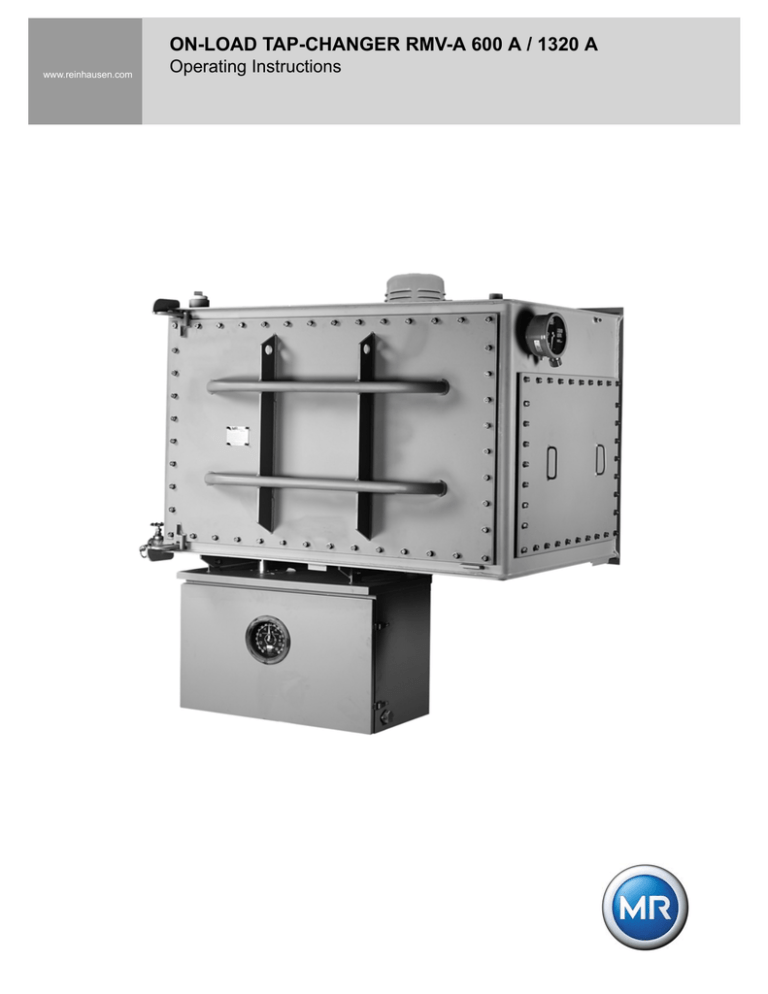

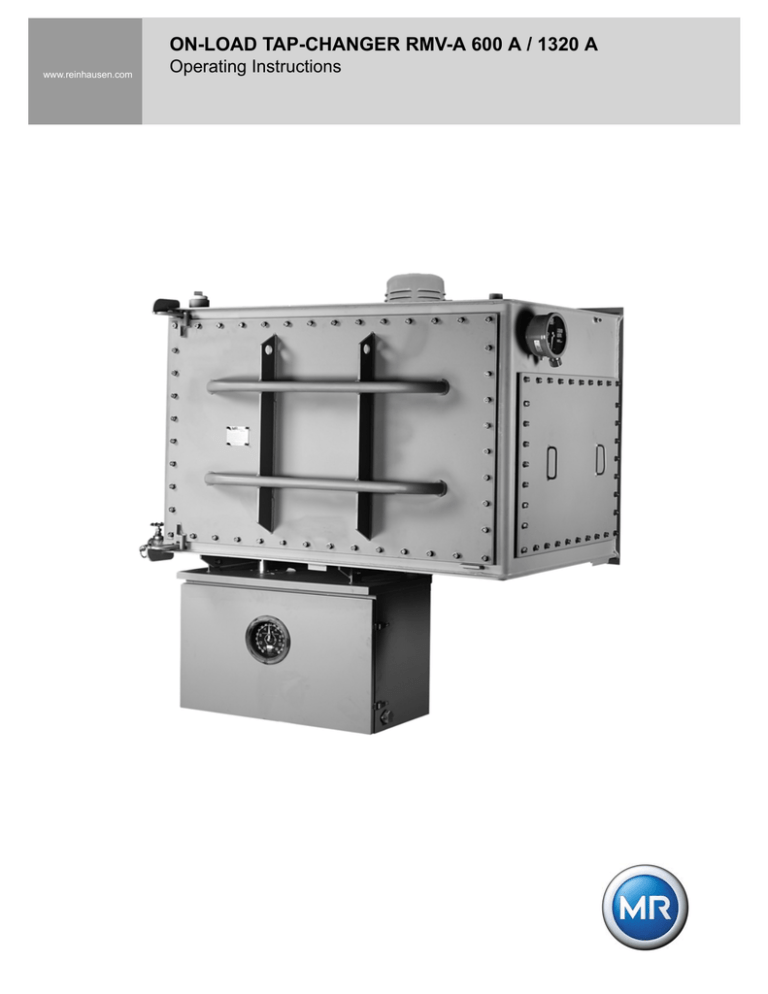

ON-LOAD TAP-CHANGER RMV-A 600 A / 1320 A

www.reinhausen.com

Operating Instructions

© 2010 All rights reserved, Maschinenfabrik Reinhausen

Unauthorised copying and distribution of this document and the utilisation and communication of its contents

are strictly prohibited unless expressly authorised.

Offenders will be held liable for the payment of damages. All rights reserved in the case of registration of a patent,

utility model or registered design.

The product may have been modified after this document went to press.

We expressly reserve the right to make changes to the technical data, the design or the scope of delivery.

The information provided and the arrangements agreed during processing of the relevant quotations and orders are

strictly binding.

The original operating instructions were drawn up in German.

Content

Content

1

Technical Data ............................................................................. 11

1.1

General Data........................................................................................... 11

1.2

Application Limits .................................................................................... 11

1.3

Equipment Standard Features ................................................................12

2

Safety instructions...................................................................... 13

3

Description .................................................................................. 15

3.1

Design .....................................................................................................16

3.2

Operation ................................................................................................18

3.3

Tap Selector ............................................................................................20

3.4

Change-over Selector (Reversing or Coarse/Fine).................................21

3.5

Vacuum Interrupter..................................................................................21

3.6

By-Pass Switch .......................................................................................22

3.7

Monitoring System ..................................................................................23

3.8

Drive Mechanism/Cam Switch Assembly................................................25

3.8.1

Option ................................................................................................................. 26

4

Installation ................................................................................... 27

4.1

Receiving, Handling and Storage............................................................27

4.2

Mechanical Set-up ..................................................................................28

4.2.1

4.2.2

Attaching the Oil Compartment .......................................................................... 28

Mounting the Drive Mechanism Air Compartment.............................................. 28

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

3

Content

4.3

Electrical Connections ............................................................................ 29

4.3.1

4.3.2

Connecting the Tap Leads to the LTC ................................................................ 29

Connecting the Monitoring System and the Drive Mechanism........................... 29

4.4

Test Procedures...................................................................................... 29

4.4.1

4.4.2

4.4.3

Manual Test Procedures..................................................................................... 29

Motorized Test Operations ................................................................................. 30

Monitoring System Tests .................................................................................... 31

4.5

Oil Filling/Transformer Vacuum Processing............................................ 34

5

Maintenance-Free Schedules and Service................................35

5.1

Maintenance-Free Intervals .................................................................... 35

5.2

Taking the LTC out of Service................................................................. 36

5.3

Draining the Oil ....................................................................................... 36

5.4

Internal Examination ............................................................................... 37

5.4.1

5.4.2

By-Pass Switch .................................................................................................. 38

Vacuum Interrupter Examination ........................................................................ 38

5.5

Preparing the LTC for Service ................................................................ 42

6

Replacement of the Vacuum Interrupter Assembly .................45

6.1

Removing the Old Vacuum Interrupter Assembly................................... 45

