Level 4 Evidence Guide

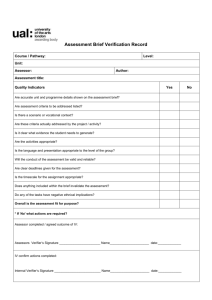

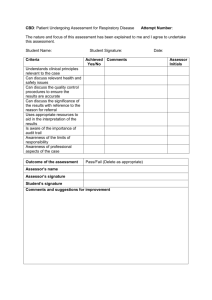

advertisement