wet-pipe sprinkler systems part 1

advertisement

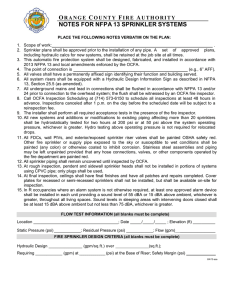

MID-CABIN HANGAR ALTERATIONS SECTION 21 13 13 – WET-PIPE SPRINKLER SYSTEMS PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including Outagamie County Bid Documents, apply to this Section. SUMMARY A. Section Includes: 1. 2. 3. 4. 5. 6. 7. 8. B. 1.3 Pipes, fittings, and specialties. Fire-protection valves. Fire-department connections Sprinklers. Alarm devices. Manual control stations. Control panels. Pressure gages. Related Sections: 1. Section 211339 "High Expansion Foam Systems” 2. Section 213113 "Electric-Drive, Centrifugal Fire Pumps" 3. Section 213900 "Controllers for Fire-Pump Drivers" DEFINITIONS A. 1.4 Standard-Pressure Sprinkler Piping: Wet-pipe sprinkler system piping designed to operate at working pressure of 175 psig maximum. SYSTEM DESCRIPTIONS A. 1.5 Wet-Pipe Sprinkler System: Automatic sprinklers are attached to piping containing water and that is connected to water supply through alarm valve. Water discharges immediately from sprinklers when they are opened. Sprinklers open when heat melts fusible link or destroys frangible device. Hose connections are included if indicated. PERFORMANCE REQUIREMENTS A. Standard-Pressure Piping System Component: Listed for 175-psig maximum working pressure. B. High-Pressure Piping System Component: Listed for 300-psig maximum working pressure. WET-PIPE SPRINKLER SYSTEMS 211313 - 1 MID-CABIN HANGAR ALTERATIONS 1. Available fire-hydrant flow test records indicate the following conditions: a. b. c. d. e. f. C. Sprinkler system design shall be approved by authorities having jurisdiction. 1. Sprinkler Occupancy Hazard Classifications: a. b. c. Office and Public Areas: Light Hazard Mechanical Equipment Rooms: Ordinary Hazard Group I Service Hangar Bay: Group II Hangar per NFPA 409 2. Minimum Density for Automatic-Sprinkler Piping Design: a. Light-Hazard Occupancy: .10 gpm/sq.ft. over 1,500 sq.ft. b. Ordinary-Hazard, Group 1 Occupancy: .15 gpm/sq.ft. over 1,500 sq.ft. c. Group II Hangar: see specification section 211339 High Expansion Foam Systems 3. Total Combined Hose-Stream Demand Requirement: According to NFPA 13 unless otherwise indicated: a. b. c. 1.6 Date: 09/11/2013 Location of Residual Fire Hydrant R: Hydrant in front of W6316 Discovery Dr. Location of Flow Fire Hydrant F: Hydrant in front of W6306 Discovery Dr. Static Pressure at Residual Fire Hydrant: 78 PSI. Measured Flow at Flow Fire Hydrant: 1,744 GPM. Residual Pressure at Residual Fire Hydrant: 42 PSI. Light-Hazard Occupancies: 100 gpm. Ordinary-Hazard Occupancies: 250 gpm Group II Hangar: 500 gpm SUBMITTALS A. Product Data: For each type of product indicated. 1. Pipe 2. Pipe Fittings 3. Sprinkler Heads 4. Valves 5. Flow and Supervisory switches 6. Hanger Material 7. Fire Department Connection B. Shop Drawings: For wet-pipe sprinkler systems. Include plans, elevations, sections, details, and attachments to other work. 1. C. Wiring Diagrams: For power, signal, and control wiring. Approved Sprinkler Piping Drawings: Working plans, prepared according to NFPA 13, that have been approved by authorities having jurisdiction, including hydraulic calculations if applicable. WET-PIPE SPRINKLER SYSTEMS 211313 - 2 MID-CABIN HANGAR ALTERATIONS 1.7 QUALITY ASSURANCE A. Installer Qualifications: 1. Installer's responsibilities include designing, fabricating, and installing sprinkler systems and providing professional engineering services needed to assume engineering responsibility. Base calculations on results of fire-hydrant flow test. a. Engineering Responsibility: Preparation of working plans, calculations, and field test reports by a qualified designer B. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70, by a qualified testing agency, and marked for intended location and application. C. NFPA Standards: Sprinkler system equipment, specialties, accessories, installation, and testing shall comply with the following: 1. 2. 3. 4. 5. 6. 1.8 NFPA 11, "Standard for Low-, Medium-, and High-Expansion Foam." NFPA 13, "Standard for the Installation of Sprinkler Systems." NFPA 14, "Standard for Installation of Standpipe and Hose Systems." NFPA 16, "Standard for the Installation of Foam-Water Sprinkler and Foam-Water Spray Systems." NFPA 20, "Standard for the Installation of Stationary Pumps for Fire Protection." NFPA 24, "Standard for the Installation of Private Fire Service Mains and Their Appurtenances." COORDINATION A. 1.9 Coordinate layout and installation of sprinklers with other construction that penetrates ceilings, including light fixtures, HVAC equipment, and partition assemblies. EXTRA MATERIALS A. Furnish extra materials that match products installed and that are packaged with protective covering for storage and identified with labels describing contents. 1. Sprinkler Cabinets: Finished, wall-mounted, steel cabinet with hinged cover, and with space for minimum of six spare sprinklers plus sprinkler wrench. Include number of sprinklers required by NFPA 13 and sprinkler wrench. WET-PIPE SPRINKLER SYSTEMS 211313 - 3 MID-CABIN HANGAR ALTERATIONS PART 2 - PRODUCTS 2.1 STEEL PIPE AND FITTINGS A. Piping used for water-based fire suppression systems shall be black steel welded and seamless Type F, Grade A, ASTM A53; black welded and seamless steel pipe, Type F, ASTM A795; electric resistance welded steel pipe, Grade A, ASTM A135. Approved manufacturers accepted by Architect/Engineer: Allied, Wheatland, Youngstown, and Bull Moose Tube 1. Piping wall thickness shall be Schedule 40 for threaded for 1” up to 2” 2. Piping wall thickness shall be Schedule 10 for 2” up to and including 8” for rolled grooved and welded. 3. Threaded light wall (XL) pipe is not considered as acceptable. CPVC plastic pipe listed for fire protection is acceptable in light hazard concealed areas. No exposed CPVC pipe. B. Fittings 2” and smaller shall be threaded fittings, Class 125 and 250, ASTM A126/ANSI B16.4. Ductile iron threaded fittings, Class 150 and 300, ASTM 197/ANSI B16.3. Standard weight seamless carbon steel weld fittings, ASTM A234 grade, ANSI B16.9. All piping 2” and larger shall be mechanical grooved fittings with EPDM gaskets, ASTM A536 ductile iron, ASTM A47 malleable iron or ASTM A53 fabricated steel. Fittings as manufactured by Victaulic, Star Pipe, Anvil International, Ward, Tyco, or approved equal will be acceptable. C. Black Steel Pipe Nipples: ASTM A 733, made of ASTM A 53/A 53M, standard-weight, seamless steel pipe with threaded ends. D. Ductile Iron Couplings: ASTM A 865, threaded. E. Malleable- or Ductile-Iron Unions: UL 860. F. Cast-Iron Flanges: ASME 16.1, Class 125. G. Steel Flanges and Flanged Fittings: ASME B16.5, Class 150. H. Steel Welding Fittings: ASTM A 234/A 234M and ASME B16.9. I. Grooved-Joint, Steel-Pipe Appurtenances: 1. Mechanical grooved pipe couplings and fittings, as manufactured by Victaulic, Tyco, Star Pipe, or Anvil International shall be used for 2” and larger pipe. 2. Pressure Rating 175 psig minimum 3. Standard, Grooved-End Fittings for Steel Piping: ASTM A 47/A 47M, malleable-iron casting or ASTM A 536, ductile-iron casting; with dimensions matching steel pipe. 4. Grooved-End-Pipe Couplings for Steel Piping: AWWA C606 and UL 213, rigid pattern, unless otherwise indicated, for steel-pipe dimensions. Include ferrous housing sections. WET-PIPE SPRINKLER SYSTEMS 211313 - 4 MID-CABIN HANGAR ALTERATIONS 2.2 PIPING JOINING MATERIALS A. Pipe-Flange Gasket Materials: AWWA C110, rubber, flat face, 1/8 inch thick. 