TDD-D-1

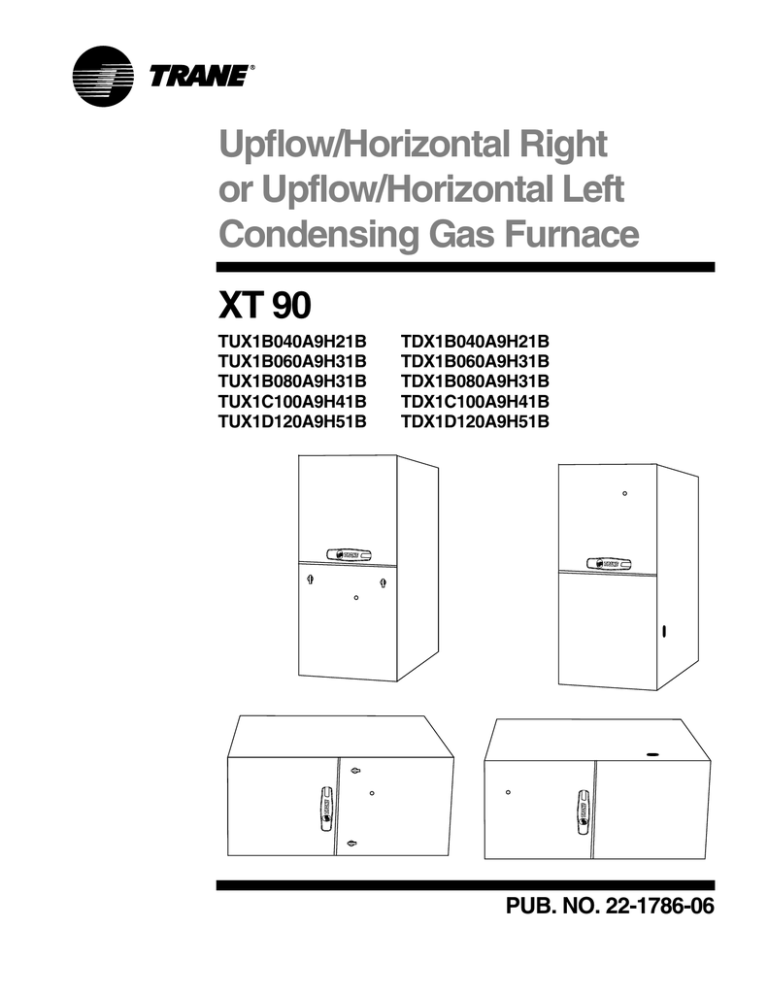

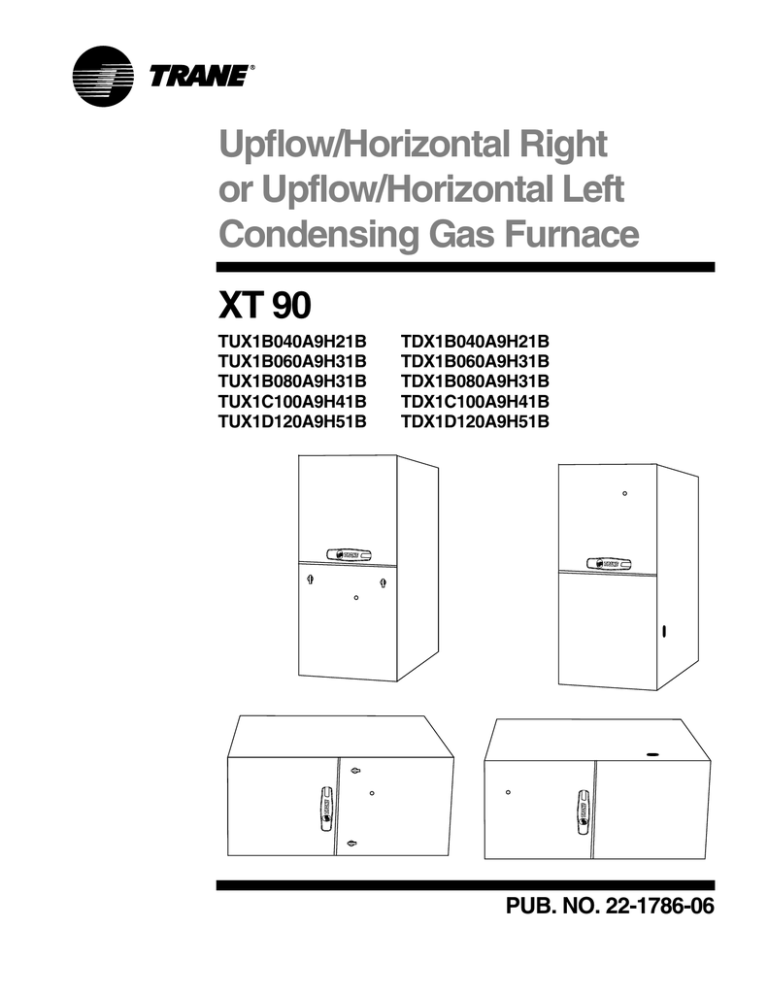

Upflow/Horizontal Right

or Upflow/Horizontal Left

Condensing Gas Furnace

XT 90

TUX1B040A9H21B

TUX1B060A9H31B

TUX1B080A9H31B

TUX1C100A9H41B

TUX1D120A9H51B

TDX1B040A9H21B

TDX1B060A9H31B

TDX1B080A9H31B

TDX1C100A9H41B

TDX1D120A9H51B

PUB. NO. 22-1786-06

General

Features

NATURAL GAS MODELS

Central Heating furnace designs are

certified by the American and Canadian

Gas Association for both natural and L.P.

gas. Limit setting and rating data were

established and approved under standard rating conditions using American

National Standards Institute standards.

SAFE OPERATION

The Integrated System Control has solid

state devices, which continuously monitor

for presence of flame, when the system is

in the heating mode of operation. Dual

solenoid combination gas valve and

regulator provide extra safety.

QUICK HEATING

Durable, cycle tested, heavy gauge

aluminized steel heat exchanger

quickly transfers heat to provide warm

conditioned air to the structure. Low

energy power vent blower, to increase

efficiency and provide a positive discharge of gas fumes to the outside.

BURNERS

Multiport Inshot burners will give years of

quiet and efficient service. All models

can be converted to L.P. gas without

changing burners.

INTEGRATED SYSTEM CONTROL

Exclusively designed operational program provides total control of furnace

limit sensors, blowers, gas valve, flame

control and includes self diagnostics for

ease of service. Also contains connection points for E.A.C./humidifier.

© 2009 Trane

All Rights Reserved

2

AIR DELIVERY

The four speed, direct drive blower

motor, has sufficient airflow for most

heating and cooling requirements, will

switch from heating to cooling speeds on

demand from room thermostat. The

blower door safety switch will prevent or

terminate furnace operation when the

blower door is removed.

STYLING

Heavy gauge steel and “wrap-around”

cabinet construction is used in the

cabinet with baked-on enamel finish for

strength and beauty. The heat exchanger section of the cabinet is completely lined with foil faced fiberglass

insulation. This results in quiet and

efficient operation due to the excellent

acoustical and insulating qualities of

fiberglass. Built-in bottom pan and

alternate bottom, left or right side return

air connection provision.

FEATURES AND

GENERAL OPERATION

The XT90 High Efficiency Gas Furnaces

employ a Silicon Carbide Hot Surface

Ignition system, which eliminates the

waste of a constant burning pilot. The

integrated system control lights the main

burners upon a demand for heat from the

room thermostat. Complete front service

access.

a. Low energy power venter

b. Vent proving pressure switch.

