CSE1206_COVER.indd 2

5/30/12 4:19 PM

Standby

for Big Power

Every Baldor generator set,

standard or custom, is designed

and engineered to meet the

individual needs of your application.

Whether it’s a 2,000 kW genset to

keep your industrial facility up and

running, or a 30 kW generator for

your remote agricultural needs,

Baldor has the right products to

meet your need.

Engineered to the highest

performance standards and built

with unmatched quality, Baldor

gensets give you the power you

need, when you want it.

baldor.com

479-646-4711

©2012 Baldor Electric Company

Download a QR reader app

and scan this code for

more information.

http://qr2.it/Go/1031258

input #1 at www.csemag.com/information

CSE120601-MAG_Ads.indd 2

5/31/2012 12:42:32 PM

Challenge your building!

Extraordinary pumping solutions inside

EXPERTISE

40 years of expertise

– EXPERIENCE AND CUTTING EDGE TECHNOLOGY UNITE

E for excellence

Maybe you are not familiar with Grundfos, but we

have news that can change the efficiency of your

buildings forever.

Grundfos is the world market leader in intelligent,

high-quality pumps and pump systems, and

electronically controlled pumps – or E-pumps as we

call them – have been on the Grundfos agenda for

decades. Ever since the late 1980’s when the world’s

first speed-controlled pump was constructed in our

laboratories, we have been dedicated to fine-tuning

the technology of our extensive E-pump range.

E for Exceptional Savings and

Environment

A Grundfos E-pump is characterized by its highefficiency motor and integrated frequency converter

and controller. That means that the pump is able

to control its pump speed according to the current

demand – and that means savings. Approximately

85% of the total cost of owning a pump has to do

with power consumption, and a Grundfos E-pump

can reduce your energy consumption drastically

– up to 50% in fact. That’s a good number for both

your energy bill and the environment. Contact us

today to hear how we can boost your building’s

efficiency with an E-pump solution.

Visit www.thinkingbuildings.us for

even more energy efficient solutions.

Our bestsellers

PACO LF with CUE

The PACO LC and LF is our line of single stage, close coupled and framemounted pumps for end suction. Combined with the CUE frequency drive,

it guarantees efficiency on demand and is the smart choice for anyone

looking for reduced operating and maintenance costs, maximum reliability,

and quiet operation.

MAGNA

The MAGNA is our renowned, intelligent variable-speed wet rotor

circulator. The patented AUTOADAPT function and the integrated frequency

drive ensure maximum efficiency and maximum savings at all times.

BoosterpaQ

The BoosterpaQ is our answer to any commercial challenge

involving water boosting. A Grundfos BoosterpaQ system fitted

with Grundfos CRE – intelligent, frequency

drive-controlled pumps − ensures the right

pressure and flow at any time with an

unbeatable high efficiency.

RETROFIT

Retrofit for incredible savings!

What do you need?

A pump retrofit can deliver fantastic savings in older

buildings – even without changes to the building

envelope or piping. A Grundfos retrofit considers the

pump system as part of the whole building system,

since this will ensure the highest possible energy

efficiency and shortest possible paybacks – in some

cases as little as 2 years.

A Grundfos pump retrofit can be adapted to suit your specific

needs – all the way from a simple pump replacement to a full

analysis and reconfiguration of your building system.

80% savings for Radisson Blu

Based on a full system assessment, the Radisson Blu

Hotel in Lisbon, Portugal achieved energy savings of

80%. The new BoosterpaQ system saves 74,692 kWh

every year, allowing the Radisson Blu to improve other

aspects of the hotel experience.

“Our old equipment used 3.25 kWh to raise 1 m3 of

water. The new Grundfos solution uses just 0.66 kWh

to do the same job.”

Fernando Cristóvão

Head of Maintenance

Radisson Blu

See how we can help and find great cases on

www.thinkingbuildings.us/grundfoscrew

The retrofit scale

SMALL (replacement)

The customer is assisted in selecting an appropiate

replacement pump featuring cutting edge energy

efficiency.

MEDIUM (energy check)

In an energy check, the purpose is dual:

1)to get an overview of the energy consumption

of the customer’s installed base.

2)to get an overview of where and when a

replacement is profitable.

LARGE (pump audit)

A pump audit is a diagnostic tool that identifies

excessive energy consumption in any kind of pumping

system. Pump audits are concluded by a full report that

proposes solutions to improve the efficiency.

SMART BUILDING

Building for tomorrow

Intelligent solutions for intelligent

buildings

Grundfos pump solutions are based on a holistic

approach that considers the building system as a

whole. Coupled with 65 years of pump experience, this

approach allows us to deliver the renowned Grundfos

efficiency.

Because of our systems approach, all Grundfos

products are designed for easy integration into

Building Management Systems and for in-depth data

capture and distribution.

Combining this level of system intelligence with

pump efficiencies that are way ahead of legislative

standards around the world, we guarantee that your

new Grundfos solution will draw admiring glances well

into the future.

Sign up!

Sign up for more intelligent input! Get our electronic

magazine BLUEPRINT four times a year.

Go to www.thinkingbuildings.us and sign up now.

Introducing Grundfos GO

Grundfos GO is the market’s most comprehensive

platform for mobile pump control, live monitoring

and operation assistance.

Built around an intuitive and user-friendly

mobile application, Grundfos GO allows pump

professionals to save time on installation,

configuration, maintenance, data collection

and replacement.

Mobile efficiency

Compatible with a wide range of

Grundfos products, Grundfos GO is

packed with features that increase

efficiency – including easy

paper-less reporting,

descriptive alarm

logs, full access

to Grundfos

online tools and

documentation, as well as

the ability to clone pump

settings.

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

Visit us online

For more information on Grundfos Commercial

Building Services and our offerings , please visit

www.thinkingbuildings.us. Here, you can read all

about our products or use our online tools, including

the timesaving Quick Pump Selection tool.

Sign up to stay ahead

Do you want to stay ahead of

the curve in pumps and pump

technology? Then sign up for our

free, digital newsletter BLUEPRINT.

www.thinkingbuildings.us

Grundfos

17100 W. 118th Terrace

Olathe, KS 66061

USA

Tel: (+1) 913-227-3400

www.grundfos.us

The name Grundfos, the Grundfos logo, and the payoff Be–Think–Innovate are registrated trademarks

owned by Grundfos Holding A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

How do you

define redundancy?

Look at the world the way Generac Industrial Power does and you might change your mind.

To you, redundancy means repetition, overlap, and duplication. To Generac Industrial

Power, redundancy means fully integrated, built-in paralleling technology; advanced digital

controls; and rigorous prototype testing on solutions as large as 9MW. That’s just how

we see the world. And thousands of mission critical service providers, municipalities and

other commercial and industrial facilities that installed a Generac industrial power system,

The College of William and Mary in

Williamsburg, Virginia, defines redundancy

with Generac’s Modular Power System.

For this and more case studies,

visit generac.com.

know just what we mean. For more information on our products, call 1-888-GENERAC

or visit us at generac.com.

input #2 at www.csemag.com/information

CSE120601-MAG_Ads.indd

Consulting

Spec Eng SEP.indd 1 1

6/4/2012

11:29:45

AMPM

7/26/2011

3:50:17

For long runs, 20' conduit is the smart choice.

Prove it to yourself with our free 20' savings calculator!

20' Conduit

Wheatland 20' steel conduit takes half the time to couple compared to 10'.

With 50% fewer couplings, it’s the smart choice for warehouses, big-box retail,

airports, data centers and other long-run applications. Now you can use our

free savings calculator on your smart phone to figure just how much you

can save. It’s a powerful tool to help you win more jobs, and greater profits.

Ideal for long runs

Uses 50% fewer couplings

Cut connection times in half

Start using Wheatland’s 20' savings calculator

wheatland.com/worksmarter

input #3 at www.csemag.com/information

CSE120601-MAG_Ads.indd 2

12-JMC-0170_ad_20ft_savings_app_forECMag.indd

1

6/4/20124/12/12

11:30:348:12

AM AM

A DV E R T I S E M E N T

Wheatland Tube Sets the “Standard” for Innovation

in the Steel Industry

The highlight of Wheatland’s social media platform

is its weekly blog: the Wheatland Standard.

The blog was created to provide insight, information, and perspective on the issues that matter in

the steel industry. From “green” energy solutions

to what “Made in America” truly means, the

Wheatland Standard is committed to staying

current with posts featuring best practices and

emerging technologies.

