Management of Biological Products

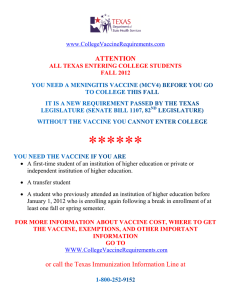

advertisement