. Careful monitoring of air condition in

the manufacturing plant is necessary to prevent

the cellulose-based windings from absorbing

moisture. With the FDS technique, both oilfilled and non-filled units can now be tested

after tanking.

It is suggested that FDS measurements are

made prior to testing the transformer in the

manufacturing plant, on arrival at site, and prior

to energising.

Transformers that have been repaired should

be dried to between 0.8 – 1.2%, but these

values will depend on the wetness of the unit

prior to being repaired. Note that the degree

of polymerisation plays a major role in this

decision. If the degree of polymerisation is

found to be low, the dry-out may damage the

insulation to the point of no return. Multiple

drying cycles will deplete the paper life, since

the more heat applied, the greater will be the

ageing effect on the cellulose. If the cellulose’s

degree of polymerisation is already low then

drying to an unnecessarily low value will only

cause further loss of life!

It is suggested that the unit should be tested

prior to and after repairs, and also prior to

energising.

Transformers in service should typically be < 2%

for large units (e.g. 100 MVA and above) and <

2.5% for smaller units.

Good maintenance practice is to test the

transformer every 2 to 5 years with the FDS

method but as stated, retain the moisture-in-oil

data to keep your finger on the pulse.

In summary

Keeping transformers dry is the preferred

practice. To do this, a molecular sieve or other

on-line drying technology can be deployed for

continuous drying of the oil and solid insulation

system, thus avoiding the need for major dry

outs when the unit is found to be wet.

Measuring moisture in an operating transformer

is not practical without the oil temperature

being taken along with the sample. However,

for reliable results it is best to have a trained

sampler to take the sample from the

transformer using the correct techniques and

equipment, and transporting the sample reliably

to the laboratory. Oil sampling is still a good

first line defence, but follow up measurements

must be made if the transformer shows signs of

undue moisture increases that are unrelated to

variations resulting from the sample process.

The other methods that are mentioned in this

article are second tier methods and are used

to gather further and more detailed condition

information. However, in many cases these

methods have their own limitations. A good

solution is the frequency domain spectroscopy

technique which has made this uncertainty

a thing of the past. Spectroscopy and data

modelling offer clear advantages in modern

science and laboratory practice, and now FDS

has brought this modern laboratory technology

into the field, complemented by well-proven

modelling techniques that provide very specific

decision support for the user.

Different asset owners have different priorities

for the operation and maintenance of

transformers. Some, for example, focus on

optimisation and return on investment rather

than reliability, whereas for others reliability

is paramount. In reality, however, a balanced

approach is best.

In closing, it is always worth remembering that

a wet transformer is an unreliable transformer.

www.megger.com

ART - Attached Rod Technique

in earth / ground testing

Figure 3: Example of Earth coupling

as a result of overlapping spheres of influence

to the building. As a result, the sphere of

influence of the electrode and that of the

building overlap. In effect, “earth coupling” is

occurring and this changes the

equivalent circuit.

The overlapping of the spheres of influence

introduces additional impedances that make

resolving the resistance of the electrode difficult

using ART. The most likely result will be either a

“clamp low” warning or an unexpectedly high

electrode resistance reading. In cases like this,

the traditional three-pole test method should be

used, with the electrode under test disconnected.

Figure 1: ART - principal of the technique

Paul Swinerd - Product portfolio

manager - Power

The art of earth electrode testing

The testing of earth systems has, for many years,

principally relied on the tried-and-tested fall-ofpotential method and similar techniques. These

techniques give reliable results, but they can

be time consuming. To measure the resistance

of an individual earth electrode, it is necessary

to disconnect that electrode from the rest of

the earth system. Not only does this take time,

disconnecting the electrode may also compromise

the safety of the installation it is protecting.

To address these problems, a novel form of

earth electrode testing has been developed.

This is known as the Attached Rod Technique,

or simply ART.

When an earth tester injects a test current

into an earth electrode that is still connected

to the earthing system, the current flows not

only into the electrode under test but also into

other electrodes that are connected in parallel

and into any other available paths to earth.

However instruments with ART capabilities use

a current clamp (iClamp) to directly measure

the current flowing in the electrode under

test. The instrument then uses this current

to calculate the electrode’s resistance. No

disconnection is needed, so there’s no wasted

time, no unnecessary plant downtime, no

inconvenience and no scraped knuckles!

the electrode under test can have a resistance

of up to 20 times that of the total system and

ART will still give reliable measurements. If the

resistance is more than 20 times the resistance

of the total system, the traditional three-pole

measuring method should be used.

Do not, however, underestimate the usefulness

of ART! If the current in the electrode under

test is less than 5% of the total test current,

the tester will display a “clamp low” warning.

If, under these conditions, users measure the

resistance of the complete earth system using

the three-pole method, they will know that

the resistance of the electrode under test is at

least 20 times this value. Often, this is enough

information to decide whether or not the

resistance of the electrode is satisfactory.