1. 2. Class 125, Cast-Iron Flanges and Class 150, Bronze Flat-Face Flanges: Full-face gaskets. Class 250, Cast-Iron Flanges and Class 300, Steel Raised-Face Flanges: Ring-type gaskets. B. Metal, Pipe-Flange Bolts and Nuts: ASME B18.2.1, carbon steel unless otherwise indicated. C. Brazing Filler Metals: AWS A5.8/A5.8M, BCuP Series, copper-phosphorus alloys for generalduty brazing unless otherwise indicated. D. Welding Filler Metals: Comply with AWS D10.12M/D10.12 for welding materials appropriate for wall thickness and chemical analysis of steel pipe being welded. 2.3 VALVES A. General Requirements: 1. 2. 3. B. Ball Valves: 1. 2. 3. 4. C. Standard: UL 1091. Pressure Rating: 175 psig. Body Material: Bronze. End Connections: Threaded. Iron Butterfly Valves: 1. 2. 3. 4. 5. E. Standard: UL 1091 except with ball instead of disc. Valves NPS 1-1/2 and Smaller: Bronze body with threaded ends. Valves NPS 2 and NPS 2-1/2: Bronze body with threaded ends or ductile-iron body with grooved ends. Valves NPS 3: Ductile-iron body with grooved ends. Bronze Butterfly Valves: 1. 2. 3. 4. D. Valves shall be UL listed or FM approved. Minimum Pressure Rating for Standard-Pressure Piping: 175 psig. Minimum Pressure Rating for High-Pressure Piping: 300 psig. Standard: UL 1091. Pressure Rating: 175 psig. Body Material: Cast or ductile iron. Style: Lug or wafer. End Connections: Grooved. Check Valves: 1. 2. Standard: UL 312. Pressure Rating: 250 psig minimum. WET-PIPE SPRINKLER SYSTEMS 211313 - 5 MID-CABIN HANGAR ALTERATIONS 3. 4. 5. F. Bronze OS&Y Gate Valves: 1. 2. 3. 4. G. Standard: UL 262. Pressure Rating: 175 psig. Body Material: Bronze. End Connections: Threaded. Iron OS&Y Gate Valves: 1. 2. 3. 4. H. Type: Swing check. Body Material: Cast iron. End Connections: Flanged or grooved. Standard: UL 262. Pressure Rating: 250 minimum. Body Material: Cast or ductile iron. End Connections: Flanged or grooved. Indicating-Type Butterfly Valves: 1. 2. 3. Standard: UL 1091. Pressure Rating: 175 psig minimum. Valves NPS 2 and Smaller: a. b. c. 4. Valves NPS 2-1/2 and Larger: a. b. c. 5. I. Valve Type: Butterfly. Body Material: Cast or ductile iron. End Connections: Flanged, grooved, or wafer. Valve Operation: Integral electrical, 115-V ac, prewired, two-circuit, supervisory switch visual indicating device. NRS Gate Valves: 1. 2. 3. 4. 5. J. Valve Type: Ball or butterfly. Body Material: Bronze. End Connections: Threaded. Standard: UL 262. Pressure Rating: 250 psig minimum. Body Material: Cast iron with indicator post flange. Stem: Nonrising. End Connections: Flanged or grooved. Indicator Posts: 1. 2. 3. 4. Standard: UL 789. Type: Horizontal for wall mounting. Body Material: Cast iron with extension rod and locking device. Operation: Hand wheel. WET-PIPE SPRINKLER SYSTEMS 211313 - 6 MID-CABIN HANGAR ALTERATIONS 2.4 TRIM AND DRAIN VALVES A. General Requirements: 1. 2. 2.5 Standard: UL's "Fire Protection Equipment Directory" listing or "Approval Guide," published by FM Global, listing. Pressure Rating: 175 psig minimum. a. Angle Valves b. Ball Valves c. Globe Valves d. Plug Valves SPECIALTY VALVES A. General Requirements: 1. 2. Standard: UL's "Fire Protection Equipment Directory" listing or "Approval Guide," published by FM Global, listing. Pressure Rating: a. b. 3. 4. B. Body Material: Cast or ductile iron. Size: Same as connected piping. Automatic (Ball Drip) Drain Valves: 1. 2. 3. 4. 5. 2.6 Standard-Pressure Piping Specialty Valves: 175 psig minimum. High-Pressure Piping Specialty Valves: 300 psig. Standard: UL 1726. Pressure Rating: 175 psig minimum. Type: Automatic draining, ball check. Size: NPS 3/4. End Connections: Threaded. FIRE-DEPARTMENT CONNECTIONS A. Install wall-type, fire-department connection UL 405 B. Install automatic (ball drip) drain valve at each check valve for fire-department connection. C. Inlets: Brass with threads according to NFPA 1963 and matching local fire-department sizes and threads. Include extension pipe nipples, brass lugged swivel connections, and check devices or clappers. D. Caps: Brass, lugged type, with gasket and chain. E. Escutcheon Plate: Round, brass or red finished F. Escutcheon Plate Marking: “AUTO SPKR FIRE DEPT CONN” or Similar WET-PIPE SPRINKLER SYSTEMS 211313 - 7 MID-CABIN HANGAR ALTERATIONS 2.7 SPRINKLERS A. Manufacturers: Subject to compliance with requirements, provide products by one of the following: 1. Reliable Automatic Sprinkler Co. Inc 2. Tyco Fire & Building Products LP 3. Viking Corporation 4. Victaulic Company B. General Requirements: 1. 2. 3. Standard: UL's "Fire Protection Equipment Directory" listing or "Approval Guide," published by FM Global, listing. Pressure Rating for Residential Sprinklers: 175 psig maximum. Pressure Rating for Automatic Sprinklers: 175 psig minimum. C. Automatic Sprinklers with Heat-Responsive Element: 1. Nonresidential Applications: UL 199>. 2. Characteristics: Nominal 1/2-inch orifice with Discharge Coefficient K of 5.6, and for "Ordinary" temperature classification rating unless otherwise indicated or required by application. D. Sprinkler Finishes: 1. 2. 3. E. Special Coatings: 1. 2. 3. F. Ceiling Mounting: Chrome-plated steel, two piece, with vertical adjustment. Sidewall Mounting: Chrome-plated, one piece, flat, or two piece extended. Sprinkler Guards: 1. 2. 2.8 Wax. Lead. Corrosion-resistant paint. Sprinkler Escutcheons: Materials, types, and finishes for the following sprinkler mounting applications. Escutcheons for concealed, flush, and recessed-type sprinklers are specified with sprinklers. 1. 2. G. Chrome plated. Bronze. Painted. Standard: UL 199. Type: Wire cage with fastening device for attaching to sprinkler. ALARM DEVICES A. Alarm-device types shall match piping and equipment connections. B. Electrically Operated Alarm Bell: WET-PIPE SPRINKLER SYSTEMS 211313 - 8 MID-CABIN HANGAR ALTERATIONS 1. 2. 3. 4. Standard: NFPA 71 and UL 464. Type: Vibrating, metal alarm bell. Size: 6”, 8” and 10” diameter. Finish: Red-enamel factory finish, suitable for outdoor use. C. Electrically Operated Horn/Strobe 1. Standard: NFPA 72 and UL 464 2. Audible/visual notification appliance shall be exterior, weatherproof with back box 3. Minimum intensity of 15/75 candela, flash rate range from 1 to 3 Hz, a minimum pulse duration of .2 sec with a maximum duty cycle of 40% D. Water-Flow Indicators: 1. 2. 3. 4. 5. 6. E. Pressure Switches: 1. 2. 3. 4. F. Standard: UL 346. Type: Electrically supervised water-flow switch with retard feature. Components: Single-pole, double-throw switch with normally closed contacts. Design Operation: Rising pressure signals water flow. Valve Supervisory Switches: 1. 2. 3. 4. G. Standard: UL 346. Water-Flow Detector: Electrically supervised. Components: Two single-pole, double-throw circuit switches for isolated alarm and auxiliary contacts, 7 A, 125-V ac and 0.25 A, 24-V dc; complete with factory-set, fieldadjustable retard element to prevent false signals and tamperproof cover that sends signal if removed. Type: Paddle operated. Pressure Rating: 250 psig. Design Installation: Horizontal or vertical. Standard: UL 346. Type: Electrically supervised. Components: Single-pole, double-throw switch with normally closed contacts. Design: Signals that controlled valve is in other than fully open position. Indicator-Post Supervisory Switches: 1. 