Pub. No. 22-1786-06

Contents

General Features

2

Features and Benefits

4

Standard Equipment

Optional Equipment

General Data

Pub. No. 22-1786-06

4

4

5

TUX1B040A9H21B

TUX1B060A9H31B

TUX1B080A9H31B

TUX1C100A9H41B

TUX1D120A9H51B

TDX1B040A9H21B

TDX1B060A9H31B

TDX1B080A9H31B

TDX1C100A9H41B

TDX1D120A9H51B

5

5

6

6

6

7

7

7

7

8

Performance Data

10

Field Wiring

12

Dimensions

14

Electrical Data

15

3

Features

and Benefits

XT 90 UPFLOW/HORIZONTAL RIGHT or LEFT STANDARD EQUIPMENT

• Convertible to horizontal with left or

right airflow

• Gasketed blower door

• Common vent capability

• Internal filter rack

• Power supply 115/1/60

• Type 29-4CTM stainless steel

secondary heat exchanger

• Standard filter sizes

• Heavy gauge reinforced wrap-around

steel cabinet

• Cleanable high velocity filters

• Optional L.P. conversion kit

• Silicon Nitride Hot surface igniter with

adaptive heat up

• Heavy gauge aluminized steel heat

exchanger

• Left/right gas connection

• Integrated solid state control with selfdiagnostics

• Blower door safety switch

• Multi-port In-shot burners

• Selectable cooling fan off eliminates

need for BAY24X045 time delay relay

• Single wire twinning

• Complete front service access

• 24 volt fuse

• Attractive color accents

• Alternate bottom/left/right return air

• Manual reset flame roll-out switches

• Hinged blower door

• Slide out blower assembly

• Prefect Fit door latches

• Constant torque ECM blower motor

• Insulated blower door

• Adjustable fan off times

• Accessory hook-up capability

XT90 Optional Equipment

✓ ] indicates accessories included).

OPTIONAL EQUIPMENT FOR CONDENSING UNITS (Check mark [✓

For Comfort Controls, See price book pages ................................................................................................................................ [

CleanEffectsTM Whole House Air Cleaner (14-1/2" Wide, Upflow / Side Return Furnace) ............................... TFD145ALFR000A [

CleanEffectsTM Whole House Air Cleaner (17-1/2" Wide, Upflow / Side Return Furnace) ............................... TFD175ALFR000A [

CleanEffectsTM Whole House Air Cleaner (21" Wide, Upflow / Side Return Furnace) ..................................... TFD210ALFR000A [

CleanEffectsTM Whole House Air Cleaner (24-1/2" Wide, Upflow / Side Return Furnace) ............................... TFD245ALFR000A [

CleanEffectsTM Whole House Air Cleaner (14-1/2" Wide, Downflow Furnace) ............................................... TFD14DALFR000A [

CleanEffectsTM Whole House Air Cleaner (17-1/2" Wide, Downflow Furnace) ............................................... TFD17DALFR000A [

CleanEffectsTM Whole House Air Cleaner (21" Wide, Downflow Furnace) ..................................................... TFD21DALFR000A [

CleanEffectsTM Whole House Air Cleaner (24-1/2" Wide, Downflow Furnace) ............................................... TFD24DALFR000A [

Air Filter, “Perfect Fit” High Efficiency (14-1/2" Wide Gas Furnace) ....................................................................... TFM145A9FR0 [

Air Filter, “Perfect Fit” High Efficiency (17-1/2" Wide Gas Furnace) ....................................................................... TFM175A9FR0 [

Air Filter, “Perfect Fit” High Efficiency (21" Wide Gas Furnace) ............................................................................. TFM210A9FR0 [

Air Filter, “Perfect Fit” High Efficiency (24-1/2" Wide Gas Furnace) ....................................................................... TFM245A9FR0 [

Air Filter, “Perfect Fit” Standard Efficiency (14-1/2" Wide Gas Furnace) ................................................................ TFP145A9FR0 [

Air Filter, “Perfect Fit” Standard Efficiency (17-1/2" Wide Gas Furnace) ................................................................ TFP175A9FR0 [

Air Filter, “Perfect Fit” Standard Efficiency (21" Wide Gas Furnace) ...................................................................... TFP210A9FR0 [

Air Filter, “Perfect Fit” Standard Efficiency (24-1/2" Wide Gas Furnace) ................................................................ TFP245A9FR0 [

Coil Enclosure (14-1/2" Wide Cabinets) .......................................................................................................... BAYCLE14A1422A [

Coil Enclosure (17-1/2" Wide Cabinets) .......................................................................................................... BAYCLE17A1722A [

Coil Enclosure (21" Wide Cabinets) ................................................................................................................ BAYCLE21A2130A [

Coil Enclosure (24-1/2" Wide Cabinets) .......................................................................................................... BAYCLE24A2430A [

High Altitude Switch ................................................................................................................................................ BAYHALT248 [

Downflow Subbase ................................................................................................................................................. BAYBASE205 [

Propane Conversion Kit ........................................................................................................................................ BAYLPKT210B [

Propane Conversion Kit (With Stainless Steel burners) ......................................................................................... BAYLPSS210B [

Masonry Chimney Vent Kit .................................................................................................................................. BAYVENT800B [

Filter Access Door Kit (Downflow models) ............................................................................................................... BAYFLTR206 [

4

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

Pub. No. 22-1786-06

General

Data

PRODUCT SPECIFICATIONS 1

MODEL

TYPE

RATINGS 2

Input BTUH

Capacity BTUH (ICS) 3

AFUE

Temp. rise (Min.-Max.) °F.