There is, however, another factor that needs

to be considered when using ART testing and

this relates to the spheres of influence around

the earth electrode(s) and building earth paths,

which may be through water or gas pipes, or

through the metal framework of the building.

Consider the situation shown in Figure 2. Here,

In Figure 1, the test current is injected between

points X and C. The instrument measures the

voltage between points X and P at the test

frequency only, which enables it to ignore the

effects of other currents that may be flowing

in the earth system. It then uses Ohm’s law to

calculate and display the electrode resistance.

As can be seen from the diagram, the addition

of the iClamp allows the current in an

individual electrode to be measured separately.

The iClamp also responds only to currents at

the frequency produced by the instrument,

allowing other currents flowing in the electrode

to be ignored.

In practice, ART testing works well provided

that the current in the electrode under test, as

measured by the iClamp, is at least 5% of the

total test current. To look at it in another way,

There are a few other situations where ART

testing is unsuitable, and one of these is

illustrated in Figure 4, which shows guy lines

connected to a metal tower. The problem may

not, at first, be obvious.

An attempt is being made to measure the earth

resistance of the guy line that has the iClamp

attached, but all of the guy lines on this tower

are shorted together. This means that the

current being measured by the iClamp is not

only flowing to ground at the anchor point, but

is also flowing back up the other guy lines and

then to earth via the tower. ART testing will,

therefore, give an incorrect result.

To avoid problems of this type, always consider

carefully where the test current will flow. For

successful ART measurements, the current from

the electrode under test must flow only into the

soil mass surrounding the electrode.

Let’s look a little more closely at how a typical

earth electrode resistance tester with ART

functionality works. Figure 1 shows

the essentials.

Testers with ART functionality are also capable

of traditional three-pole fall-of-potential

measurements. When used in this way they

inject a test current at a frequency that has

been chosen so that it doesn’t clash with the

power frequency or its harmonics. A frequency

of 128 Hz, which avoids the harmonics of both

50 Hz and 60 Hz supplies, is often used.

(More detailed information about spheres

of influence can be found in the publication

“Getting Down to Earth”, which is available as

a free download www.megger.com. Simply log

in or register, and navigate to the publications

section.)

Figure 2: Spheres of influence

the spheres of influence are separate from each

other, and the equivalent circuit is, therefore,

as shown at the bottom of the figure. In cases

like this, ART testing will work well. Subject, of

course, to the 20:1 rule.

This article has outlined how ART earth

electrode testing works and has discussed some

of its limitations. It is important to remember,

however, that there are very many applications

where ART testing works extremely well.

Examples include earth farms, pole-mounted

transformers, domestic TT installations, single

guy lines on towers and lightning protection

electrodes. In short, provided its limitations are

clearly understood, ART testing is an invaluable

tool that saves time, money and trouble.

Now consider the situation shown in Figure

3. Here the electrode under test is very close

Figure 4: Mixed readings can be caused by multiple guy-lines

ELECTRICAL TESTER - April 2014

3

ELECTRICAL

TESTER

The industry’s recognised information tool

Time Domain Reflectometers

- the physical basics

Figure 1: Oversampling technique

Peter Herpertz - Product manager,

power, SebaKMT

When choosing or using a time domain

reflectometer (TDR), it is very useful to have

at least some knowledge of the theory that

underpins reflectometer operation and the

technology that is used to turn that theory into

a practical instrument. The objective of this

article is to provide this essential knowledge in

a concise form that can be readily related to

real-world requirements and applications.

As a starting point, it is useful to note that

reflectometers can be divided into two main

groups – instruments that are intended for

use on power cables (power reflectometers)

and those that are intended for use on

telecommunications systems (telecom

reflectometers). The essential difference is that

power reflectometers use flash A/D conversion

technology, while telecom reflectometers use

sampling technology.

Power reflectometers

Power reflectometers have at their heart a fast

and expensive flash analogue-to-digital converter.

The latest instruments have sampling rates of up

to 400 MHz, which is at least twice the rate used

in the previous generation of instruments.

It is widely believed that the higher the

sampling rate, the better the instrument,

because higher sampling rates provide

increased resolution. In theory this is true,

but in practice there is little benefit to be had

from further increasing sampling rates, as the

resulting higher resolution is only relevant

at short distances. At larger distances, the

instrument display cannot show the full

measured resolution.

(80m/μs)80.000km/s

Res =

= 0.2m

400MHz

Range and resolution

To explore in more detail the relationship

between sampling rate, range and display

resolution, we will examine the situation with

a modern power reflectometers that is among

the best of its type – the Teleflex SX or its large

equivalent the Teleflex VX.

Assuming that the measuring pulse travels with

a typical propagation velocity of 80 m/µs, with

a sampling rate of 400 MHz the theoretical

resolution will be 0.2 m, as this equation shows:

The lowest range of the Teleflex SX is 20 m.

The display is 1,024 pixels wide so, when the

20 m range is in use, in round terms 20 m =

1,000 pixels. This means that 0.2 m = 10 pixels.