2. 3. 4. Standard: UL 346. Type: Electrically supervised. Components: Single-pole, double-throw switch with normally closed contacts. Design: Signals that controlled indicator-post valve is in other than fully open position. WET-PIPE SPRINKLER SYSTEMS 211313 - 9 MID-CABIN HANGAR ALTERATIONS 2.9 CONTROL PANELS A. Description: Single-area, two-area, or single-area cross-zoned control panel as indicated, including NEMA ICS 6, Type 1 enclosure, detector, alarm, and solenoid-valve circuitry for operation of deluge valves. Panels contain power supply; battery charger; standby batteries; field-wiring terminal strip; electrically supervised solenoid valves and polarized fire-alarm bell; lamp test facility; single-pole, double-throw auxiliary alarm contacts; and rectifier. 1. 2.10 Panels: UL listed and FM approved when used with thermal detectors and Class A detector circuit wiring. Electrical characteristics are 120-V ac, 60 Hz, with 24-V dc rechargeable batteries. PRESSURE GAGES A. Standard: UL 393. B. Dial Size: 3-1/2- to 4-1/2-inch diameter. C. Pressure Gage Range: 0 to 250 psig minimum. D. Water System Piping Gage: Include "WATER" or "AIR/WATER" label on dial face. E. Air System Piping Gage: Include "AIR" or "AIR/WATER" label on dial face. PART 3 - EXECUTION 3.1 SERVICE-ENTRANCE PIPING A. Connect sprinkler piping to water-service piping for service entrance to building. Comply with requirements for exterior piping in Section 211100 "Facility Fire-Suppression Water-Service Piping." B. Install shutoff valve, double check backflow preventer, pressure gage, drain, and other accessories indicated at connection to water-service piping. 3.2 PIPING INSTALLATION A. Locations and Arrangements: Drawing plans, schematics, and diagrams indicate general location and arrangement of piping. Install piping as indicated, as far as practical. B. Piping Standard: Comply with requirements for installation of sprinkler piping in NFPA 13. C. Install seismic restraints on piping. Comply with requirements for seismic-restraint device materials and installation in NFPA 13. WET-PIPE SPRINKLER SYSTEMS 211313 - 10 MID-CABIN HANGAR ALTERATIONS D. Use listed fittings to make changes in direction, branch takeoffs from mains, and reductions in pipe sizes. E. Install flanges, flange adapters, or couplings for grooved-end piping on valves, apparatus, and equipment having NPS 2-1/2 and larger end connections. F. Install "Inspector's Test Connections" in sprinkler system piping, complete with shutoff valve, and sized and located according to NFPA 13. G. Install sprinkler piping with drains for complete system drainage. H. Install sprinkler control valves, test assemblies, and drain risers adjacent to standpipes when sprinkler piping is connected to standpipes. I. Install automatic (ball drip) drain valve at each check valve for fire-department connection, to drain piping between fire-department connection and check valve. Install drain piping to and spill over floor drain or to outside building. J. Install alarm devices in piping systems. K. Install hangers and supports for sprinkler system piping according to NFPA 13. Comply with requirements for hanger materials in NFPA 13. L. Install pressure gages on riser or feed main and at top of each standpipe. Include pressure gages with connection not less than NPS 1/4 and with soft metal seated globe valve, arranged for draining pipe between gage and valve. Install gages to permit removal, and install where they will not be subject to freezing. M. Pressurize and check preaction sprinkler system piping and air-pressure maintenance devices. N. Fill sprinkler system piping with water. O. Install escutcheons for piping penetrations of walls, ceilings, and floors. 3.3 JOINT CONSTRUCTION A. Install couplings, flanges, flanged fittings, unions, nipples, and transition and special fittings that have finish and pressure ratings same as or higher than system's pressure rating for aboveground applications unless otherwise indicated. B. Install flanges, flange adapters, or couplings for grooved-end piping on valves, apparatus, and equipment having NPS 2-1/2 and larger end connections. C. Ream ends of pipes and tubes and remove burrs. Bevel plain ends of steel pipe. D. Remove scale, slag, dirt, and debris from inside and outside of pipes, tubes, and fittings before assembly. E. Flanged Joints: Select appropriate gasket material in size, type, and thickness suitable for water service. Join flanges with gasket and bolts according to ASME B31.9. WET-PIPE SPRINKLER SYSTEMS 211313 - 11 MID-CABIN HANGAR ALTERATIONS F. Threaded Joints: Thread pipe with tapered pipe threads according to ASME B1.20.1. Cut threads full and clean using sharp dies. Ream threaded pipe ends to remove burrs and restore full ID. Join pipe fittings and valves as follows: 1. 2. Apply appropriate tape or thread compound to external pipe threads. Damaged Threads: Do not use pipe or pipe fittings with threads that are corroded or damaged. G. Twist-Locked Joints: Insert plain end of steel pipe into plain-end-pipe fitting. Rotate retainer lugs one-quarter turn or tighten retainer pin. H. Welded Joints: Construct joints according to AWS D10.12M/D10.12, using qualified processes and welding operators according to "Quality Assurance" Article. 1. Shop weld pipe joints where welded piping is indicated. Do not use welded joints for galvanized-steel pipe. I. Steel-Piping, Cut-Grooved Joints: Cut square-edge groove in end of pipe according to AWWA C606. Assemble coupling with housing, gasket, lubricant, and bolts. Join steel pipe and grooved-end fittings according to AWWA C606 for steel-pipe joints. J. Steel-Piping, Roll-Grooved Joints: Roll rounded-edge groove in end of pipe according to AWWA C606. Assemble coupling with housing, gasket, lubricant, and bolts. Join steel pipe and grooved-end fittings according to AWWA C606 for steel-pipe grooved joints. K. Brazed Joints: Join copper tube and fittings according to CDA's "Copper Tube Handbook," "Brazed Joints" Chapter. L. Copper-Tubing, Pressure-Sealed Joints: Join copper tube and copper pressure-seal fittings with tools recommended by fitting manufacturer. M. Dissimilar-Material Piping Joints: Make joints using adapters compatible with materials of both piping systems. N. Plastic-Piping, Solvent-Cement Joints: Clean and dry joining surfaces. Join pipe and fittings according to the following: 1. 2. 3.4 Comply with ASTM F 402 for safe-handling practice of cleaners, primers, and solvent cements. Apply primer. CPVC Piping: Join according to ASTM D 2846/D 2846M Appendix. VALVE AND SPECIALTIES INSTALLATION A. Install listed fire-protection valves, trim and drain valves, specialty valves and trim, controls, and specialties according to NFPA 13 and authorities having jurisdiction. B. Install listed fire-protection shutoff valves supervised open, located to control sources of water supply except from fire-department connections. Install permanent identification signs indicating portion of system controlled by each valve. WET-PIPE SPRINKLER SYSTEMS 211313 - 12 MID-CABIN HANGAR ALTERATIONS C. 3.5 Install check valve in each water-supply connection. Install backflow preventers instead of check valves in potable-water-supply sources. SPRINKLER INSTALLATION A. Install sprinklers in suspended ceilings in center of acoustical ceiling panels. B. Install dry-type sprinklers with water supply from heated space. Do not install pendent or sidewall, wet-type sprinklers in areas subject to freezing. 