B100

EMERGENCY LIGHTING EQUIPMENT

Replaces model BDL100

For Damp locations;

Convenient code compliance;

End-of-lamp-life compatible

A Division Of Philips Electronics North America Corporation

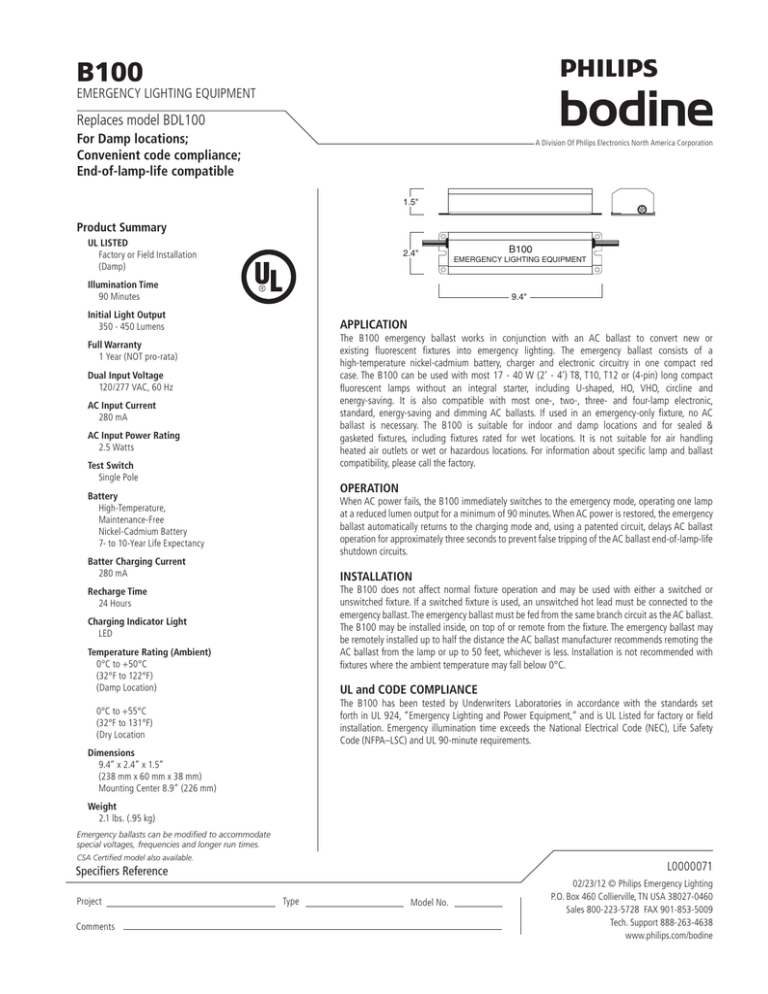

1.5"

Product Summary

UL LISTED

Factory or Field Installation

(Damp)

2.4"

B100

EMERGENCY LIGHTING EQUIPMENT

Illumination Time

90 Minutes

9.4"

Initial Light Output

350 - 450 Lumens

APPLICATION

The B100 emergency ballast works in conjunction with an AC ballast to convert new or

existing fluorescent fixtures into emergency lighting. The emergency ballast consists of a

high-temperature nickel-cadmium battery, charger and electronic circuitry in one compact red

case. The B100 can be used with most 17 - 40 W (2’ - 4’) T8, T10, T12 or (4-pin) long compact

fluorescent lamps without an integral starter, including U-shaped, HO, VHO, circline and

energy-saving. It is also compatible with most one-, two-, three- and four-lamp electronic,

standard, energy-saving and dimming AC ballasts. If used in an emergency-only fixture, no AC

ballast is necessary. The B100 is suitable for indoor and damp locations and for sealed &

gasketed fixtures, including fixtures rated for wet locations. It is not suitable for air handling

heated air outlets or wet or hazardous locations. For information about specific lamp and ballast

compatibility, please call the factory.

Full Warranty

1 Year (NOT pro-rata)

Dual Input Voltage

120/277 VAC, 60 Hz

AC Input Current

280 mA

AC Input Power Rating

2.5 Watts

Test Switch

Single Pole

Battery

High-Temperature,

Maintenance-Free

Nickel-Cadmium Battery

7- to 10-Year Life Expectancy

Batter Charging Current

280 mA

OPERATION

When AC power fails, the B100 immediately switches to the emergency mode, operating one lamp

at a reduced lumen output for a minimum of 90 minutes. When AC power is restored, the emergency

ballast automatically returns to the charging mode and, using a patented circuit, delays AC ballast

operation for approximately three seconds to prevent false tripping of the AC ballast end-of-lamp-life

shutdown circuits.