Wheatland Tube, the largest steel pipe and electrical

manufacturer in North America, sets the “standard” in

innovation. Wheatland has become the “one-stop-shop”

for quality standard pipe, sprinkler pipe, electrical conduit, and electrical elbows, couplings, and nipples in the

industry. Known for its outstanding service as well as its

superior products, Wheatland has developed the expertise

and knowledge to meet all of one’s steel product needs.

Wheatland is also proud to proclaim that all of its products

meet stringent Made in America standards, with 100%

of its product portfolio manufactured from steel that was

made and melted in the USA.

By finding new

and exciting ways

to communicate

and connect with

its customers and

agents, as well as

continuing to set

and create new levels

of industry standards

with its high quality,

American-made

products, Wheatland

Tube is truly an innovative

manufacturer for the ages.

However, providing high quality products is only part of the

equation at Wheatland Tube. Aside from cutting-edge

investments in facilities and systems, Wheatland has also

begun to set the mark when it comes to disseminating

relevant, important information to its clients.

With the launch of its social media program that

encompasses a wide range of platforms including

YouTube, Twitter , and a quarterly eNewsletter,

“eConduit”, Wheatland is finding new ways to effectively

communicate with both its customers as well as its

agents. The objective of this social media program is to

create a new level of interactive dialogue between the

manufacturer, customers, and end users of Wheatland’s

products.

info@wheatland.com | 800-245-8115 | www.wheatland.com

JUNE 2012

FEATURES

28 | Boiler systems:

Economics and efficiencies

Engineers can meet a building’s

hot water needs with today’s boiler

systems.

BY DOMINIC TABRIZI, PE

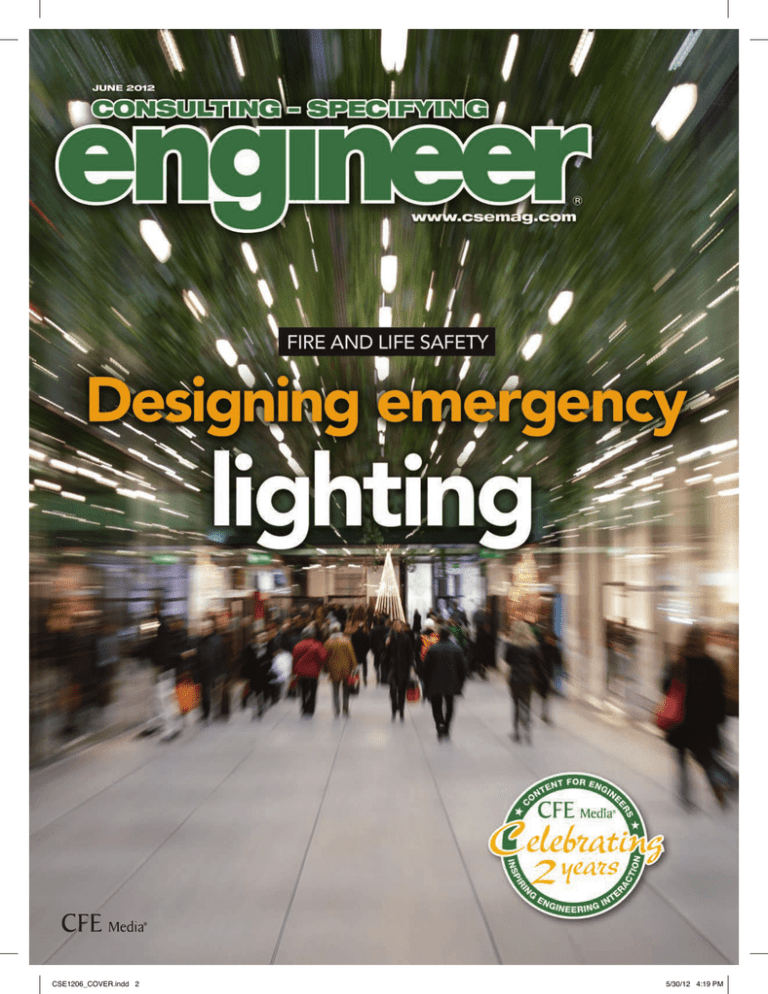

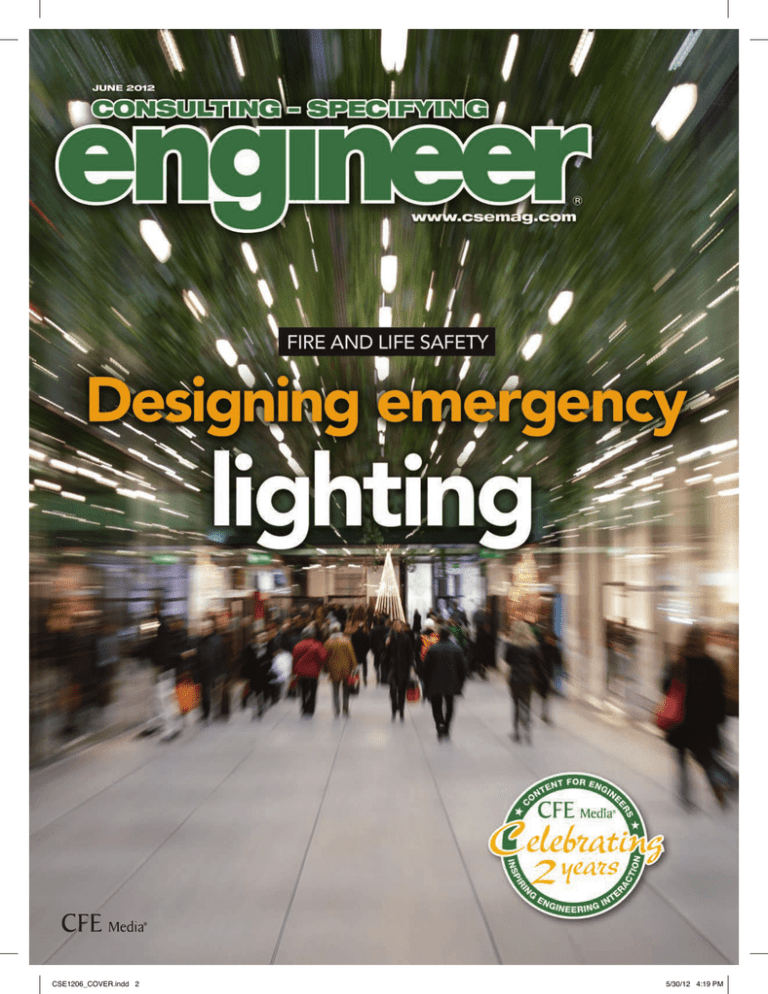

ON THE COVER: In an emergency, people

rush from a facility in a confused state. This

photo also represents the minimal and obstructed visibility

that is possible during an emergency evacuation situtation.

Courtesy: istockphoto.com

33 | Automatic transfer switch protection

Automatic transfer switch short-circuit current protection

has some common misconceptions. Here we’ll discuss the

deficiencies of “non-current limiting” protection.

BY MIKE STANEK

COVER STORY

20 | Fire and life safety: Emergency lighting

Emergency lighting is just one component of the meansof-egress, a part of a building’s life safety system. In the

event of a power outage, a backup lighting system may be

the occupants’ only guide to a safe exit.

BY DALE WILSON, AIA

DEPARTMENTS

40 | Economic analysis

in individual project

selection

Using net present value analysis

instead of the rate of return will

treat investment scale as one of

the key value drivers, and will help

engineers select money-making

projects.

07 | Viewpoint

16 | Codes & Standards

Innovating our way

through the recession

Documenting ASHRAE 90.1

compliance

08 | MEP Roundtable

27 | New Products

Industrial strength

Emergency lighting

15 | Career Smart

63 | Advertiser Index

The art of asking a good

question

AUTOMATION & CONTROLS

HVAC

64 | 2 More Minutes

COMMUNICATIONS

LIGHTING

The next big thing in

data centers

ELECTRICAL

PLUMBING

BY STEVE KIHM, CFE

SCOTT HACKEL, PE

AND

KEY

FIRE, SECURITY & LIFE SAFETY

CONSULTING-SPECIFYING ENGINEER (ISSN 0892-5046, Vol. 49, No. 5, GST #123397457) is published 11x per year, monthly except in February, by CFE Media, LLC, 1111 W. 22nd Street, Suite

#250, Oak Brook, IL 60523. Jim Langhenry, Group Publisher /Co-Founder; Steve Rourke CEO/COO/Co-Founder. CONSULTING-SPECIFYING ENGINEER copyright 2012 by CFE Media, LLC. All rights reserved. CONSULTINGSPECIFYING ENGINEER is a registered trademark of CFE Media, LLC used under license. Periodicals postage paid at Oak Brook, IL 60523 and additional mailing offices. Circulation records are maintained at CFE Media, LLC, 1111

W. 22nd Street, Suite #250, Oak Brook, IL 60523. Telephone: 630/571-4070 x2220. E-mail: customerservice@cfemedia.com. Postmaster: send address changes to CONSULTING-SPECIFYING ENGINEER, 1111

W. 22nd Street, Suite #250, Oak Brook, IL 60523. Publications Mail Agreement No. 40685520. Return undeliverable Canadian addresses to: 1111 W. 22nd Street, Suite #250, Oak Brook, IL 60523.