On this range, the full theoretical resolution

of the instrument can, therefore, be used.

However, when the 200 m range is selected,

0.2 m is equivalent to only one pixel, so the

usable resolution is starting to be limited by the

display rather than the sampling rate. At longer

ranges, even if the display is magnified with the

zoom function, the limiting effect of the display

is completely dominant and the theoretical

resolution of the instrument calculated from

the sampling rate alone can never be used.

Impulse covering zone

Another factor that affects measurement

resolution is the pulse width. With the smallest

4

Figure 2: Full sampling

pulse width of 20 ns and a propagation

velocity of 80 m/µs, the pulse width is

equivalent to 1,6 m. Similarly, a pulse width of

10 µs is equivalent to 800 m. These distance

equivalents are known as the covering zone

(CZ) for a particular pulse width and are easily

calculated as:

lmpcz = impulse width [µs] * propagation

velocity [m/µs]

The pulse width is typically related directly to

the range being used on the instrument.

Some leeway – one step up or down – is

possible, but in general a pulse that is too

short will be lost because of cable attenuation,

while too large a pulse will limit the useful

resolution. Taken together the resolution and

the pulse width determine the accuracy of the

measurement made by the instrument, which

is typically around 0.1%.

This means, for example, that for a given pulse

width, events with a shorter distance between

them than the covering zone cannot be

resolved. They are, therefore, either not visible

at all or visible only as merged reflection of

signals from both events.

Principles of power reflectometer

flash conversion

A flash converter takes the whole returning

analogue signal and converts it continuously

at a high conversion rate into a digital

signal. Ideally, it should complete the whole

conversion process in a single pass, as shown

in Figure 2.

However, to reduce costs, some instrument

manufacturers use “oversampling” technology.

This typically means that the A-to-D converter

operates at one quarter of the claimed

sampling rate, but runs sequentially four times.

As is shown in Figure 1, this means that, in

reality, the instrument makes four different

measurements – those in the first pass are

shown in blue, those in the second pass in red,

those in the third pass in green and those in

the fourth pass in orange.

For example, an instrument with a 50 MHz

converter and four-times oversampling will be

presented as an instrument with a sampling

rate of 200 MHz. It is an indisputable fact,

however, that oversampling does not provide

the same quality as a single pass measurement.

With oversampling, after the four measuring

cycles, the instrument interpolates the

measuring points. Real signal details can be

lost in this interpolation process, and spurious

details can be generated.

An arcing fault, for example, changes very

rapidly and its signature can be completely

different on consecutive oversampling cycles.

This can be seen in Figure 1 where only the

blue conversion cycle has changed, producing

a completely different signature.

instant, producing one “pixel” of the trace.

This process is repeated until the complete

trace has been recorded. This method of

capturing information is much slower than

the flash conversion method used in power

reflectometers, but it yields more accurate

information. Fast events like arc reflection are,

however, unlikely to be captured.

In telecom fault location, high accuracy is

more important that high measuring speed

because pinpointing is much more difficult on

telecom cables than it is on power cables. The

construction of telecom cables does, however,

provide greater consistency for important

parameters like propagation velocity, making it

easier to determine an accurate distance to the

fault using reflectometry. This high prelocation

accuracy makes pinpointing somewhat easier.

immediately triggers the reflectometer. In almost

all circumstances, this provides a perfect trace

on cables up to several kilometres in length.

There are, however, always exceptions. These

typically relate to very long cables or cables

affected by water/humidity problems. In these

cases, there is a delay in response either due

to the extended signal travelling time on long

cables, or the unpredictable propagation

velocity of cables affected by water. Here

another technology – ARMslide – comes into

its own. This records up to 15 traces during

one ARM discharge, which ensures that at

least one trace will provide the required data.

To deal with the most challenging applications,

it is even possible to adjust the trigger timing

to intermediate values between the 15

measurements.

Triggering

With power reflectometers, a widely used

measuring technique is the arc reflection

method (ARM), where a surge generator is

used to produce an arc at the fault location,

and this arc (while burning, it is low resistive)

reflects the pulse from the reflectometer. For

this method of measurement to work well, the

reflectometer needs a very reliable trigger.

The conventional triggering method is delay

time adjustment, where the instrument user

manually adjusts the delay time between

the power surge that strikes the arc and

the release of the measuring pulse from the

reflectometer. This approach requires the user

to have a high level of skill as the delay time

needed depends on several parameters related

to the ARM oscillation, which is determined

by the resonant circuit formed by the surge

capacitor, the cable capacitance and the cable

inductance. These factors change with cable

length, so it’s clear that a fixed delay time

is not a reliable solution. The objective is to

trigger the reflectometer when the arc from

the ARM discharge has reached its highest

current value and is burning solidly. One

method of compensating for the difficulty of

triggering at exactly the right moment is to

take several reflectometer recordings of the

same ARM shot. This increases the probability

of capturing at least one useable trace.