3.6 IDENTIFICATION A. Install labeling and pipe markers on equipment and piping according to requirements in NFPA 13. B. Identify system components, wiring, cabling, and terminals. 3.7 FIELD QUALITY CONTROL A. Perform tests and inspections. B. Tests and Inspections: 1. 2. 3. 4. 5. 6. 7. Leak Test: After installation, charge systems and test for leaks. Repair leaks and retest until no leaks exist. Test and adjust controls and safeties. Replace damaged and malfunctioning controls and equipment. Flush, test, and inspect sprinkler systems according to NFPA 13, "Systems Acceptance" Chapter. Energize circuits to electrical equipment and devices. Coordinate with fire-alarm tests. Operate as required. Coordinate with fire-pump tests. Operate as required. Verify that equipment hose threads are same as local fire-department equipment. C. Sprinkler piping system will be considered defective if it does not pass tests and inspections. D. Prepare test and inspection reports. 3.8 CLEANING A. Clean dirt and debris from sprinklers. B. Remove and replace sprinklers with paint other than factory finish. END OF SECTION 211313 WET-PIPE SPRINKLER SYSTEMS 211313 - 13 MID-CABIN HANGAR ALTERATIONS SECTION 21 13 39 – AIRCRAFT HANGAR HIGH-EXPANSION FOAM AND FIRE PROTECTION SYSTEMS 1.1 WORK INCLUDED This section describes the design and installation of the new Fire Protection System and a new High-Expansion Foam (HEF) Fire Protection System. The design flow rate shall be based on the information indicated on the drawings and this specification. The system shall be in accordance with NFPA 13, NFPA 11, NFPA 409 and Wisconsin Dept. of Safety and Professional Services Building Codes. The Contractor is responsible for designing, furnishing, and installing all Fire Protection services, including but not limited to, piping, wiring, equipment and devices as required for a complete, approved, and functioning system. 1.1.2 The Contractor shall install the new Aircraft Hangar Fire Protection System to include the HEF System in the protected hangar and for the adjacent areas as required. Include all detectors, switches, alarms, wiring, and controls for activation of the HEF system. The Contractor shall provide a closed head water, fire sprinkler system for the hangar, pump room, work areas and offices per the contract drawings. 1.1.3 The Contractor shall hydraulically calculate and size all Fire Protection equipment, piping and devices to ensure adequate flow to all system components. 1.1.4 The Contractor shall be responsible for State submittal and fees for final system design. 1.2 RELATED WORK 1.2.1 Drawings and general provisions of Contract, including Outagamie County Bid Documents, apply to work of this section. The contract drawings describe the fire protection requirements. The Contractor shall also coordinate with the other discipline drawings and Contractors. A. Sections in Division 21 – Fire Pump B. Sections in Division 26 – Electrical 1.3 SYSTEM DESCRIPTION 1.3.1. Design Responsibility: A. Responsibility for the working plans shall meet one of the HIGH EXPANSION FOAM SYSTEMS 211339 - 1 MID-CABIN HANGAR ALTERATIONS requirements below. 1. The fire protection system working plans shall be signed and dated by the contractor responsible for the design and installation of the system. The Wisconsin license no. of the automatic fire sprinkler contractor shall be included with their signature. 2. A Wisconsin registered architect, professional engineer, or designer of fire protection systems may assume responsibility for the design of the fire protection working plans. Where this option is selected, the plans shall be signed, dated and sealed by the design professional. B. 1.3.2 The contractor is responsible for the design and installation of the fire protection system in accordance with these specifications and the contract drawings. The contractor shall coordinate with architectural, civil, mechanical, and electrical, design and construction documents, to ascertain the required information, to affect a properly designed fire protection system for the building construction and occupancy classification. Codes and Standards A. The Contractor shall install the fire protection systems in accordance with the current AHJ adopted editions of the following Standards: 1. NFPA 11 - Standard for Low-, Medium-, High-Expansion Foam 2. NFPA 13- Installation of Sprinkler Systems 3. NFPA 16- Standard for the Installation of Foam-Water Sprinkler and Foam-Water Spray Systems 4. NFPA 70- National Electric Code 5. NFPA 72- National Fire Alarm Code 6. NFPA 409- Standard on Aircraft Hangars 1.3.3. Materials and Equipment A. All equipment and devices shall be of a make and type listed by UL or approved by FM, or other nationally recognized testing laboratory for the specific purpose for which it is used. B. The Contractor shall provide fire protection products in accordance with UL standards; provide UL label on each product. C. All products shall be listed for fire protection service. HIGH EXPANSION FOAM SYSTEMS 211339 - 2 MID-CABIN HANGAR ALTERATIONS D. The fire protection systems shall be in conformance with all Federal, State, and Local requirements. 1.4 SUBMITTALS 1.4.1 Submit under provisions of Section 01 33 00 – Submittals. A. Product Data: Submit manufacturer’s product data, including Type, Model, and physical dimensions. B. All literature and instructions provided by the manufacturer of all installed equipment and devices describing proper operation, maintenance, and safety concerns. C. Shop drawings shall show all piping layout drawings, electrical interface schematics, and hydraulic calculations. Hydraulic calculations and drawings shall be submitted to, and approved by, the owner’s insurance carrier and the State of Wisconsin prior to installation. 1.5 CONDUIT A. Conduit shall be in accordance with the National Electrical Code (NEC, local and state requirements). All wiring shall be installed in conduit. B. Conduit shall not exceed 40 percent of interior cross-sectional area where three or more cables are contained within a single conduit. Cable must be separated from any open conductors of power or Class 1 circuits, and shall not be placed in any conduit, junction box, or raceway containing these conductors, as per NEC Article 760-29. 1.6 WIRE A. All fire alarm system wiring shall be new. B. Wiring shall be in accordance with local, state, and national codes (e.g., NEC Article 760). Number and size of conductors shall be as recommended by the fire alarm system manufacturer, but not less than 18 AWG for initiating device circuits and 14 AWG for notification device circuits. C. All wire and cable shall be listed and/or approved by a recognized testing agency for use with a protective signaling (fire alarm) system. 