6.2

Installing the New Vacuum Interrupter Assembly ................................... 49

6.2.1

Adjustment of the Closing Travel ....................................................................... 51

7

Dehydrating Breather Assembly................................................53

7.1

Receiving ................................................................................................ 53

7.2

Installation............................................................................................... 53

4

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

Content

7.3

Operation ................................................................................................54

7.4

Maintenance............................................................................................54

8

Vacuum Interrupter Monitoring (VIM) System .......................... 57

8.1

Vacuum Interrupter Monitoring System Description ................................57

8.2

Evolution of Design .................................................................................58

8.3

Installation and Wiring.............................................................................59

8.4

In-Service Monitoring System Verification...............................................59

8.5

In-Service Monitoring System Trip (Lockout / 86RL)...............................60

8.6

Replacement, Spare or Upgrade Parts ...................................................60

8.7

Monitoring System Vintage Identification ................................................61

9

Spare parts List ........................................................................... 63

10

Appendix...................................................................................... 65

10.1

Operational Sequence Chart...................................................................65

10.2

Dehydrating Breather Assembly .............................................................66

10.3

Vacuum Interrupter Assembly.................................................................67

10.4

Parts Designation: Vacuum Interrupter Assembly ..................................68

10.5

Bypass Switch Assembly ........................................................................69

10.6

Parts Designation: Bypass Switch Assembly..........................................70

10.7

Cam Switch Assembly ............................................................................71

10.8

Parts Designation: Cam Switch Assembly ..............................................72

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

5

Content

10.9

Adjustment of Main Drive Shaft Coupling ............................................... 73

10.10

Parts Designation: Main Drive Shaft Coupling........................................ 74

10.11

Drive Mechanism, Ground Level Mounting............................................. 75

10.12

Parts Designation: Drive Mechanism, Ground Level Mounting .............. 76

10.13

Drive Mechanism, Standard Mounting.................................................... 77

10.14

Parts Designation: Drive Mechanism, Standard Mounting ..................... 78

6

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

Figures

Figures

Figure 1

Three-phase RMV-A load tap changer ............................................15

Figure 2

Tap changer oil compartment ..........................................................16

Figure 3

Vacuum interrupter, schematic layout .............................................17

Figure 4

Typical winding layout with LTC on position 16L with tap

sequence to position 15 L................................................................19

Figure 5

Tap selector, by-pass switch and change-over selector,

three-phase assembly .....................................................................20

Figure 6

Vacuumm interupter, single phase assembly ..................................21

Figure 7

By-pass switch.................................................................................22

Figure 8

Monitoring system schematic diagram ............................................23

Figure 9

Drive mechanism cam switch assembly, hinged door open

showing monitoring system and handcrank.....................................25

Figure 10

Monitoring system, cover removed..................................................32

Figure 11

CT connection for test......................................................................33

Figure 12

By-pass contact wear evaluation .....................................................37

Figure 13

Vacuum interrupter mechanical test ................................................38

Figure 14

Anvil Gap .........................................................................................39

Figure 15

Hi-Pot test connection A ..................................................................40

Figure 16

Hi-Pot test connection B1 ................................................................41

Figure 17

Hi-Pot test connection B2 ................................................................41

Figure 18

Coupling assembly (90) ...................................................................46

Figure 19

Cam disk (5) pointing toward the LTC door .....................................46

Figure 20

Removal / Installation of the vacuum interrupter assembly .............47

Figure 21

Removal / Installation of the vacuum interrupter assembly .............47

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

7

Figures

Figure 22

By-pass moving contact assembly .................................................. 48

Figure 23

Bearing half shells ........................................................................... 49

Figure 24

Closing travel C ............................................................................... 51

8

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

Tables

Tables

Table 1

General data ...........................................................................................11

Table 2

Application Limits ....................................................................................11

Table 3

Annual checks.........................................................................................35

Table 4

Routine checks........................................................................................35

Table 5

Spare parts..............................................................................................63

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

9

1 Technical Data

1

Technical Data

The RMV-A load tap changer fulfills all requirements in IEC 60214-1 and ANSI/

IEEE C57.131-1995. The Motordrive Mechanism complies to IEEE C57.1311995.

1.1

General Data

Design

3 phase, preventive autotransformer (reactor) switching

principle (to break load current by vacuum interrupters)

Tank

Will withstand full vacuum (+/- 15 psi)

Size (LxWxH)

Tank: 57 x 35 x 40 in.

Air compartment: 34 x 17 x 23.5 in. (250 lbs)

Total weight (incl.

oil)

4,190 lbs

Oil filling quantity

280 gals./2,100 lbs

Time per operation

Approximately 2 seconds

Table 1

1.2

General data

Application Limits

The maximum allowable recovery voltage across the reversing switch during

its operation is 12 kV. Tie-in resistors are necessary in case 12 kV are exceeded.

Tap changer type

RMV-A-1320*

RMV-A-600*

Operating voltage phase-to-phase and to ground

15 kv

15 kv

Three phase kVA of regulation

9,500 kVA

9,500 kVA

LTC through-current

1,320 Amp

600 Amp

Tap-to-tap Voltage

300 Volts

300 Volts

Impulse withstand voltage (full wave) phase-toground

150 kV

150 kV

Impulse withstand voltage

(full wave) phase-to-phase

125 kV

125 kV

Power frequency test voltage phase-to-ground

50 kV r.m.s.

50 kV r.m.s.

Table 2

Application Limits

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

11

1 Technical Data

Power frequency test voltage phase-to-phase

40 kV r.m.s.

40 kV r.m.s.

Impulse withstand voltage (full wave) across tap

range

75 kV

75 kV

Power frequency test Voltage across tap range

26 kV r.m.s.

26 kV r.m.s.

Impulse withstand voltage (full wave) tap-to-tap

45 kV

45 kV

Power frequency test voltage tap-to-tap

15 kV r.m.s.

15 kV r.m.s.

Number of positions (standard)

33

33

Regulating winding sections

9 (8 effective)

9 (8 effective)

Table 2

Application Limits

*Both LTCs are also available as RMV-A320Y and RMV-A-600Y variants providing one common output point P (neutral connection inside the LTC compartment for location of the LTC at the neutral end of Y-connected windings).

1.3

12

Equipment Standard Features

•

Finish: light gray epoxy solid resin primer

•

Oil gauge with low level SPDT contacts

•

Provision for pressure relief device

•

Drain valve, 1 in. globe with sampler

•

Guide pins for inspection door

•

Non-corrosive hardware

•

Dehydrating breather

•

Handcrank with interlocking switch

•

Cam switch control: tap changer pilot shaft 10 cams, tap changer limit shaft

4 cams

•

Position indicator: 16L-N-16R, 33 positions/32 steps

•

Wiring: 12 pt. terminal blocks, PVC-insulated wire, pre-insulated terminals

•

Air compartment heater with thermostat

•

Stainless steel inspection door studs

•

Vacuum interrupters with monitoring system

•

Drive motor: single-phase, 208-240 V, 60 Hz, 1,725 r.p.m. (standard, other

available on request).

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

2 Safety instructions

2

Safety instructions

All personnel involved in installation, commissioning, operation, maintenance or

repair of the equipment must:

•

be suitably qualified

•

strictly observe these Operating Instructions.

Improper operation or misuse can lead to

•

a reduction in the efficiency of the equipment

•

damage to the equipment

•

serious or fatal injury to personnel.

Safety instructions in this manual are presented in three different forms to

emphasize important information.

WARNING

This information indicates particular danger to life and health. Disregarding

such a warning can lead to serious or fatal injury.

CAUTION

This information indicates particular danger to the equipment or other property

of the user. Serious or fatal injury cannot be excluded.

These notes give important information on a certain subject.

The instructions contained in this manual apply for tap changers with standard

position designation 16L...N...16R only. For LTC’s with a different position designation please refer to the LTC sequence chart supplied for each order.