BLOWER DRIVE

Diameter - Width (In.)

No. Used

Speeds (No.)

CFM vs. in. w.g.

Motor HP 5

R.P.M.

Volts / Ph / Hz

COMBUSTION FAN - Type

Drive - No. Speeds

Motor HP - RPM

Volts / Ph / Hz

FLA

FILTER — Furnished?

Type Recommended

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER— Min (in.)67

HEAT EXCHANGER

Type-Fired

-Unfired

Gauge (Fired)

ORIFICES — Main

Nat. Gas. Qty. — Drill Size

L.P. Gas Qty. — Drill Size

GAS VALVE

PILOT SAFETY DEVICE

Type

BURNERS — Type

Number

POWER CONN. — V / Ph / Hz 4

Ampacity (In Amps)

Max Overcurrent Protection (Amps)

PIPE CONN. SIZE (IN.)

DIMENSIONS

Crated (In.)

WEIGHT

Shipping (Lbs.) / Net (Lbs)

TUX1B040A9H21B

Upflow / Horizontal

TUX1B060A9H31B

Upflow / Horizontal

TUX1B080A9H31B

Upflow / Horizontal

40,000

38,000

92.1

30 - 60

DIRECT

10 x 7

1

4

60,000

56,000

92.1

30 - 60

DIRECT

10 x 7

1

4

80,000

74,000

92.1

35 - 65

DIRECT

10 x 8

1

4

See Fan Performance Table

See Fan Performance Table

See Fan Performance Table

1/2

1075

115/1/60

Centrifugal

Direct - 1

1/55 - 3000

115/1/60

1.0

Yes

High Velocity

1 - 17x25 - 1in.

2 Round

1/2

1075

115/1/60

Centrifugal

Direct - 1

1/55- 3000

115/1/60

1.0

Yes

High Velocity

1 - 17x25 - 1in.

2 Round

1/2

1075

115/1/60

Centrifugal

Direct - 1

1/24 - 3200

115/1/60

1.35

Yes

High Velocity

1 - 17x25 - 1in.

2 Round

Aluminized Steel

Aluminized Steel

Aluminized Steel

20

20

20

2 — 45

2 — 56

3 — 45

3 — 56

4 — 45

4 — 56

Redundant - Single Stage

Redundant - Single Stage

Redundant - Single Stage

Hot Surface Ignition

Multiport Inshot

2

115/1/60

9.7

15

1/2

HxWxD

Hot Surface Ignition

Multiport Inshot

3

115/1/60

9.7

15

1/2

HxWxD

Hot Surface Ignition

Multiport Inshot

4

115/1/60

10.0

15

1/2

HxWxD

41-3/4 x 19-1/2 x 30-1/2

41-3/4 x 19-1/2 x 30-1/2

41-3/4 x 19-1/2 x 30-1/2

139 / 129

150 / 140

158 / 148

1 Central Furnace heating designs are certified by AGA and CSA.

2 For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level.

For Canadian applicaitons, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

3 Based on U.S. government standard tests.

4 The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

5 Constant torque ECM blower motor.

6 Refer to the Vent Length Table in the Installer's Guide or the Allowable Vent Length labelon the furnace.

7 All *UX1 and *DX1 furnace models have a vent outlet diameter that equals 2".

Pub. No. 22-1786-06

5

General

Data

PRODUCT SPECIFICATIONS 1

MODEL

TYPE

RATINGS 2

Input BTUH

Capacity BTUH (ICS) 3

AFUE

Temp. rise (Min.-Max.) °F.

BLOWER DRIVE

Diameter - Width (In.)

No. Used

Speeds (No.)

CFM vs. in. w.g.

Motor HP 5

R.P.M.

Volts / Ph / Hz

COMBUSTION FAN - Type

Drive - No. Speeds

Motor HP - RPM

Volts / Ph / Hz

FLA

FILTER — Furnished?

Type Recommended

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER— Min (in.)67

HEAT EXCHANGER

Type-Fired

-Unfired

Gauge (Fired)

ORIFICES — Main

Nat. Gas. Qty. — Drill Size

L.P. Gas Qty. — Drill Size

GAS VALVE

PILOT SAFETY DEVICE

Type

BURNERS — Type

Number

POWER CONN. — V / Ph / Hz 4

Ampacity (In Amps)

Max Overcurrent Protection (Amps)

PIPE CONN. SIZE (IN.)

