A specification of manufacturing processes for planning

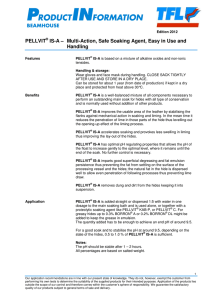

advertisement