Drawings and illustrations contained in this instruction manual are subject to

change without notice and are for reference only. For specific details refer to

drawings submitted with each individual customer order.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

13

3 Description

3

Description

The RMV-A Load Tap Changer is used in conjunction with oil-immersed network

power transformers and voltage regulators to change taps under load, thereby

controlling the voltage magnitude, Figure 1.

Figure 1

Three-phase RMV-A load tap changer

The tap changer works on the preventive autotransformer (reactor) switching

principle with vacuum interrupters to accomplish the tap change. Vacuum interrupters are used to interrupt the circuit within a half cycle. The interruption takes

place in a vacuum of approximately 10-6 torr instead of the usual arcing under

oil. Thus, oil contamination is eliminated.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

15

3 Description

3.1

Design

The RMV-A load tap changer is a three-phase design with full insulation between phases and to ground, Figure 2.

Figure 2

Tap changer oil compartment

It consists of an oil compartment containing tap and change-over selectors

(reversing or coarse/fine), vacuum interrupters and by-pass switches, a separately housed drive mechanism/cam switch assembly and other accessories as

required by customer specification. Each phase consists of a tap selector, a

change-over selector and a vacuum interrupter with bypass switch positioned

on a vertical insulating panel. Three of these phase assemblies are connected

with tie rods and mounted rigidly from the bottom of the tap changer oil compartment. All switching elements involved in the tap change operation, tap and

changeover selectors, vacuum interrupters and by-pass switches of all phases,

are driven by one main shaft from the drive mechanism.

The vacuum interrupter drive assembly is a cam-action, spring-driven mechanism which moves an operating rod when opening and closing. The operating

rod is connected to the vacuum interrupter moving contact.

16

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

3 Description

The vacuum interrupter consists of a stationary and a moving contact enclosed

in a vacuum-tight, ceramic insulating envelope, Figure 3.

Figure 3

Vacuum interrupter, schematic layout

The moving contact is sealed through flexible metal bellows protected from the

arc by a shield. A metal shield surrounds the contacts, forming an arc chamber

and condensing surface to collect vaporized contact material which arises

during arcing.

The motor drive/cam switch assembly is normally housed in a separate air compartment and is accessible through a weatherproof, hinged door. Optionally, the

compartment can be lowered to ground level.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

17

3 Description

3.2

Operation

The tap changer operation is divided into three major functions, Figure 4.

•

Arc interruption and reclosing by use of the vacuum interrupters in conjunction with the associated bypass switches.

•

Selection of the next position by the tap selector assemblies in proper

sequence with the operation of the vacuum interrupters and by-pass switches.

•

Operation of reversing or coarse/fine selector in order to double the number

of tap positions.

The tap changer is operated by a motor drive mechanism which rotates the

main drive shaft through a reduction gear. A bevel gear assembly drives the

operating mechanism inside the oil compartment. This gear unit distributes the

input torque to the three horizontal insulating drive shafts assuring a precise

operational sequence.

The selector shaft is driven by a geneva gear mechanism which also provides

the pinion for the geneva gear segment of the reversing switch shaft. A crank

mechanism drives the vacuum/by-pass switch shaft.

When moving from one tap position to the next, one set of by-pass switch contacts opens, while the second one stays closed, routing the current through the

vacuum interrupter just prior to its operation. The vacuum interrupter opens by

a spring-operated mechanism before the corresponding moving tap selector

contact selects the next tap.

After the vacuum interrupter recloses under spring force and is locked into position, the by-pass switch closes shunting the vacuum interrupter, thus completing the tap change operation.

The tap selector connects the preventive autotransformer alternately into

bridging (F) or nonbridging position (A). The reversing or coarse/fine switch

operates only when changing from position 1L to N or N to 1L, Figure 4.

18

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

3 Description

Figure 4

Typical winding layout with LTC on position 16L with tap sequence to

position 15 L

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

19

3 Description

3.3

Tap Selector

The tap selector consists of one contact arm operated by geneva gear,

Figure 5.

The geneva gear also locks the movable contacts on position between operations. The stationary contacts are equally spaced forming a circle on the vertical

insulating panel. They are connected by bus bars to a cast epoxy terminal board

which becomes the interface between tap changer and transformer. The stationary contacts and the inner collector rings are silverplated.

Each moving contact assembly consists of parallel contact fingers. They are

spring-loaded and digitally calibrated prior to assembly to provide safe contact

force not only during normal operating but also during shortcircuit conditions.

Figure 5

20

VACUTAP® RMV-A

Tap selector, by-pass switch and change-over selector, three-phase

assembly

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

3 Description

3.4

Change-over Selector (Reversing or Coarse/Fine)

The silverplated stationary contacts of the change-over selector are mounted

on the vertical insulating panel adjacent to the tap selector assembly, Figure 5.

The change-over selector moving contact assembly is of the same design as

the tap selector moving contact assembly but uses an increased number of parallel contact fingers.

3.5

Vacuum Interrupter

The vacuum interrupter assembly of each phase is mounted vertically on one

side of the insulating panel, Figure 6. Vacuum filling, therefore, is not required

when oil is replaced in the field. Cam action drives the vacuum interrupter

through a spring mechanism which latches at its end positions. The mechanism

provides a direct drive by its operating rod to the vacuum interrupter contact,

both moving in the same action line. The interrupter is locked in the open position while the tap selector changes taps. Upon completion of the tap selection,

the interrupter mechanism unlocks and the moving contact recloses under positive spring force. Opening and closing speeds of the vacuum interrupter are

dashpot controlled.

Figure 6

Vacuumm interupter, single phase assembly

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

21

3 Description

3.6

By-Pass Switch

The by-pass switch is located on the opposite side of the insulating panel from

the interrupter mechanism and is operated from the same drive shaft, Figure 7.

It consists of two moving contact assemblies with parallel spring-loaded contact

fingers closing on a silver-plated contact.

Both moving contacts are operated by the same drive shaft to open and reclose.

The by-pass switch normally bridges between the legs of the preventive autotransformer, thus by-passing the vacuum interrupter.

During a switching operation the by-pass switch opens one set of contacts routing the current through the remaining closed set of contacts to the vacuum

interrupter before it operates.

Figure 7

22

VACUTAP® RMV-A

By-pass switch

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

3 Description

3.7

Monitoring System

A unique monitoring system is utilized to protect the LTC in the unlikely event

that a vacuum interrupter fails to interrupt and transfer the load current during a

tap change operation, Figure 8.

Figure 8

Monitoring system schematic diagram

WARNING

Do not operate the LTC without this monitoring system properly connected and

functional if the transformer is energized. Follow the test procedures outlined in

Chapter 4.4.3.

During operation, if the monitoring system trips, do not reset until the LTC has

been inspected and the cause of the trouble corrected. Failure to adhere to these

requirements can lead to property damage and/or personal injury.

Please contact Reinhausen Manufacturing for assistance and refer to Chapter 8

for further details.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

23

3 Description

Three saturating current transformers in the moving contact leads of the

vacuum interrupters are provided. The electrical signal from the current transformer is transmitted by fibre optic cable to the monitoring circuit board. These

cables must be handled with reasonable care. DO NOT BEND OR COIL these

cables to a radius smaller than 100 mm (3.94”). Overbending will damage the

cable and destroy its ability to carry a light pulse.

The system monitors the current in all three phases at a threshold of less than

20 amperes after the interrupters are open but prior to the movement of the tap

selector contacts. The logic circuit evaluates these signals and protects the LTC

in case of vacuum interrupter failure by operating a bistable output relay. This

relay operation returns the LTC to the original position before the tap selector

opens the circuit and prevents further operations.

CAUTION

The monitoring system is functional only when the RMV-A load tap changer is

operated by control power (either by manual control switch raise/ lower or

automatically). It does not function if the unit is operated by hand cranking.

Therefore, never hand crank the unit if the transformer is energized as damage

to the transformer and/or personal injury may result if any of the vacuum

interrupters fails to interrupt.

