TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709

advertisement

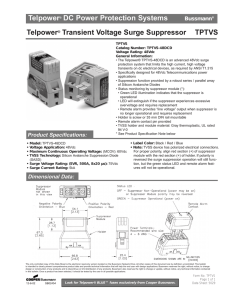

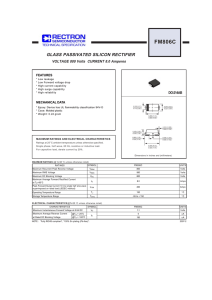

SECTION 16709 - TRANSIENT VOLTAGE SURGE SUPPRESSORS PART 1 - GENERAL 1.01 1.02 DESCRIPTION A. Surge Suppressors for AC Power Systems B. Surge Suppressors Communication Circuits RELATED WORK A. 1.03 Section 16110: Raceways and Conduits APPLICABLE PUBLICATIONS A. General: The latest edition of the following standards and publications shall apply to the work of this section; 1. ANSI/IEEE C62.33 IEEE Standard Test Specifications for Varistor Surge Protective Devices. 2. ANSI/IEEE C62.35 IEEE Standard Test Specification for Avalanche Junction Semiconductor Surge Protective Devices. 3. ANSI/IEEE C62.36 IEEE Standard Test Methods for Surge Protectors Used in Low-Voltage AC Power Circuits. 4. ANSI/IEEE C62.41 IEEE Guide on Surge Testing for Equipment Connected to Low-Voltage AC Power Circuits. 5. ANSI/IEEE C62.45 Guide on Surge Testing for Equipment Connected to Low Voltage AC Power Circuits. 6. IEEE Standard 142 - Recommended Practice for Grounding 7. IEEE Standard 518 Recommended Guide on Electrical Noise 8. UL-1283 Standard for Safety - Electromagnetic Interference Filters 9. UL-1449, 2nd Edition Standard for Safety - Transient Voltage Surge Suppressors 10. NFPA 70 National Electrical Code 11. NFPA 75 Standard for Protection of Electronic Computer Systems TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-1 12. NFPA 780 Standard for the Installation of Lightning Protection Systems 13. Military Standard (MIL Std.) 220A 14. Federal Information Processing Standards (FIPS) Publication 94 a. CCITT Rec. K-17 Waveform specification for electronic systems 15. NEMA LS-1 Low Voltage Surge Protective Devices 1.04 SYSTEM DESCRIPTION A. B. 1.05 General: Transient voltage surge suppressor (TVSS) or Surge Protective Device (SPD) is the equipment required for the protection, within specified and tested limits, of AC electrical circuits and electronic equipment from the effects of lightning induced voltages, external switching transients and internally generated switching transients. Individual suppressors shall be provided where shown on the drawings. Definitions (Clauses) SUBMITTALS A. Submit in accordance with Section 16010, Basic Electrical Requirements. B. Submit installation details for all suppressors demonstrating mechanical and electrical connections to equipment being protected. C. Submit specific test data for the actual method of installation proposed. Submittals will not be reviewed unless they include proper project related data. Interpretation of standard manufacturers published data will not be acceptable unless the data coincides with the actual installation procedure. D. Submittals shall include, but shall not be limited to, the following data; 1. Complete data for each suppressor type indicating conductor sizes, conductor types, connection configuration, lead lengths and all appropriate dimensions. 2. Dimensions for each suppressor type indicating mounting dimensions and required accessory hardware. 3. Certified test data from a nationally recognized independent testing laboratory indicating the ability of the product to meet or exceed all requirements of this specification. Tested units shall survive all testing and be fully functional without damage. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-2 4. If requested, a sample, which will be returned, of each suppressor type to be used shall be submitted. 5. Drawings shall be provided indicating suppressor mounting arrangement and lead length configuration, and mounting arrangement of remote diagnostic equipment and assemblies. 6. List and detail all protection systems such as fuses, disconnecting means and protective materials. 7. Documentation of type of suppression Components utilized within the TVSS to perform the rated and tested purpose. Documentation provided to UL for listing purposes is acceptable. Confidentiality agreements will be signed as required for access to this documentation. 