Energy Efficiency by Power

Factor Correction

Reducing energy costs

Reducing grid losses and CO2 emissions

ZVEI - Zentralverband Elektrotechnikund Elektronikindustrie e. V.

Fachverband Starkstromkondensatoren

Lyoner Straße 9

60528 Frankfurt am Main

Fon: 069 6302-440

Fax: 069 6302-413

Mail: starkstromkondensatoren@zvei.org

www.zvei.org

Energy Efficiency by Power Factor Correction

Advantages of Power Factor Correction – an overview

Advantages of Power Factor Correction – an overview

3

How reactive power originates

4

Effects of reactive power

4

Power factor correction

5

Economic Advantages of Power Factor Correction

6 7

Network losses – Status and Potential in Germany

89

Technology of Power Factor Correction Systems

Further advantages

2

10 11

12

One technique that has been used for many years to

promote the efficient use of electrical energy is power

factor correction (PFC).

A major economic advantage of this is that the consumer cuts down on energy costs. In addition, power factor correction reduces the amount of current flowing in

the transmission and distribution networks. Reduced

current levels mean lower power losses in the distribution network, savings in electrical energy and hence

reduced CO2 emissions.

Power factor correction

= Decreased power losses

= Reduced CO2 emissions

= Active climate protection!

Calculations show that in 2007 the power factor correction systems then installed in Germany reduced

network losses by about 5.5 billion kilowatt-hours.

Expressed in terms of the energy source mix conventionally applied to Germany, this is equivalent to nearly 3 million tonnes of CO2 emissions that were thus

avoided.

Power factor correction offers the potential for a

further reduction in network losses of some 3.5 billion

kilowatt-hours from present-day levels, equivalent to

cutting CO2 emissions by nearly 2 million tonnes per

annum.

3

Energy Efficiency by Power Factor Correction

How reactive power originates

Energy Efficiency by Power Factor Correction

Power Factor Correction

Many electrical devices, such as AC single-phase and

3-phase motors, require both active power and reactive power. The active power is converted into useful

mechanical power, while the reactive power is needed

to maintain the device’s magnetic fields. This reactive

power is transferred periodically in both directions between the generator and the load.

Effects of reactive power

Power stations and transmission network operators

must make the apparent power S (see figure) available and transmit it. This means that generators, transformers, power lines, switchgear, etc. have to be dimensioned for greater power ratings than if the load

only drew active power. Power supply companies are

therefore faced with extra expenditure on plant and

additional power losses. They therefore make additional charges for reactive power if this exceeds a certain

threshold.

4

If the lagging power factor is corrected, for example

by installing a capacitor at the load, this totally or partially eliminates the reactive power draw at the power

supply company. Power factor correction is at its most

effective when it is physically near to the load and can

respond rapidly.

5

Energy Efficiency by Power Factor Correction

Energy Efficiency by Power Factor Correction

Economic Advantages of Power Factor Correction

Saving the costs of reactive energy

As an example we can take an industrial company with

an average power of 500 kW, operating for 4000 hours

per annum at an average cos wi of 0.7. The power

supply tariff allows the user to draw 50% of the active

energy as reactive energy at no extra charge, corresponding to a target cos wi of 0.9. The payback time of

less than one year illustrates the enormous economic

viability of power factor correction.

Part of annual energy bill

Energy at normal tariff

Reactive energy at normal tariff

Reactive energy at no charge

Chargeable reactive energy

2,000.000 kWh

2,040.408 kvarh

1,000.000 kvarh

1,040.408 kvarh

Additional savings from reduced active power

losses

The company taken as example has power losses in its

own distribution network, and, like every other consumer, must pay the cost of the active energy lost. The

use of power factor correction reduces the apparent

power in the company network, and hence also the power losses and the costs for active energy. In addition

to saving reactive energy costs, the power factor correction system in this example also reduces the costs

for the active power expended on network losses by

several hundred € annually.