An optional mechanical interlock is available to prevent hand cranking if a

vacuum interrupter failure occurs or upon loss of control power. As with any

safety device, the mechanical interlock should not be intentionally defeated or

tampered with.

The monitoring system’s control and indicating components are located inside

the door of the drive mechanism cabinet. It contains the electronic circuitry,

power supply, 86 L, 86 C and 86 R trip relays, SP supervision power relay, 3 red

and 3 yellow LEDs and a green LED, a TEST push-button (green) and a RESET

push-button (red).

The red LEDs indicate energizing of the associated trip relays. The yellow

LED’s indicate energizing of the SP relay denoting loss of CT signal for the

associated phase. The green LED indicates operability of the system. The

green TEST push-button is used to test the internal circuitry of the monitoring

system.

Pressing the TEST push-button simulates a failure condition of all three phases,

energizes the trip relays and lights the three red LEDs. After testing the monitoring system must be reactivated by pressing the red RESET push-button.

24

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

3 Description

The system should be tested at installation and scheduled examination intervals. The physical layout of the monitoring system circuit board is shown in

Figure 12.

3.8

Drive Mechanism/Cam Switch Assembly

Figure 9

Drive mechanism cam switch assembly, hinged door open showing

monitoring system and handcrank

The drive mechanism and cam switch control assembly are housed in a separate air compartment attached to the bottom of the tap changer oil compartment,

Figure 9. The entire assembly, together with the position indicator, motor capacitors and terminal blocks, is mounted to a detachable mounting plate affixed to

the rear wall of the motor drive housing.

The drive mechanism is powered by a single-phase, 208 - 240 Volt, 60 Hertz,

permanent split capacitor motor which is flange-mounted to a self-contained

reduction gear unit. This gear unit is grease filled and sealed at the factory to

eliminate the need for subsequent lubrication. Its output shaft couples directly

to the tap changer main shaft which extends through the tap changer oil compartment bottom. An auxiliary reduction gear driven from this gear unit operates

the factory preset cams and the position indicator.

The air compartment is accessible through a front mounted, weather-proof, hinged door. The LTC tap position indicator is visible through a viewing port in the

door.

The position indicator has two red drag hands indicating the maximum and minimum positions (raise and lower) of the actual operating range.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

25

3 Description

A handcrank coupling with interlocking switch is provided at the main gear unit

and can be used with the air compartment door open.

A modified version of the drive mechanism/cam switch assembly with weatherproof drive shaft seal on top of the housing allows for separate attachment of

the air compartment to the transformer main tank at a lower level, if required. In

this case, a single drive shaft couples tap changer and drive mechanism. Its

length may be varied according to customer specifications (max. shaft length

2,500 mm (98.4 in.).

The drive mechanism requires a separate customer supplied control cabinet

with appropriately sized motor control relays and protective circuit breaker. On

request this control cabinet can be supplied by Reinhausen. Please consult

wiring diagram supplied with each order for specification guidelines concerning

motor control relays and protective circuit breaker.

3.8.1

Option

The drive mechanism assembled on the mounting plate including cam switch

assembly, monitoring system circuit board, position indicator, drive shaft and

required fittings is also available to be mounted into the transformer control

cabinet by the customer.

26

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

4 Installation

4

Installation

4.1

Receiving, Handling and Storage

Before mounting on the transformer the tap changer oil compartment and the

drive mechanism air compartment should be opened and inspected for damage

which may have occurred in shipment due to rough handling. If shipping

damage is evident, file a claim with the transporting company. The sales office

of Reinhausen Manufacturing should be notified promptly of damage occurring

during shipment from its plant.

No special handling of the tap changer is required other than that accorded the

transformer in general. The tap changer is shipped from Reinhausen Manufacturing filled with dry nitrogen under positive pressure. If the tap changer is opened and the nitrogen fill is lost the tap changer oil compartment must be purged

and filled with dry nitrogen at a pressure not exceeding 4 psi, when stored again

indoors.

The LTC and drive mechanism are not prepared for storage in an unheated building or outdoors. Such conditions require:

•

filling the LTC tank with clean, dry oil and the gas space with dry nitrogen,

•

weather protecting of the exterior of the tank and terminal board,

•

heating the drive mechanism air compartment by connecting the built-in

space heater to power.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

27

4 Installation

4.2

Mechanical Set-up

4.2.1

Attaching the Oil Compartment

CAUTION

Welding adjacent to the epoxy terminal board may distort its mounting surface

and cause damage to the terminal board or its oil seal.

Check the size of the opening in the transformer main tank. For minimum tank

opening dimensions see customer dimensional arrangement drawing. Weld the

LTC compartment to the transformer main tank taking care that the weld is oiltight, pressure and vacuum resistant.

The transformer manufacturer is responsible for mounting the LTC on a transformer tank wall that is designed to withstand normal test and operating pressures (15 psi maximum). A 0.25-in. oil tight weld is required around the outside

perimeter of the LTC mounting flange. Welding on the transformer side of the

LTC is not required.

4.2.2

Mounting the Drive Mechanism Air Compartment

WARNING

Do not turn the LTC input shaft nor the drive mechanism output shaft until they

are coupled with each other. Coupling LTC and motor drive in non-matching

positions may cause mechanical damage.

The LTC and motor drive are shipped on separate pallets in the neutral position.

The LTC and motor drive serial numbers should be checked prior to assembly

to ensure they match.

Prior to shipment the LTC is locked in the neutral position by a cotter pin which

is inserted through the boss and the drive shaft extension on the bottom of the

tank. This cotter pin should not be removed until the motor drive is ready for

assembly to the LTC.

The motor drive unit is also shipped in the neutral position. Confirm this by

checking that:

28

•

the position indicator is on neutral

•

the cam switch timing wheel is at zero degrees

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

4 Installation

4.2.2.1

Standard Mounting (Attachment to the LTC oil compartment)

The LTC and motor drive must be coupled in the neutral position per drawing

4D32012 (see appendix).

4.2.2.2

Detached (Ground Level) Mounting (Attachment to the transformer

main tank)

This version requires, provided by the transformer manufacturer, a mounting

support on the transformer main tank. The support is fastened to the rear of the

drive mechanism housing.

The LTC and motor drive must be coupled in the neutral position per drawing

4D32009 (see appendix).

4.3

Electrical Connections

4.3.1

Connecting the Tap Leads to the LTC

Connect tap leads to the proper LTC terminal on the epoxy terminal board. For

terminal location and designation see dimensional arrangement drawing.

4.3.2

Connecting the Monitoring System and the Drive Mechanism

The drive mechanism is to be wired according to the wiring diagram which is

supplied with each order. To connect the monitoring system, insert the cable

plug from the motordrive cabinet into the receptacle on the bottom of the LTC

tank per drawing 4D32012 (see appendix).

4.4

Test Procedures

4.4.1

Manual Test Procedures

Open the LTC compartment and the drive mechanism. Insert the handcrank into

the guide lever and engage the motor drive. Sequence check the LTC operation

by hand cranking one step in the lower direction, position N to 1L (see sequence

chart in drawing DD00001 of appendix). This movement requires 7.5 handcrank

revolutions.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

29

4 Installation

While hand cranking from N to 1L (counter-clockwise) observe that the by-pass

switch P2 opens, then the vacuum interrupter trips open and the tap selector

moving contact P1 (nearest to the insulating panel) moves from M to 11. At the

same time as the tap selector, the changeover selector will move from B to A.

Continue cranking and the vacuum interrupter will reclose and finally the bypass

switch P2 closes, positioning the tap changer in “on position”. (Both by-pass

moving contacts are fully engaged to their respective stationary contacts.)

Observe the engagement of tap and change-over selector moving contacts for

smooth, non-binding operation. Observe closure of by-pass switch.

Hand crank in the raise direction (clockwise) back to neutral (position N). The

same events should take place in the same order as above except that the

movement is from 11 to M and from A to B.

