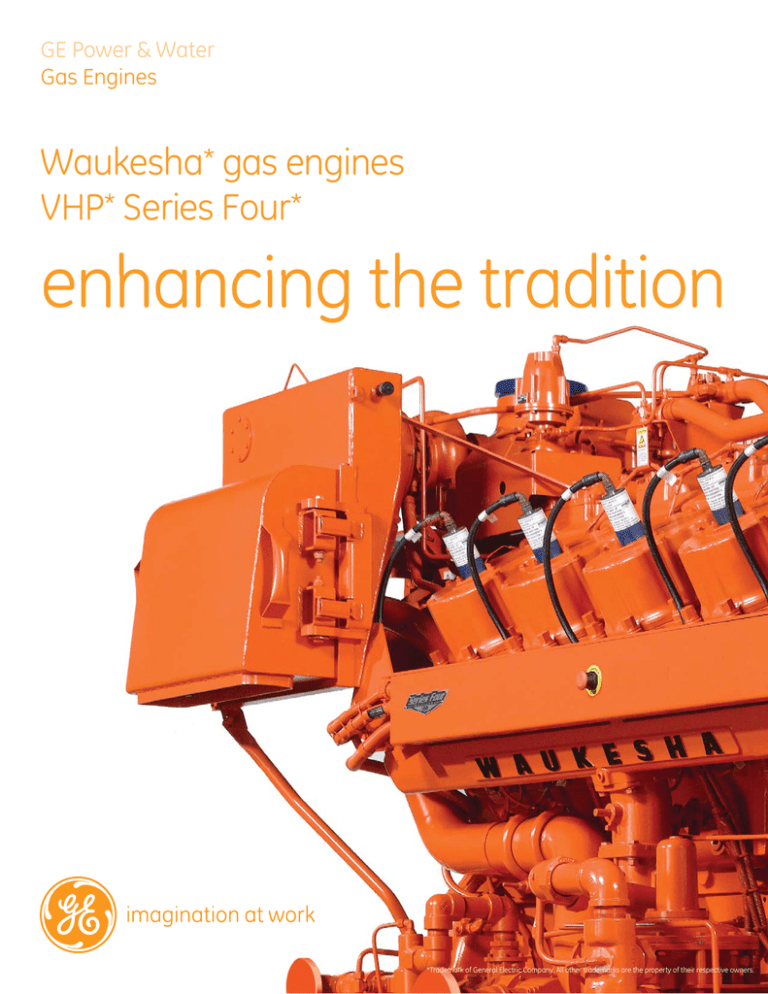

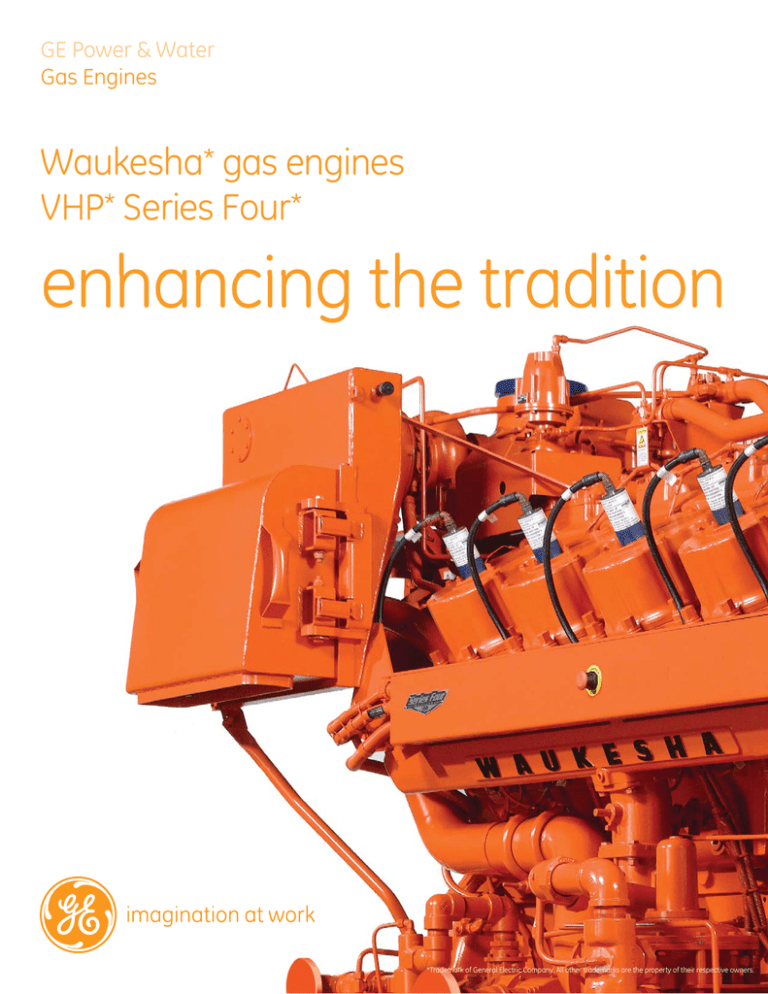

GE Power & Water

Gas Engines

Waukesha* gas engines

VHP* Series Four*

enhancing the tradition

*Trademark of General Electric Company. All other trademarks are the property of their respective owners.

VHP Series Four Enhancements

GE Power & Water’s Waukesha Series Four rich-burn engines have

traditionally been the engines of choice for some of the harshest and

most demanding gas compression, power generation, and mechanical

drive applications across the world.

This tradition has been built on the Series Four engines’ ability to reliably

produce more power on hot field gases, at high altitudes, and in remote

locations, all while providing the opportunity to deliver the lowest

available emissions when paired with a 3-way catalyst (NSCR).

Series Four rich-burn engines are known for their application flexibility

and reliability. A series of upgrades to the F3524GSI, L5794GSI, and

L7044GSI now further enhance the tradition and durability of the

Series Four.

Cylinder Head Components & Valves

Rich-burn engines are about heat. The same heat and high-exhaust

gas temperature that enables the highly-effective emission reduction

capability of a 3-way catalyst must also be managed properly within

the cylinder head.

Series Four cylinder heads now incorporate intake and exhaust valves

with a new proprietary design for improved seating, sealing, and heat

transfer. Both the intake and exhaust valves now use positive valve

rotators for better temperature distribution and sealing, resulting in

lower wear and longer life.

