Introducing the worlds only truly safe safety harness

advertisement

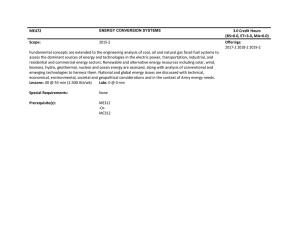

Gordon Leicester Founded facelift in 1985 with one vehicle and built the company into a £15m turnover business with over 830 assets nationally. He has been the driving force behind the growth of facelift since its inception. He initiated a number of patents including the ZT Harness, the I Foot and Sky Hook. The History of Safety Harnesses 1407 The earliest evidence dates back to the renaissance period. 1595 Fausto Veranzio designed parachute harness named ‘Flying man’ or ‘The man with the angels blessing’ 1911 Gleb Kotelnikov invented first parachute harness made of webbing. 1918 Floyd Smith first patented parachute harness with groin straps 1930-1950’s There is no evidence of the use of any safety harness in the construction industry 1950s Fall prevention was a waist strap going around the individuals back. 1960-1980’s The first waist belts appeared, probably originating from pole climbing in America. 1980’s - 2008 The first full body harness are introduced probably originating from the parachute harness. THE FUTURE What is a conventional harness? It is a structure made from webbing, designed to hold the human body in the event of a fall. It is NOT designed to prevent injury from it’s use. In 2007 initial testing was carried out by the HSE and in 2008 further tests were conducted by Sussex University and Millbrook proving ground. Testing was carried out using identical Crash test dummies and techniques used in establishing car safety standards. Video of crash test dummy wearing a conventional front mounted safety harness taken at Millbrook laboratories. Points of impact and force distribution in a conventional harness A conventional front mounted safety harness over a 4 metre drop produces enough whiplash to break the neck. * Data from Millbrook laboratories A poorly fitted conventional harness can cause strangulation in a fall. Wearing a correctly fitted traditional harness severely reduces air circulation around the groin. Therefore, creating the risk of testicular heat stress. Possible injuries sustained in the event of a fall wearing a conventional harness • • • • • • • • • Tr a u m a t o t e s t i c l e s , w o m b , a n u s Spinal trauma Groin tissue damage/testicular heat stress Te a r i n g t o f e m o r a l a r t e r y Damage to kidneys and internal organs Hip dislocation Breast tissue damage Whiplash Collar bone fractures Suspension Trauma? Everybody w ho i s suspended i n a safety harness runs the ri sk of shock and unconsci ousness due to bl ood fl ow i nsuffi ci ency. U nconsci ousness can become l i fe threateni ng after onl y a few mi nutes . * M Lieblich and W Rensing (1997) Some form of pump is required in order to move fluid against gravity, and it is no different in the legs. The heart is an efficient organ, but with up to 20% of the blood volume being in the legs at any one time, it would have to work extremely hard at all times to maintain adequate venous return. Additional methods are required. These are provided by one-way valves in the veins and by the contraction of the calf muscles, which squeeze blood upwards towards the heart. If someone stood still for a number of minutes, up to 20% of the blood volume would be in the legs. This would place the body in to class 2 shock which could easily lead to loss of consciousness. He gives the analogy of the soldier fainting while on guard duty, described earlier in 1.2, and his rapid return to consciousness as the blood flow to the brain is restored. Having made the point that an unconscious person suspended in a harness would not automatically assume a horizontal position, he continues: “There are a number of factors that make suspension trauma in a climber/casualty different from that in our soldier.” * Dr R Dawes (2000) To f u r t h e r c o m p l i c a t e m a t t e r s , a f t e r 2 0 o r 3 0 m i n u t e s o f the harness directly compressing tissue, the condition known as 'crush injury' will result. This causes the release of large proteins (myoglobin) from damaged tissues and when the harness (or bodyweight) is removed can be very damaging to the kidneys . * Dr R Dawes (2000) Failure of the muscle pump the legs Circulatory insufficiency Reduction of venous return Organ damage Decrease in volume of circulatory blood Acute Oxygen deficiency Fall in cardiac output Fall in blood pressure Paul Seddon HSE 2002 G O L I A D , Te x a s - A n o i l f i e l d w o r k e r i n S o u t h Te x a s h a s d i e d a f t e r f a l l i n g w h i l e near the top of a 50-foot rig. The Goliad County Sheriff's Office on Wednesday identified the accident victim as 40-year-old Scotty O'Neal Stanley of Livingston. Deputies were summoned Monday night to a rural area after other workers heard a hardhat fall and looked up to see Stanley dangling