Then check the LTC operation by hand cranking from position N to 1R. While

hand cranking in the raise direction (clockwise) observe that the by-pass switch

P3 opens, then the vacuum interrupter trips open, followed by the tap selector

moving contact P4 (furthest from the insulating panel) moving from M to 4. Continue hand cranking and the vacuum interrupter will reclose, then the by-pass

switch P3 will reclose, positioning the LTC in “on position”.

Observe the engagement of tap selector moving contacts for smooth, non-binding operation. Observe closure of by-pass switch.

Hand crank in the lower direction (counter-clockwise) back to neutral

(position N). The same events should take place in the same order as above

except that the movement is from 4 to M.

Withdraw the handcrank and place it in the storage holder provided.

4.4.2

Motorized Test Operations

Operate the tap changer with the drive mechanism connected to electrical

power. Do not run more than 120 consecutive operations or damage to the

motor may occur.

Extended operation of the LTC without oil is not recommended. However, the

LTC may be run once to both limits and back to neutral position for test purposes. When running the LTC electrically it typically stops between 0° to 18° on

the timing wheel. This is a normal condition.

30

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

4 Installation

Make sure that both the monitoring system and the drive mechanism are connected to power. Make sure that the motor control breaker is closed and the

handcrank is in its storage holder. Place the monitoring system into “Maintenance Mode” as per Chapter 8.1 of this manual. Operate the LTC by closing

the raise/ lower switch one step from neutral position toward the lower limit.

Check the movement of the position indicator to confirm that the motor is connected properly. The drive mechanism should operate and stop “on position”.

Operate the LTC one step of at a time from position N toward the lower limit.

Open the handcrank interlock switch by lifting the handcrank guide lever while

operating the LTC. The tap changer should not operate. Release and continue

with the operation toward the lower limit. Stop on the lowest limit position (position 16L). With one hand on the motor control breaker, close the raise/lower

switch in the lower direction. The drive mechanism should not run. If it does, turn

off the circuit breaker at once because either the limit switch timing or connections are wrong.

Remove the handcrank from its storage holder and insert. Try to hand crank the

tap changer in lower direction. The mechanical stop should operate in approximately 3 handcrank revolutions. This can be felt readily on the handcrank. Do

not force the handcrank.

Run the tap changer one step at a time in the raise direction and repeat the

checks as above in the raise limit (position 16R).

Upon completion of the checks return the tap changer to the assembly position

(position N), return the handcrank to its storage holder. Close the drive mechanism air compartment.

4.4.3

Monitoring System Tests

CAUTION

The monitoring system is functional only when the RMV-A load tap changer is

operated by control power (either by manual control switch raise/ lower or

automatically). It does not function if the unit is operated by hand cranking.

Therefore, never hand crank the unit if the transformer is energized as damage

to the transformer and/or injury to the operator may result if any of the vacuum

interrupter tails to interrupt.

Open the drive mechanism door for access to the system. There is a green LED

which indicatesoperability of the system. Two push-buttons are provided, one

red to reset and one green to test. Figure 10 shows the layout of these items.

Check the green LED to ensure that the monitoring system is operative.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

31

4 Installation

4.4.3.1

Power-off Test at the Transformer Control Cabinet

Open the transformer control cabinet. The green lamp 86 GL in the control cabinet should be on indicating that the monitoring system is energized.

Drop control power. Remove cover from monitoring system circuit board. Interrupt the power supply to the circuit board by removing the 0.25 A fuse. Reinstate control power. The 86 GL lamp should then be off and the red lamp 86 RL,

on. Try to operate the LTC drive mechanism. It should not start. Reinstall the

monitoring system fuse and it’s cover. Close the transformer control cabinet

3 red and 3 yellow LEDs

Right, Center, Left

Green push button=TEST

Red push button=RESET

Green LED

Figure 10

4.4.3.2

Monitoring system, cover removed

Operational Tripping Test

Connect a variable CT to busbar P2 and the stationary end of the flexible connector on the moving contact of one of the vacuum interrupter assemblies, for

example left phase, Figure 11. The CT should be able to drive a current of at

least 20 Amperes.

A monitoring system trip test set is available, reference Chapter 9.

Place monitoring system into “Maintenance Mode” so that all three yellow LED’s

are flashing slowly, Chapter 8.1. Raise the CT input voltage to drive a primary

current of approximately 20 A. Start the drive mechanism in one direction. The

86 L relay should trip, the associated red LED should light, the drive mechanism

32

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

4 Installation

should stop and return to its previous position. The moving selector contact

must not disconnect from the stationary during the process. The drive mechanism must not be operable in either direction, until the monitoring system is

reset.

Perform same test procedure with the vacuum interrupter assemblies of center

and right phase. Observe tripping of 86 C and 86 R relays. Be sure to reset the

monitoring system so that all 86 relays are untripped and all red lights out. Close

the LTC compartment access door.

Do not overtighten the LTC access door nuts. These nuts should be tightened

to a maximum torque of 15 Nm (11.1 ft. lbs.), which corresponds to a compression of the gasket to 5/16” thickness.

Figure 11

CT connection for test

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

33

4 Installation

4.5

Oil Filling/Transformer Vacuum Processing

During transformer vacuum processing (druing) the LTC should be considered

part of the transformer. Therefore, the tap changer and transformer gas spaces

should be connected together through the vent plug. The differential pressure

across the terminal board and its gasket system will then be zero during the

entire processing cycle. Auxiliary devices, e.g. dehydrating breather, sudden

pressure relay, etc., must be removed or disconnected during processing or

filling to prevent damage due to oil “flooding”. The sudden pressure relay can

also be damaged by rapid pressure changes (consult the instruction leaflet).

The vacuum should always be broken with dry, inert gas to prevent moisture

contamination.

In preparation for factory testing of the transformer at the maximum tap changer

voltage rating (15 kV, 25 kV or 69 kV), vacuum fill the LTC tank with oil to the

proper level prior to initiating any transformer tests.

1. Make the oil input and vacuum connections to the compartment. Remove

and plug the 1/4-in. coupling to the dehydrating breather system.

2. Hold a vacuum of 1 torr, or better, on the tap changer compartment for

2 hours prior to filling. Continue to hold this vacuum during filling. Degassed

oil will facilitate this process.

3. Break the vacuum with dry, inert gas.

4. Take three oil samples from the LTC oil compartment and test for breakdown

voltage. All three samples should have a minimum breakdown voltage of 30

kV by ASTM D 877 or 28 kV by ASTM D 1816. Moisture content should not

exceed 20 ppm by ASTM D1533.

5. Run the tap changer with motor power through the complete range limit-tolimit, 16 L to 16 R.

6. Reclose the compartment openings.

The RMV-A tank is designed to withstand a full vacuum. The terminal board is

designed to withstand a maximum differential pressure of 18 psi. This allows

for full vacuum in the LTC tank with a maximum positive pressure of 3.3 psi

from the transformer side of the terminal board.

34

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

5 Maintenance-Free Schedules and Service

5

Maintenance-Free Schedules and Service

Prior to initial energization of the transformer, perform tests and examinations

per Chapter 4.4.3 and 5.4.2.

Because of its basic design, the RMV-A Load Tap Changer will require a minimum of maintenance. However, as with any mechanical device, it should

receive periodic examination.

5.1

Maintenance-Free Intervals

The RMV-A is a Maintenance-Free Load Tap Changer through 250,000 operation count intervals or through 5 year time spans, whichever occurs first.

The Maintenance-Free interval can become strictly operation count based

regardless of time span by use of the Model 'B' monitoring system. Refer to

Chapter 8 for detailed information.