INSTALLATION

The B100 does not affect normal fixture operation and may be used with either a switched or

unswitched fixture. If a switched fixture is used, an unswitched hot lead must be connected to the

emergency ballast. The emergency ballast must be fed from the same branch circuit as the AC ballast.

The B100 may be installed inside, on top of or remote from the fixture. The emergency ballast may

be remotely installed up to half the distance the AC ballast manufacturer recommends remoting the

AC ballast from the lamp or up to 50 feet, whichever is less. Installation is not recommended with

fixtures where the ambient temperature may fall below 0°C.

Recharge Time

24 Hours

Charging Indicator Light

LED

Temperature Rating (Ambient)

0°C to +50°C

(32°F to 122°F)

(Damp Location)

UL and CODE COMPLIANCE

The B100 has been tested by Underwriters Laboratories in accordance with the standards set

forth in UL 924, “Emergency Lighting and Power Equipment,” and is UL Listed for factory or field

installation. Emergency illumination time exceeds the National Electrical Code (NEC), Life Safety

Code (NFPA–LSC) and UL 90-minute requirements.

0°C to +55°C

(32°F to 131°F)

(Dry Location

Dimensions

9.4” x 2.4” x 1.5”

(238 mm x 60 mm x 38 mm)

Mounting Center 8.9” (226 mm)

Weight

2.1 lbs. (.95 kg)

Emergency

ballasts can be modified to accommodate

special voltages, frequencies and longer run times.

CSA Certified model also available.

L0000071

Specifiers Reference

Project

Comments

Type

Model No.

02/23/12 © Philips Emergency Lighting

P.O. Box 460 Collierville, TN USA 38027-0460

Sales 800-223-5728 FAX 901-853-5009

Tech. Support 888-263-4638

www.philips.com/bodine

B100

EMERGENCY LIGHTING EQUIPMENT

Replaces model BDL100

For damp locations;

Convenient code compliance;

End-of-lamp-life compatible

EMERGENCY ILLUMINATION

Depending on the wattage and type of lamp selected, the B100 produces 350 to 450 lumens

initial emergency light output. During emergency illumination, one lamp is illuminated, even if

installed with a multi-lamp AC ballast. Emergency lumen output will be less with a compact

fluorescent lamp.

SPECIFICATION

Emergency lighting shall be provided by using a standard fluorescent fixture equipped with a

Philips Bodine B100 emergency ballast. This emergency ballast shall consist of a high-temperature,

maintenance-free nickel-cadmium battery, charger and electronic circuitry contained in one

9 3/8” x 2 3/8” x 1 1/2” red metal case. A solid-state charging indicator light to

monitor the charger and battery, a single-pole test switch and installation hardware shall

be provided. The emergency ballast, using a patented circuit, shall delay AC ballast

operation for approximately three seconds to prevent false tripping of AC ballast end-oflamp-life shutdown circuits. The emergency ballast shall be capable of operating one 17 - 40 W

(2’ - 4’) T8, T10 or T12 or (4-pin) long compact fluorescent lamp at reduced illumination in

the emergency mode for a minimum of 90 minutes. It shall be suitable for indoor and damp locations

and for sealed & gasketed fixtures, including fixtures rated for wet locations. The B100 shall

produce 350 to 450 lumens initial emergency light output, have 3.5 Watts of input power and a 9.6

Watt-hour battery capacity and comply with emergency standards set forth by the current NEC. The

emergency ballast shall be UL Listed for installation inside, on top of or remote from the fixture

and shall be warranted for a full year from date of purchase.

WARRANTY

Model B100 is warranted for one (1) full year from date of purchase. This warranty covers only

properly installed Philips Bodine emergency ballasts used under normal conditions. For the

warranty period, Philips Emergency Lighting will, at its option, repair or replace without charge

a defective emergency ballast, provided it is returned to the factory transportation prepaid and

our inspection determines it to be defective under terms of the warranty. Repair or replacement,

as stated above, shall constitute the purchaser’s exclusive warranty, which does not extend to

transportation, installation, labor or any other charges; nor does it apply to any equipment of

another manufacturer used in conjunction with the emergency ballast.

