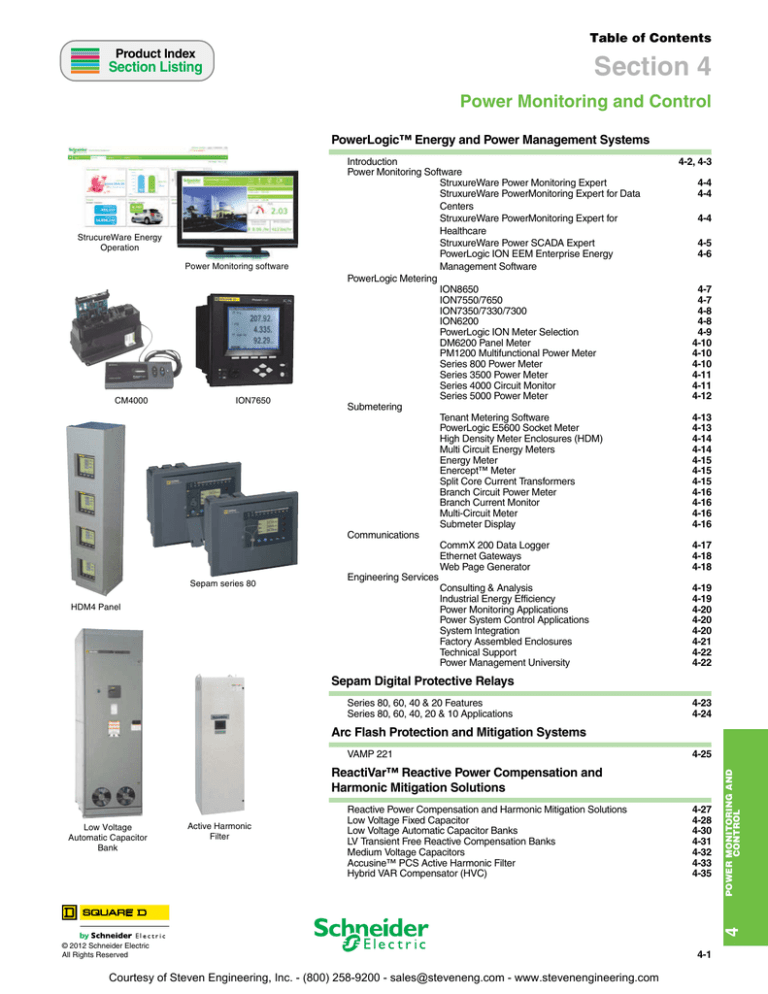

Schneider Electric Digest 176 - Power Monitoring and Control

advertisement