1.7 HIGH EXPANSION SYSTEMS DESIGN HIGH EXPANSION FOAM SYSTEMS 211339 - 3 MID-CABIN HANGAR ALTERATIONS A. Design of the HEF system shall be done by hydraulically calculating the system for uniform distribution of high expansion foam over the entire protected area of the aircraft hangar. The HEF shall conform to the NFPA standards listed above and the requirements specified herein. Before HEF systems equipment is ordered the Contractor shall confirm the number of foam generators and bladder tanks capacity are selected correctly based on the systems supply calculations. B. The HEF system shall be sized to provide a rated output of 3 cfm/ft² of high expansion foam to the protected hangar floor area. In addition an automatic closed-head water sprinkler system with a minimum design density of 0.17 gpm/ft² based on the hydraulically most remote area of 5,000 ft² Group II Hangars, shall be required per NFPA 409 (2007) section 7.2.5. The high-expansion foam generators shall be supplied with JET-X® foam solution for a minimum 12 minute duration. C. 500 gpm outside water hose allowance shall be included. 1.8 FRICTION LOSSES A. Calculate losses in pipe and fittings in accordance with the Hazen-Williams formula with "C" value of 120 for steel pipe. 2.0 PRODUCTS 2.1 All equipment and components shall be new, and the manufacturer’s current model. All equipment and components shall be installed in strict compliance with manufacturer’s recommendations. All equipment shall be attached to walls and ceiling/floor assemblies and shall be held firmly in place. Fasteners and supports shall be adequate to support the required load per NFPA standards. 2.1.2 Deluge Valve A. Valve shall be operated by a detection and control system listed for the releasing service. The Deluge valve shall be provided with electrical solenoid compatible with the voltage and current supplied by the control panel. In addition to the automatic operation, arrange each valve for manual hydraulic release at the valve. Provide pressure gauges and the other appurtenances at the deluge valve. 2.1.3 Sprinkler Heads A. In the hangar provide standard sprinkler heads with nominal 1/2 in (5.6 K) HIGH EXPANSION FOAM SYSTEMS 211339 - 4 MID-CABIN HANGAR ALTERATIONS or 17/32” (8.0 K) orifice. Sprinkler heads shall be standard pendent or upright type in all spaces. B. Sprinklers in the hangar shall be 365 degree F standard response. C. Sprinklers in the office and work areas shall be 155 degree F, quick response brass upright sprinklers with a K-Factor of 5.6. Sprinklers in suspended ceiling shall be chrome plated semi recessed pendent type. D. Sprinklers shall be provided to provide 2 hour protection of columns below roof line. Per NFPA 409 section 5.6 (2004) 2.1.4 High-Expansion Foam Concentrate A. Foam concentrate for high expansion system shall be a UL listed 2% JET-X® Concentrate as manufactured by Ansul Incorporated or approved alternate. Foam concentrate shall be metered into the system riser(s) by the use of balance pressure proportioning utilizing a modified venturi proportioner(s) and bladder tank(s). This system shall include all piping and appurtenances necessary to form a complete working system. Contractor shall supply sufficient concentrate to fill the tanks and for refilling after testing of the foam system. 2.1.5 High-Expansion Foam System Bladder Tanks A. Per NFPA 409 Main and Reserve bladder tanks shall be required. Tanks shall be a vertical or horizontal cylindrical steel ASME coded pressure rated vessel with a UL approved bladder shaped to conform to the inner pressure vessel configuration. Tanks shall be designed for a working pressure of 175 psi (12.1 bar) and hydrostatically tested to at least 255 psi (17.6 bar). The tank(s) interior shall be coated with a high build epoxy sealer for additional corrosion resistance. The bladder tank(s) shall be UL listed or FM approved together with the type of concentrate and proportioner(s) being used in the system. B. The Bladder tanks are to have a minimum capacity to provide sufficient foam concentrate for the time specified when the system is discharging foam solution at total discharge flow. The bladder tanks are to be complete with all necessary outlets and supports such as a continuous welded skirt equal to the tank diameter or two saddles supports as appropriate. C. Associated trim on the bladder tanks shall include bronze pipe and fittings, four 1 in. bronze ball valves with secured nameplate depicting the valve name and operating position, and a break resistant HIGH EXPANSION FOAM SYSTEMS 211339 - 5 MID-CABIN HANGAR ALTERATIONS polycarbonate sight gauge. D. The bladder tanks, proportioner(s) and foam concentrate shall be the product of a single manufacturer. 2.1.6 High-Expansion Foam Proportioner A. The foam proportioners are to be a modified venturi type designed to accurately proportion and control the mixing of pressurized foam concentrate into the water system. B. The proportioner(s) shall have either NPT threaded (2 in. and 2 1/2 in. sizes) or "between flange" type (3 in., 4 in., 6 in. and 8 in. sizes) designed to fit between two 150 lb pipe flanges. C. Proportioner(s) shall be sized for the specified flow rate(s) and either be UL listed or FM approved with the type of foam concentrate and bladder tank(s) being used in the system. D. A fixed metering orifice, secured with a stainless steel retaining ring, shall be sized according to the type and percentage of foam concentrate used. 2.1.7 Hydraulic Concentrate Control Valve A. The hydraulic concentrate control valve shall be a FM Approved assembly that is factory assembled and tested. It shall include a threaded bronze body ball valve with mounting kit for securely attaching the hydraulic actuator to ball valve. The ball valve shall be designed for a minimum 400 psi (27.6 bar) WOG. The valve shall be fitted with a stainless steel ball, stem, and packing nut. Valve seats shall be of glass reinforced Teflon™ material. B. The Stainless Steel Hydraulic Actuator must be approved by the manufacturer for using water as the medium to operate the actuator. The actuator shall have a position indicator and have the capability for manual override. The actuator shall be designed to operate the valve with a minimum of 30 psi (2.1 bar) water pressure and shall contain no external moving parts which could cause fouling of adjacent equipment, injury to personnel, misalignment problems common to external linkage systems, or potential for disengagement caused by tampering. HIGH EXPANSION FOAM SYSTEMS 211339 - 6 MID-CABIN HANGAR ALTERATIONS 2.1.8 High Expansion Foam Generators A. The foam generator(s) shall be powered by a water reaction motor. The water reaction motor shall provide both the screen wetting solution and the energy to drive the fan. The foam generator(s) shall not require any outside power source, such as electricity or gasoline engines. All foam generator(s) designed for fixed installation shall be equipped with a stainless steel screen for maximum reliability under fire conditions. B. The foam generator(s) shall be Underwriters Laboratories (UL) listed and/or Factory Mutual (FM) approved. The generator(s) shall be JET-X Generator(s) Part No420005 JetX-15A UL Generator as manufactured by ANSUL Inc or approved alternate. 