Reduction in investment costs

Our company is planning to extend its facilities, and

increase its power demand by 200 kW from the present

level of 500 kW. The existing transformer with a rating

of 800 kVA has been adequate to date, but would be

overloaded after the plant expansion, making it necessary to extend the power infrastructure with a transformer, switchgear, cabling, distribution board, etc. In

this case the apparent power can be reduced by means

of power factor correction so that the existing infrastructure is still adequate. A power factor correction

system is significantly less expensive than a network

expansion.

Power factor correction

reduces both energy costs

and investment costs.

x 0.013 €/kvarh = € 13,525

Required PFC capacity

Installed PFC capacity

268 kvar

300 kvar

Investment cost incl. installation = ca. € 8,000

Payback period = ca. 7 month

6

7

Energy Efficiency by Power Factor Correction

Energy Efficiency by Power Factor Correction

Network losses – Status and Potential in Germany

Power factor correction reduces the apparent power in

a network, and thus the current loading in the same

proportion.

5% less current = 10% lower losses.

The power factor cos wi is an indication of the proportion of reactive power in a network. The graph on the

right illustrates how the current loading and network

losses depend on the power factor, with the case when

cos wi equals 1 (i.e. with full power factor correction)

being defined as 100%.

The lower the power factor, the higher the reactive power, current loading and network losses. This applies

just as much to the power consumer’s (industrial or

special contract customer’s) own distribution network

as to the general transmission and distribution networks for the supply of electric power.

8

Power factor correction reduces network losses in

Germany

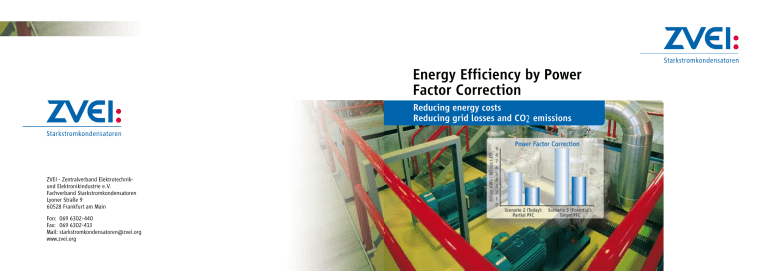

The effect of power factor correction on the magnitude of network losses is analysed by examining three

scenarios:

Scenario 1: No PF correction Scenario 2: Partial PF correction Scenario 3: Target PF correction

Network losses without existing power factor correction

systems

Status quo with partial power Network losses with the maxifactor correction to a cos wi mum reasonable use of power

of 0.90

factor correction (full compensation and target cos wi = 0.95)

Comparison of Scenario 2 with Scenario 1 shows that:

• The existing power factor correction systems already installed reduce annual network losses by 5.5 billion kWh.

• This is roughly equivalent to 2.86 million tonnes CO2 or

the electricity consumption of 1.83 million households.

Comparison of Scenario 3 with Scenario 2 shows that:

• With the maximum reasonable use of power factor

correction, there is the potential for a further reduction in

network losses of 3.5 billion kWh.

• This is almost equivalent to 1.83 million tonnes CO2 or

the electricity consumption of 1.17 million households.

9

Energy Efficiency by Power Factor Correction

Energy Efficiency by Power Factor Correction

Technology of Power Factor Correction Systems

Complete panel for power factor correction

Power factor correction systems are low voltage systems which are erected in the course of building installation. They are to be regarded as self-contained units.

The systems are connected to the existing building installation and can also be retrofitted without any major

adaptations.

10

Power factor controller and PF correction capacitor

Monitoring and control of the system are performed

independently by corresponding controllers which are

normally integrated in the system. These controllers

automatically regulate the reactive power factor to the

target cos wientered.

Correction itself is performed by the PF correction capacitors installed in the system. These capacitors are

specially developed and manufactured for this application.

Power factor correction must take place rapidly and

close to the load, i.e. directly at the machine generating the reactive power, so that reduction of the burden on the transmission channels and thus reduction

of losses are optimally effective.