A better approach, however, is the ∆U

triggering system, which is also known as “one

shot triggering technology”. This works by

continuously evaluating the current of the ARM

oscillation. After the current has reached its

peak, the instrument waits for the voltage to fall

by a predetermined amount (∆U) and then

Figure 3: ∆U triggering (above) and ARMslide

recording (below) showing the effect of timing

adjustments

Range compensation

For both power and telecom reflectometers,

the attenuation and dispersion of the cable

cause problems. Impedance and resistive

losses, cable length and other influences

change the amplitude and shape of the

pulse transmitted by the cable. Attenuation

makes the signal smaller as distance

increases. The effect of attenuation is

shown by the red line in Figure 4. Since

attenuation follows an exponential function,

it can be calculated and compensated

for. The distance-related amplitude

correction provided as part of the ProRange

compensation function is shown in Figure 5.

Dispersion is another factor that affects

pulse shape. Higher signal frequencies are

attenuated more than lower frequencies,

Telecom reflectometer technology

As has already been mentioned,

reflectometers designed principally for use in

telecommunications applications work in a

different way from those designed for use in

power applications. Telecom reflectometers use

sampling technology, which basically means

that information about points along the cable

is captured sequentially. A measuring pulse

is sent out into the cable, and the amplitude

of the return pulse is recorded at a specific

ELECTRICAL TESTER - April 2014

Figure 4: Cable attenuation and dispersion

www.megger.com

ELECTRICAL

TESTER

The industry’s recognised information tool

with a result that distant reflections appear

wider and lower in amplitude than nearby

reflections. The combination of attenuation

and dispersion mean that very distant

reflections are sometimes difficult to recognise

and evaluate.

TDR fault finding: cable fault basics

Figure 5: Distance related amplitude correction

The ProRange function allows all events

to be displayed with the correct amplitude

irrespective of their distance, which makes

evaluating the events much easier. Dispersion

still affects the trace, but has far less influence

on event visibility.

Dead zone

The dead zone is the basis for endless

discussions. It results from the fact that the

transmit pulse, which looks to the instrument

just the same as a reflected pulse except

that it is much larger in amplitude, saturates

the instrument for a certain distance at

the beginning of the trace. Only beyond

this distance do reflected pulses become

visible. Various technologies are available

to compensate for the dead zone, one of

the most effective being the use of a split

transformer. The basic circuit for this type of

compensation is shown in Figure 6.

Peter Dennis - Product manager communications

Introduction

A TDR (time domain reflectometer) uses the

radar principle to identify faults on cables.

The instrument fires a pulse down the cable,

and any change in the impedance of the

cable will result in reflections being sent

back down the cable toward the instrument.

These reflections are measured and displayed

so that a “map” of the cable is shown. Many

faults are found at terminations, cable joints

and other locations where there has been

disruption to the route of the cable.

Since they work by identifying changes in

impedance, TDRs require two conductors

that run parallel to each other in order

to operate. Any connection, change of

cable type, break in the cable, or fault will

cause a change of impedance. Each type

of change has a different effect on the TDR

display; a positive reflection shows higher

impedance, a negative reflection shows

lower impedance.

Using a TDR

Identify the location of fault by testing from

both ends of the cable.

Figure 6: Dead zone compensation

With this arrangement, the variable resistance

R is compared with the impedance of the

cable, and is adjusted until the impulse

currents I1 and I2 are as nearly as possible

identical, which means that they cancel each

other out in the transformer. The reflectometer

does not, therefore, see the measurement

pulse.

In practice, R should be set using the

reflectometer’s lowest measurement range

and should be adjusted until the positive and

negative reflections are equal in size and as

small as possible in amplitude. The returning

reflected pulses produce current I3 in the

transformer, and are completely unaffected by

the compensation circuit.

Even better dead zone compensation can be

achieved in telecom reflectometers, when a

second cable pair that is nominally identical

with the pair under test is connected to the

second input (Z2) to provide compensation.

Since both cable pairs have identical

parameters – at least in theory – they will

cancel each other out completely except for

differences that represent the fault on the pair

under test.

The next article in this series will look at

measuring techniques using reflectometers,

and will include a range of practical examples

showing typical traces that are produced by

faults of various types.

www.megger.com

Identify the faulty cable with an insulation

tester. If the fault is low resistance,

Cable type

Construction

Velocity factor %

Velocity factor m/μs

Power

Paper oil filled

0.72 to 0.84

216 to 252

Power

XLPE

0.54 to 0.62

162 to 186

Power

EPR

0.45 to 0.57

135 to 171

Twisted pair

Polyethylene

0.64 to 0.67

192 to 201

Twisted pair

PTFE

0.71

213

Twisted pair

Paper

0.72 to 0.88

216 to 264

Telecomms

PIC

0.65 to 0.72

195 to 216

Telecomms

Pulp

0.66 to 0.71

198 to 213

Telecomms

Gel filled

0.58 to 0.68

174 to 204

Telecomms

Coax

0.82 to 0.98

246 to 294

determine the value – typically, a TDR can

only identify faults below 200 Ω. The lowest

measurement possible with an insulation

tester is often around 10 kΩ, so a multimeter

may be needed to fill in the resistance

measurements between continuity (below

100 Ω) and insulation (above 10 kΩ).