L0000071

02/23/12 © Philips Emergency Lighting

P.O. Box 460 Collierville, TN USA 38027-0460

Sales 800-223-5728 FAX 901-853-5009

Tech. Support 888-263-4638

www.philips.com/bodine

For the most current technical information and notices, please visit TechNotes on our website.

B100

Replaces model BDL100

Installation Instructions

EMERGENCY LIGHTING EQUIPMENT

! IMPORTANT SAFEGUARDS !

WHEN USING ELECTRICAL EQUIPMENT, BASIC

SAFETY PRECAUTIONS SHOULD ALWAYS BE

FOLLOWED, INCLUDING THE FOLLOWING:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. To prevent high voltage from being present on red & yellow output leads prior to installation, inverter connector must be open. Do not join inverter connector until installation is complete and AC power is supplied to the emergency ballast.

2. This product is for use with most 17 W through 40 W T8, T10 or T12 single pin or bipin fluorescent lamps,

including energy saving, circline, U-shaped and rapid-start (4-pin) long compact fluorescent lamps.

3. Make sure all connections are in accordance with the National Electrical Code and any local regulations.

4. To reduce the risk of electric shock, disconnect both normal and emergency power supplies and inverter connector of the emergency ballast before servicing.

5. This emergency ballast is for factory or field installation in either the ballast channel or on top of the

fixture.

6. This product is suitable for dry as well as damp locations where the ambient temperature is 0°C minimum,

+50°C maximum. Product is not suitable for heated air outlets and wet or hazardous locations.

7. An unswitched AC power source is required (120 or 277 VAC, 60 Hz).

8. Do not install near gas or electric heaters.

9. Do not attempt to service the battery. A sealed, no-maintenance battery is used that is not field

replaceable. Contact the manufacturer for information on service.

10. The use of accessory equipment not recommended by the manufacturer may cause an unsafe

condition.

11. Do not use this product for other than intended use.

12. Servicing should be performed by qualified service personnel.

SAVE THESE INSTRUCTIONS

Ni - Cd

THIS PRODUCT CONTAINS A RECHARGEABLE NICKEL-CADMIUM BATTERY.

THE BATTERY MUST BE RECYCLED OR DISPOSED OF PROPERLY.

03/27/12

© Philips Emergency Lighting

A Division of Philips Electronics North America Corporation

236 Mt. Pleasant Rd. • Collierville, TN USA 38017-2752 • Tech Support 888-263-4638 • Fax 901-854-1630 • www.philips.com/bodine

443529080761

71000034

INSTALLATION

WARNING: TO PREVENT HIGH VOLTAGE FROM BEING PRESENT ON RED & YELLOW OUTPUT

LEADS PRIOR TO INSTALLATION, INVERTER CONNECTOR MUST BE OPEN. DO NOT JOIN

INVERTER CONNECTOR UNTIL INSTALLATION IS COMPLETE AND AC POWER IS SUPPLIED TO

THE EMERGENCY BALLAST.

NOTE:

STEP #1

Make sure the necessary branch circuit wiring is available. An unswitched source of

power is required. The emergency ballast must be fed from the same branch circuit

as the AC ballast.

INSTALLING THE EMERGENCY BALLAST

> Disconnect AC power from the fixture. Remove the ballast channel cover and install the emergency ballast either

in the ballast channel or on top of the fixture. * Remote mounting distance must be less than half the maximum

remote mounting distance for the AC ballast. Consult AC ballast manufacturer before remote installation.

> Depending on the type of fixture in use install emergency ballast using one of the methods illustrated below.

InsideBallast

Ballast Channel

Inside

Channel

Inside strip

Strip Fixture

Inside

fixture

On top

Top of

of Fixture

on

fixture

* For installation on top of the fixture, wire bundle covers (RMC-60) may be required by state or local codes. These covers are

available from the manufacturer as an accessory kit and must be ordered separately. Call your local distributor or the factory for complete

information.

STEP #2

Fixture

INSTALLING THE TEST SWITCH

> Refer to the illustrations above and install the test switch

through the ballast channel cover of a troffer or through the

side of a strip fixture.

> Drill a 1/2" hole and install the switch as shown.

> Refer to the diagrams on page 4 and wire the test switch so

that it removes AC power from the unswitched hot line to the

emergency ballast.

