Downloaded

advertisement

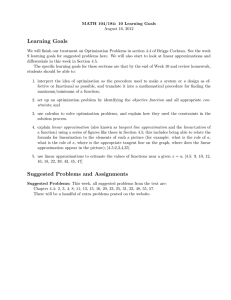

Personal use of this material is permitted. However, permission to reprint/republish this material for advertising or promotional purposes or for creating new collective works for resale or redistribution to servers or lists or to reuse any copyrighted component of this work in other works must be obtained from the IEEE. Linear Models for Optimization of Interconnected Gas and Electricity Networks Bjorn H. Bakken, Member IEEE, and Sigrun Kavli Mindeberg Abstract— This presentation demonstrates a new natural gas network module implemented in the optimization model "eTransport", including nodes, pipes, valves and compressors. A special linearization technique is used to keep track of the gas pressure in a generic network structure. Together with models for gas source and storage, gas-fired power plants and the existing electricity network module, the new gas module makes it possible to analyze interconnected natural gas and electricity networks where both operational and structural (investment) changes in one part of the system will influence capacities and performance in the rest of the system. Index terms-- Gas network, Electricity network, Linear programming, Power system planning, Energy markets I. INTRODUCTION - THE ETRANSPORT MODEL. The optimization model "eTransport" is developed for energy systems where several parallel energy carriers and technologies are considered simultaneously [1, 2]. The model uses a detailed network representation of technologies and infrastructure to enable identification of single components, cables and pipelines. eTransport optimizes both operation and investments over a planning horizon of 10 to 30 years for most relevant energy carriers (electricity, gas, heat, biomass etc) and conversion between these. It is not limited to continuous transport like lines, cables and pipelines, but can also include discrete transport by ship, road or rail. The model is separated into an operational model (energy system model) and an investment model [3]. In the operational model there are sub-models for each energy carrier and for different conversion components. The operational planning horizon is relatively short (1-3 days) with a typical time-step of one hour. The operational model finds the cost-minimising diurnal operation for a given infrastructure and for given energy loads. Annual operating costs for different energy system designs are calculated by solving the operational model repeatedly for different seasons (e.g. peak load, low load, intermediate etc), different investment periods (e.g. 5 year intervals) and relevant system designs. Annual operating and environmental costs for all different periods and energy system designs are then used by the investment model to find the investment plan that minimizes the present value of all costs over the planning horizon. __________________________ This work is sponsored in part by the Research Council of Norway. Bjorn H. Bakken and Sigrun K. Mindeberg are with SINTEF Energy Research, Trondheim, NO-7465, Norway (e-mail: bjorn.h.bakken@sintef.no). To enable a simultaneous optimization of several parallel infrastructures, a generalized network structure is developed. The sub-models for different components are connected by general energy flow variables that identify the flow between energy sources, network components for transport, conversion and storage, and energy sinks like loads and markets. The connections between these are case-specific, and are identified by sets of pairs where each pair shows a possible path for the energy flow between component types. General energy flow variables are defined over the energy system structure to account for the actual energy flow between different components (except for internal flow within each model). These general variables are included in and restricted by the various models and they establish the links between the different models. In the operational model the different technology models are added together to form a single linear optimization problem where the object function is the sum of the object functions from the different models, and the restrictions of the problem include all the restrictions defined in the models. Emissions are caused by a subset of components (power plants/CHP's, boilers, road/ship transport etc) that are defined as emitting CO2, NOx, CO and SOx. Further environmental consequences can be defined. Emissions are calculated for each module and accounted for as separate results. However, if emission penalties are specified by the user (e.g. a CO2 tax), the resulting costs are included in the objective function and thus added to operating costs. The task for the investment model is to find the optimal set and order of investments during the period of analysis, based on investment costs for different projects and the precalculated annual operating costs for different periods and states. The optimal investment plan is defined as the plan that minimizes the discounted present value of all costs in the planning period, i.e. operating costs plus investment costs minus the rest value of investments. The optimal plan will therefore identify the optimal design of the energy system (i.e. the optimal state) in different periods. More details of the investment algorithm in eTransport can be found in [3]. Mathematically, the model uses a combination of linear programming (LP) and mixed integer programming (MIP) for the operational model, and dynamic programming (DP) for the investment model. The operational model is implemented in the AMPL programming language with CPLEX as solver [4], while the investment model is implemented in C++. A modular design ensures that new technology modules developed in AMPL for the operational model are automatically embedded in the investment model. A full-graphical Windows interface is developed for the 978-1-4244-4241-6/09/$25.00 ©2009 IEEE Authorized licensed use limited to: Sintef. Downloaded on January 15, 2010 at 06:38 from IEEE Xplore. Restrictions apply. 