2.1.9. AFFF Foam-Water Hand Hose Stations A. The foam-water hand hose stations shall be self-contained foam proportioning units, which require no external power supply other than pressurized water. Unit shall consist of a 36 gal (136 L) minimum capacity vertical bladder tank having the same general features as described for the foam bladder tank. Tank shall be fitted with a 4 in. (102 mm) inside diameter fill opening in the shell head and be provided with a threaded fill cap. A 2 in. threaded proportioner having the same general features as described for the foam proportioner. Concentrate shutoff valve to allow water only operation. B. Metal hose reel with straight-through internal fittings, design to provide a minimum pressure drop, shall be provided. The reel shall be capable of holding 100 ft of 1 1/2 in. hose with nozzle and shall be manual rim rewind. The reel shall be provided with a locking mechanism to prevent unwinding of the hose. The hose shall be continuous flow type, oil and chemical resistant, with a minimum working pressure of 175 psi (12.1 bar) and tested to 400 psi (27.6 bar). C. The nozzle shall be a variable pattern (fog – straight stream), rated for a nominal flow of 95 gpm at 100 psi (6.9 bar). Foam concentrate for foam-water hose stations shall be a UL listed aqueous film-forming foam (AFFF) solution for 3% proportioning. Contractor shall supply sufficient concentrate to fill the tank(s) and for testing of the foam system. Foam concentrate to be Ansulite AFFF manufactured by Ansul or approved alternate. 2.2 Above Grade Piping and Fittings HIGH EXPANSION FOAM SYSTEMS 211339 - 7 MID-CABIN HANGAR ALTERATIONS 2.2.1 Pipe for sprinklers A. Piping used for water-based fire suppression systems shall be black steel welded and seamless Type F, Grade A, ASTM A53; black welded and seamless steel pipe, Type F, ASTM A795; electric resistance welded steel pipe, Grade A, ASTM A135. Approved manufacturers accepted by Architect/Engineer: Allied, Wheatland, Youngstown, and Bull Moose Tube 1. Piping wall thickness shall be Schedule 40 for threaded pipe sizes 1” through 2” diameter. 2. Piping wall thickness shall be Schedule 10 for rolled grooved pipe sizes 2” through 8” 3. Threaded light wall (XL) pipe is not considered acceptable. 4. CPVC plastic pipe listed for fire protection is acceptable in light hazard concealed areas. No exposed CPVC pipe. 2.3 Control System 2.3.1 General. All control systems shall be UL Listed or FM approved and be utilized with listed or approved compatible operating devices and shall be capable of the following functions: A. B. C. D. E. F. G. H. Ground fault indication Supervised alarm circuit Supervised primary power circuit Remote Trouble Alarm Battery standby Front panel indicating lamps (LEDs) or (LCD) display Key lock steel enclosure Control Panel 2.3.2 The control panel shall be a UL Listed and FM approved microprocessor controlled control panel. Provide AUTOPULSE® Deluge Panel or approved equal. A. Equipped with and abort switch stops release while activated B. The door shall provide a key lock and include a glass or other transparent opening for viewing of all indicators. C. All interfaces and associated equipment are to be protected so they will not be affected by voltage surges or line transients. D. The control panel shall receive one (1) 120 volt dedicated power feed. HIGH EXPANSION FOAM SYSTEMS 211339 - 8 MID-CABIN HANGAR ALTERATIONS 2.3.3 Power Supply. Each power supply shall operate on 120 VAC, 60 Hz, and shall provide all necessary power for the foam fire protection system. A. It shall provide a battery charger for 24 hours of standby. B. It shall provide an earth detection circuit. C. It shall provide optional meters to indicate battery voltage and charging current. 2.3.4 Batteries A. Batteries shall be 12 volt. B. Batteries shall have sufficient capacity to power each fire alarm system for not less than 24 hours in standby plus 5 minutes of alarm upon a normal AC power failure. C. Batteries are to be completely maintenance free. No liquids are required. Fluid level checks, refilling, spills, and leakage are not acceptable. 3. EXECUTION 3.1 Foam System Installation 3.1.1 Equipment, materials, installation, workmanship, fabrication, assembly, erection, examination, inspection and testing shall be in accordance with the NFPA standards referenced herein. A. Install piping straight and true to bear evenly on the hangers and supports. Provide fittings for changes in direction of piping and for all connections. B. Make changes in piping sizes through standard reducing pipe fittings; do not use bushings. C. Cut pipe accurately and work into place without springing or forcing. D. Ream pipe ends and free pipe and fittings from burrs. Clean with solvent to remove all varnish and cutting oil prior to assembly. E. Make screw joints with PTFE tape applied to the male threads only. HIGH EXPANSION FOAM SYSTEMS 211339 - 9 MID-CABIN HANGAR ALTERATIONS 3.2 Foam System Tests 3.2.1 The Contractor shall hydrostatically test the entire Fire Protection system At 200 psi (13.8 bar) for 2 hours. Bladder tanks shall be isolated by manual valves and not be included in this test. For the hydrostatic test, the water pressure shall be increased in 50 psi (3.5 bar) increments with observations of the joint and gasket stability during each step increase. Only increase pressure to the next increment after joint and gasket stability has been demonstrated. After the required hydrostatic test pressure has been reached and maintained for one hour, the pressure shall be returned to zero while examining for leakage. The pressure shall be slowly increased again to the required hydrostatic test pressure and maintained for two hours while the leakage measurement is determined. All lines shall be relieved of pressure after completion of the test. In the event of repairs or additions, the affected piping shall be retested at the installation Contractor’s expense. 3.2.2 Environmental Protection Provide temporary measures to prevent foam solution from entering storm drains, sanitary sewers, drainage ditches, streams and water courses. Contain all foam solution on paved surfaces or specific containment area. Collect all discharge foam solution and dispose of it in an EPA approved wastewater treatment facility that provides a secondary (biological) treatment. 3.2.3 Foam Discharge and Concentration Testing The manufacturer’s representative shall test samples of foam solution to ensure proper HEF and AFFF concentration by means of refractive index. The HEF testing shall insure proper operation and floor coverage is achieved in the hangar area. The Contractor shall provide protection for all electrical fixtures and equipment exposed to possible damage during the tests and protect doors and other openings leading from the protected area, to prevent migration of the foam solution into other areas or spaces. 3.2.4 Flushing and Rinsing After completion of tests, flush all piping carrying foam solution with fresh water and drain these deluge systems. 3.2.5 Foam Concentrate Storage Tank After acceptance of the system testing, bladder tanks shall be charged to no less than the systems required capacity. Typically tanks will be filled to their maximum rated capacity. HIGH EXPANSION FOAM SYSTEMS 211339 - 10 MID-CABIN HANGAR ALTERATIONS 3.2.6 A Contractor’s Material and Test Certificate shall be furnished by the Contractor and countersigned by the Owner’s Representative. All shutoff valves shall be fully closed and opened under system pressure to ensure proper operation. 3.3 Coordination 3.3.1 The Contractor shall coordinate with Owner any activity requiring an interface with existing plant services or other contractors to implement fire protection in the Building. 