Valves made of gunmetal and stainless steel

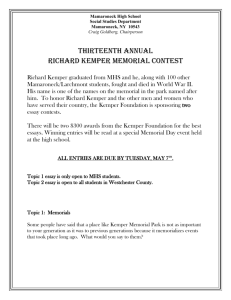

advertisement