1 model in MS Visio. All data for a given case are stored in a database and can be accessed by the user through the GUI. A special sub-module for CO2 capture and storage (CCS) technologies has recently been published [5]. The models for the CCS infrastructure are formulated consistent with the models for gas, electricity and heat infrastructures. This has introduced the flow of mass [tonne/h] in parallel with the flow of energy [MWh/h]. Furthermore, the CCS models are able to draw energy from the rest of the network to operate compressors, pumps, absorbers etc. Currently, work is performed in the operational model on advanced biomass modules with natural long-term drying and decaying processes, and in the investment model on stochastic optimisation with uncertain prices (both fuel and technologies) and uncertain energy demand. III. SUMMARY In this presentation a new natural gas network module implemented in the optimization model "eTransport" is demonstrated. The new module includes sources, nodes, pipes, valves, compressors, loads and markets. A special linearization technique is used to keep track of the gas pressure in a generic network structure. The new gas module is formulated consistent with existing electricity and heat network modules, so the model can be used to analyze both operation and investments in a complex interconnected energy system with multiple suppliers, markets and loads. IV. REFERENCES 1. II. GAS NETWORK MODULE The original gas pipeline model implemented in eTransport was a point to point pipeline for bulk transmission of large amounts of natural gas. This model did not allow representation of more complex gas infrastructures, however, so it has been replaced by a completely new module with pipelines, compressors and valves interconnected through a flexible nodal structure. In the new network structure each gas component must be connected to a node that keeps track of the pressures in the system. The pressure in all components connected to one specific node has to equal the pressure in this node. This structure makes it possible to model a general natural gas network where several sources, pipelines, compressors, valves and markets/customers are interconnected. The nodal structure of the gas infrastructure is based on piecewise linearization of the Weymouth equation [6, 7, 8]. One of the advantages of the Weymouth equation is that the friction coefficient (transmission factor) is only given by the inner diameter of the pipe. In [6] the friction factor used in the Weymouth equation is compared with among others the friction factor used in the AGA Fully Turbulent Equation. It is shown that the Weymouth equation overestimates the friction factor when compared to AGA, but at higher diameters (15” and above) the difference is small. The linearization is done around a set of L pairs of inlet and outlet pressures (PIi, POi) for each compressor and pipeline. The user specifies the number of linearization pressure points between the maximum/minimum values of inlet and outlet pressure defined for the component, and the pressure pairs are then generated automatically in the model. 2. 3. 4. 5. 6. 7. 8. Bakken BH, Wolfgang O, Roynstrand J, Frydenlund F, Skjelbred HI: "eTransport: A novel tool for energy system planning", Technical Report A6255, SINTEF Energy Research, Trondheim, Norway, 2006, ISBN 82-594-2966-7 Bakken BH, Holen AT: "Energy service systems: Integrated planning case studies", in Proc. of the IEEE PES 2004 General Meeting, Denver, CO, USA, 2004. Bakken BH, Wolfgang O, Skjelbred HI: "eTransport: Investment planning in energy supply systems with multiple energy carriers", Energy 32 (2007), pp 1676–1689 Fourer R, Gay DA, Kerninghan BW: AMPL: A Modeling Language for Mathematical Programming, Toronto, Thomson, 2003 Bakken BH, Velken, I: "Linear Models for Optimization of Infrastructure for CO2 Capture and Storage", in IEEE Transactions on Energy Conversion 23 (2008), pp 824-833 P. M. Coelho and C. Pinho, "Considerations about equations for steady state flow in natural gas pipelines," in Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 29 (2007), pp. 262-273 Tomasgard A, Bjørndal M, Midthun K: "Modeling optimal economic dispatch and flow externalities in natural gas networks", in Proc. of the Trans-Atlantic Infraday Conference on Applied Infrastructure Modeling and Policy Analysis, Maryland, USA, 2007 Midthun, K: Optimization models for liberalized natural gas markets, Doctoral thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2007, ISBN 978-82-471-4526-5 2 Authorized licensed use limited to: Sintef. Downloaded on January 15, 2010 at 06:38 from IEEE Xplore. Restrictions apply.