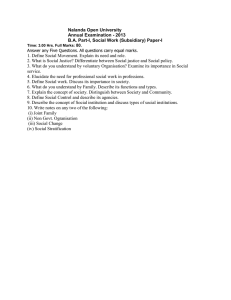

model curriculum for post ssc programme in diploma in

advertisement