DIMENSIONS

Crated (In.)

WEIGHT

Shipping (Lbs.) / Net (Lbs)

TUX1C100A9H41B

Upflow / Horizontal

TUX1D120A9H51B

Upflow / Horizontal

100,000

93,000

92.1

35 - 65

DIRECT

11 x 10

1

4

120,000

112,000

92.1

40 - 70

DIRECT

11 x 10

1

4

See Fan Performance Table

See Fan Performance Table

3/4

1100

115/1/60

Centrifugal

Direct - 1

1/20- 3450

115/1/60

.71

Yes

High Velocity

1 - 20x25 - 1in.

2.5 Round

1

1100

115/1/60

Centrifugal

Direct - 1

1/20- 3450

115/1/60

.71

Yes

High Velocity

1 - 24x25 - 1in.

2.5 Round

Aluminized Steel

Aluminized Steel

20

20

5 — 45

5 — 56

6 — 45

6 — 56

Redundant - Single Stage

Redundant - Single Stage

Hot Surface Ignition

Multiport Inshot

5

115/1/60

12.4

20

1/2

HxWxD

Hot Surface Ignition

Multiport Inshot

6

115/1/60

14.5

20

1/2

HxWxD

41-3/4 x 23 x 30-1/2

41-3/4 x 26-1/2 x 30-1/2

171 / 162

205 / 193

1 Central Furnace heating designs are certified by AGA and CSA.

2 For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level.

For Canadian applicaitons, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

3 Based on U.S. government standard tests.

4 The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

5 Constant torque ECM blower motor.

6 Refer to the Vent Length Table in the Installer's Guide or the Allowable Vent Length labelon the furnace.

7 All *UX1 and *DX1 furnace models have a vent outlet diameter that equals 2".

6

Pub. No. 22-1786-06

General

Data

PRODUCT SPECIFICATIONS 1

MODEL

TYPE

RATINGS 2

Input BTUH

Capacity BTUH (ICS) 3

AFUE

Temp. rise (Min.-Max.) °F.

BLOWER DRIVE

Diameter - Width (In.)

No. Used

Speeds (No.)

CFM vs. in. w.g.

Motor HP 5

R.P.M.

Volts / Ph / Hz

COMBUSTION FAN - Type

Drive - No. Speeds

Motor HP - RPM

Volts / Ph / Hz

FLA

FILTER — Furnished?

Type Recommended

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER— Min (in.)67

HEAT EXCHANGER

Type-Fired

-Unfired

Gauge (Fired)

ORIFICES — Main

Nat. Gas. Qty. — Drill Size

L.P. Gas Qty. — Drill Size

GAS VALVE

PILOT SAFETY DEVICE

Type

BURNERS — Type

Number

POWER CONN. — V / Ph / Hz 4

Ampacity (In Amps)

Max Overcurrent Protection (Amps)

PIPE CONN. SIZE (IN.)

DIMENSIONS

Crated (In.)

WEIGHT

Shipping (Lbs.) / Net (Lbs)

TDX1B040A9H21B

Downflow / Horizontal

TDX1B060A9H31B

Downflow / Horizontal

TDX1B080A9H31B

Downflow / Horizontal

40,000

38,000

91.0

30 - 60

DIRECT

10 x 7

1

4

60,000

56,000

91.0

30 - 60

DIRECT

10 x 8

1

4

80,000

74,000

91.0

35 - 65

DIRECT

10 x8

1

4

See Fan Performance Table

See Fan Performance Table

See Fan Performance Table

1/2

1080

115/1/60

Centrifugal

Direct - 1

1/55- 3000

115/1/60

1.14

Yes

High Velocity

1 - 14x20 - 1in.

2 Round

1/2

1075

115/1/60

Centrifugal

Direct - 1

1/55- 3000

115/1/60

1.0

Yes

High Velocity

2 - 14x20 - 1in.

2 Round

3/4

1075

115/1/60

Centrifugal

Direct - 1

1/25- 3200

115/1/60

1.35

Yes

High Velocity

2 - 14x20 - 1in.