from his safety harness. Authorities believe Stanley slipped and fell, striking his head and being left unconscious . Another worker lowered the victim to the base of the rig. Stanley had died by the time emergency personnel arrived. Sgt John Pape says the w o r k e r h a d a v i s i b l e h e a d i n j u r y. No cause of death was released. Investigators didn't say how far Stanley fell. Additional details weren't immediately released . * News Report February 2015 To d a t e , t h e r e i s n o i d e a l s a f e t y h a r n e s s , b u t i t i s l i k e l y that — whatever the appearance of the safety harness — a relatively long period of time spent suspended motionless can lead to death . It is recommended as a matter of urgency that when a safety harness is purchased, it should be tested while suspended so that one can find the model which best fits t h e s h a p e o f t h e b o d y. N o s a f e t y h a r n e s s e s s h o u l d b e used that does not adjust to the body…. * Bariod and Théry (1997) The Dynamic Safety Harness A Dynamic Harness should NOT be considered as a first line of fall prevention for persons working at height. The Dynamic Harness, as with any other type of safety harness, should only be considered for the primary means of fall prevention while working at height as a last resort or as an additional safety measure. Working at height risks must be properly assessed by a competent person and alternate means of fall prevention considered first, such as safe working platforms, fixed guard rails/toe boards, Mobile elevated working platforms (Cherry Pickers, Scissor lifts etc). The Concept • Comfortable to wear • Create a stylish safety harness which becomes the users uniform • Eliminate or reduce injuries sustained in the event of a fall • Remains comfortable and pain free when in suspension Timeline 2007 The idea is conceived 2007 Initial testing is carried out by the UK HSE laboratories 2008 Testing carried out by Sussex University and Millbrook Crash Test laboratories 2011 SATRA grants CE EN361-2002 2015 SAI Global grants AUS/NZ AS/NZS 1891.1:2007 Vi d e o o f c r a s h t e s t d u m m y wearing a front mounted Dynamic safety harness taken at Millbrook laboratories. 2011 - Awarded APAF & IAPA ‘Contribution to Safe Working at Height’ 22 of the 26 acceleration/ moment / load values are lower for the Dynamic Harness suggesting it can reduce the potential risk for certain adverse effects on the body during a fall. Point of impact and force distribution in a Dynamic harness The Dynamic harness distributes forces away from the groin to a more appropriate load bearing structure of the lower limbs and pelvis Conventional Dynamic The Dynamic Safety Harness reduces whiplash and fall forces by up to 60% Conventional Dynamic Strangulation When deployed, the orange webbing A slides through the black upper structure B preventing the chest strap C from being pulled upwards towards the neck C The Dynamic Safety Harness allows complete air circulation around the groin area as there are no restrictive straps. Front attachment suspension position The user comes to rest in a semi-seated position. Rear attachment suspension position The user comes to rest in a kneeling position. Component Strengths Orange webbing: 3,000kg Black webbing: 3,000kg Leg Gaiter: 1,000kg (each leg) L e g G a i t e r R o p e : 500kg Chest buckle: x 6 loops = 6,000kg (each leg) 18kN (rear & work position harness only) Rated for persons up to 150kg, 23st, 330lbs Standard conventional harnesses are only rated to 100kg A Dynamic harness does not need to be adjusted tightly, contrary to guidance for a conventional harness. It will automatically tighten and adjust to the body in the event of a fall. Inspect in the same manner as a conventional harness, daily before use and every 6 months* An individual trained on inspecting a conventional harness should not require additional training to inspect a Dynamic harness. * This will vary on local legislation Fully machine washable. The harness is washed 70 times at 60°C, prior to final strength / drop testing to achieve CE approval. Interchangeable Trouser option Harness can be removed from trouser Trouser section can be replaced Optional flame retardancy, tested and approved when used in conjunction with flame retardant coveralls BS EN361:2002 The ZT Dynamic Harness is manufactured in the UK using the finest quality materials and components* * Garments vary upon customer requirements Manufactured utilizing the same technology as used in the production of car air bags Harness Types Standard Harness Front Attachment Dual Harness Front & Rear Universal Harness Front, Rear & Work Positioning Garment options Work wear Heavy duty Undergarment Fire Service Flame Retardant High visibility Anti-Static High visibility Extreme weather Companies who have adopted the ZT Dynamic Harness www.ztsafety.com