8. Listing to UL 1449, 2nd Edition and include UL 1449 2nd Edition listing/classification page verifying UL clamping voltage stated on catalog data. 9. Conformance to appropriate referenced standards and publications listed in paragraph 1.03A. 1.06 10. The submittal shall include a listed comparison and proof of compliance with each paragraph of these specifications. E. Submitted components shall comply through verified testing to the minimum and maximum values listed and shall be equal to or better than the characteristics specified herein. F. Electrical performance data shall be provided on form A included at the end of this section. SUBMITTALS FOR INFORMATION A. 1.07 Submit in accordance with Section 16010, Basic Electrical Requirements. PROJECT CLOSEOUT SUBMITTALS A. Record actual locations of suppressors, grounding terminations, bonding connections, and routing of system conductors in project record documents. B. Installation Certification: After installation, the manufacturer shall furnish a letter indicating that the installation was inspected by a factory authorized representative, the date of inspection, date equipment was put into service, and that it meets all of the manufacturer's wiring and installation requirements. Submit three copies to the Engineer for review. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-3 1.08 1.09 1.10 QUALITY ASSURANCE A. Surge suppression, grounding and bonding shall effectively protect within tested limits, the systems to which applied against lightning transients, internal and external switching transients, and other surge transients throughout the useful life of the system. Surge Protective devices (SPD) and related grounding and bonding systems shall be designed and installed in such a manner that normal operation, performance ratings, and listing of the system is not impaired by the installation of such devices, wiring or connections. B. Any SPD which shows evidence of failure or incorrect operation during the ten year warranty period shall be repaired or replaced at no expense to Owner including labor and materials. Since "Acts of Nature" or similar statements include the lightning threat to which these suppression devices shall be exposed, any such general clause limiting warranty responsibility in the general conditions of this specification shall not apply to this section. The warranty shall cover the entire device not just the modules. C. Installation of SPD in or on electrical or electronic distribution systems and equipment shall in no way compromise or violate equipment listing, function, labeling, or warranty of the distribution equipment. D. All surge protective devices (SPD) and supporting components shall be guaranteed by the installing contractor to be free of defects in materials and workmanship for a period of ten years from the date of substantial completion for the system to which the SPD is attached. Suppressors or components damaged prior to substantial completion shall be replaced at no cost to the Owner. QUALIFICATIONS A. Manufacturer: Company specializing in surge suppression equipment of the type herein specified with minimum ten years documented experience. B. Installer: Installation shall be by the manufacturer or a duly licensed electrical contractor. FIELD MEASUREMENTS A. 1.11 Verify that field measurements are as indicated on shop drawings. COORDINATION A. Coordinate work with electrical installations. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-4 PART 2 - PRODUCTS 2.01 MANUFACTURERS A. The intent of this specification is to allow manufacturers with similar equipment utilizing silicon avalanche diode or metal oxide varistor (MOV) technology to provide transient voltage surge suppression which will adequately protect equipment within the guidelines set forth herein. B. The surge protective devices manufacturer shall offer factory repair service and replacement for all units. The manufacturer shall provide this service within four working days, and provide replacement components shipped to the Owner for installation within the allocated response time. C. Single Sources of Supply: All AC power suppressors (SPD) shall be manufactured by a single manufacturer - Transtector, PowerLogics, Advanced Protection Technology (APT), Raychem Rayvoss, Leviton, Cutler Hammer, Northern Technologies, Inc. All electronic system suppressors shall be manufactured by a single manufacturer, Transtector, Northern Technologies, EDCO, Phoenix, Polyphaser or Atlantic Scientific. Manufacturers listed herein have demonstrated that they can provide equipment that meets or exceeds all specification requirements, however other manufacturers will also be considered. Specific demonstration of meeting all specification requirements is required for any submitted equipment whether listed herein or not. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-5 2.02 COMPONENTS A. Main Service and Distribution Equipment Suppressors (SPD): The A.C. Voltage Surge Protective Devices shall be a high speed, high current solidstate device designed to protect electronic equipment and electrical systems from transient over voltages. It shall limit the magnitude of a transient overvoltage present on the A.C. service or distribution power lines. The suppressor shall provide continuous bi-polar, bi-directional, non-interrupting protection and be capable of instant automatic reset with no degradation in protection capabilities. Gas tubes are not acceptable. The suppressor shall be solid state, utilizing silicon junction avalanche diodes or MOV's. It shall start to suppress the transient at a minimum of 115% of the peak voltage of the sine wave. This is the Minimum Voltage Protection Level (MVPL). At maximum surge current dissipation, the device shall not exceed the maximum voltage protection level (MXVPL). The suppressor assembly shall be installed in parallel with the service main disconnect, distribution or branch panel main lugs as shown. Connect suppressor to over current protection sized as shown with an AIC rating equal to panel rating. The suppressor shall be contained in an enclosure appropriate for the environmental application in accordance with paragraph 2.02C. In addition, it shall have status indicator lights, dry contacts with remote alarm capabilities and an audible alarm. Suppressors shall be assembled as modular units to permit quick, easy replacement of failed components. Provide one spare “module” of each type suppressor for Owner’s use. If entire suppressor is one module, provide one complete spare. 1. Electrical Service Voltage Frequency Phases Wiring configuration e. IEEE 62.41-1991 (Table 4) catagories unless otherwise indicated on the drawings: Service Entrance Sizes < 600A > 600 A to 1.2 kA > 1.2 kA Distribution or Sub –panels f. IEEE 62.41-1991 (Table 8) 10/1000 waveform requirements. Use “High Exposure” level for all suppressor a. b. c. d. 480/277 VAC 50/60 Hz 3 phase 4 wire, Wye 120/208 VAC 50/60 Hz 3 phase 4 wire, Wye B3/C1 C2 C3 B3/C1 C2 C3 B2 B2 TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-6 locations. 2. 1 kV & 4 kA 0.5 kV & 2 kA Electrical Performance a. Min. Voltage Protection Level 470 volts (MVPL)(L-N) (10x1000 µsec peak waveform) 200 volts peak b. Max. Voltage Protection Level 700 volts 300 volts peak (MXVPL)(L-N)(10x1000 µsec peak waveform) c. Max. Voltage Protection Level per IEEE 6241-1991 (6 & 10kV 1.2/50µs, 3 & 5 Ka 8/20µs) 800 volts peak 400 volts peak (20KV 1.2/50µs; 10KA 8/20µs) 900 volts peak 500 volts peak UL 1449 2nd Edition SVR’s 700 volts (6 kv, 1.2/50µs;0.5 ka 8/20µs) peak 330 volts peak d. Max. Continuous Operating Voltage (MCOV) of nominal line 115% minimum TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-7 115% minimum e. Max. Surge Current Dissipation See 2.02.A.1.e & f See 2.02.A.1.e & f per Phase per Polarity (the voltage protection levels per paragraphs 2.02.A.2.b & c shall not be exceeded during this performance test.) f. Response Time ≤5 ns ≤5 ns g. Min. Service Life The suppressor shall be provided with a 10 year unconditional warranty or shall meet the following surge tests without being damaged or changing the voltage protection level (clamping voltage) by 10% of initial value provided. Maximum 50-60 seconds between pulses. (1) Shortwave Test – surge current 1000 surges (6kV, 1.2/50µs; 3kA, 8/20µs) (2) Longwave - surge current 5000 surges (10 x 1000 µs) (1kv & 4 kA @ 277V 0.5 kV & 2 kA @ 120V) 1000 surges 5000 surges h. Temperatures – (1) Operating (2) Storage 0oC to +50oC. -20oC to +65oC. i. Electrical Safety UL 1449 2nd Edition Lst. j. Suppression system shall be normal mode (L-N) only (for 480/277VAC & 208/120 VAC services). 0oC to +50oC. -20oC to +65oC. UL 1449 2nd Edition Lst. k. Power On Indicators and Failure Detection (for 480/277VAC & 208/120 VAC): A lighted panel on the cover shall provide indication that the suppressor is properly activated and shall also indicate mode failure. If the suppressor fails, an isolated 2 amp 120 VAC contact shall close. In addition, an audible alarm shall be provided with manual reset. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-8 l. Failure mode – SPD’s shall be designed to fail shorted. Any fuses in series with the SPD’s shall not open during a surge event. B. Disconnect: Main service suppressors shall be provided with an integral fused disconnect switch or external branch circuit breaker as shown or required by UL. Breakers and suppressors shall have an AIC fault withstand rating equal or greater than the AIC rating of the equipment to which it is connected. The length of wiring from the tap at the service conductors to the suppressor being protected, however, shall not exceed the maximum length permitted by manufacturer, to maintain the maximum voltage protection level. Suppressors may be installed within switchgear or panelboards where UL label or listing is not affected, suppressors are completely and easily accessible, indicator lights are visible and audible alarm can be easily heard. C. Enclosures: Enclosures for main service suppressors shall be as follows; 1. Minimum 14 gauge painted steel or suitable enclosure to meet the NEMA selected requirements as listed with fully hinged door and lockable latch. a. b. c. d. D. NEMA 1 (General Purpose). NEMA 4 Watertight, and dust-tight. NEMA 4X Watertight, dust-tight and corrosion resistant. NEMA 12 Dust-tight and drip-tight (where specified on drawings). Operation Status Indicator Audible remote signaling and Visual Systems: Service entrance equipment 1. Install in front enclosure of equipment a. Visual System Equipment with LED indicator lights per phase. 1. 2. 3. (4) b. Protection: Suppressor Working - Green LED's. Warning/Fault: Suppressor Burnout - Red LED's. LED's shall be field replaceable. Other visual indicators where approved. Remote Signaling (1) Relay with Auxiliary Form C contacts: Two sets @ 2 ampere, 120 volts each. 1 Set N.O. and 1 set N.C. to operate upon failure of suppression module, blown fuse or tripped circuit breaker in suppressor module or in disconnect switch for alarm connection to remote location. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-9 c. E. Audible – The audible alarm shall activate upon a fault condition within the suppressor. An alarm silence/reset switch and push-totest switch shall be provided. Plug-in Receptacle SPD Devices: (Receptacles Suppressor) - Unit shall include the following features: 1. Instant automatic reset after safely eliminating transient surges from switching transients, induced lightning, inductive motor switching and other forms of transient over voltages in normal mode (L-N) only. 2. Designed for 120 VAC, 1 phase (3 wire service), plug-in applications arranged to plug into any 15 or 20 amp, duplex, grounded receptacle. 3. A minimum of two single or one duplex, grounded 20 amp receptacles. 4. To be connected in parallel. 5. Employ only solid-state, silicon avalanche junction diode suppressors or metal oxide varistors. 6. Response time: less than 5 nanoseconds. 7. Suppression power: Minimum 12,000 watts or 12 joules. (10 x1000 µs pulse), at a max.VDL of 300Vpeak. 8. Operating temperature: -0/C to 50/C. 9. Voltage (V peak) protection level: 220 Minimum, 300 Maximum (10x1000 µs pulse). 330 maximum per UL 1449. 2nd Edition. 10. Service Frequency: 50/60 Hertz. 11. Life expectancy: 10 years plus. 12. Indicator light to turn on when unit is non-operational. (Usually Off) 13. Internally fused to take unit off-line if it self-sacrifices to protect against catastrophic power failure. Equipment plugged into suppressor shall continue to operate. 14. Warranty: 3 year guarantee to be repaired or replaced at no cost if damaged by normal operating use during the warranty period. 15. U.L. 1449, 2nd Edition listed (6kV 1.2/50 µs; 500 A 8/20 µs). 16. IEEE C62.41 Cat. A3 and B3 tests. (B3 = 6kV and 3kA) Minimum 10 year unconditional warranty. TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-10 F. G. Receptacle suppressor with one input and one output RJ-11 jacks: Unit shall be same as in paragraph `A' above with the addition of 1-telephone protector and 2-RJ-11 (input and output) jacks with common grounds with the AC power. Telephone protector shall have the following characteristics and shall provide common and normal mode protection. 1. D-C Protective Level voltage (maximum) T-R .....................................300-380V T-G......................................300-380V R-G......................................300-380V 2. Leakage Current (max @ 60HZ).............<10µa 3. Holding current (min.)...................260 ma 4. Peak On-State Voltage IT = 1A............3V 5. Response time............................<1ns 6. Peak Pulse Current (10x1000µs) a. Applied between T-R, T-G, R-G…….100A b. Applied simultaneously T-G and R-G.......200A 7. Capacitance..............................<100pf 120V direct connected Hard Wired suppressors shall be provided with mounting provisions and wire leads for hardwire connection. Suppressors shall have the same characteristics as the above specified receptacle suppressors (E). H. Bonding and Grounding Conductors and Materials for Main Service Suppressors: 1. Size: Conductors utilized for surge suppressor connections to service conductors shall be a minimum of #6 AWG stranded insulated copper unless otherwise specified. 