3.3.2 The Contractor shall protect piping and system components from freezing in exterior or unheated spaces. 3.4 Automatic Sprinkler system 3.4.1 Sprinkler piping shall be installed so that the entire system may be drained in accordance with NFPA 13. 3.4.2 Mains, test connections, and other equipment shall be labeled as per FM and NFPA. 3.4.3 Pipe hangers and supports shall comply with NFPA. Seismic bracing is not required. 3.4.4 Penetrations through fire walls and floors shall be provided using appropriate methods to maintain their integrity as per NFPA. 3.4.5 All piping shall be closely coordinated with other trades to avoid interferences (process piping, utility piping, HVAC, plumbing, electrical, general construction). 3.5 Electrical system/ Fire detection system. 3.5.1 Electrical installation shall be in accordance with the NEC, NFPA 72, local and state codes and as recommended by the major equipment manufacturer. 3.5.2 All fire detection and alarm system devices, control panels and remote annunciators may be surface mounted. HIGH EXPANSION FOAM SYSTEMS 211339 - 11 MID-CABIN HANGAR ALTERATIONS 3.6 Training. 3.6.1 Provide the service of a competent factory-trained engineer or technician authorized by the manufacturer of the fire alarm equipment to technically supervise and participate during all of the adjustments and tests for the system. The factory representative shall demonstrate that the Foam Fire Protection Systems function properly in every respect. 4.0 WARRANTY 4.1. Warranty Terms The Contractor shall warranty all work performed and all material and equipment furnished under this contract to be free from defects and shall remain so for a period of at least one (1) year from the date of acceptance. HIGH EXPANSION FOAM SYSTEMS 211339 - 12 MID-CABIN HANGAR ALTERATIONS SECTION 21 31 13 - ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including Outagamie County Bid Documents, apply to this Section. SUMMARY A. Work included: Provision of materials, installation and testing of: 1. Pumps supplying water to fire suppression water supplies, including the following: a. Horizontal Split-case Electric Motor Driven Fire Pumps 2. Accessories 3. Exterior Fire Pump Test Header 4. Gauges for Fire Pumps 5. Fire Pumps Circulation Relief Valve 6. Fire Pumps Relief Valve 7. Fire Pumps Electric Motor Drive Controllers 8. Fire Jockey Pump 9. Fire Jockey Pump Controller 10. Fire Pumps System Monitoring B. Related Sections: 1. Section 211313 “Wet-Pipe Sprinkler Systems” Section 213900 “Controllers for Fire-Pump Drivers” 1.3 PERFORMANCE REQUIREMENTS A. 1.4 Pumps Equipment, Accessories, and Specialties Pressure Rating: 175 psig minimum unless higher pressure rating is indicated. ACTION SUBMITTALS A. Product Data: For each type of product indicated. Include rated capacities, operating characteristics, performance curves, electrical characteristics, and furnished specialties and accessories. B. Shop Drawings: For fire pumps, motor drivers, and fire-pumps accessories and specialties. Include plans, elevations, sections, details, and attachments to other work. 1. Detailed Fire Pump room layout, ¼” Scale Minimum, plan views, with transverse and longitudinal sections. Indicate components, sizes, dimensions and clearances. 2. Wiring Diagrams: For power, signal, and control wiring. ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 1 MID-CABIN HANGAR ALTERATIONS 1.5 INFORMATIONAL SUBMITTALS A. Source quality-control reports. (see section 2.5) B. Field quality-control reports. (see section 3.6) 1.6 CLOSEOUT SUBMITTALS A. 1.7 Operation and Maintenance Data: For fire pumps to include in operation and maintenance manuals. QUALITY ASSURANCE A. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70, by a qualified testing agency, and marked for intended location and application. B. NFPA Compliance: Comply with NFPA 20, "Installation of Stationary Pumps for Fire Protection." 1.8 COORDINATION A. Coordinate sizes and locations of concrete bases with actual equipment provided. PART 2 - PRODUCTS 2.1 GENERAL REQUIREMENTS FOR CENTRIFUGAL FIRE PUMPS A. Description: Factory-assembled and -tested fire-pumps and driver units. B. Base: Fabricated and attached to fire-pumps and driver units with reinforcement to resist movement of pumps during seismic events when base is anchored to building substrate. C. Finish: Red paint applied to factory-assembled and -tested unit before shipping. 2.2 HORIZONTALLY MOUNTED, SINGLE-STAGE, SPLIT-CASE FIRE PUMPS A. Manufacturers: Subject to compliance with requirements, provide products by one of the following: 1. AC Fire Pump: a business of ITT Industries 2. Aurora 3. Fairbanks Morse 4. Patterson 5. Peerless 6. Or approved equivalent ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 2 MID-CABIN HANGAR ALTERATIONS B. Pumps: 1. 2. 3. 4. 5. Standard: UL 448, for split-case pumps for fire service. Casing: Axially split case, cast iron with ASME B16.1 pipe-flange connections. Impeller: Cast bronze, statically and dynamically balanced, and keyed to shaft. Wear Rings: Replaceable bronze. Shaft and Sleeve: Steel shaft with bronze sleeve. a. b. 6. Shaft Bearings: Grease-lubricated ball bearings in cast-iron housing. Seals: Stuffing box with minimum of four rings of graphite-impregnated braided yarn and bronze packing gland. Mounting: Pump and driver shafts are horizontal, with pump and driver on same base. C. Coupling: Flexible and capable of absorbing torsional vibration and shaft misalignment. Include metal coupling guard. D. Driver: 1. 2. E. Capacities and Characteristics: 1. 2.3 Standard: UL 1004A Type: Electric motor; NEMA MG 1, polyphase Design B. Provide (2) 1,500 GPM rated pumps, operating at 1770 RPM and 75 HP at 65 PSI Head. One pump is primary and one pump is secondary per NFPA 409 6.2.10.8.2 (2004). Pump sizes are an estimate. Size pumps to meet Sprinkler System, High Expansion Foam System and hose stream demands per NFPA and building codes.>. FIRE-PUMPS ACCESSORIES AND SPECIALTIES A. Match fire-pumps suction and discharge ratings as required for fire-pumps capacity rating. Include the following: 1. Automatic air-Release valve 2. Circulation relief valve 3. Suction and discharge pressure gauges 4. Eccentric-tapered reducer at suction inlet 5. Concentric-tapered reducer at discharge outlet 6. Test-Header Manifold: Ductile-iron or brass body for hose valves. Included nozzle outlets, number of outlets required by NFPA 20 7. Escutcheon plate, wall mounting, with lettering equivalent to “PUMP TEST CONNECTION” 8. Hose Valves: UL 668, straightway pattern, bronze with cap and chain. NFPA 1963 hose thread that complies with local fire department standards. 9. Ball drip valve: UL 1726 ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 3 MID-CABIN HANGAR ALTERATIONS 2.4 GROUT A. Standard: ASTM C 1107, Grade B, post-hardening and volume-adjusting, dry, hydrauliccement grout. B. Characteristics: Nonshrink and recommended for interior and exterior applications. C. Design Mix: 5000-psi, 28-day compressive strength. D. Packaging: Premixed and factory packaged. 2.5 SOURCE QUALITY CONTROL A. Testing: Test and inspect fire pumps according to UL 448 requirements for "Operation Test" and "Manufacturing and Production Tests." 