Email: customerservice@cfemedia.com. Rates for nonqualified subscriptions, including all issues: USA, $ 145/yr; Canada, $ 180/yr (includes 7% GST, GST#123397457); Mexico, $ 172/yr; International air delivery $318/yr.

Except for special issues where price changes are indicated, single copies are available for $20.00 US and $25.00 foreign. Please address all subscription mail to CONSULTING-SPECIFYING ENGINEER, 1111 W. 22nd Street, Suite

#250, Oak Brook, IL 60523. Printed in the USA. CFE Media, LLC does not assume and hereby disclaims any liability to any person for any loss or damage caused by errors or omissions in the material contained herein, regardless

of whether such errors result from negligence, accident or any other cause whatsoever.

www.csemag.com

CSE1206_TOC_V5msFINAL.indd 3

Consulting-Specifying Engineer • JUNE 2012

3

6/5/12 1:48 PM

online now csemag.com

When engineering systems for manufacturing and industrial facilities,

what is the No. 1 most difficult issue you face?

Automation

and controls

38%

Energy efficiency,

sustainability

32%

Electrical

and power

10%

Fire and

life safety

10%

Codes and

standards

5%

HVAC

5%

Read the roundtable discussion about manufacturing

and industrial facilities on page 8. For more poll results,

visit www.csemag.com/poll/cse.

Career Smart

Engineers Conference

Build career development and business management skills at the nation’s

only dedicated soft-skills training event for professionals in the buildings industry

at the Career Smart Engineers Conference. Gain tools and insights through two

tracks of educational sessions covering business development, personal development, marketing, networking, mentoring and communications. The two-day event

is October 17-18, in downtown Chicago at the Hilton Chicago. Register today at

www.csemag.com/careersmart.

2012 Product of the Year

Last chance to vote! Consulting-Specifying Engineer’s

Product of the Year contest is a premier award for new

products in the HVAC, fire, electrical, and plumbing systems engineering markets. Review the 2012 POY finalists and cast your vote by June 29 for your favorite product online at www.csemag.

com/votePOY. The winners will be announced in the September 2012 issue of CSE

and online.

4

Would you prefer to

receive this issue as a digital publication? Update

your subscription, and

get our digital edition, on

our new more interactive

platform, in your e-mail inbox: www.csemag.com/

subscribe.

Subscribe directly to e-newsletters,

and receive focused technical content

on a regular basis. Subscribe at www.

csemag.com/newsletters. Select from:

CSE Codes & Standards

Electrical Solutions

Energy Solutions

Fire & Life Safety

HVAC Solutions

News Watch

Product & Media Showcase

Pure Power

View live and on-demand webcasts at

www.csemag.com/webcast. Topics

include:

Electrical Distribution:

Innovative Approaches That

Save Money

Strategies for Implementing

Energy Efficient Data Centers

Critical Power: Gensets—

Designing Reliable and Flexible

Emergency and Standby Power

Systems

Fire Systems: Protecting

Hospitals

Update on the 2011 National

Electric Code

Consulting-Specifying Engineer is now

on Facebook, Google+, LinkedIn, and

Twitter. Follow CSE, join the discussions, and receive news and advice

from your peers.

Facebook:

www.facebook.com/CSEmag

Cut the Copper

Google+:

http://tinyurl.com/CSEgoogleplus

Read Consulting-Specifying Engineer’s newest blog, Cut the Copper, by Joe Guentert. Guentert is owner and sole proprietor of Power Distribution Systems, Charlotte, N.C., which focuses on mission critical electrical power systems, with the vast

majority of projects being large data centers. Join him in discussing electrical and

power topics such as liquid-filled transformers, vacuum circuit breakers, power distribution, and much more: www.csemag.com/blogs.

LinkedIn:

http://tinyurl.com/CSElinkedin

Twitter:

www.twitter.com/AmaraRozgus

Consulting-Specifying Engineer • JUNE 2012

CSE1206_ECONTENTS_V3msFINAL.indd 4

6/5/12 1:48 PM

One box. Countless applications.

raised floor

wood floor

concrete floor

Wiremold® Evolution™ Series Floor Boxes work everywhere – and

change everything. Designed to work in any type of floor construction,

these advanced boxes have the capacity to handle up to ten gangs

of power, communications and A/V. In addition, these boxes feature

a fully finished interior, removable modules, a cover designed to

open 180° and a choice of five finishes. Learn more by visiting

www.legrand.us/efb.

input #4 at www.csemag.com/information

CSE120601-MAG_Ads.indd 5

6/4/2012 11:32:01 AM

usa.siemens.com/sinorix

The environment is just one of

the critical assets we’re protecting.

Siemens Sinorix™ 1230 fire suppression system gives you an intelligent, reliable

and environmentally friendly way to protect your people and valuable assets.

Your fire suppression system may be effective, but is

it green? Siemens Sinorix 1230 fire suppression

system provides superior protection from fires, and

is environmentally friendly. Sinorix 1230 uses 3M™

Novec™ 1230 Fire Protection Fluid, an innovative

suppressant agent that’s non-toxic, HFC free and

leaves no residue. At design concentrations, it won’t

damage your assets or the health of your people.

When Sinorix 1230 is paired with Siemens sophisticated

detection technology, you get an intelligent and reliable

fire detection system that eliminates false alarms, detects

real fires and extinguishes them promptly. Whether you

are protecting a critical data center, clean rooms or

priceless art, with Siemens and Sinorix 1230 you have

the confidence to know that your business and the

environment are protected.

Answers for infrastructure.

input #5 at www.csemag.com/information

CSE120601-MAG_Ads.indd 6

6/4/2012 11:33:27 AM

Editor’s Viewpoint

1111 W. 22nd St. Suite 250, Oak Brook, IL 60523

630-571-4070 Fax 630-214-4504

CONTENT SPECIALISTS/EDITORIAL

AMARA ROZGUS, Editor in Chief/Content Manager

630-571-4070, x2211, ARozgus@CFEMedia.com

PATRICK LYNCH, Project Manager

630-571-4070, x2210, PLynch@CFEMedia.com

AMANDA MCLEMAN, Project Manager

Amara Rozgus

Editor in Chief

630-571-4070 x2209, AMcLeman@CFEMedia.com

BOB VAVRA, Content Manager

630-571-4070, x2212, BVavra@CFEMedia.com

MARK HOSKE, Content Manager

630-571-4070, x2214, MHoske@CFEMedia.com

PETER WELANDER, Content Manager

630-571-4070, x2213, PWelander@CFEMedia.com

MICHAEL SMITH, Creative Director

630-779-8910, MSmith@CFEmedia.com

CHRIS VAVRA, Content Specialist

630-571-4070, x2219, CVavra@CFEMedia.com

BRANDON MARCELLIS, Content Specialist

BMarcellis@CFEMedia.com

EDITORIAL ADVISORY BOARD

ANIL AHUJA, PE, LEED AP, RCDD,

President, CCJM Engineers, Chicago

PATRICK BANSE, PE, LEED AP,

Senior Mechanical Engineer,

Smith Seckman Reid Inc., Houston

PAUL BEARN, PE,

Associate Electrical Services Engineer,

KlingStubbins, Philadelphia

MICHAEL CHOW, PE, LEED AP BD+C,

Principal, Metro CD Engineering LLC, Dublin, Ohio

DOUGLAS EVANS, PE, FSFPE,

Fire Protection Engineer, Clark County Building Division, Las Vegas

RAYMOND GRILL, PE, FSFPE,

Principal, Arup, Washington, D.C.