If possible, use a good pair of cables running

alongside the pair under test so that a direct

comparison can be made between the good

pair and the bad pair. The fault will often

be easier to identify by looking for the

difference between the two traces. Some

TDRs offer the facility to show both traces on

the same display or to show the difference

between the two traces.

Velocity factor

When using a TDR it is necessary to tell it the

speed of the pulse in the cable. This enables

the TDR to convert the time the reflected

pulses take into distance. Different types of

cable have different velocity factors (VF).

VF is the ratio of the speed of the pulse

in the cable to the speed of light. It may

alternatively be entered as m/µs when it

is called velocity of propagation. If you do

not know the VF of the cable under test it

may be possible to test a known length and

adjust the VF until the distance displayed to

the end of the cable is correct.

Typical velocity factors

Accuracy

Open conductor

A large positive trace

Bridge tap - A small positive followed by a

small negative trace after a few mintues

A TDR cannot be used to pinpoint a fault.

The TDR accuracy will depend on the velocity

factor (maybe only with a resolution of 1%);

the cable may twist or not lie in a straight

line and the resolution of the display will not

show fine detail unless zoom is used. The

best way to locate a fault is to test the cable

from both ends; the fault will lie between

the points identified.

Output pulse level

Short circuit

A negative trace

Split/resplit - Negative trace followed by a

small negative trace after a few metres

The output pulse level can be varied to assist

in locating the fault. Small faults and those

at the far end of the cable will require a high

pulse level. High pulse energy with near-end

faults will, however, distort a large section of

the displayed trace and so lower pulse levels

will be better.

Range

Cables splice/joint

A small positive followed by a small negative

Wet splice/water

Short positive/negative trace

Initially it is best to set the range to well above

the expected length of the cable so you can

see the complete picture. Even a large fault

will be missed if it is off the display.

Automatic fault finding

T Joint - A negative trace

followed by a long positive

Water ingress

A negative trace

Many TDRs have an automatic facility that

may help identifying some faults, but it is also

necessary to be able to use the TDR manually

in order to get the most from the instrument.

ELECTRICAL TESTER - April 2014

5

ELECTRICAL

TESTER

The industry’s recognised information tool

When reflection isn’t the answer

The first is that the instrument should perform

bipolar measurements – that is, it should

automatically carry out measurements first

with one polarity and then with the reverse

polarity, and average the results.

This is necessary because, if dissimilar metals

or temperature differences are present in the

cable, offset voltages can be generated both

by thermoelectric effects and, particularly in

the presence of moisture, by electrochemical

(galvanic) effects. These effects are inherently

unipolar and the inaccuracies they would

otherwise introduce are, therefore, eliminated

by making bipolar measurements.

This technology also gives results that are

unaffected by resistance differences in the

sheath and core conductor, and by the

resistance of the auxiliary connections. In

addition, the performance of the connecting

clamps has little influence, and no special

calibration procedures are needed when

carrying out the measurements. Typical

connections for the voltage-drop method are

shown in Figure 2.

The second key factor to be considered

when choosing a high-voltage bridge is the

instrument’s discharge capability. All cables

have capacitance and, for power cables, this

typically amounts to 0.5 µF per kilometre. A

cable that is, say, 50 km long will therefore

have a capacitance of 25 µF and, when this

cable is charged to 10 kV, the energy stored will

be 1250 J. Unless the instrument can discharge

this energy safely, it is likely to sustain damage,

and there is also a significant risk of injury to

the operator. To eliminate these possibilities,

the best instruments not only have a high

discharge capability, they also measure the

cable capacitance before any measurements are

made and, if it is too high, they inhibit the test

and either reduce the voltage or even prevent

the cable being charged.

There are two points to be aware of when

selecting a high-voltage bridge for fault

location on power cables irrespective

of whether the instrument is a classical

galvanometer-based bridge or one that uses

the superior voltage drop method.

A good example of a high-voltage bridge that

makes effective use of the latest technological

developments is the new HVB10 (see Figure

3). As might be expected, this uses bipolar

measuring methods and has a high discharge

capability of 25 µF. As an additional safety

Figure 1: Cable jointing boxes with cross-bonded shields

Peter Herpertz - Product manager,

power, SebaKMT

For locating faults on power cables, pulse

reflection techniques are the most widely used

approach and, in most cases, these techniques

provide accurate and dependable results.

There are however circumstances where they

don’t work so well – for example, with highresistance faults in long paper-insulated (PILC)

cables, faults in very long cables, especially

in offshore applications, and faults in crossbonded cable systems (see Figure 1).