STEP #3

1/2” Hole

Test Button

Push to Test

Hex Nut

Test Switch

Leads

Hex Nut

INSTALLING THE CHARGING INDICATOR LIGHT

> Install the CHARGING INDICATOR LIGHT as shown in the illustration below so that it will be visible after the fixture is installed.

2

INSTALLATION

TROFFER STYLE FIXTURE

STRIP STYLE FIXTURE

Fixture

Fixture

Emergency

Ballast

Leads to Charging

Indicator Light

Ballast

Channel

Cover

Charging

Indicator

Light

Charging

Indicator

Light

7/8” Bushing

Inserted into

Ballast Channel

Cover

7/8” Punch

Plastic Tubing

(please cut to

necessary

length)

1/2” White Bushing

to Hold Charging

Indicator Light

Charging Indicator Light

Violet (+)

Brown (–)

Brown (–)

5/8" Black

Bushing

1/2" White

Bushing

Fixture Lens

Violet (+)

1/2" White

Bushing

5/8" Black

Bushing

1/2" Punch

* If violet and brown leads are detached, connect to

unit by matching wire colors.

NOTE: After installing the charging indicator light and test switch, mark each with the appropriate label.

STEP #4

WIRING THE EMERGENCY BALLAST

> Determine the type of AC ballast installed in the fixture.

> Select the appropriate wiring diagram on back to connect the emergency ballast to the AC ballast and lamp(s). Make sure all connections are in accordance with the National Electrical Code and any local regulations.

> After installation is complete, supply AC power to the emergency ballast and join the inverter connector.

> At this point, power should be connected to both the AC ballast and the emergency ballast, and the Charging Indicator Light should illuminate indicating the battery is charging.

> A short-term discharge test may be conducted after the emergency ballast has been charging for one hour. Charge for 24 hours before conducting a long-term discharge test. Refer to OPERATION.

> In a readily visible location, attach the label "CAUTION - This Unit Has More Than One Power Connection Point.

To Reduce The Risk Of Electric Shock, Disconnect Both The Branch Circuit-Breakers Or Fuses And Emergency

Power Supplies Before Servicing."

OPERATION

When AC power is applied, the charging indicator light is illuminated, indicating the battery is being charged. When power

fails, the emergency ballast automatically switches to emergency power, operating one lamp at reduced illumination for

at least 90 minutes. When AC power is restored, the emergency ballast returns to the charging mode and delays AC ballast

operation for approximately three seconds to prevent false-tripping of AC ballast (end-of-lamp-life) shutdown circuits.

MAINTENANCE

Although no routine maintenance is required to keep the emergency ballast functional, it should be checked periodically to

ensure that it is working. The following schedule is recommended:

1. Visually inspect the charging indicator light monthly. It should be illuminated.

2. Test the emergency operation of the fixture at 30-day intervals for a minimum of 30 seconds. One lamp should operate at reduced illumination.

3. Conduct a 90-minute discharge test once a year. One lamp should operate at reduced illumination for at least 90 minutes.

! REFER ANY SERVICING INDICATED BY THESE CHECKS TO QUALIFIED PERSONNEL !

3

EMERGENCY BALLAST AND AC BALLAST MUST BE FED FROM THE SAME BRANCH CIRCUIT

TYPICAL SCHEMATICS ONLY. MAY BE USED WITH OTHER BALLASTS. CONSULT THE FACTORY FOR OTHER WIRING DIAGRAMS.

WIRING DIAGRAMS FOR 1-LAMP EMERGENCY OPERATION

FIG A

ONE (1) LAMP INSTANT START BALLAST

FIG B

ONE (1) LAMP RAPID START BALLAST

WALL SWITCH

WALL SWITCH

HOT

WHT/RED

B

L

K

RED

INVERTER

CONNECTOR

TEST

SWITCH

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

B

L

K

BROWN

(CAP UNUSED LEAD)

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

HOT

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

RED

1 LAMP

INSTANT

START

BALLAST

WHT/RED

RED

INVERTER

CONNECTOR

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

BROWN

(CAP UNUSED LEAD)

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

RED

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

BROWN

(CAP UNUSED LEAD)

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

FIG D

RED

RED

1 LAMP

RAPID

START

BALLAST

BLK

TWO (2) LAMP RAPID START BALLAST

HOT

YELLOW

WHT/RED

B

L

K

LAMP 1 (EMERGENCY)