RAJ P. GUPTA, PE, LEED AP,

President, Environmental Systems Design Inc., Chicago

GERSIL KAY,

President, Conservation Lighting Intl. and Building Conservation

Intl., Philadelphia

WILLIAM KOSIK, PE, LEED AP,

Managing Principal, EYP Mission Critical

Facilities Inc., Chicago

TIMOTHY E. KUHLMAN, PE, RCDD,

Electrical Engineer CH2M Hill, Portland, Ore.

KEITH LANE, PE, RCDD, LC, LEED AP,

President, Lane Coburn & Assocs., Seattle

KENNETH L. LOVORN, PE,

President, Lovorn Engineering Assocs., Pittsburgh

ALI MAHMOOD, PE,

Senior Mechanical Engineer, Stanley

Consultants Inc., Chicago

ERIN MCCONAHEY, PE,

Associate Principal, Arup, Los Angeles

SYED PEERAN, PE, Ph.D.,

Senior Engineer, Camp Dresser & McKee Inc.,

Cambridge, Mass.

MARTIN H. REISS, PE, FSFPE,

President, CEO, The RJA Group Inc., Framingham, Mass.

BRIAN RENER, PE, LEED AP,

Senior Manager, M+W Zander U.S. Operations Inc., Chicago

DAVID SELLERS, PE,

Senior Engineer, Facility Dynamics Engineering Inc., Portland, Ore.

GERALD VERSLUYS, PE, LEED AP,

Innovating our way through the recession

A

difficult—and yet rewarding—

outcome of this recession has

been the boom of small engineering firms and other businesses.

Individuals, once cut loose from larger

firms that have trimmed back on the

workforce, have launched their own

firms—a dream they may have never

considered unless pushed. By forging their own paths, engineers have

been forced to succeed independently. Small firms have had

to expand their capabilities

by adding new services or

refocusing their business.

Even large firms, seemingly

untouched by the recession, have

repositioned themselves, bringing in

new business development teams or

expanding services to include previously untouched markets. Kudos to

those firms who are staying competitive and innovative in our industry.

One of the best things about being

in the engineering field is that we

get to witness new technologies and

processes as soon as they’re on the

market—new products, groundbreaking projects, and unique engineering

solutions.

The engineering firms that fill these

pages with technical articles each

month are at the forefront of innovation. For example, the cover story

on emergency lighting (page 20) discusses the most important issues in

life safety and lighting with special

coverage that includes relevant new

products (page 27).

On page 16, best practices for

documenting ASHRAE Standard 90.1

compliance are detailed. While many

of these tips seem obvious, they are

frequently overlooked in the documentation phase, so they remain vital

to any successful project with ambitions to comply with and exceed

ASHRAE Standard 90.1.

To me, innovation means

staying ahead of the competition, making decisions

quickly, thinking differently, and

setting the curve, not responding to

it. I’ve been fortunate in my career to

work at innovative firms—CFE Media

LLC (the publisher of this publication

and others in the engineering field) is

one of these cutting-edge companies.

Our company is celebrating its 2-year

anniversary with the issue you hold in

your hands, and we got here by practicing innovation in action.

No matter the size of your firm, I’d

like to hear about how you and your

team have been innovative in the past

year. We’ll post these innovations

online at www.csemag.com for everyone to learn from. Please send me

your success stories, tips, tricks, best

practices, photos, videos, etc. Keep

it short, and we’ll help you show off

your own innovative spirit.

Principal, Senior Electrical Engineer, TLC Engineering

for Architecture, Jacksonville, Fla.

MIKE WALTERS, PE, LEED AP,

Principal,Principal,

AEI/Affiliated

Confluenc,

Engineers

Madison,

Inc., Madison,

Wis.

Wis.

PETER D. ZAK, PE,

Send your questions and comments to:

Principal, GRAEF, Milwaukee

ARozgus@CFEMedia.com

www.csemag.com

CSE1206_VIEW_V2ms_FINAL.indd 7

Consulting-Specifying Engineer • JUNE 2012

7

6/5/12 1:51 PM

PARTICIPANTS

MEP Roundtable

Industrial strength

Michael Chow,

PE, LEED AP BD+C

Principal

Metro CD Engineering LLC

Dublin, Ohio

Manufacturing and industrial structures can have wide-ranging

engineering needs, depending on the processes conducted inside.

CSE: When starting out on a manufacturing/industrial facility, what are some

questions to ask early in the project?

Jonathan M. Eisenberg, PE

Vice President

Rolf Jensen & Assocs. Inc.

Framingham, Mass.

Jason R. Gerke,

PE, LEED BD+C, CxA

Mechanical Engineer

GRAEF

Milwaukee

Timothy E. Kuhlman,

PE, RCDD

Telecommunication Design

CH2M HILL

Portland, Ore.

8

Michael Chow: It is important to develop the

owner’s project requirements (OPR) and the

basis of design (BOD). Questions to be asked

early in the project include: Is the project going

for U.S. Green Building Council LEED certification? Is U.S. EPA Energy Star a requirement?

Is commissioning a requirement?

Jonathan M. Eisenberg: One of the first

pieces of information to learn is the process

description, starting with the incoming raw

materials (how they are delivered, stored, and

transferred into the batch or continuous process

areas of the facility). The next step of our study

of the process is to understand the conditions.

Is this a chemical synthesis or simply a mixing

process? What are the temperature and pressure

conditions? What is the duration of the process

and what role does the operations staff play?

Is there a purification and/or drying step, and

how is the final product packaged and stored?

Jason R. Gerke: The most important piece of

information to obtain when starting an industrial project, or any project for that matter, is

to find out from the end client what it wants to

achieve with this project. Defining and understanding the client’s project goal is the most

important piece of information you will document during a project.

Timothy E. Kuhlman: Similar to the components of any good story, you need to know

the basics of what, where, when, how, and,

of course, what the budget is. An established

manufacturer will know most of these prior to

contacting an architectural/engineering (A/E )

firm. A startup company may need more time

understanding the design process or possibly

the scaling up of its own manufacturing process. As the A/E I need to know what you want

Consulting-Specifying Engineer • JUNE 2012

CSE1206_MEP_Roundtable_V7msFINAL.indd 8

to manufacture and how much of it you want

to make. Do you have a manufacturing process

and is it scaled for the output you are targeting?

Have you selected a site and have an understanding of the local permitting and taxes?

When do you want the new factory to start up?

Have you established a design, construction,

and tool budget? Do you have funding?

CSE: What are some common missteps

that engineers might make on a manufacturing/industrial facility project? Any lessons that you’ve learned?

Kuhlman: Once you have answered the basic

project questions for a new facility, it is necessary to take the time to identify with the client

the goals of the project. This goes beyond setting target dates and spending budgets. Through

the use of a chartering session you can document the other goals and priorities of a client.

For example, is the client targeting this project

for LEED certification? What are the client’s

criteria for considering this a successful project? What is the client’s perception of a quality design? Answering these questions at the

beginning of the design process can make a

difference in whether a client believes you have

provided them a quality design. This comes

down to communication. Our client has a corporate culture, and so do we. The time spent

between our client and our design team in the

project charting will help us to communicate.

Gerke: I see many engineers going into

industrial facilities with the mind-set with ruleof-thumb estimates and “that’s how we have

always done it” attitudes. It is a real disappointment to see that happen and wonder at what

point the client will become frustrated with

the results. My goal is listen to what clients

have to say about their project goals and then

strategize a game plan to help them achieve

www.csemag.com

6/5/12 2:16 PM

their goals in the most energy efficient

and cost effective way. It is my objective

whenever meeting a new industrial client

to find out what the client actually wants

to accomplish with the current project.

Eisenberg: Every industrial project

is different, even if it may seem quite

similar to a past job. We need to ask the

same questions and look for those subtle

differences that always seem to translate

into unique fire protection and process

safety features.

CSE: When working on such facilities outside the U.S., what differences, challenges, or best practices

have you observed?

Kuhlman: There are the obvious language and cultural differences. We are

often asked by a U.S. manufacturer

to replicate a manufacturing facility

in another country. A client may not

understand that the level of detail in

the design we show for a facility in the

U.S. may need to be greater or less for

a given system in foreign country. For

example, on a project where we replicated a manufacturing facility in China,

the U.S. design for the automation network cabling would typically show each

network port, the cable plant layout,

cable tray layout, and communication

rooms all in 1/8-in. plan drawings. For

the same facility in China, the system

would be issued as a performance specification with a system one-line but no

communication system plan drawings

since the vendor is expected to do the

detail design. In this case it has to be

discussed with the client up front, do the

client want a U.S. level of detail design

in a foreign country or is it looking for a

competitively locally produced design?

