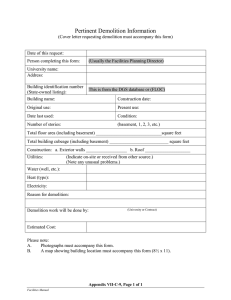

Code of Practice for DEMOLITION OF BUILDINGS YEAR 2004

advertisement