The Maintenance-Free intervals, whether time-based or operations countbased, will only need complementing by checks (annually) as follows:

Test

Check

Oil Sampling

Check for dielectric, combusti- Chapter 4.5

ble gases and water content

VIM System Test

Check circuit board ‘test &

reset’ function; simulated

monitoring runback & ‘power

off’ test

Chapter 8.4, 4.4.3

Motor drive condition

Check heater & accessory

operation; general mechanical

condition

Chapter 4.4.2

Table 3

Reference

Annual checks

Routine site visits should include as good practice the following:

Test

Check

Reference

Dehydrating Breather

check

Check for oil level and desiccant material color

Chapter 7.3,

Chapter 7.4

Check for oil leaks

All areas with seals or gaskets

that retain oil should be examined

Table 4

Routine checks

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

35

5 Maintenance-Free Schedules and Service

5.2

Taking the LTC out of Service

1. De-energize the transformer and ground all external bushings.

2. Open the drive mechanism motor control breaker.

3. Record the number of operations on the tap changer operations counter.

5.3

Draining the Oil

1. Take a tap changer oil sample.

2. Test and record the breakdown voltage.

3. Remove the vent plug on top of the LTC compartment and drain the oil.

CAUTION

Transformer oil should always be handled as a flammable liquid. LTC tanks

may, under some conditions, accumulate explosive gasses. Filtering and

handling the oil may generate static electricity. A damaging explosion could

result if any electrical discharge takes place in an explosive gas mixture. Safety

precautions should include purging the gas space with dry nitrogen before

filtering and grounding the transformer, its bushings, and all oil handling

equipment.

If the drained oil is to be reused it should be pumped through a filter press to

remove the small amount of carbon and metallic particles produced by the switching duty of the by-pass switch and the normal wear of the mechanism.

The oil should be stored in clean, dry containers if it is to be reused.

Open the LTC front inspection door. Check the door gasket for signs of deterioration. Replace with a new gasket if necessary.

36

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

5 Maintenance-Free Schedules and Service

5.4

Internal Examination

CAUTION

The monitoring system uses FIBRE OPTIC CABLES inside the LTC to transmit

signals to the electronic control box. These cables must be handled with

reasonable care. DO NOT BEND OR COIL these cables to a radius smaller

than 100 mm (3.94"). Overbending will damage the cable and destroy its ability

to carry a light pulse.

1. Check the LTC compartment floor and horizontal surfaces for debris that

might indicate abnormal wear.

2. Check all sliding surfaces for signs of excessive wear.

Make a general inspection of the tightness of bolts and nuts on those parts

which are subjected to mechanical shock and vibrations during the tap change

operation.

Figure 12

By-pass contact wear evaluation

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

37

5 Maintenance-Free Schedules and Service

5.4.1

By-Pass Switch

Check the condition of the by-pass switch contacts P2 and P3, Figure 7. These

contacts are subjected to light arcing as they re-route the tap changer current

to the vacuum interrupter during a tap change operation. For this reason the stationary and moving contact assemblies are equipped with copper-tungsten tips.

Both moving and arcing by-pass contact assemblies must be replaced when

the area of erosion is closer than 8 mm (0.3") to the end of the copper-tungsten

tip on any location on the stationary by-pass contact P2 or P3, Figure 12.

5.4.2

Vacuum Interrupter Examination

Inspect the condition of the flexible connector for broken strands.

5.4.2.1

Mechanical Test

To open the vacuum interrupters, crank the LTC between position N and 1L

(timing wheel 180°). At the end of the power spring lift the lever and watch the

operating rod move down until it engages the latch, Figure 13. Repeat a few

times to get a feel for the movement and the force required.

CAUTION

During this check lift the lever only until the operation rod just touches the edge

of the latch. Beyond that point the additional force required to operate the latch

will show to a misleading result.

Figure 13

38

VACUTAP® RMV-A

Vacuum interrupter mechanical test

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

5 Maintenance-Free Schedules and Service

5.4.2.2

Contact Erosion Indicator

Due to the expected very small contact erosion (less than 2 mm during the life

of the vacuum interrupter) a contact erosion indicator is not provided. A much

more precise and reliable method to determine the contact wear is to measure

the gap between the operating rod and the lever (in the following paragraph this

gap is called "anvil gap") using a set of feeler gages.

The vacuum interrupter is rated for 750,000 operations at full load (overload

conditions may reduce the operational life of the vacuum interrupter). However,

when the anvil gap is equal or less than 0.5 mm, the vacuum interrupter is worn

beyond its limit and must be replaced. Independently from the contact erosion

measurement the vacuum interrupter must be replaced after 750,000 operations due to mechanical wear.

Recording the anvil gap at commissioning and subsequent routine maintenance will provide the best estimate of the remaining contact life.

To measure the anvil gap, crank the LTC off position until the lever is engaged

to the latch. This means, until the tripping edge of the lever is seated against the

latch, but the vacuum interrupter is still closed, Figure 14.

Figure 14

Anvil Gap

When the load tap changer is opened for the first time and at subsequent inspections, the anvil gap should be measured to allow the evaluation of the contact wear.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

39

5 Maintenance-Free Schedules and Service

5.4.2.3

Hi-Pot Test

Due to the high reliability we have experienced with our products over many

years in service, we recommend the Hi-Pot Test only as a means of troubleshooting in the unlikely event of a specific suspicion that a vacuum interrupter

might be defective.

With the tap changer in “off position” between Pos. N and 1R (180° on the cam

switch timing wheel) test each vacuum interrupter by applying a hi-pot test of

10 kV AC or 14 kV DC for one minute as follows:

Ground all transformer windings. Open the vacuum interrupter contacts by turning the hand crank approximately 3 1/2 revolutions clockwise until the P3

bypass contact is open and the cam switch timing wheel is at 180°. Temporarily

remove the stationary contact P3, Figure 7. Ground the P3 contact stud.

A) Testing with an Asymmetrical Test Transformer (AC) or with a DC Test

Set

(A test set with one hot lead and one ground lead, Figure 15)

Figure 15

Hi-Pot test connection A

Connect the ground test lead to the aluminum casting which carries the vacuum

interrupter mechanism, and the hot test lead to the stud which connects to the

stationary vacuum interrupter contact (bottom) on the right side of the phase

board. Perform the hi-pot test.

40

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

5 Maintenance-Free Schedules and Service

B1) Testing with a Symmetrical Center-Tapped Test Transformer

(A test set with two hot leads and with test voltage of 20 kV or higher, Figure 16)

Figure 16

Hi-Pot test connection B1

Connect the ground test lead to the aluminum casting which carries the vacuum

interrupter mechanism, and the hot test lead to the stud which connects to the

stationary vacuum interrupter contact (bottom) on the right side of the phase

board. Perform the hi-pot test.

B2) Testing with a Symmetrical Center-Tapped Test Transformer

(A test set with two hot leads and with maximum test voltage lower than 20 kV,

Figure 17)

Figure 17

Hi-Pot test connection B2

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

41

5 Maintenance-Free Schedules and Service

Temporarily disconnect the flexible connector from the bus bar shunt connector

P2 carrying the CT and tie it to the aluminum housing. Apply the two hot test

leads as shown and perform the hi-pot test. This is a special test method when

the maximum voltage of the test transformer is less than 20 kV.

5.4.2.4

Hi-Pot Test Spare Parts Kit

Reinhausen Manufacturing offers spare parts kits to replace lock nuts, lock tabs

and other not reusable items after the Hi-Pot test. For ordering information refer

to the spare parts list in Chapter 9 of this manual.

Reassemble the previously disconnected or removed items. Use new locking

hardware as provided in the respective spare parts kit.

Once the Hi-Pot test has been completed bring the LTC back to “on position”.

A vacuum Interupter Hi-Pot Test Set is available; reference spare parts

Chapter 9 of this manual.

5.5

Preparing the LTC for Service

Examine the vacuum interrupter as per Chapter 5.4.2.1.

Wipe the LTC compartment clean to remove all dirty oil, metallic fall-out and

moisture that may have condensed on the walls and insulating surfaces during

the time the oil compartment was open.

Ensure the drive mechanism and monitoring system are operating properly.