There are also situations where verification

is needed for the results obtained by pulse

reflection fault location techniques. This is

often the case with subsea cables where,

because of the enormous cost of deploying a

vessel to raise and repair the cable, operators

often insist on using two independent fault

location techniques to ensure that the location

has, in fact, been correctly determined.

In these situations where an alternative to pulse

reflection methods is needed, an attractive

option is the use of a high-voltage bridge.

However, conventional bridges also have their

limitations, so bridge-type instruments that

support voltage-drop fault location technology

are much to be preferred. With this technology,

the current, voltage and resistance before

and after the fault are considered in relation

to the cable length, and the test instrument

automatically carries out the necessary

calculations to display the distance to the fault,

typically in less than a minute.

Voltage-drop technology has many benefits,

not the least being that it is much less

error sensitive than bridge-based methods,

which means that the accuracy of the

results it delivers is significantly improved.

Connection principle sheath fault location

Figure 2: Typical connections for voltage drop fault location technology.

collaboration brings benefits for all

An on-going joint project between Megger

and the University at Buffalo, a flagship

institution in the State University of New York

system, is delivering major benefits for the

university and its students as well as for users

of power test equipment.

The project, which forms part of the iSEED

(Institute for Strategic Enhancement of

Educational Diversity) program and CSTEP

(Collegiate Science and Technology Program),

involves the students developing new

6

This versatile instrument offers two operating

modes. Standard mode gives good results

for typical sheath faults with resistances

up to several hundred kilohms and sheath

cross-sections from 25 mm2 to 50 mm2.

Measurements in this mode typically take

around 30 seconds.

High accuracy mode uses the full potential of

the instrument and is ideally suited for locating

difficult high resistance faults in, for example,

the inner insulation of PILC cables. This mode

also incorporates an intermittent fault detection

algorithm, and measurements – depending

on the actual cable and fault behaviour – take

approximately one minute to complete.

Designed to be easy and convenient to use,

the HVB10 has an adjustable output voltage

of up to 10 kV and incorporates an intuitive

user interface that allows all major functions to

be selected with a single turn-and-push rotary

control. Results and settings are shown on a

large high-resolution display.

For the foreseeable future at least, pulse

reflection techniques are likely to remain the

preferred method for locating the majority

of faults on power cables. Where, however,

there is a need for an alternative method,

either because pulse reflection techniques are

unsuitable or because the results produced

by these techniques must be verified, a high

voltage bridge that uses the voltage drop

method is an invaluable tool. In choosing such

a bridge, however, care should be taken to

ensure that it offers the full range of desirable

– and, in some cases, essential – features

outlined in this article.

Connection core-to-screen or core to fault location

University at Buffalo

Casey Henry

marketing program manager

feature, it not only checks the capacity of the

cable before tests are made, it also verifies the

test leads are correctly connected.

software modules for the latest state-ofthe-art relay protection test systems. While

participating in the project, the students work

under the guidance not only of the university’s

tutors, but also of Megger engineers who

have wide and current practical experience in

the relay test field and who act as mentors.

The university benefits by having access to the

latest test equipment and from the up-to-theminute input provided by the mentors, while

the students enjoy both of these benefits

plus the confidence-boosting opportunity to

produce work that will ultimately be tested

and used in a commercial environment. The

project makes additional resources available

ELECTRICAL TESTER - April 2014

Figure 3: The new HVB 10 high-voltage bridge.

thankful and appreciative to be a small part

in this experience”, said Dr Zirnheld at the

University at Buffalo.

To date, the students involved in the project

have produced software modules for testing

to develop the software modules with the

result that the end users benefit by having

faster delivery on new modules than would

be possible without the cooperation of the

university and its students.

three popular and widely used types of

“Using state of the art equipment and being

guided by industrial mentors adds value

to our student educational program. Our

students get the best of all worlds. They gain

support and knowledge from an industrial

partner; they are part of new institute on

campus; they participate in multiple programs

that immerse them into an intensive research

experience, and they have numerous

opportunities to present their work. I am

relay test software suite, and will be available

protection relay. After final evaluation and

verification have been completed, these

new modules will be added to the library of

modules that already forms part of the AVTS

for download by users of the associated relay

test equipment.

www.megger.com

ELECTRICAL

TESTER

The industry’s recognised information tool

Putting cables to the test......

Clive Pink

Product manager

Many techniques are available for assessing

the condition of underground power cables

and for diagnosing faults that occur on

these cables, but these techniques are often

presented as alternatives that compete with

each other. This is unfortunate and misleading

as, in reality, the various techniques are

complementary.

Faults on underground cables are a major

concern for every organisation involved in

the transmission and distribution of electrical

power. Such faults can have consequences

that are extremely costly and disruptive, so

it’s not surprising that there is strong demand

for test equipment that can provide accurate

information about the condition of cables and

also assist in the rapid location of faults.