Eisenberg: We need to get alignment

from the design team on the applicable

codes and standards and obtain English

translations. If we do not have a local

office, we look to retain local engineers

www.csemag.com

CSE1206_MEP_Roundtable_V7msFINAL.indd 9

On one CH2M HILL project, chilled water storage tanks are used to provide thermal

storage for a high-performance data center. Courtesy: CH2M HILL

that are able to assist in analyzing the

requirements, speak the native language,

and attend meetings as needed. We turn to

these resources to review our reports so we

don’t miss anything that may be specific to

the local country or regional codes.

CSE: What factors do you need to

take into account when designing

BAS and controls for a manufacturing/industrial facility?

Gerke: The design engineer needs to

determine how the end users will make use

of the information that is available to them

through the proposed automation system.

Defining how the client will use the information it can obtain through the control system will direct the design engineer down

the path to a happy client. So many clients

will ask for an automation system or say

they want a full direct digital control (DDC)

system. However, really, the client simply

needs a system that will schedule equipment run times/setpoints and will provide

alarms if critical situations occur. Working

with the client on what is actually important and whether it will really be able to use

the information obtained through the DDC

system will save the client money now and

in the long run.

Eisenberg: A key is to understand and

document how the controls and interlocks

will function and what will occur when

they are activated. What are the alarm

points? Who responds to an alarm and

what is the response protocol? Is the local

fire department notified and the plant

evacuated?

CSE: Which aspect of codes and

standards has presented the most

challenges or obstacles?

Kuhlman: In the manufacturing of

semiconductors, the types and quantities of

hazardous production materials can have an

effect on the occupancy classification of the

building. In turn this can affect the design of

the building and systems. In leading-edge

technologies it is not uncommon to see new

chemistries not yet comprehended by the

codes or by the local jurisdiction enforcing

the codes. We go through a process with the

factory owner, the local jurisdiction, and the

underwriter for all parties to comprehend

the hazardous production materials in the

factory along with design and operation of

the facility.

Eisenberg: There are many codes and

standards on the chemical process side

that are not well-known and understood.

One of our roles is to identify the applicable code for a specific industrial process

(e.g., NFPA 86 for ovens and furnaces)

and help a facility understand how it

applies to its situation.

CSE: What’s the most important

factor to keep in mind when wrestling with codes/standards issues?

Kuhlman: The local authority having

jurisdiction (AHJ) has to understand and

Consulting-Specifying Engineer • JUNE 2012

9

6/5/12 2:16 PM

MEP Roundtable

The 100% pre-tested,

pre-assembled,

seismic-ready joint

It’s goof-proof.

No assembly required.

You know you’ll meet code.

You know it will work.

Get the details at

www.Metraflex.com

©2012 The Metraflex Company

Revit®...Revit®

CAD drawings

online

312-738-3800

input #6 at www.csemag.com/information

ASPIRATION

PLAYS

DIRTY

st

The late

from

thinking

Sensor

System

r

FREE fo

ng.

the aski

How your detectors

should handle

the toughest

environments

www.systemsensor.com/knowledgecenter

Engineers with GRAEF provided an exhaust system for indoor

testing of a multi-engine electric-driven crawler machine on a

recent project. Courtesy: GRAEF

be comfortable that the new facility will meet its requirements

and be code compliant. A manufacturing or industrial facility can be very complex. A company deciding to open a new

manufacturing facility in a small town can sound like blessing

to the local workforce, but it can also be a nightmare for a local

jurisdiction or fire marshal to comprehend the complexities of

the facility and the applicable codes. Often third-party consulting services for the jurisdiction are required to bolster the local

permitting processes. As the design firm for the new factory, it is

necessary to be constantly engaged with the jurisdiction and its

permitting or code consultant such that when it is time to grant

operational readiness to the factory, there are no outstanding

code issues.

Eisenberg: It is important to know that a facility may not be able

to implement all of the applicable code requirements immediately

or even in the first year after a survey or audit. As consultants,

one of the most important tasks is to help categorize our recommendations into priorities, so facility managers can put together a

multiyear compliance plan. Also, our findings need to be in a form

that is useful for the facility—i.e., 1. code requirement, 2, how it

applies to the specific site condition, and 3. our recommended solution. Simply put, a code summary with no context or recommended

solutions is of little use to a plant manager.

CSE: What’s the one factor most commonly overlooked in electrical and power systems?

Chow: Proper arc-flash training and procedures are often

overlooked. We heard of an arc-flash that occurred on a project

that had a 480-V panelboard left energized with its cover off. A

input #7 at www.csemag.com/information

CSE1206_MEP_Roundtable_V7msFINAL.indd

CSE120601-MAG_Ads.indd

10

10

6/5/2012

6/5/12

4:07:35

2:17

PMPM

painter got too close to the panel and an

arc-flash occurred, resulting in injuries.

Kuhlman: In a manufacturing/industrial facility it is important to perform a

circuit breaker coordination study. Due

to the critical nature of the manufacturing

process or the cost impact to the interruption of manufacturing, it is important

that an electrical fault is isolated at the

source without unnecessarily impacting

other systems.

Eisenberg: There should be a clear

agreement on what systems should be

on emergency or standby power, and for

how long.

CSE: How have sustainability

requirements affected how you

approach electrical systems?

Kuhlman: One of the largest costs

to manufacturing is the cost of energy.

Therefore, these types of facilities would

typically have some degree of power

monitoring to help them in understanding their energy use. There continues

to be progress in the industry to reduce

energy usage in lighting systems. This is

being achieved in implementing lighting

controls and new products for efficient

lighting.

Chow: Energy efficiency is an important part of a sustainable facility. Lighting

controls are important in reducing energy

consumption. Our firm commissioned a

large distribution center with over 2,000

lighting fixtures each with their own

occupancy sensor. The cost savings with

using occupancy sensors was tremendous compared to leaving the lights on

24/7/365. More LED lighting fixtures are

being specified due to their long life (up

to 50,000 hours), and in LEDs there are

not any toxins such as the mercury found

in fluorescent lamps. Also, LEDs are able

to be switched on and off continuously

without shortening their life; fluorescent lamp life is decreased if the lamp is

switched on and off frequently (e.g., with

an occupancy sensor).

Eisenberg: On laboratory ventilation systems, for example, we are often

faced with questions on the number of air

changes required in occupied and unoccupied modes. There may be acceptable

methods for maintaining employee and

facility safety, while addressing some of

the sustainability challenges.

CSE: When commissioning electrical/power systems in such facilities, what issues do you face?

Kuhlman: It is not uncommon for our

Bryan Triple-Flex™ boiler

technology delivers minimum

90% operating efficiencies.

GUARANTEED.

• Minimum 90% thermal

efficiency with 160° return,

180° supply@max. input

• Efficiencies of up to 99%

will be delivered with

lower temperature

design systems

• Retrofit systems or

new installations,

one boiler does it all,

Bryan Triple-Flex™

• Get the whole story now

at bryanboilers.com

Patent Pending

MINIMUM 90% THERMAL EFFICIENCY

AT 160 F. RETURN, 20 F. RISE,

MAX. INPUT, TF150-300

Originators of the

“Flexible Water

Tube” design

TRIPLE-FLEX

TM

Bryan Steam LLC • Leaders Since 1916

783 N. Chili Ave., Peru, IN 46970

Phone: 765-473-6651 / Fax: 765-473-3074

E-Mail: inquiry@bryansteam.com

www.bryanboilers.com

Commercial/Industrial Steam and Hot Water Boilers, Boiler Room Accessories

input #8 at www.csemag.com/information

CSE1206_MEP_Roundtable_V7msFINAL.indd

CSE120601-MAG_Ads.indd

11

11

6/5/2012

6/5/12

4:08:57

2:17

PMPM

MEP Roundtable

clients to include in the commissioning

requirements for us to field verify such

things as power system circuiting or that

the wire gauge matches the design. To

do this requires our field personnel to

observe panels with the covers removed.

The issue with this is personnel safety.

Our field personnel are typically engineers and designers that were part of the

design team. They are not electricians.

However, they too need to be trained in

arc flash safety, how to recognize and

validate a de-energized panel before they

start the field verification work.