2 Round

Aluminized Steel

Aluminized Steel

Aluminized Steel

20

20

20

2 — 45

2 — 56

3 — 45

3 — 56

4 — 45

4 — 56

Redundant - Single Stage

Redundant - Single Stage

Redundant - Single Stage

Hot Surface Ignition

Multiport Inshot

2

115/1/60

9.7

15

1/2

HxWxD

Hot Surface Ignition

Multiport Inshot

3

115/1/60

9.7

15

1/2

HxWxD

Hot Surface Ignition

Multiport Inshot

4

115/1/60

12.4

15

1/2

HxWxD

41-3/4 x 19-1/2 x 30-1/2

41-3/4 x 19-1/2 x 30-1/2

41-3/4 x 19-1/2 x 30-1/2

145 / 135

155 / 145

168 / 158

1 Central Furnace heating designs are certified by AGA and CSA.

2 For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level.

For Canadian applicaitons, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

3 Based on U.S. government standard tests.

4 The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

5 Constant torque ECM blower motor.

6 Refer to the Vent Length Table in the Installer's Guide or the Allowable Vent Length labelon the furnace.

7 All *UX1 and *DX1 furnace models have a vent outlet diameter that equals 2".

Pub. No. 22-1786-06

7

General

Data

PRODUCT SPECIFICATIONS 1

MODEL

TYPE

RATINGS 2

Input BTUH

Capacity BTUH (ICS) 3

AFUE

Temp. rise (Min.-Max.) °F.

BLOWER DRIVE

Diameter - Width (In.)

No. Used

Speeds (No.)

CFM vs. in. w.g.

Motor HP 5

R.P.M.

Volts / Ph / Hz

COMBUSTION FAN - Type

Drive - No. Speeds

Motor HP - RPM

Volts / Ph / Hz

FLA

FILTER — Furnished?

Type Recommended

Hi Vel. (No.-Size-Thk.)

VENT PIPE DIAMETER— Min (in.)67

HEAT EXCHANGER

Type-Fired

-Unfired

Gauge (Fired)

ORIFICES — Main

Nat. Gas. Qty. — Drill Size

L.P. Gas Qty. — Drill Size

GAS VALVE

PILOT SAFETY DEVICE

Type

BURNERS — Type

Number

POWER CONN. — V / Ph / Hz 4

Ampacity (In Amps)

Max Overcurrent Protection (Amps)

PIPE CONN. SIZE (IN.)

DIMENSIONS

Crated (In.)

WEIGHT

Shipping (Lbs.) / Net (Lbs)

TDX1C100A9H41B

Downflow / Horizontal

TDX1D120A9H51B

Downflow / Horizontal

100,000

94,000

91.0

35 - 65

DIRECT

11 x 10

1

4

120,000

110,000

91.0

40 - 70

DIRECT

11 x 10

1

4

See Fan Performance Table

See Fan Performance Table

3/4

1075

115/1/60

Centrifugal

Direct - 1

1/20- 3450

115/1/60

.71

Yes

High Velocity

2 - 16x20 - 1in.

2.5 Round

1

1075

115/1/60

Centrifugal

Direct - 1

1/20- 3450

115/1/60

.71

Yes

High Velocity

2 - 16x20 - 1in.

2.5 Round

Aluminized Steel

Aluminized Steel

20

20

5 — 45

5 — 56

6 — 45

6 — 56

Redundant - Single Stage

Redundant - Single Stage

Hot Surface Ignition

Multiport Inshot

5

115/1/60

12.4

20

1/2

HxWxD

Hot Surface Ignition

Multiport Inshot

6

115/1/60

15.5

20

1/2

HxWxD

41-3/4 x 23 x 30-1/2

41-3/4 x 26-1/2 x 30-1/2

185 / 175

206 / 196

1 Central Furnace heating designs are certified by AGA and CSA.

2 For U.S. applications, above input ratings (BTUH) are up to 2,000 feet, derate 4% per 1,000 feet for elevations above 2,000 feet above sea level.

For Canadian applicaitons, above input ratings (BTUH) are up to 4,500 feet, derate 4% per 1,000 feet for elevations above 4,500 feet above sea level.

3 Based on U.S. government standard tests.

4 The above wiring specifications are in accordance with National Electrical Code; however, installations must comply with local codes.

5 Constant torque ECM blower motor.

6 Refer to the Vent Length Table in the Installer's Guide or the Allowable Vent Length labelon the furnace.

7 All *UX1 and *DX1 furnace models have a vent outlet diameter that equals 2".

8

Pub. No. 22-1786-06

Performance

Data

FURNACE AIRFLOW (CFM) VS. STATIC PRESSURE (ins.w.g.)