11

Energy Efficiency by Power Factor Correction

Energy Efficiency by Power Factor Correction

Further advantages

Enhanced network voltage quality

An additional positive effect can be achieved by the application of de-tuned power factor correction systems

and filter circuits. These have the property of suppressing harmonics. This effect enhances the quality of the

power supply, since the desired sinusoidal waveforms

are achieved for voltage and current, and no harmonic

currents then flow into the distribution and transmission networks. Less harmonic current flowing in the

networks therefore means further reductions in power

losses and CO2 emissions.

Increased network capacity

As previously shown in connection with the additional

grid losses, power factor correction relieves the network

of the unnecessary transmission of reactive power. There is currently discussion on the grid reaching its limits

in the wake of increased electricity trading and rising

input from wind farms. Even if power factor correction

surely cannot replace further expansion of the grid or

can only assist in individual cases, the additional capacity set free by greater use of power factor correction

would free some bottlenecks which have already been

identified and gain urgently needed time to implement

the further expansion.

Impressum

Energy Efficiency by Power Factor

Correction

Although great care has been exercised

to ensure accuracy, no liability can be

accepted for the contents of this publiPublished by:

cation.

ZVEI - Zentralverband ElektrotechnikAll rights reserved, especially those of

und Elektronikindustrie e.V.

duplication, distribution and translati(German Electrical and Electronic

on. No part of this publication may be

Manufacturers’ Association)

reproduced in any form (print, phoZVEI Division Power Capacitors

tocopy, microfilm or other process) or

Editor: Johannes Stein

Lyoner Str. 9 • 60528 Frankfurt am Main stored, processed, duplicated or disseFon 069 6302-440 • Fax 069 6302-413 minated by means of electronic systems

without the written consent of ZVEI.

www.zvei.org

Mail starkstromkondensatoren@zvei.org

12

April 2008 edition

13

Energy Efficiency by Power Factor Correction

Energy Efficiency by Power Factor Correction

EnQ – the ZVEI Energy Intelligence Initiative for the intelligent use of energy-efficient technologies.

Reducing greenhouse gas emissions is one of the

central challenges facing government, society and

industry in Germany. European and national politicians have set ambitious goals in this respect: By

2020, these emissions are to be reduced by at least

30 percent from the 1990 level. At the same time, the

German government has set a target of doubling energy productivity by 2020 in comparison with 1990. The

electrical and electronics industries are making a decisive contribution to this process with their intelligent

and energy-efficient technologies. The consistent use

of intelligent technologies would already be capable

of reducing power consumption by around 40 billion

kWh, corresponding approximately to the annual consumption of a state as large as Hessen. Nevertheless,

these technologies are not as yet being optimally exploited.

ZVEI, through its Energy Intelligence Initiative “EnQ”,

is therefore promoting the intelligent use of energyefficient technologies.

www.en-q.de – the initiative’s Internet platform

Condensator-Dominit Dr. Christian Dresel

Gesellschaft für Leistungselektronik, Energietechnik und

Netzqualität mbH

Telefon +49 2961 782 21 • www.condensator-dominit.de

ELECTRONICON Kondensatoren GmbH

Fon +49 365 7346 0 • www.electronicon.com

EPCOS AG

Fon +49 89 636 21051 • www.epcos.com/pfc

FRAKO Kondensatoren- und Anlagenbau GmbH

Fon +49 7641 453 0 • www.frako.de

KBR GmbH

Fon +49 9122 63 73 0 • www.kbr.de

14

Maschinenfabrik Reinhausen GmbH

Fon +49 361 30103 11 • www.reinhausen.com

Modl GmbH

Fon +49 9143 603 0 • www.modl.de

Schneider Electric GmbH

Fon +49 180 575 3 575 • www.schneider-electric.de

System Electric Power Quality GmbH

Fon +49 6051 74158 • www.system-electric.de

Vishay Electronic GmbH

Fon +49 871 862594 • www.vishay.com/capacitors

15