Focus: HOPE – Advanced Machining Program Course Curriculum

advertisement

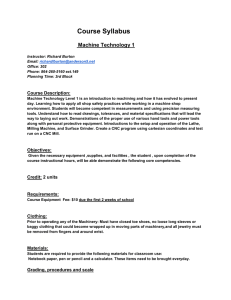

Focus: HOPE – Advanced Machining Program Course Curriculum Advanced Machining (AM) consists of a 10-week program requiring 285 contact hours. This course consists of daily hands-on machine training along with classroom instruction. Taking the instruction to a higher level Advanced Machining adds to skills obtained in Machining Essentials (ME) program. Machining Essentials is a pre-requisite to Advanced Machining The AM Program gives qualified students knowledge needed to enter the industry as a machinist, rather than a machine operator. Graduates are able to interpret blueprints, set- up and operate machines, write M & G code programs, qualify and inspect manufactured parts. The AM program provides students with a strong foundation in machining, allowing them to meet challenging careers with opportunities for advancement and specialization . Teaching Methodology: The course simulates the workplace. Successful students approach each day at MTI with the same discipline he or she will be expected to have on the job. The machining industry's tight production schedules and standards make this daily routine an important and practical part of job preparation. The program design assures that an Advanced Machining MTI graduate not only will be employable, but will also be a higher skilled entry-level employee capable of advancing in the craft. Advanced Machining Courses: Courses Shop Math Blue Print Reading Shop Theory Quality Measurement Manual Mills Manual Lathes CNC Turning & Machining Center CAD Total Hours Contact Hours 30 30 20 20 40 30 75 40 285 Shop Theory provides an overview of the principles and techniques used in the machine shop. Students learn to use precision measuring instruments such as the micrometer, calipers and gage blocks. Properties of metals and alloys are examined in some detail, along with the basic machines used in metalworking operations. Speeds and feeds and the use of tables and handbook data are studied. Shop Mathematics gives students the basic mathematical skills necessary to enter the machinist trade. Basic Shop Math topics range from fractions and decimals to algebra and geometry. Efficient use of calculators is a regular part of instruction. Advanced Shop Mathematics concentrates on problem solving in general math and trigonometry. Practical shop applications are an integral part of the course. Blueprint Reading teaches how to read a blueprint and take a job from blueprint to prototype. The student develops an understanding of the standards, signs, symbols, and other techniques the draftsperson uses to describe a part, unit or mechanism completely. Topics include dimensions, tolerances, product specification, number of parts to be machined, process engineering and tool instructions. Manual Lathes/Mills gives students hands-on experience in setting up jobs and operating manual lathes, manual horizontal, vertical and Bridgeport mills, all integral aspects of the ME course. Students also receive instruction in instrument reading and make actual machine-tooled parts from blueprints. CNC Turning/Machining Center entails practical application of all learning. Students receive hands-on experience in the safe operation of CNC machines. They are introduced to programming and the use of G and M Codes. They will be able to use Master CAM to transfer information from a blueprint to a program that can be downloaded to a CNC machine . Quality Measurement will teach students the basics of using measuring tools (including CMM) to measure parts and populated simple SPC charts. They should be able to read quality charts and determine what adjustments need to be made to correct an out-of specification situation on a part. Introduction to CAD will give students the basic in Computer Aided Design using AutoCAD. They will be able to produce simple 2D and 3D drawings as well as modify and print existing documents. The grading system is as follows: Traditional letter grades are not assigned at MTI. Assignments, tests, and projects are the instruments used to monitor progress through the various learning areas. Percent grades are assigned to the work. Excellent Above Average Average Not Passing 90 – 100 80 - 89 70 - 79 69% and below Students will receive grades at the end of each machine assignment area (benchmark). Books, computer access, smocks, safety glasses, handouts, shop machine access, and tools are provided to students at no extra cost. Students are responsible for their own writing utensils, paper and notebooks.