An improved spark plug carrier sealing system ensures robustness and

long life.

These designs have been proven in multiple field tests and have

exceeded the goal of running up to full rated load for 24,000 hours.

The success of these field tests indicate the extended time-betweenoverhauls (TBO) capabilities of the new cylinder head design†. Frequent

monitoring and inspection throughout testing showed cylinder heads

to be in excellent condition after more than 30,000 hours of operating

time. Exhaust valve recession was measured at less than half of the

guideline as published by Waukesha gas engines.

Enhanced

d Air/Fuel

/

l Ratio Controll

A rich-burn engine with a 3-way catalyst (NSCR) provides a scalable

emission solution with the lowest overall emissions in the market. With

enhancements to the ESM* air/fuel ratio control system, Series Four

engines are able to achieve these low emission levels across an even

wider range of applications.

An enhanced ESM air/fuel ratio control algorithm was created to

optimize the performance of a new fuel pressure regulator. Included

in the new algorithm are updated gains in the fuel system to improve

the interaction between the regulator, engine, and controls, as well

as improved oxygen sensor signal processing specifically matched to

Waukesha’s oxygen sensor.

Together, the enhanced ESM air/fuel ratio control algorithm and new

fuel pressure regulator create up to a 17% wider air/fuel ratio range

where 3-way catalyst performance is optimized. The system also

maintains the air/fuel ratio set-point across a wide fuel quality range.