A first thought might well be that this test

equipment should energise the cable at power

frequency – after all, in this way it would be

subjected to stresses that closely resemble

those it experiences when in service. There is,

however, a problem.

Cables are highly capacitive which means

that if they are to be energised continuously

at power frequency during testing, the test

set must be capable of supplying a large

amount of reactive power. A test set capable

of doing this necessarily has to be physically

large, heavy and expensive. For this reason,

power frequency testing of cables is not

commonly used.

One potential alternative is dc insulation

resistance testing, and this has many

benefits. Suitable test equipment is compact,

lightweight, moderately priced and relatively

easy to use. Typically performed at 5 kV or

10 kV, dc insulation resistance tests take just

a few minutes to carry out and, in addition

to quickly revealing major faults, they give a

valuable indication of the overall condition

of the cable. This is a very useful guide when

deciding whether the cable is fit for immediate

return to service, or whether it should be

tested further using other techniques.

A recently published article (Charles Q Su and

C R Li, IEEE Electrical Insulation Magazine,

January/February 2013) describes how, during

a five-year study, dc insulation testing was used

to decide which of a group of 6.6 kV cables

operated by a Chinese utility should be further

tested using the VLF and OWTS techniques

described later in this article.

Only 5% of the cables in the study were

selected for testing with these techniques,

but the failure rate across the whole group of

cables was nevertheless reduced by over 30%.

This clearly shows that dc insulation resistance

testing is a valid technique for determining

which cables are most at risk of failure and,

therefore, in need of further analysis.

To get the best from dc insulation resistance

testing it is important to choose the right

test set. A critical characteristic is test current

capability, as an instrument that can only

supply a small current will take a long time to

charge the cable under test, particularly if it is a

long cable, and this will unnecessarily prolong

the testing time. Market leading instruments

will typically supply 3 mA to 6 mA short circuit

current. As a rule of thumb, this will mean that

capacitive loads like cables take 2.5 seconds or

less per microfarad to charge to 5 kV.

In many medium, high and extra high voltage

substations, noise immunity and filtering is

a desirable feature. The best instruments are

capable of accommodating between 3 mA and

8 mA of noise, and filter the output in realtime to provide stable measurements. Finally,

the test set’s power source should not be

neglected. As mains power may not be readily

www.megger.com

available in locations where cable testing

must be carried out, a test set with an internal

rechargeable battery – ideally a rapid-recharge

Li-ion type – is greatly to be preferred.

While dc insulation resistance testing at

modest voltages is, as we have seen, an

invaluable and convenient first-line tool for

assessing cable condition, there are some

cases where further study is needed. These

tests most usually take the form of insulation

withstand testing at voltages higher than the

nominal working voltage of the cable under

test. In fact, in many countries withstand

testing before new cables are put into service is

obligatory, as it is part of the relevant standard.

Because of the risk of cable damage, dc testing

at these higher voltages is no longer widely

used, having been supplanted by ac very low

frequency (VLF) testing, usually performed at a

frequency of 0.1 Hz.

VLF test sets are divided into two groups –

those that apply a sine wave to the cable under

test, and those that use a cosine rectangular

(CR) waveform. Both types produce useful and

reliable results, but it is worth noting that CR

test sets are usually smaller and lighter than

similarly rated sine wave equivalents, and that

some users prefer the CR waveform as its rise

and fall times are very similar to those of a

power frequency sine wave.

VLF insulation withstand tests at 0.1 Hz usually

involve applying a test voltage of three times

the nominal working voltage to the cable for

15 minutes or, in the case of aged cables, one

hour. VLF testing therefore takes longer to

perform than dc insulation resistance testing,

but it will reliably uncover a wider range of

cable problems and will enable the majority of

“dubious” cables to be confidently classified as

either good for return to service or susceptible

to imminent failure.

Even after VLF testing, some subtle problems

may remain hidden, and detecting these is

the role of partial discharge (PD) analysis. This

involves coupling a high ac test voltage to the

cable under test and using a sensitive detector

to look for the characteristic signals produced

by PD events. Since research has shown that

PD testing at VLF using sine wave voltages does

not give good results, an alternative method

of providing an ac test voltage for the cable

is needed. This typically takes the form of

damped ac (DAC) voltage.

This works by connecting an inductor in series

with the cable under test, then charging the

cable from a high-voltage dc source. When

the cable is charged, a high-speed solid-state

switch connects the inductor in parallel with

the capacitance of the cable to form a resonant

circuit. As a result, damped oscillations at

approximately power frequency are set up in

the cable, and these provide the test voltage.

Although it is one of the more recent

additions to the family of cable test techniques,

PD analysis using DAC voltages is rapidly

growing in popularity. It is already included in

standards for cable commissioning in Spain

and the Netherlands, and is also recommended

in Germany.