Chow: It is difficult to find qualified

commissioning agents for electrical and

power systems. Lighting controls (e.g.,

light sensors) are frequently not calibrated correctly from the factory and/or

installed incorrectly.

CSE: What sustainability issues

concern your clients?

Gerke: One of the most prevalent

issues I have seen is water use. There are

so many older existing factories with city

water-cooled equipment still in operation.

Most of these manufacturers are attempting to reduce water use not from a monetary savings point of view, but rather from

the angle of this is the right thing to do.

Many manufacturers will then market the

fact they have reduced water use in their

facilities. Water use reduction importance

will vary from point to point in this country and may count for even more in other

parts of the world.

Kuhlman: The issues concerning manufacturing have more to do with their

resources and materials for manufacturing than the facility we are designing.

The facility is still a concern, but unlike

commercial or institutional facilities, the

highest monthly costs for manufacturing

will be from resources and manufacturing and not the facility operations. We

will consult with our clients on whether

the use of a manufacturing material will

have an impact on the design or operation of the facility. For example, the

manufacturing choice for an etching process may have an impact on the waste

treatment process. We would consult

with our client if the process it selected

meets the project sustainability goals.

Chow: Several manufacturing clients

are demanding LEED certification, and

some require a minimum of LEED Silver certification.

Eisenberg: We field many questions

these days on supply and exhaust ventilation requirements, and how they

match up with sustainability goals.

CSE: Are you seeing increased

demand for sustainable building

features in manufacturing/industrial

facilities? Has the economy affected

this?

SigniFire... the best

track record in high-speed fire detection

SigniFire represents a critical advantage for early warning fire detection, identifying and reacting to situations in

their earliest stages, and FASTER than other detection methods. SigniFire is state-of-the-art protection for lives

and property … and so much more.

• Detects flame and smoke in seconds

• Supplies live video to remote locations

• Provides pre-recorded video forensic evidence

• Triggers fire alarm systems

• Provides video surveillance capabilities

Visit Fike at NFPA booth #1525

Scalable, Dependable, Innovative and Intelligent

input #9 at www.csemag.com/information

CSE1206_MEP_Roundtable_V7msFINAL.indd

CSE120601-MAG_Ads.indd

12

12

www.signifire.com

410•472•6590

6/5/2012

6/5/12

4:10:50

2:17

PMPM

Kuhlman: When the “green building” initiative such as

LEED was developed, I don’t think they had manufacturing or industrial facilities in mind. However, we are seeing

some of our clients press for LEED certification for their

semiconductor manufacturing facilities or industrial facilities. I haven’t seen where the current state of the economy

has impacted this. The current business culture is that

sustainability is good for business and good for corporate

image.

Eisenberg: We are seeing this trend more in our commercial

and higher education laboratory work. On the industrial/chemical side, the focus is more on the hazards involved, although

occasionally we field questions on sustainable materials for

finishes in areas such as clean rooms.

CSE: What unique requirements do manufacturing

HVAC systems have that you wouldn’t encounter on

other structures?

The Ultimate Simultaneous

Heating and Cooling Solution

• Heat Pump/Heat

Recovery configuration

• Integral control valves

• True electrical and

mechanical redundancy

• Lower system energy

costs by 50% or more

• Index any module for

heating, cooling or both

• True piping flexibility

• Smallest operating

footprint

SHC onDemand®

30, 50, 70 and 85 ton modules configurable to 1,000 tons/bank

Chow: Manufacturing HVAC systems may need to exhaust

fumes, vapors, or mists from oil. Also, dust collection may be

a requirement.

Eisenberg: There are often requirements for dedicated

exhaust systems from certain areas of the facility, with complications around the routing of the exhaust to the outdoors.

Some areas need low supply and exhaust to get a complete air

change for vapors that are heavier than air.

www.climacoolcorp.com - 405.815.3000

ClimaCool Corp. is a subsidiary of LSB Industries, Inc. - NYSE: LXU

input #10 at www.csemag.com/information

Fry Communications, Inc. printed this unique cover!

A combination of Spot Gloss UV, Spot Dull UV, and Foil colorized with UV inks

in one pass on the first of its kind press at the Fry WOW Factory.

CSE: How can automated features and remote HVAC

system control benefit these clients?

Gerke: An automated HVAC control system is able to ben-

efit end users in many ways. Take for example the “run to failure” operator. The HVAC control system is able to provide

this client type with simple status signals and alarms that

help recognize system components that are nearing failure.

The client can then perform maintenance on this equipment

before it does fail. Now take a look at the “preventive maintenance (PM) checklist for everything client.” This client is

able to leverage the capabilities of the HVAC control system

to help it improve its monitoring and diagnostic activities.

The client who has an organized PM program will be able

to take advantage of the system to fine-tune setpoints and

use trend log data to review system performance. This performance can be reviewed down to the level of a particular

system component and schedule maintenance for this item

directly from the HVAC control system data.

Eisenberg: Features such as real-time exhaust monitoring

can automatically alert the facility staff (including off-hours),

initiate their response, and also log the data and time to help

determine the cause of a spill or release.

CSE1206_MEP_Roundtable_V8msFINAL.indd

CSE120601-MAG_Ads.indd

13

13

INVESTED IN YOUR FUTURE

u

Generate More Revenue.

Engage More Readers.

Contact Fry to learn how we’re shaping

the future of content distribution through

print, mobile, online, and tablet.

6/8/2012

6/8/12

11:48:59

10:27

AMAM

We drive data center innovations

so your data center can drive

your business.

EcoBreeze with Two

Economizer Modes

StruxureWare for

Data Centers

Facility Power Module

Reference Designs

Our physical infrastructure with full-visibility management

software enables responsive, energy-efficient data centers.

> EcoBreeze with Two Economizer Modes

Rack-to-row-to-room-to-building architecture lowers cost.

Improving both efficiency and system uptime requires a second look at today’s

data centers! Featuring innovative and industry-leading physical infrastructure

components, Schneider Electric™ data centers uniquely span traditional

IT “white space” and facilities to improve interoperability, deliver true data

center agility, and achieve cost-saving energy and operational efficiency. Our

integrated architecture also lowers total cost of ownership, enables fast and

easy design and deployment, and promises the highest availability.

It comprises best-of-breed components available from a single source and

through a global supply and services chain. From our well-known APC™

InRow™ cooling units to our innovative EcoBreeze™ facility cooling module with

two economizer modes to our unparalleled data center management software

StruxureWare™ for Data Centers, Schneider Electric products can be found

literally in every data center domain.

We offer the most energy-efficient components — all uniquely engineered as a

system. In the long run, the Schneider Electric rack-to-row-to-room-to-building

approach reduces total data center life cycle cost up to 13 percent and 30

percent of data center physical infrastructure cost over 10 years! In fact, it’s the

foundation of our Business-wise, Future-driven™ data centers.

TM

TM

Only the scalable EcoBreeze automatically switches

between air-to-air heat exchange and indirect evaporative

cooling to maximize conditions year-round.

> Data Center Facility Power Module

Our modular, step-and-repeat approach to facility power

lets you expand capacity in 500 kW increments as

needed, cutting OpEx by up to 35 percent and CapEx

from 10 to 20 percent.

> StruxureWare for Data Centers

With building-to-server visibility, StruxureWare for Data

Centers enables you to make informed decisions about

your physical infrastructure.

> Reference Designs

Our standardized architectures for various data center

configurations, from 200 kW to 20 MW, reduce time, cost,

complexity, and system risk.

> Data Center Life Cycle Services

Including energy management services, professional

services from planning, build/retrofit, and operations help

ensure highest system availability and efficiency.

Business-wise, Future-driven.

Is your data center efficient? Download our White

Paper Efficiency Kit and register to win an Apple TV®.

Visit www.SEreply.com Key Code p351v

or Call: 888-289-2722 x:7275

©2012 Schneider Electric. All Rights Reserved. Schneider Electric, APC, InRow, EcoBreeze, StruxureWare, Business-wise, Future-driven, and Square D are trademarks owned by Schneider Electric Industries SAS

or its affiliated companies. All other trademarks are property of their respective owners. • 998-6243_GMA-US • 132 Fairgrounds Road, West Kingston,RI 02892 • Tel. 800-890-4272

input #11 at www.csemag.com/information

CSE120601-MAG_Ads.indd 14

6/4/2012 12:06:54 PM

Career Smart

BY JANE SIDEBOTTOM

AMK LLC, Louisville, Ky.