BLU/WHT

BLUE

LAMP 2

BLUE

2 LAMP

INSTART

START

BALLAST

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

B

L

K

BLUE

RED

INVERTER

CONNECTOR

TEST

SWITCH

YEL/BLK

BROWN

(CAP UNUSED LEAD)

RED

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

LAMP 1 (EMERGENCY)

YEL/BLK

BLU/WHT

BLUE

BLUE

BLUE

WHT/BLK

BLK

WHT

WHT

FIG F

RED

RED

2 LAMP

RAPID

START

BALLAST

BLK

LAMP 2

YELLOW

YELLOW

THREE (3) LAMP RAPID START BALLAST

HOT

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

WHT/RED

B

L

K

LAMP 1 (EMERGENCY)

YEL/BLK

BLU/WHT

TEST

SWITCH

B

L

K

BLUE

BLUE

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

BROWN

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

LAMP 3

BLUE

RED

INVERTER

CONNECTOR

(CAP UNUSED LEAD)

LAMP 2

BLUE

3 LAMP

INSTANT

START

BALLAST

WHT/BLK

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

LAMP 1 (EMERGENCY)

YEL/BLK

BLU/WHT

BLU/WHT

BLU/WHT

BLUE

BLUE

BLUE

YELLOW

YELLOW

3 LAMP

RAPID

START

BALLAST

WHT/BLK

RED

LAMP 2

LAMP 3

BLK

BLK

RED

WHT

WHT

RED

TWO (2) LAMP RAPID START STEP DIMMING BALLAST

COMMON

WHT/RED

RED

INVERTER

CONNECTOR

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

BROWN

TEST

SWITCH

HOT

BLUE

WHT

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

WHT/RED

INVERTER

CONNECTOR

FIG G

BLUE

WALL SWITCH

HOT

B

L

K

BLU/WHT

BLUE

WHT

THREE (3) LAMP INSTANT START BALLAST

TEST

SWITCH

LAMP

YEL/BLK

WHT/BLK

WALL SWITCH

B

L

K

WHITE

YELLOW

BLK

WHT/BLK

FIG E

OR

E

MB

EA

RL

GL

EA

NS

CT

Y

WALL SWITCH

HOT

B

L

K

BLACK 120V

ORANGE 277V

COMMON

TWO (2) LAMP INSTANT START BALLAST

TEST

SWITCH

BROWN

(CAP UNUSED LEAD)

BLUE

BLUE

WALL SWITCH

B

L

K

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

B

L

K

RED

RED

INVERTER

CONNECTOR

TEST

SWITCH

BLU/WHT

WHT/BLK

FIG C

WHT/RED

B

L

K

LAMP

YEL/BLK

BLK

WHITE

BLK

(CAP UNUSED LEAD)

BLACK 120V

OR

ORANGE 277V

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

BLU/WHT

BLUE

BLUE

BLUE

WHT/BLK

WHT

S1

RED

2 LAMP

RAPID

START

STEP

DIMMING

BALLAST

LAMP 2

RED

YELLOW

YELLOW

BLK

S2

FIG H

The white/black lead must connect to the white

lead of the step-dimming ballast associated with

the emergency ballast only. Connections to other

ballasts or fixtures could result in abnormal

operation and cause product damage.

LAMP 1 (EMERGENCY)

YEL/BLK

BLK

FOUR (4) LAMP INSTANT START BALLAST

FIG I FOUR (4) LAMP RAPID START BALLAST

WALL SWITCH

WALL SWITCH

HOT

WHT/RED

B

L

K

TEST

SWITCH

B

L

K

RED

INVERTER

CONNECTOR

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

BROWN

(CAP UNUSED LEAD)

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

HOT

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

LAMP 1

YELLOW

TEST

SWITCH

YEL/BLK

BLU/WHT

BLUE

WHT/RED

B

L

K

(EMERGENCY )

YELLOW

BLUE

BLUE

4 LAMP

INSTANT

START

BALLAST

WHT/BLK

LAMP 2

RED

CHARGING

INDICATOR

LIGHT

(CAP UNUSED LEAD)

COMMON

LAMP 3

RED

WHITE

VIOLET

BROWN

BLACK 120V

OR

ORANGE 277V

WHITE

RED

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

LAMP 1 (EMERGENCY)