2. Bus: Ground bus or strip material where used shall be copper, a minimum of 1/4 inch thickness and two inches wide unless otherwise specified. Bus materials shall be secured to surfaces with a appropriate insulators and mechanical fasteners. Bus connections shall be bolted and reinforced as necessary to provide a permanent and secure connection. 3. Connections Compliance: Connectors, splices, and other fittings used to interconnect grounding conductors, bonding to equipment or ground TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-11 bars, shall comply with requirements of the National Electric Code and be accepted by Underwriters' Laboratories for the purpose. 4. Connectors: Connectors and fittings for grounding and bonding conductors shall be of the compression type in above grade locations. Connections below grade shall be exothermically welded. 5. Dissimilar Materials: Bonding connections between electrically dissimilar metals shall be made using exothermic welds or using bimetal connectors designed to prevent galvanic corrosion. I. Communication Lines: The following standard for separately mounted telephone and signal line suppressors shall apply. All protectors shall be securely mounted at protected equipment location. All suppressors shall provide common (L-G) and normal (L-L) protection. Suppressors shall be tested in accordance with IEEE C62.36-1994 as a minimum. Protective interfacing with the telephone wire pairs shall be listed to UL 497A. J. Data Line Protection: Solid state, silicon avalanche diode circuitry for protection from over voltages on long cable runs employing standard RS-232, 9, 15, or 25-pin "D" connectors utilized to interface a remote station with a host CPU. Unit shall have 2 built-in or ribbon cable attached connectors (in and out) and an external ground lug or cable. Connect ground lug or cable to CPU or terminal grounding system with a No. 12 copper green insulated stranded ground wire as short as possible. Select pins requiring protection based on protected equipment wiring requirements. Protectors shall be designed to be easily installed on multiplex panels with connector spacing at a minimum of 1.0 inch centers. 1. 2. 3. 4. 5. 6. Signal line voltage (max).........................15v peak Leakage at signal voltage........................<5m amp Voltage protection level. .........................16v peak Response time...................................5 nanoseconds or less Impedance per line................................40 OHM max. Peak power dissipation..........................15,000 watts (10/1000 Test Wave form) 7. Temperature range...............................-20oC to +65oC TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-12 8. Capacitance: a. data rates <20,000 baud - <2,000 pf b. data rates 20,000 baud to 2Mhz - <100 pf c. data rates >2MHz to 100 Mhz - <40 pf 9. UL 497B listed. K. Signal line protection (telephone) - solid state, silicon avalanche diode circuitry for protection from over voltages on 2 or 4 wire signal lines such as balanced pair telephone, metallic pair telephone, buried and overhead field cable, remote radio equipment, and control systems. Unit shall have an external ground lug or wire. Connect ground lug or wire to protected equipment grounding system with a No. 12 green insulated stranded ground wire as short as possible. 1. L-L & L-G voltage (peak) 13 27 54 120 160 L-L & L-G Voltage Protection Level 16 33 67 150 200 2. 3. 4. 5. L-L and L-G Leakage @ max L-L and L-G voltage...<5µa Response time......................................,.<5 nanoseconds Series impedance(each line)........................33 Ohm max. Peak power dissipation (L-L) or (L-G)......15,000 watts (10 x 1000 Test Form) 6. Temperature Range...............................-20oC to +65oC 7. U.L. 497B listed Wave L. Modem protector for leased lines - solid state silicon avalanche diode circuitry for non-faulting/non-interrupting protection from over voltages on leased phone lines. Full duplex protection shall be provided for both send and receive channels. Terminals shall be provided for 4-wire leased line input and output to equipment plus ground. Connect ground terminal to equipment ground. 1. 2. 3. 4. 5. 6. 7. M. Signal line voltage (max)...................160V peak Leakage @ signal voltage............................5µa Clamp point.......................................200V peak Response time...............................<5 nanoseconds. Series impedance..........................33 Ohm max. Peak power dissipation...................15,000 watts Operating Temperature................