The art of asking a good question

Asking good questions as an interviewee is an art, not a game.

R

ecently, I interviewed a candidate for a newly created business development position within

a client’s organization. The candidate

had been prescreened by both the head

hunter and the hiring manager, and the

individual’s resume looked very strong.

After the initial 20 to 25 minutes of asking about him, his experience, and his

interests, I turned the conversation over

to the candidate and offered to answer

any questions he may have. Unfortunately, he didn’t have any questions

for me or any of the other interviewers.

That ended his possible career with this

firm—he didn’t receive an offer as his

actions sent a negative message. Asking

good questions is often associated with

setting a good first impression.

A quick poll of my colleagues

revealed that few were ever taught how

to ask questions. Yet it is a skill that is

important, whether you are looking for

a new job, trying to win new business

for your firm, or attempting to make a

positive impression on your business

leaders or colleagues.

There are two key parts to developing

a good question: formulating the question and listening closely to the response.

Whether you are starting from scratch

or just brushing up on your skills, these

guidelines will serve you well.

Do your homework: Know your

audience. Make sure you understand

their position and level of influence.

Use your contacts to learn as much as

you can about their background, experience, and interests. As other Career

Smart authors and I have encouraged in

www.csemag.com

CSE1206_CAREER_V2msFINAL.indd 15

previous articles, effective networking

and good research using LinkedIn and

other social media sources can give you

a starting point.

Have a cheat sheet: During an interview or meeting, you may not have control over the time or schedule, so have

some notes and questions prepared for

each interviewer. Then, identify one or

two must-ask questions that will help

you present yourself well and allow

you to glean as much information as

possible. Consider adding these to your

cheat sheet:

1. If you were sitting in my seat, what

do you think would be most important to

understand about this company or role?

2. How much will I be working with

you in this role, and how would you

measure success?

3. What role do you have in the decision-making process?

4. Do you have any concerns with

how I have answered your questions? If

so, how can I alleviate those concerns?

5. Would you feel comfortable sharing with me your impressions of me?

Would I be a good fit for this position?

Develop a context for your question; interviewers are busy people.

They are often taking a few minutes out

of their day to meet with you and sometimes their brains are focused on other

priorities. So use an old media trick to

focus the questioning. For example: “I

have a couple of questions that focus

on the culture of the company and how

it impacts the team with whom I will

be working.” Or: “You mentioned earlier that you are looking for stronger

communications from the team. Could

you give me some specific examples of

where it has failed in the past?” These

types of questions not only show that

you are listening but can provide relevant, focused answers.

Speaking of listening, listen to

understand, not just to respond. Take

a few brief notes based on the interviewer’s reply and then take a moment

to make sure you understand what his

or her answer means. Don’t be so busy

preparing your response that you miss

the point of the answer. And, don’t be

afraid to give yourself a moment to

think. Showing that you are thinking

about your next question can be powerful and demonstrates understanding of

the opportunity.

Asking good questions is an art, not

a game. Focusing on the quality and

not the quantity will showcase your

interest, give you the opportunity to

confidently share your knowledge and

expertise, and make a positive impression. Don’t wait until you have been

passed over for a new job, promotion,

or other opportunity to strengthen your

questioning skills.

Sidebottom is the owner of AMK LLC, a

management and marketing consulting

firm that provides market development

and growth expertise to small- and

medium-size firms. She has 20 years

of management and leadership experience in both consulting engineering

and Fortune 100 organizations. Sidebottom is a graduate of the University

of Maryland.

Consulting-Specifying Engineer • JUNE 2012

15

6/5/12 2:00 PM

Codes & Standards

Documenting ASHRAE 90.1 compliance

There are three paths to ASHRAE 90.1 compliance, and documenting

compliance with Standard 90.1 is not as difficult or confusing as engineers

believe it to be.

BY JIM HUBER, NEBB CP, CEM, Complete Commissioning Inc., Annapolis, Md.

A

The

requirements

of 90.1 affect

the overall

energy

efficiency of any

structure and

can reduce the

energy needed

to maintain

a healthy,

comfortable, and

fully functioning

indoor

environment.

16

SHRAE Standard 90.1—Energy Conservation in New Buildings Except LowRise and Residential Buildings—was

originally published in 1975. The current standard is 90.1-2010, and it was rewritten with the

goal of reducing building energy costs by 30%

compared to the 2004 version of the standard.

ASHRAE 90.1 addresses the energy-efficiency

requirements for the design, materials, and equipment used in nearly all new construction, additions, renovations, and construction techniques.

The requirements of 90.1 affect the overall energy efficiency of any structure and can reduce the

energy needed to maintain a healthy, comfortable,

and fully functioning indoor environment. The

standard applies to:

Building envelope

HVAC systems, equipment, and controls

Service water heating systems and equipment

Power

Lighting systems, equipment, and controls

Other equipment.

While ASHRAE 90.1 covers many areas in

a building, this article will concentrate on the

HVAC requirements of ASHRAE 90.1 (Section 6

of the standard). There are several common methods available to document compliance, including

prescriptive forms, software-generated forms,

and modeling runs. ASHRAE also publishes the

90.1-2010 user’s guide, which can be a big help

in clarifying the requirements of the standard and

includes the necessary compliance forms.

ASHRAE 90.1 provides for exceptions to the

compliance requirements. Simply put, the exceptions are:

When HVAC serving a building addition is

provided by existing HVAC systems and equip-

Consulting-Specifying Engineer • JUNE 2012

CSE1206_CODES_V6msFINAL.indd 16

ment (new systems installed as part of the addition still must comply with the standard)

Equipment that is being modified or repaired

but not replaced

Where replacement or alteration of a piece of

equipment requires extensive revisions to other

systems, equipment, or elements of a building

For a refrigerant change of existing equipment

For the relocation of existing equipment

For ducts and pipes where there is insufficient

space to meet the requirements of Section 6.

The easiest method for documenting compliance with 90.1 is to download the compliance

forms from the ASHRAE website. The forms

are provided as PDFs and can be modified and

printed. They also serve as a good template if

you prefer to create compliance forms on your

company letterhead. If, as we do, you place too

much value on your time to “reinvent the wheel,”

just use the “stock” ASHRAE form.

Once you have determined whether your

building must comply with the standard, the next

step is to determine the best path for compliance.

Standard 90.1 gives you three options:

1. The simplified approach option for HVAC

systems (Section 6.3)

2. Mandatory provisions (Section 6.4) required

for prescriptive path (Section 6.5)

3. Mandatory provisions (Section 6.4) required

for energy cost budget (ECB, Section 11).

The simplified approach option for HVAC

systems can reduce the effort required to show

compliance for small buildings with gross floor

area less than 25,000 sq ft. Many of the requirements in Section 6 do not apply to simple

systems, so the small building criteria have been

compiled into one section (6.3). It is intended to

alleviate the designer’s burden of sorting through

www.csemag.com

6/5/12 2:02 PM

plants

arms

ms

rooms

aries data centers cold storage

msrecord storage

warehouses atriums clean rooms

art galleries

FAASTcomputer

ants

manufacturing plants

server farms

art galleries

mis

corre

data centers

n/prisons

atriums

clean rooms

detention centers

server farms

a l l e r i e s manufacturing plants

data centers

dat

compute

ms

libraries clean rooms

record storage museums atriums server farms

warehouses libraries rec

FAAST cold storag

ooms

data

centers

clean

muse

record st

ies

wa

houses

manuf

serv

data

art gal

Aspiration anywhere.

The FAAST

Fire Alarm Aspiration Sensing Technology® provides

the earliest and most accurate smoke detection available.

FAAST not only reduces costly downtime in your most critical

applications, its unique combination of nuisance immunity,

incipient fire detection, integral Internet communications,

and e-mail notification capabilities opens up a world of

application possibilities. It can even protect many spaces

deemed impossible for traditional fire detection technologies.

With FAAST, you can truly take aspiration anywhere.

To learn more, visit systemsensor.com/faast.

©2012 System Sensor. All Rights Reserved. 02/12

input #12 at www.csemag.com/information

SYS4371P4CSE0612.indd 1

CSE120601-MAG_Ads.indd 17

5/4/12 2:55 PM

6/4/2012 12:10:15 PM

Codes & Standards

Prescriptive

requirements

(Section 6.5)

HVAC

design

Mandatory

provisions

(Section 6.4)

Energy cost

budget method

(Section 11)

Equipment

efficiencies

(Section 6.8)

Submittals

(Section 6.7)

Standard 90.1

compliant

HVAC system

Simplified

approach

(Section 6.3)

Figure 1: This shows the compliance path for ASHRAE 90.1-2010. Courtesy: Complete Commissioning Inc.

requirements that are not applicable while using the simplified approach option. that applies to your system. If the system

still maintaining consistent requirements It is laid out as a simple checklist for requirement is not applicable, just leave

documenting compliance with each of the box blank. Section 2 also includes

with the prescriptive path.