Perform test operations of the drive mechanism and a monitoring system test

according to Chapter 4.4.

Close the LTC compartment.

Do not overtighten the LTC inspection door gaskets. Inspection door nuts

should be tightened to a maximum torque of 15 Nm (11.1 ft. lbs.), which corresponds to a compression of the gasket to 5/16”.

Using a filter press fill the LTC compartment with clean, dry oil to the proper

level. Vacuum filling is not required during field service.

Make the oil fill connections to the LTC drain valve. Make sure the vent opening

is unplugged. Remove and plug the 1/4" coupling to the dehydrating breather

system.

After oil filling reclose the LTC compartment openings and reconnect the dehydrating breather system.

42

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

5 Maintenance-Free Schedules and Service

Run the Tap Changer with motor power from the neutral (or assembly position)

to position 16L (or the lowest position) for approximately 100 operations without

pausing. Return to the neutral position.

Let the tap changer sit de-energized for one hour to allow gas bubbles to dissipate from the oil.

Take three oil samples and test for break-down voltage. All three should have a

minimum breakdown voltage of 30 kV by ASTM D877 or 28 kV by ASTM

D1816. Moisture content should not exceed 20 ppm by ASTM D1533.

The dehydrating breather should be checked to verify that the desiccant is dry

and the oil level in the clear plastic oil collection cell is between the two fill level

lines (refer to drawing DD10008 in the appendix).

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

43

6 Replacement of the Vacuum Interrupter Assembly

6

Replacement of the Vacuum Interrupter Assembly

Due to the high life expectancy of the vacuum interrupter a replacement is

necessary only after 750,000 operations. After this period the contacts may not

have reached their maximum erosion, but in order to insure continued reliability

the vacuum interrupter assembly must be replaced as a unit. With this all the

parts subjected to mechanical wear are replaced as well. Reinhausen Manufacturing offers a pre-assembled replacement kit. Refer to DD10005 in the appendix and Figure 18 through Figure 24 for the item numbers used in the following

instructions.

6.1

Removing the Old Vacuum Interrupter Assembly

CAUTION

The Fibre Optic Cables must be handled with reasonable care. DO NOT BEND

OR COIL these cables to a radius smaller than 100mm (3.94"). Overbending

will damage the cable and destroy its ability to carry a light pulse.

CAUTION

If the vacuum interrupter is being removed for reasons other than replacement

DO NOT TWIST the moving contact. This may damage the bellows and cause

the vacuum interrupter to fail.

When removing the old vacuum interrupter assembly carefully observe the configuration of the parts and hardware during disassembly so that reinstallation

can be completed easily and correctly. To remove the old vacuum interrupter

proceed as indicated below.

1. Remove the coupling assembly (90) which connects the vacuum/by-pass

switch shaft assembly to the operating mechanism, Figure 18.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

45

6 Replacement of the Vacuum Interrupter Assembly

Figure 18

Coupling assembly (90)

2. Turn the shaft assembly 90°, so the the cam disk (5) points toward the door,

Figure 19.

Figure 19

46

VACUTAP® RMV-A

Cam disk (5) pointing toward the LTC door

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

6 Replacement of the Vacuum Interrupter Assembly

3. Unscrew the socket head screw (22) and lock washer (11) to take off the

front guide (47), Figure 19.

4. Open the hex head screws (1) and disassemble the clamp (4),Figure 18.

5. Rotate the cam disk (5) toward the LTC door and set aside. Check that the

socket head screw (15) is loose on the clamp (52), Figure 19, 21.

Figure 20

Removal / Installation of the vacuum interrupter assembly

Figure 21

Removal / Installation of the vacuum interrupter assembly

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

47

6 Replacement of the Vacuum Interrupter Assembly

6. Disconnect the flexible connector (12) from the CT assembly (97) by

removing the mounting hardware (20, 29, 30), Figure 19.

7. In order to remove the vacuum interrupter assembly, remove the mounting

hardware, flat washer (91), lock washer (92) and hex head bolt (93), on the

back of the aluminum mounting base from the vacuum interrupter

mechanism (49), Figure 18.

8. Remove the mounting hardware (34, 28,31) from the vacuum bottle carrier

(50).

9. Disconnect the carrier (50) from the P3 stationary contact by taking out the

hex head bolts (94) and their related lock washers (95), Figure 19.

10.Take out the mounting hardware (21, 29, 23) from the support (52), Figure

20.

11. The vacuum interrupter assembly can then be removed by carefully pulling

it to the left and tilting it to an almost horizontal orientation Figure 20.

12.Take the moving by-pass contact assembly (98) of all three phases away

from the drive shaft by opening the clamp on its back, Figure 22.

Figure 22

48

VACUTAP® RMV-A

By-pass moving contact assembly

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

6 Replacement of the Vacuum Interrupter Assembly

Move the drive shaft towards the operating mechanism on the left until the bearing half shells (99) can be removed from the bore in the left and right phase

board, Figure 23.

Figure 23

6.2

Bearing half shells

Installing the New Vacuum Interrupter Assembly

Lock tabs and lock nuts should not be reused for reasons of reliability. Always

use new lock tabs and lock nuts when reassembling the unit. Sufficient spare

tabs and nuts are contained in our spare parts kit.

1. To install the new vacuum interrupter assembly, follow the steps previously

described but in reverse order.

2. Insert new bearing half shells (99) and move the drive shaft back into its

original location, Figure 23.

3. Reinstall the By-Pass stationary contact assemblies, Figure 22. Refer to

Chapter 5.4.1 to decide if they need to be replaced with new ones.

CAUTION

Avoid excessive twisting of the bellows during assembly and adjustment.

Excessive twisting will reduce the mechanical life of the bellows or will fracture

it, making the vacuum interrupter inoperative.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

49

6 Replacement of the Vacuum Interrupter Assembly

4. Careful not to damage the bellows of the vacuum interrupter insert the spare

assembly in reverse order.

5. Tighten the fasteners (34, 28, 31) for the vacuum bottle carrier (50) and the

connection to the P3 stationary contact (94, 95).

6. Insert the mounting hardware (91, 92, 93) on the back of the aluminum

mounting base (49) and tighten.

7. Reassemble the mounting hardware (21, 29, 23) of the support (52), but do

not fasten the socket head screw (15) to close the clamp yet.

8. Connect the flexible connector (12) to the CT assembly (97) using new lock

nuts (30).

9. Check, if the operating rod (53) can move freely. For this refer to the

mechanical test described in Chapter 5.4.2. If this is not the case, loosen the

hardware on the back of the aluminum mounting base (49) and move it

within the clearance of the bolt holes to improve the alignment of the

operating rod (53) within the bearing (13).

10.Retighten the hardware. There should be no binding now.

11. Reassemble the new cam disk (5) using the new hardware (1, 2) and guide

(47) with the fasteners (11) and (22).

12.Rotate the vacuum/by-pass switch shaft assembly back to "on position" and

reconnect the coupling assembly (90) using new locking tabs (96).

13.Check that the By-Pass moving contact assemblies are centered in relation

to the stationary contacts and the contact finger assemblies are floating

within their carriers.

14.Align if necessary.

50

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

6 Replacement of the Vacuum Interrupter Assembly

6.2.1

Adjustment of the Closing Travel

Figure 24

Closing travel C

1. With the LTC "on position" measure the dimension "A" from the top of the

brake cylinder (86) to the top of the operating rod (53) using a depth gage.

Make sure to take the reading away from the M4 tap in the center of the operating rod to avoid a false result, Figure 24.

2. Hand crank the LTC between positions until the vacuum interrupter opens.

Continue hand cranking slowly until the operating rod is just retained by the

latch (62) but the tang on the back of the lever (43) is not touching the latch

(62) yet. Measure the dimension "B" from the top of the brake cylinder (86)

to the top of the operating rod (53).