This wider “sweet spot” provides greater confidence in emissions

compliance and less frequent adjustment, resulting in lower operating

costs.

Fuel pressure regulator applies to all VHP engines.

Improved ESM air/fuel ratio control algorithm applies to F3524GSI,

L5794GSI and L7044GSI

Applies to F3524GSI, L5794GSI and L7044GSI

Time between overhauls may vary based on operating conditions and maintenace.

†

Old

New

New exhaust valves have a proprietary design

to improve robustness and reduce wear rate.

The ESM air/fuel ratio control algorithm was

enhanced to optimize the performance of the

new fuel pressure regulators.

New fuel pressure regulators provide

wider air/fuel ratio range where catalyst

performance is optimized

Cam Tappet Rollers

Front-End Gear Cover Sealing

An improved cam tappet roller design provides long life with minimal

wear. A 3-piece pin/bushing/roller design and optimized oil channels

improve lubrication for smooth operation.

Single piece gear housing and gear cover gaskets eliminate gasket

joints, providing a highly-engineered sealing system between the

crankcase and the front-end gear cover.

Applies to all VHP engines

Further gasket refinements include higher strength material and an

optimized contour, which produces a more uniform sealing pressure.

These gasket enhancements, coupled with longer bolts for better

clamp load, improve the margin against joint relaxation and minimize

opportunities for leaks.

Pistons and Cylinder Liners

The Series Four piston has been enhanced for improved scuff resistance

under even the most challenging operating conditions.

Applies to L5794GSI, L7042GSI and L7044GSI

Piston enhancement applies to F3524GSI, L5794GSI and L7044GSI

Enhancement Features Summary

New Feature

Service

Parts

L5794GSI

L7044GSI

Series Four

Cylinder Head

X

X

X

X

ESM Air/Fuel Ratio

Control Algorithm

X

X

X

X

Gas Regulator

X

X

X

X

X

X

Cam Tappets

X

X

X

X

X

X

Series Four Pistons

X

X

X

NA

X

X

Front-End Gear

Cover Sealing

Cam tappet rollers provide better lubrication

for smoother operation.

L7042GSI

All Other

VHP

F3524GSI

X

X

X

New piston design provides optimal scuff

resistance

Sealing has been enhanced through the use of

a single-piece gasket between the crankcase

and the front-end gear cover.

GE Power & Water

1101 West Saint Paul Avenue

Waukesha, WI 53188-4999

P: 1.262.547.3311

F: 1.262.549.2759

Visit us online at:

www.ge-waukesha.com

©2013 General Electric Company

All Rights Reserved

GE’s Gas Engines business

GE’s Gas Engines business is a recognized leader in the

industry for fuel flexibility, low emissions and performance

excellence with energy solutions providing efficiencies

as high as 98 percent. A specialist in combined heat and

power (CHP), mechanical drive, waste heat-to-power and

fuel rating technologies, GE’s Gas Engines business boasts

a combined 170-year legacy of technological innovations

crossing three product lines ― Jenbacher gas engines,

Waukesha gas engines and Heat Recovery Solutions.

GE’s Gas Engines business manufactures gas-fueled

reciprocating engines, generator sets, CHP modules,

ORC systems and auxiliaries for power generation and

compression, delivering cleaner, more efficient, and

affordable onsite energy with products that generate a wide

range of distributed power outputs. Our fuel-flexible engines

of up to 10 MW operate on a wide range of field and natural

gas as well as biogas and landfill, coal mine, associated

petroleum and sewage gas. The business is supported by

life-cycle service solutions such as remote monitoring and

diagnostics as well as contractual services and upgrades

that increase availability and performance and underscore

our global excellence in customer value.

Part of GE Power & Water, GE’s Gas Engines business is

headquartered in Jenbach, Austria. Its main production

facilities are located in Jenbach, Austria, and Waukesha,

Wisconsin, United States. It has more than 2,600 employees

and over 32,000 engines installed in more than 80 countries.

8060 0113

GEA-19640