MODEL

SPEED TAP

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

*UX1B040A9H21B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1159

938

844

772

1131

910

814

732

1102

881

783

691

1077

851

750

656

1052

820

717

621

1022

786

681

581

992

751

645

540

961

717

604

497

930

662

563

454

*UX1B060A9H31B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1358

1196

1025

863

1327

1166

1000

830

1296

1135

975

797

12721109

943

762

1248

1082

910

726

1215

1053

878

687

1182

1023

845

648

1122

989

813

601

1061

955

780

554

*UX1B080A9H31B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1436

1334

1239

1160

1404

1308

1209

1131

1371

1281

1179

1101

1346

1250

1149

1070

1320

1219

1119

1039

1289

1193

1090

1007

1257

1167

1060

974

1214

1132

1030

940

1170

1097

999

905

*UX1C100A9H41B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1888

1751

1530

1245

1852

1715

1491

1204

1815

1679

1452

1162

1776

1643

1415

1115

1737

1606

1378

1067

1698

1571

1336

1023

1659

1536

1293

979

1626

1493

1253

931

1593

1450

1212

882

*UX1D120A9H51B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

2153

1895

1777

1618

2121

1856

1743

1579

2089

1817

1708

1540

2056

1779

1673

1504

2023

1741

1637

1467

1983

1708

1601

1430

1943

1674

1564

1393

1907

1634

1524

1354

1870

1593

1484

1315

*DX1B040A9H21B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1156

935

835

752

1128

859

803

726

1100

859

771

700

1072

828

736

648

1043

797

701

596

1012

757

652

554

981

717

602

511

917

679

569

471

852

641

536

431

*DX1B060A9H31B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1337

1159

967

863

1314

1127

930

823

1291

1094

893

782

1257

1065

856

742

1223

1036

818

702

1187

997

774

657

1150

957

729

611

1090

920

690

571

1030

883

651

531

*DX1B080A9H31B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1614

1322

1098

970

1585

1295

1067

934

1555

1267

1036

898

1489

1239

1003

868

1423

1211

970

837

1363

1180

933

794

1303

1149

896

750

1202

1111

864

712

1101

1072

831

674

*DX1C100A9H41B

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

1844

1748

1429

1203

1808

1716

1392

1134

1771

1683

1354

1124

1736

1648

1312

1077

1700

1612

1269

1029

1669

1574

1235

983

1638

1535

1200

937

1590

1497

1154

887

1542

1459

1108

837

4 - HIGH - Black

3 - MED-HIGH - Blue

2 - MED-LOW - Yellow

1 - LOW - Red

2162

1928

1782

1552

2127

1888

1743

1520

2091

1848

1703

1488

2049

1811

1665

1450

2006

1774

1626

1412

1964

1736

1582

1370

1922

1698

1537

1328

1849

1653

1500

1295

1775

1607

1462

1261

NOTE: Do NOT use the

LOW speed tap for heating

*DX1D120A9H51B

* May be "A" or "T"

Pub. No. 22-1786-06

9

Performance

Data

CFM VS. TEMPERATURE RISE

CFM (CUBIC FEET PER MINUTE)

MODEL

400 500 600 700 800 900 1000

*UX1B040A9H21B

56

48

*UX1B060A9H31B

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

42

37

33

30

63

56

50

45

42

38

36

33

31

29

67

61

56

51

48

44

42

39

37

35

64

60

56

52

49

46

44

42

40

71

67

63

59

56

53

50

48

1800

1900

2000

2100

*UX1B080A9H31B

*UX1C100A9H41B

*UX1D120A9H51B

* May be "A" or "T"

CFM VS. TEMPERATURE RISE

MODEL

CFM (CUBIC FEET PER MINUTE)

400 500 600 700 800 900 1000

*DX1B040A9H21B

*DX1B060A9H31B

*DX1B080A9H31B

56

48

1100

1200

1300

1400

1500

1600

1700

42

37

33

30

63

56

50

45

42

38

36

33

31

29

67

61

56

51

48

44

42

39

37

35

64

60

56

52

49

46

44

42

40

71

67

63

59

56

53

50

48

*DX1C100A9H41B

*DX1D120A9H51B

* May be "A" or "T"