YEL/BLK

YELLOW

YELLOW

BLU/WHT

RED

BLUE

RED

RED

WHT/BLK

LAMP 4

BLU/WHT

4 LAMP

RAPID

START

BALLAST

YELLOW

BLK

WHT

B

L

K

INVERTER

CONNECTOR

BLU/WHT

BROWN

BROWN

BLK

BLUE

WHT

BLUE

WIRING DIAGRAM for EMERGENCY-ONLY fixtures

FIG J ONE (1) 17-40 W LAMP WITHOUT AC BALLAST

CAP

HOT

B

L

K

TEST

SWITCH

B

L

K

WHITE

VIOLET

CHARGING

INDICATOR

LIGHT

BROWN

(CAP UNUSED LEAD)

BLACK 120V

OR

ORANGE 277V

WHITE

COMMON

CAP

RED

WHT/RED

RED

INVERTER

CONNECTOR

E

MB

EA

RL

GL

EA

NS

CT

Y

YELLOW

LAMP

YEL/BLK

BLU/WHT

CAP

BLUE

CAP

WHT/BLK

4

LAMP 2

LAMP 3

LAMP 4

Linear

Emergency Operation for Linear Fluorescent Lamp Fixtures

The Philips Bodine Linear Fluorescent Emergency Ballasts

Philips Bodine fluorescent emergency ballasts allow you to

convert virtually any new or existing fluorescent fixture

into code-compliant emergency lighting.

Linear

Philips Bodine linear fluorescent emergency

ballasts (FEBs) are designed specifically for

linear lamp fluorescent fixtures. These emergency ballasts allow you to convert virtually

any new or existing fluorescent fixture into

code-compliant emergency lighting. Singlelamp or multilamp fixtures fitted with T5-T12

lamps can be converted using a Philips Bodine

linear FEB.

Philips Bodine linear FEBs are compatible with

most electronic, standard, energy-saving and

dimming AC ballasts, as well as with energy

management systems, such as occupancy

detectors and photo sensors. In addition, the

wide variety of linear products we design

and build means that we have something for

almost every emergency lighting application,

including indoor-dry, damp, extended

temperature, extended runtime, self-testing

and remote testing.

What is a Fluorescent Emergency

Ballast?

A FEB is a battery-powered device that, in

the absence of normal AC power, supports

one or more fluorescent lamps, providing a

minimum 90 minutes of emergency lighting. Emergency lighting is vital to life safety

programs and is required in all commercial,

industrial and institutional facilities. When

normal power fails, emergency lighting guides

building occupants along the path of egress

to designated exits and helps them avoid

obstacles en route.

Fluorescent emergency ballasts allow you to use the same light

source for normal and emergency lighting. Because the same

light source is used, emergency lighting looks similar to normal

lighting – no drastic lighting changes or unwanted glare results.

2

Linear brochure

Linear brochure

3

FEB vs. AC Ballast

Fluorescent lamps require AC ballasts for

start-up and for current regulation during

normal operation. When AC power fails and

normal lamp operation ceases, Philips Bodine

battery-powered FEBs are critical. FEBs supply

power to the lamp(s) and allow the lamp(s)

to provide full or reduced illumination for a

minimum of 90 minutes in compliance with

national safety codes for emergency lighting

(e.g., NFPA® Life Safety Code®, National

Electrical Code®).

FEB Installation

FEB Operation

When AC power fails, Philips Bodine FEBs immediately switch to emergency mode, operating one, two or three lamps for a minimum of

90 minutes. When AC power is restored, the

emergency ballasts return to charging mode.

FEBs are fully recharged in 24 hours.

4

Linear brochure

Philips Bodine FEBs may be used with either a

switched or unswitched fixture. If a switched

fixture is used, an unswitched hot lead must

be connected to the emergency ballast. The

emergency ballast must be fed from the same

branch circuit as the AC ballast. Philips Bodine

FEBs may be installed inside, on top of or

remote from the fixture, depending on factors

such as FEB model and fixture type.

Philips Bodine FEBs truly provide emergency lighting you’ll

never see … until you need it.

Linear Lamp ID

Linear fluorescent lamps are given designations

such as T5, T8 and T12. The “T” indicates the

Code Compliance

Philips Bodine FEBs are tested by Underwriters

Laboratories (UL) in compliance with standards set forth

in UL 924, Emergency Lighting and Power Equipment.*

Products are UL Listed for factory and field installation

or UL Component Recognized for factory installation

only. Emergency illumination time exceeds the National

Electrical Code, Life Safety Code and UL 90-minute

requirements.

lamp is linear, while the number is the diameter

of the lamp measured in eighths of an inch.