-20oC to +65oC Modular, twisted pair protection - solid state, silicon avalanche diode circuitry for protection from over voltages on twisted pair data or audio lines. Protectors shall clip mount on 66 punch down blocks furnished with grounding bar or studs and shall be totally enclosed. Units shall be securely mounted at TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-13 terminal locations where shown and shall be grounded to the main building ground with a minimum No. 8 stranded copper green insulated ground conductor as short as possible. Terminals shall be screw insertion lug type. No crimp fork or ring type permitted. 1. 2. 3. 4. 5. N. Response time..............................<5 nanoseconds Peak power dissipation (1ms)...............15,000 watts Temperature range..........................-20o C to +50o C Maximum voltage protection levels (peak) utilizing a 10 x 1000µs waveform for normal and common mode protection shall be 240-380V or 45V as indicated on the drawings. Peak repetitive pulse current. a. 1. x 2. µsec - 225 amp b. 8 x 20µsec - 150 amp c. 10 x 1000µsec - 100 amp 75 ohm coaxial cable protectors - Solid state, silicon avalanche diode circuitry for non-interrupting overvoltage protection of RG- 59/U coaxial cable. Unit shall be provided with one female input connector for "F" series male connector, one output RG-59/U coax cable terminated with an "F" series male cable end connector and A #16 stranded, 18 inch long grounding wire on output end of unit or similar arrangement. Securely mount adjacent to protection equipment and ground to equipment or local building ground if an equipment ground is not available. 1. Normal Operating Characteristics a. b. c. d. 2. Voltage .........................5.8V max Current.......................500ma max Frequency.....................DC to 10 Mhz Insertion Loss................3.5db @ 4Mhz Protection Requirements a. b. c. d. Transient suppression level.........7.5v Voltage Protection Level Transient response............<5 nanoseconds Operating temp................-20o C to +50o C Energy dissipation............15,000 watts (10X1000 Test Wave) PART 3 - EXECUTION 3.01 INSTALLATION OF MAIN SERVICE AND DISTRIBUTION EQUIPMENT SURGE SUPPRESSORS A. Suppressors shall be installed at Service Entrance switchboards and distribution equipment where shown as close as practical to equipment to be protected consistent with the available space. Where installation space permits and where no code restrictions apply, suppressors may be installed TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-14 within protected equipment. Suppressors installed in this manner shall utilize the equipment ground bus or enclosure as a medium for bonding of their ground terminals. Bonding jumpers not exceeding two inches in length shall be installed between the ground bus or enclosure and suppressor ground terminals. Bolted connections with star washers shall be used to insure electrical and mechanical integrity of connections to the ground bus or enclosure. Remove paint where connections are made to the enclosure. Conductors from suppressors shall attach to main service bus in the service entrance equipment on the load side of any electrical metering equipment. 3.02 B. Suppressors shall be installed in a neat, workmanlike manner. Lead dress shall be consistent with recommended industry practices for the system on which these devices are installed. C. All system wiring shall be classified into protected and non-protected categories. Wiring on the exposed side of suppression devices shall be considered unprotected. Surge suppressor grounding and bonding conductors shall also fall into this category. D. All wiring between surge suppressors and protected equipment shall be considered protected and connected in accordance with the latest edition of the NEC. E. A minimum of three inches of separation shall be provided between parallel runs of protected and unprotected wiring in control panels, terminal cabinets, terminal boards and other locations. In no case shall protected and unprotected wiring be bundled together or routed through the same conduit. Where bundles of protected and unprotected wiring cross, such crossings shall be made at right angles. FIELD QUALITY CONTROL A. Disconnect suppressor prior to megger testing of service entrance distribution equipment and panelboards. B. Supply certified test reports for all tested parts, elements and/or systems or where required by the Owner to substantiate published ratings of claims. END OF SECTION 16709 TRANSIENT VOLTAGE SURGE SUPPRESSORS 16709-15