3. The closing travel "C" is calculated by subtracting "B" from "A" (C=A-B). "C"

must be adjusted to 0.8 to 1 mm:

0.8 mm ≤ C ≤ 1.0 mm

4. The closing travel "C" is adjusted by rotating the vacuum interrupter (37)

within the M18 tap of the carrier (50).

5. Loosen the clamping hardware (20, 29) and (28, 27) on the carrier (50) and

the split nut (44) respectively. You may have to pry the split nut open until it

can rotate freely on the moving contact stem of the vacuum interrupter.

6. Check that the socket head screw (15) is loose on the clamp (52). Carefully

rotate the vacuum interrupter to adjust “C”. The pitch of the thread is 1.5 mm,

i.e. one rotation of the vacuum interrupter translates to an axial movement

of 1.5 mm. If “C” measured more than 1mm the interrupter must be moved

up, if “C” measured less than 0.8 mm the interrupter must be moved down.

Be careful not to loosen the operating rod (53) within the tap of the moving

vacuum interrupter contact while turning it during the adjustment.

7. Tighten all loose hardware and check again for free movement of the

operating rod.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

51

6 Replacement of the Vacuum Interrupter Assembly

8. Using a feeler gage check and record the anvil gap. It should not be less

than 2.5 mm (0.1"), Figure 14.

9. Perform several test operations between two tap positions to ensure the

correct stroke of the vacuum interrupter moving contact. Perform the

operations by hand cranking and observe the vacuum interrupter opening

and closing.

10.Finally set the load tap changer to “on position”.

Refer to Chapter 4.4 and Chapter 5.5 for testing requirements prior to placing

the LTC back inservice.

52

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

7 Dehydrating Breather Assembly

7

Dehydrating Breather Assembly

The dehydrating breather is designed to remove moisture from the air breathed

into the load tap changer. It consists of a cylindrical glass body, top connecting

flange, bottom breather/trap and an exterior protective grate with three observation ports.

7.1

Receiving

The breather is shipped detail with the dehydrating material placed in separate

containers.

7.2

Installation

To mount the disassembled breather:

1. Fill the breather chamber with dry dehydrating material (approx. 2.2 lbs)

through the opening in the flange on the breather top.

2. Place the flange gasket on top of the flange followed by the mounting

bracket, aligning the threaded hole with the flange opening. Secure with two

M10 x 35 hex head bolts, washers and locking nuts.

Mount the dehydrating chamber to the pad (provided by the user) on the

transformer tank wall. See sketch "A" on drawing DD10008 for recommended mounting pad dimensions. Secure with two M10 x 35 hex bolts, washers

and locking nuts.

Connect the tubing between the top of the breather and one of the 0.25" half

couplings provided on the LTC side walls.

All connections must be air tight. Use of a high temperature grease on the

screw joints helps prevent rust and permits the parts to be removed easily

when necessary.

3. Remove the clear plastic oil collection cell by squeezing the retaining

bracket. Fill it with clean transformer oil until the oil level is between the two

fill level lines on the cell. Carefully place the filled oil collection cell back onto

the breather housing bottom.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

53

7 Dehydrating Breather Assembly

7.3

Operation

The breather permits in- and out-breathing when there is a difference in pressure between the LTC gas space and the atmosphere exceeding the head of oil

in the breather/trap. The dehydrating material is protected from the ambient

humidity by the oil in the collection cell which also serves to trap any particles

in the air during in-breathing.

The cylindrical body is filled with dehydrating material which is orange in color

when in the dry state. When it becomes saturated with moisture, its color changes to green or colorless. The color change can be observed through the observation ports in the protective grate. The dehydrating material should be replaced when 75% of the material has changed from orange to green or colorless.

7.4

Maintenance

Two dehydrating materials (desiccant) are available:

1. Silica gel (6 to 16 mesh) which is orange in color when in dry state. It turns

green when saturated.

2. Sorbead® ORANGE (4 to 8 mesh) which is orange in color when in dry state.

It turns colorless when saturated.

The time between subsequent changes of the dehydrating material depends

upon the load cycle of the transformer and the ambient conditions. It is advisable to check the color of the material frequently at first, to determine the

approximate time interval for replacement of the desiccant for the particular

application.

A recommended method is to have a second charge of dry dehydrating material

on hand in a sealed container. This allows a quick renewal of the dehydrating

breather filling. The removed saturated desiccant can later be dried out and

stored for the next change.

To replace the desiccant, carefully remove and empty the oil collection cell and

remove the dehydrating breather from its holder by loosening the two M10 x 35

hex bolts. Empty the saturated material through the hole in the top flange into a

pan. Refill the breather with a fresh charge and fill the oil collection cell with

clean transformer oil to the level indicated on the cell. Reinstall the breather on

its holder, making sure the flange gasket is in place. Finally, place the oil collection cell in its bracket.

54

VACUTAP® RMV-A

2161246/00 EN

© Maschinenfabrik Reinhausen 2010

7 Dehydrating Breather Assembly

The saturated desiccant can be placed in an open pan and dried at a temperature of 130°C to 160°C (266°F to 320°F) for about 2- 3 hours. When dry, the

material regains its orange color. Since the particles dry from the outside

towards the center, the outer surface will change its color first. This initial

change in color should not be considered as a complete reactivation of the

desiccant. It should be allowed to dry as specified above.

© Maschinenfabrik Reinhausen 2010

2161246/00 EN

VACUTAP® RMV-A

55

8 Vacuum Interrupter Monitoring (VIM) System

8

Vacuum Interrupter Monitoring (VIM) System

Refer to Chapter 3.7 for safety instructions.

8.1

Vacuum Interrupter Monitoring System Description

The RMV LTC utilizes a unique monitoring system to abort the tap change operation in case a vacuum interrupter has failed to interrupt the current just prior to

the opening of the tap selector contacts or in the event of monitoring system

supply power loss. The system is the only one of its kind on a load tap changer.

Utilizing bias resistant fiber optic signals, which move through the LTC tank for

a portion of each tap change, the RMV provides self-examination of each and

every operation. Special DC logic within the monitoring system electronics interprets current sensing optical signals as trigger input is received from a precisely

timed cam-operated microswitch (186). Should current be flowing through the

vacuum interrupter circuit when it normally would be open, the LTC is immediately stopped and returned to the position from whence it came. Latching alarm

relays prevent further operation until the system has been reset. System verification must always take place prior to resetting and placing the LTC back in

operation.

Specific components utilized in the monitoring scheme are as follows: SP

supervisory power indication relay located on the printed circuit board; 86L,

86C, 86R latching alarm relays located on the printed circuit board; 86X, 86XL

& 86XR control relays located within customer’s control cabinet; 86GL (green/

power on) & 86RL (red/alarm) status pilot lights located within customer’s control cabinet.

Any alarm condition, whether vacuum interrupter failure, abnormal CT signal, or

loss of monitoring supply power, will cause the 86RL pilot light <alarm condition> to illuminate. Additionally, any single or combination of the latching relays

will energize the 86X relay blocking the function of the raise/lower switch while

bringing the LTC back to the position from whence it came via the 86XL or 86XR

relays, depending on which direction the LTC was moving.

Additionally the function of the CT-Light Conductor circuit within the LTC is continuously verified. Utilizing the input from the AIW (‘All is Well’) microswitch, the

© Maschinenfabrik Reinhausen 2010 2161246/00 EN

VACUTAP® RMV-A

57

8 Vacuum Interrupter Monitoring (VIM) System

circuit checks for signals between the time that the Bypass opens until the

Vacuum Interrupter opens. In this situation, CT signals should be present to

indicate that the devices (CTs, Light Conductors) and wiring are functional and

all is normal. If any component is not working properly, the associated input terminal would not have signals present, and the system would recognize the fault

condition. The appropriate phase LED (Yellow) would be illuminated, and the

(SP) trip relay would be latched causing the 86RL pilot light to illuminate and

locking out the LTC.

If the LTC is to be operated while being “out-of-service”, the Monitoring System