A T12, for example, is 12/8” and the T5 is 5/8”.

T5 .625” / 16mm

*Products tested to meet standards for the Canadian Standards Association

(CSA) and Normas Oficiales Mexicanas (NOM) are also available. Please

check with the factory at 800-223-5728 for more information.

FEB Benefits

Fluorescent emergency ballasts allow you to use the same

light source for normal and emergency lighting. Because

the same light source is used, emergency lighting looks

similar to normal lighting – no drastic lighting changes or

unwanted glare results. In addition, the FEBs’ unobtrusive

installation does not detract from interior design or encourage vandal activity. Philips Bodine FEBs truly provide

emergency lighting you’ll never see … until you need it.

T8 1” / 26mm

T12 1.5” / 38 mm

Lamp

Inches

guides building occupants along the path of

T5 .625” 16 mm

egress to designated exits and helps them

T8 1” 26 mm

T9

1.125” 29 mm

T10 1.25” 32 mm

T12 1.5” 38 mm

When normal power fails, emergency lighting

avoid obstacles en route.

Millimeters

Linear brochure

5

Why Philips Bodine FEBs?

Philips Bodine emergency ballasts paired with

fluorescent fixtures:

1.) Provide instant backup lighting

2.) Complement original lighting design

3.) Supply lighting that looks like normal lighting

4.) Mount inconspicuously inside, on top of or remote from the fixture to reduce the risk of tampering and vandalism

5.)

6

Install quickly and easily to save time, labor and money. A qualified electrician can typically install a Philips Bodine emergency ballast in less than 30 minutes.

Linear brochure

Philips Bodine emergency ballasts mount

inconspicuously inside, on top of or remote

from the fixture to reduce the risk of

tampering and vandalism.

Life Safety

7.9.2 Performance of System.

7.9.2.1 Emergency illumination shall be provided for a minimum of 1½ hours in the event of failure

of normal lighting. Emergency lighting facilities shall be arranged to provide initial illumination that is

not less than an average of 1 ft-candle (10.8 lux) and, at any point, not less than 0.1 ft-candle (1.1 lux),

measured along the path of egress at floor level. Illumination levels shall be permitted to decline to not

less than an average of 0.6 ft-candle (6.5 lux) and, at any point, not less than 0.06 ft-candle (0.65 lux)

at the end of 1½ hours. A maximum-to-minimum illumination uniformity ratio of 40 to 1 shall not

be exceeded.

7.9.3 Periodic Testing of Emergency Lighting Equipment.

7.9.3.1 Required emergency lighting systems shall be tested in accordance with one of the three

options offered by 7.9.3.1.1, 7.9.3.1.2, or 7.9.3.1.3.*

7.9.3.1.1 Testing of required emergency lighting systems shall be permitted to be conducted as follows:

(1)

(2)

(3)

(4)

(5)

Functional testing shall be conducted monthly with a minimum of 3 weeks and a maximum of 5 weeks between tests, for not less than 30 seconds, except as otherwise permitted by 7.9.3.1.1(2).

The test interval shall be permitted to be extended beyond 30 days with the approval of the authority having jurisdiction.

Functional testing shall be conducted annually for a minimum of 1½ hours if the emergency lighting system is battery powered.

The emergency lighting equipment shall be fully operational for the duration of the tests required by 7.9.3.1.1(1) and 7.9.3.1.1(3).

Written records of visual inspections and tests shall be kept by the owner for inspection by the authority having jurisdiction.

(Life Safety Code® 2009)

*7.9.3.1.2 and 7.9.3.1.3 describe testing requirements for self-testing/self-diagnostic battery-operated emergency

lighting systems and computer-based self-testing/self-diagnostic battery-operated emergency lighting systems,

respectively. Monthly 30-second and annual 90-minute tests are included for both. They were omitted here because of

space constraints. Please see LSC 7.9.3 (2009) for complete testing information.

Linear brochure

7

Linear Products

Model

# Lamps

Max.

