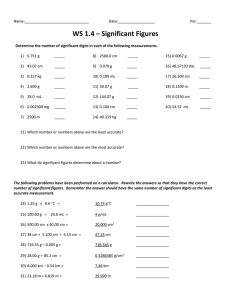

Technical data

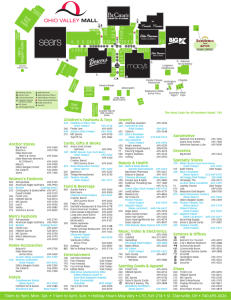

advertisement