Timely testing helps

restore power to 200,000

Erik Blichfeld,

Produktchef, SebaKMT A/S

When the 60 kV submarine cable between the

Danish island of Bornholm in the Baltic Sea

and Sweden was accidentally cut by a ship on

26th December 2012, the island’s 200,000

inhabitants were initially left completely

without power. However, thanks to test

data provided by a state-of-the-art cable test

van, the point at which the cable had been

damaged was quickly located, allowing divers

to effect a speedy repair.

Energi Net Denmark is responsible for the highvoltage cable network that supplies power

in Bornholm, and the company has a 24/7

contract with SE Energi to carry maintenance

and fault finding on this network.

This includes the link between the island and

the Swedish power network, which, at 48

km, is the longest high-voltage ac submarine

interconnect in Europe.

In this short article it has only been possible

to briefly consider three of the most popular

and most useful test techniques for power

cables – dc insulation resistance testing, VLF

testing and PD analysis using DAC voltages.

As we have seen each of these techniques

has its own merits and shortcomings. The key

factor to bear in mind, therefore, is that cable

test techniques are not competitive – none is

universally “better” than the others – which

means that the best and fastest results will

always be obtained by matching the test

method to the application in hand and, where

necessary, being ready to use more than one

method of testing.

Sweden

Bornholm

Island

In 2012, SE Energi purchased a Seba KMT

R30 test van and, prior to the incident,

had used the on-board Teleflex MX timedomain reflectometer (TDR) to determine the

characteristics of all submarine cables to the

Baltic islands and offshore wind farms.

As a result, when the Bornholm cable was cut,

SE Energi was able to accurately determine

the precise location of the fault by making

comparisons between new and historical

data. This was done using the travelling wave

method, with automatic distance calibration

base data stored in the memory of the TDR.

The results showed that the cable fault

was 17.4 km from the Swedish coast, and

subsequent investigation by divers revealed

that the cable, which is buried 1 m below

the seabed at this point, had been cut by a

ship dragging its anchor. With the site of the

fault located precisely and rapidly, SE Energi

was able to speedily restore normal energy

supplies to Bornholm, thereby taking the

strain off the island’s own very limited power

generation resources.

ELECTRICAL TESTER - April 2014

7

ELECTRICAL

TESTER

The industry’s recognised information tool

Q&A

Q:

For a long time, it has been

standard practice in my

organisation to carry out HV

insulation resistance tests at either

5 kV or 10 kV. Some of the latest

test sets, however, allow tests to be

carried out at 15 kV. Why is this?

A:

Test sets capable of working at 15 kV

have been produced in response to requests

from customers who, in turn, are typically

responding to the introduction of standards

like NETA MTS 1997 Table10.1, applicable to

the maximum voltage rating of equipment,

NETA ATS 2007 Section 1.5 for mediumvoltage motors, and IEC 60229 2007 for

electric cables with a special protective

function. All of these call for 15 kV testing in

One of the most widely used testing techniques in the power sector is high-voltage dc insulation resistance

testing. The principles of this type of testing are well known, but there are still aspects that give rise to

questions. Here are the answers to some of the most common of these.

some circumstances. While these standards are

relatively specialised, they do demonstrate a

trend toward higher insulation resistance test

voltages so, in addition to those who actually

need to work to these standards, there are also

some users who are specifying 15 kV test sets

as a form of future proofing.

Q: For users who don’t need to comply

with these standards, are there

any other benefits to be gained by

testing at 15 kV?

A:

As the use of 15 kV testing spreads, it is

becoming apparent that testing at this voltage

can detect many faults that are not apparent

when tests are performed at lower voltages.

Typically, these faults include fractured or

crushed insulation, damaged cable outer

sheaths, and insulation that has been degraded

by corrosive or conductive contaminants.

Q: Does insulation resistance

testing at 15 kV bring any new

safety requirements?

A:

In general, the safety requirements are

very similar to those associated with testing

at 5 kV or 10 kV, and safe working methods

should always be followed. It is also important

to ensure that the test leads used are

specifically designed to provide the extended

creepage paths associated with 15 kV testing.

And, of course, the instrument used should be

designed and constructed to offer the highest

possible level of user safety.

Q:

Why are some types of HV

insulation tester offered in versions that have different levels of noise

immunity?

A:

It’s often necessary to carry out

insulation resistance testing in areas where

electrical noise is present. If an instrument

with poor noise immunity is used in these

situations, it may deliver unreliable results or

even no results at all. To avoid this problem,

modern insulation resistance testers typically

have a noise immunity of around 3 mA – that

is, they will deliver dependable results with

up to 3 mA of noise present in the measuring

circuit. There are situations, however, where

even greater noise immunity is needed –

when testing in high voltage substations, for

instance. To accommodate these situations,

the latest testers are available in models with

up to 8 mA noise immunity. Building in this

extra noise immunity necessarily adds to the

cost of the instrument, however, so the 3 mA

models remain available as a cost-effective

alternative for users who don’t need to work

in high noise environments.

The stability factor

Damon Mount - power sales manager