10

Pub. No. 22-1786-06

Field

Wiring

FIELD WIRING DIAGRAM FOR 1 STAGE FURNACE

1 STAGE HEATING

USING A 1 STAGE HEATING THERMOSTAT

NO COOLING

FURNACE

SEE

NOTE 7

TWIN

B/C

SEE

NOTE 6

TO 115 V 1 PH.,

60 HZ., POWER

SUPPLY PER

LOCAL CODES

B/C

HUM SEE

NOTE 5

EAC SEE

NOTE 5

From Dwg. B341437 Rev. 1

FIELD WIRING DIAGRAM FOR 1 STAGE FURNACE

1 STAGE HEATING, 1 STAGE COOLING

USING A 1 STAGE HEATING, 1 STAGE COOLING THERMOSTAT

(OUTDOOR SECTION WITHOUT TRANSFORMER)

FURNACE

OUTDOOR UNIT

(NO TRANSFORMER)

SEE

NOTE 6

B/C

SEE

NOTE 8

B/C

TO 115 V 1 PH.,

60 HZ., POWER

SUPPLY PER

LOCAL CODES

HUM SEE

NOTE 5

EAC SEE

NOTE 5

Pub. No. 22-1786-06

11

From Dwg. B340388 Rev. 2

Twinning

TWINNING CONNECTION DIAGRAM

FOR TWINNING 1 STAGE FURNACES WITH

SINGLE WIRE TWINNING FEATURE

1 STAGE HEATING ONLY THERMOSTAT

1 STAGE HEAT

ONLY

THERMOSTAT

(WITH FAN SWITCH)

FURNACE NO. 2

FURNACE NO. 1

BLOWER OPERATION OF

UNIT NO. 2 IS SYNCRONIZED

WITH UNIT NO. 1 VIA SIGNALS

FROM TWIN CONNECTION.

TWIN

TWIN

SEE NOTE 4

ISOLATION RELAY

(FIELD SUPPLIED)

SEE NOTE 4

R1

R1

ISOLATION RELAY

SEE NOTE 4

B/C

SEE NOTE 3

B/C

B/C

From Dwg. 21B341422 Rev. 3

OUTDOOR UNIT

(WITH TRANSFORMER)

1 STAGE

HEATING / COOLING

THERMOSTAT

TWINNING CONNECTION DIAGRAM

FOR TWINNING 1 STAGE FURNACES WITH

SINGLE WIRE TWINNING FEATURE

1 STAGE HEAT / 1 STAGE COOL THERMOSTAT

FURNACE NO. 2

FURNACE NO. 1

BLOWER OPERATION OF

UNIT NO. 2 IS SYNCRONIZED

WITH UNIT NO. 1 VIA SIGNALS

FROM TWIN CONNECTION.

TWIN

TWIN

RC

ISOLATION RELAY

(FIELD SUPPLIED)

SEE NOTE 3

SEE NOTE 4

OUTDOOR UNIT

(NO TRANSFORMER)

R1

ISOLATION RELAY

SEE NOTE 4

B/C

SEE NOTE 5

R1

B/C

B/C

ISOLATION RELAY

(FIELD SUPPLIED)

SEE NOTE 4

12

From Dwg. 21B341423 Rev. 2

Pub. No. 22-1786-06

(ALL DIMENSIONS ARE IN INCHES)

TUX1-H OUTLINE DRAWING

Dimensions

Pub. No. 22-1786-06

13

(ALL DIMENSIONS ARE IN INCHES)

TDX1-H OUTLINE DRAWING

Dimensions

14

Pub. No. 22-1786-06

TUX1-H Wiring Diagram For Gas Furnaces

15

Pub. No. 22-1786-06

TUX1-H Schematic Diagram For Gas Furnaces

16

Pub. No. 22-1786-06

TDX1-H Wiring Diagram For Gas Furnaces

17

Pub. No. 22-1786-06

TDX1-H Schematic Diagram For Gas Furnaces

18

Pub. No. 22-1786-06

Notes

19

Pub. No. 22-1786-06

Trane

6200 Troup Highway

Tyler, TX 75707

www.trane.com

Library

Product Section

Product

Model

Literature Type

Sequence

Date

File No.

Supersedes

Unitary

Furnaces

Furnace

TUX1-H

Product Data

06/10

22-1786-06

22-1786-05

Since Trane has a policy of continuous product and product data improvement, it reserves the right to

change design and specifications without notice.