The prescriptive compliance path may the requirements, and is the only form a systems worksheet to help you docube used for any HVAC system, but it is required with this compliance option. ment mandatory compliance for each air

primarily used for larger buildings and There are 17 requirements in that sec- system. Part 3 of the compliance form

buildings with more complex systems tion, and your systems must comply contains a checklist of the prescriptive

where the simplified approach option is with every applicable requirement. requirements for air, hydronic, and spenot applicable, such as multi-zone systems You’ll still have to flip through the cial systems.

All told, there are 13 requirements, and

or central plants. Systems complying using standard for each section to determine

the prescriptive path also must meet the if you can “check the box.” If your there is also a systems worksheet to help

design is in compliance with all of the you document prescriptive compliance for

mandatory provisions of Section 6.4.

each system. The compliance

The energy cost budget

method is intended for buildAll told, there are 13 requirements, form also includes tables on the

third page to document the staning systems that are unable

and there is also a systems worksheet dard’s fan power requirements.

to meet all of the prescriptive

You can use either the namerequirements or for designto help you document prescriptive

plate horsepower option or the

ers who want to explore

compliance for each system.

brake horsepower option.

design alternatives. It allows

trade-offs between various

building systems and components. A 17 requirements, the next step is to fill Documenting the energy

computer program is used to calculate out the equipment efficiency table to cost budget method

the design energy cost for a proposed include with the submittal. There is a

When using the ECB method, the

building design as if all mandatory and simplified table included at the bottom building design must still meet the manprescriptive requirements had been met. of Part 1 in the compliance form you datory provision of the standard, not only

The program is then used to calculate the downloaded.

for the HVAC requirements (Section 6.4),

energy cost for the proposed design. The

but also for Sections 5.4, 7.4, 8.4, 9.4,

energy cost for the proposed design can- Documenting the prescriptive path

and 10.4. The mandatory requirements

not exceed the energy cost for the budPart 2 of the compliance form contains in each of those sections are not available

get design. Systems complying using the the mandatory requirements specified for trade-off under this method. In addiECB method must also meet the manda- in Section 6.4. This includes tables for tion to documenting compliance with the

tory provisions of Section 6.4 as well documenting the equipment efficiency. mandatory provisions, the ECB method

as the ECB requirements in Section 11. Beneath the efficiency tables are 10 has some additional compliance requiregeneral requirements and five special ments, including a summary to document

mandatory requirements. You’ll need to design energy cost versus budgeted cost.

Documenting the simplified approach

You’ll also need to provide a list of

Part 1 of the form is specifically for check the box next to each requirement

18

Consulting-Specifying Engineer • JUNE 2012

CSE1206_CODES_V6msFINAL.indd 18

www.csemag.com

6/5/12 2:02 PM

energy-related features that exceed the

standard’s requirements, as well as a list

of features that are being traded off. The

input and output reports from the simulation program must be provided, including an energy usage breakdown, and the

number of hours the heating and cooling loads are not met for both the budget

building design and the proposed building design. Any error messages provided

by the program must also be explained.

Submittal requirements

The last step in documenting compliance for all paths is the submittal requirement, and it includes the following:

1. Record drawings

a. Record drawings must be provided to the owner within 90

days of building acceptance.

2. O&M manuals: The manuals

must include (at a minimum):

a. Submittal data

b. HVAC manuals

c. Service agency

d. HVAC control information

3. System balancing

a. Construction documents must

require the systems to be balanced.

b. A test and balance report must

be provided to the owner for

spaces greater than 5,000 sq ft.

4. System commissioning

a. For projects larger than 50,000

sq ft (except warehouse and

semi-heated spaces), the instructions for commissioning the

HVAC system must be provided

by the system designer in the

project plans and specifications.

These instructions are also

included in the record drawings

provided to the owner.

Summary

Documenting compliance with

ASHRAE 90.1-2010 is a straightforward

process, as long as you follow a systematic

approach. The checklists and tables provided in the standard are not a submittal

requirement, but are an invaluable tool in

ensuring that you are not missing any of

the requirements. This article has provided

an overview of each of the three paths to

compliance, and hopefully has shown that

documenting compliance with standard

90.1 is not as difficult or confusing as

many folks believe it to be.

Huber is president of Complete Commissioning, and is a National Environmental Balancing Bureau (NEBB) Certified

Professional, and a Certified Energy

Manager.

input #13 at www.csemag.com/information

CSE1206_CODES_V6msFINAL.indd

CSE120601-MAG_Ads.indd

19

19

6/5/2012

6/5/12

4:17:15

2:02

PMPM

Emergency lighting is just one component of

the means-of-egress, and part of a building’s life safety system.

In the event of a power outage, a backup lighting system may

be the occupants’ only guide to a safe exit.

BY DALE WILSON, AIA,

Aon Fire Protection Engineering Corp., Glenview, Ill.

20

Consulting-Specifying Engineer • JUNE 2012

CSE1206_FFIRE_V4msFINAL.indd 20

www.csemag.com

6/5/12 2:27 PM

E

verywhere, people eat, work,

and shop in abundantly illuminated public facilities. But,

what if that light so many of

us take for granted suddenly

ceased to exist, especially in an unfamiliar space, during an emergency?

People may become frightened, anxious,

uncertain, or disoriented. Coupled with

the smell of smoke or another impending emergency, people may even panic.

Fortunately, most public facilities are

mandated by code to be equipped with

emergency lighting that is required to

automatically activate in the event of a

power failure.

Fire protection engineering and life

safety consulting involve a large array

of specialty services. One responsibility is to assist architects, engineers, and

owners in determining if their buildings

include the proper fire protection and

life safety amenities that help protect

the building’s occupants during an emergency. One important life safety amenity includes the design and installation

of the emergency lighting system. Fire

protection engineers work in conjunction with architects and electrical engineers to ensure that emergency lighting

is properly specified and located in the

required means-of-egress pathways in a

manner consistent with the applicable

building codes.

Emergency lighting is one component

of the means-of-egress illumination and

is part of a building’s life safety systems.

Emergency lighting can be described as

any approved illuminating device and

appurtenance designed to automatically

turn on when the primary power goes

out. Exit signs are used in combination with emergency lighting to provide

means of egress lighting. Emergency

lighting and exit signs are regulated difIn an emergency, people rush from

a facility in a confused state. This

photo also represents the minimal and

obstructed visibility that is possible during an emergency evacuation situation.

Courtesy: istockphoto.com

www.csemag.com

CSE1206_FFIRE_V4msFINAL.indd 21

Emergency lighting can serve to provide light for other emergency operations

besides egress. Courtesy: istockphoto.com

ferently but share some requirements,

like the requisite to be connected to an

emergency backup or 60-sec power system.

From the viewpoint of the various

national building codes, emergency

lighting is a backup lighting system

that illuminates a building or portion

thereof. More specifically, the purpose

of emergency lighting is to provide a

minimum level of visibility of exits or

escape routes to help direct occupants

safely out of the building in the event of

loss of primary power. Emergency lighting is also used to help building occupants, essential personnel, and emergency responders locate firefighting and

safety equipment, to perform necessary

safety functions, or to shut down equipment and operations that might become

hazardous if abandoned. It may seem

practical that all buildings should have

emergency lights, but not all facilities or

occupancies require emergency lighting,

and the requirements for installation can

also vary from facility to facility.

Historical concept

The need for emergency lighting

became imminent almost immediately

after the invention of the light bulb.

Requirements for emergency lighting

can be found in national building codes

as far back as the 1920s, and likely earlier. The National Fire Protection Assn.

(NFPA) 1927 Building Exits Code says:

The lighting source shall be

arranged to assure continued illumination of exit-ways in cases of

emergency caused by failure of

the principle lighting of the building. Where electric current is the

source of the lighting of buildings

used for public assembly or congregation, the emergency lighting shall be from a source independent of that for the general

lighting or shall be controlled by

Consulting-Specifying Engineer • JUNE 2012

21

6/5/12 2:27 PM