Lumens

Types of Lamps Operated

Features

B33

2 or 3

3400

Two or three 32 W (4’) T8s; or two or three 39 W or two 40 -55 W (4-pin) long

compacts. For use with instant start parallel AC ballasts only

3-lamp parallel illumination

B30 *

1 or 2

3500

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; one 18-55 W or

two 18 -39 W (4-pin) long compacts; or one 21-54 W (2’- 4’) standard or high output T5

High lumen output; ELC

B30RCT

1 or 2

3500

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; one 18-55 W or

two 18 -39 W (4-pin) long compacts; or one 21-54 W (2’- 4’) standard or high output T5

Remote control testing

B30ST *

1 or 2

3500

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; one 18-55 W or

two 18 -39 W (4-pin) long compacts; or one 21-54 W (2’- 4’) standard or high output T5

Automatic self-testing; ELC

B50 *

1 or 2

1400

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; or one 18-55 W

or two 18 -39 W (4-pin) long compacts

Specification grade; ELC

B50Cold-Pak

1 or 2

1200

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; or one 18-55 W

or two 18 -39 W (4-pin) long compacts

Extreme temperatures

B50RCT

1 or 2

1400

One 17-215 W (2’- 8’) or two 17- 40 W (2’- 4’) T8, T9 , T10 or T12 lamps; or one 18 -55 W

or two 18 -39 W (4-pin) long compacts

Remote control testing

B50ST *

1 or 2

1400

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; or one 18-55 W

or two 18 -39 W (4-pin) long compacts

Automatic self-testing; ELC

B60 *

1 or 2

700

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9 , T10 or T12 lamps; or one 18-55 W

or two 18 -39 W (4-pin) long compacts

Standard grade; ELC

B70A * +

1

700

One 17-215 W (2’- 8’) T8, T10 or T12 lamp or one (4-pin) long compact.

2-hr runtime, not recommended with reduced-wattage, energy-saving T8 lamps

2-hour runtime; ELC

B90 * +

1

600

One 17-215 W (2’- 8’) T8, T10 or T12 lamp or one (4-pin) long compact.

Not recommended with reduced-wattage, energy-saving T8 lamps

Minimum code-compliance grade; ELC

B100 * +

1

450

One 17-40 W (2’- 4’) T8, T10 or T12 lamp or one (4-pin) long compact.

Not recommended with reduced-wattage, energy-saving T8 lamps

Economical alternative; ELC

LP600STU

1

1325

One 14-54 W (2’- 4’) standard or high output T5; 17-55 W (2’-5’) T8; 36-55 W (4-pin)

long compact; or 22-55 W T5 circline

Low-profile fixtures; Self-testing; Ideal for lowmercury (green) lamps; Universal input; ELC

LP600

1

1325

One 14-54 W (2’- 4’) standard or high output T5; 17-55 W (2’-5’) T8; 36-55 W (4-pin)

long compact; or 22-55 W T5 circline

Low-profile fixtures; Ideal for low-mercury

(green) lamps; ELC

LP550

1

700

One 14-54 W (2’- 4’) standard or high output T5; 32-44 W (4’-5’) standard or high output

T8; or 36-55 W (4-pin) long compact

Low-profile fixtures; Ideal for low-mercury

(green) lamps; ELC

LP500

1

700

One 21-54 W (2’- 4’) standard or high output T5 or 32 W (4’) T8

Low-profile fixtures; Ideal for low-mercury

(green) lamps; ELC

B50LP

1 or 2

1300

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9, T10 or T12 lamps; or one

18-55 W or two 18-39 W (4-pin) long compacts

Low-profile fixtures; ELC

B60LP

1 or 2

700

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9, T10 or T12 lamps; or one

18-55 W or two 18-39 W (4-pin) long compacts

Low-profile fixtures; ELC

B60LPU

1 or 2

700

One 17-215 W (2’- 8’) or two 17-40 W (2’- 4’) T8, T9, T10 or T12 lamps; or one

18-55 W or two 18-39 W (4-pin) long compacts

Low-profile fixtures; Universal input; ELC

B100LP

1

500

One 17-40 W (2’- 4’) T8, T10 or T12 or 18-39 W long compact

Low-profile fixtures; Minimum code

compliance; ELC

* Available only as as ELC (end-of-lamp-life compatible).

+ Not recommended for use with reduced-wattage, energy-saving T8 lamps. Please use emergency ballasts in the B30, B50, B60 and LP600 families for these lamps.

For more information, please visit the website at www.philips.com/bodine or contact the factory directly at 800-223-5728.

© 2011 Philips Emergency Lighting

All rights reserved.

Document order number: L0000091 11.1

236 Mt. Pleasant Rd.

Collierville, TN 38017

Sales 800.223.5728

Fax 901.853.5009

www.philips.com/bodine