1. Verification of Performance: Rate fire pumps according to UL 448. B. Fire pumps will be considered defective if they do not pass tests and inspections. C. Prepare test and inspection reports. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine equipment bases and anchorage provisions, with Installer present, for compliance with requirements and for conditions affecting performance of fire pumps. B. Examine roughing-in for fire-suppression piping systems to verify actual locations of piping connections before fire-pump installation. C. Proceed with installation only after unsatisfactory conditions have been corrected. 3.2 INSTALLATION A. Fire-Pumps Installation Standard: Comply with NFPA 20 for installation of fire pumps, relief valves, and related components. B. Equipment Mounting: Install fire pumps on concrete bases. Comply with requirements for concrete bases specified in Division 03 Section “Cast-in-Place Concrete” 1. Install dowel rods to connect concrete base to concrete floor. Unless otherwise indicated, install dowel rods on 18-inch centers around the full perimeter of concrete base. 2. For supported equipment, install epoxy-coated anchor bolts that extend through concrete base and anchor into structural concrete floor. 3. Place and secure anchorage devices. Use setting drawings, templates, diagrams, instructions, and directions furnished with items to be embedded. 4. Install anchor bolts to elevations required for proper attachment to supported equipment. ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 4 MID-CABIN HANGAR ALTERATIONS C. Install fire-pumps suction and discharge piping equal to or larger than sizes required by NFPA 20. D. Support piping and pumps separately so weight of piping does not rest on pumps. E. Install valves that are same size as connecting piping. Comply with requirements for fireprotection valves specified in Section 211313 “Wet-Pipe Sprinkler Systems” F. Install pressure gages on fire-pumps suction and discharge flange pressure-gage tappings. Comply with requirements for pressure gages specified in Section 211313 “Wet-Pipe Sprinkler Systems” G. Install piping hangers and supports, anchors, valves, gages, and equipment supports according to NFPA 20. H. Electrical Wiring: Install electrical devices furnished by equipment manufacturers but not factory mounted. Furnish copies of manufacturers' wiring diagram submittals to electrical Installer. I. Wiring Method: Conceal conductors and cables in accessible ceilings, walls, and floors where possible. 3.3 ALIGNMENT A. Align split-case pumps and driver shafts after complete unit has been leveled on concrete base, grout has set, and anchor bolts have been tightened. B. After alignment is correct, tighten anchor bolts evenly. Fill baseplate completely with grout, with metal blocks and shims or wedges in place. Tighten anchor bolts after grout has hardened. Check alignment and make required corrections. C. Align piping connections. D. Align pumps and driver shafts for angular and parallel alignment according to HI 1.4 and to tolerances specified by manufacturer. 3.4 CONNECTIONS A. Comply with requirements for piping and valves specified in Section 211313 “Wet-Pipe Sprinkler Systems” Drawings indicate general arrangement of piping, fittings, and specialties. B. Install piping adjacent to pumps and equipment to allow service and maintenance. C. Connect relief-valve discharge to drainage piping or point of discharge. D. Connect fire pumps to their controllers. ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 5 MID-CABIN HANGAR ALTERATIONS 3.5 IDENTIFICATION A. 3.6 Identify system components. Comply with requirements for fire-pump marking according to NFPA 20. FIELD QUALITY CONTROL A. Test each fire pump with its controller as a unit. Comply with requirements for electric-motordriver fire-pump controllers specified in Section 213900 "Controllers for Fire-Pump Drivers." B. Manufacturer's Field Service: Engage a factory-authorized service representative to inspect, test, and adjust components, assemblies, and equipment installations, including connections. C. Perform tests and inspections. 1. D. Manufacturer's Field Service: Engage a factory-authorized service representative to inspect components, assemblies, and equipment installations, including connections, and to assist in testing. Tests and Inspections: 1. 2. 3. 4. 5. After installing components, assemblies, and equipment including controller, test for compliance with requirements. Test according to NFPA 20 for acceptance and performance testing. Leak Test: After installation, charge system and test for leaks. Repair leaks and retest until no leaks exist. Operational Test: After electrical circuitry has been energized, start units to confirm proper motor rotation and unit operation. Test and adjust controls and safeties. Replace damaged and malfunctioning controls and equipment. E. Components, assemblies, and equipment will be considered defective if they do not pass tests and inspections. F. Prepare test and inspection reports. G. Furnish fire hoses in number, size, and length required to reach storm drain or other acceptable location to dispose of fire-pump test water. Hoses are for tests only and do not convey to Owner. 3.7 STARTUP SERVICE A. Engage a factory-authorized service representative to perform startup service. 1. Complete installation and startup checks according to manufacturer's written instructions. ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 6 MID-CABIN HANGAR ALTERATIONS 3.8 DEMONSTRATION A. Engage a factory-authorized service representative to train Owner's maintenance personnel to adjust, operate, and maintain fire pumps. END OF SECTION 213113 ELECTRIC-DRIVE, CENTRIFUGAL FIRE PUMPS 213113 - 7 MID-CABIN HANGAR ALTERATIONS SECTION 21 39 00 - CONTROLLERS FOR FIRE-PUMP DRIVERS PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including Outagamie County Bid Documents, apply to this Section. SUMMARY A. Section Includes: 1. 2. 3. 1.3 Full-service, full-voltage controllers rated 600 V and less. Controllers for pressure-maintenance pumps. Remote alarm panels. DEFINITIONS A. ATS: Automatic transfer switch(es). B. ECM: Electronic control module. C. MCCB: Molded-case circuit breaker. D. N.O.: Normally open. 1.4 PERFORMANCE REQUIREMENTS A. Seismic Performance: Fire-pump controllers and alarm panels shall withstand the effects of earthquake motions determined according to ASCE/SEI 7. 1. 1.5 The term "withstand" means "the unit will remain in place without separation of any parts from the device when subjected to the seismic forces specified forces specified and the unit will be fully operational after the seismic event” ACTION SUBMITTALS A. Product Data: For each type of product indicated. Include rated capacities, operating characteristics, electrical characteristics, and furnished specialties and accessories. B. Shop Drawings: For each type of product indicated. Include dimensioned plans, elevations, sections, details, and attachments to other work, including required clearances and service spaces around controller enclosures. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 1 MID-CABIN HANGAR ALTERATIONS 1. Show tabulations of the following: a. b. c. d. e. f. g. 2. 3. 1.6 Each installed unit's type and details. Enclosure types and details for types other than NEMA 250, Type 2. Factory-installed devices. Nameplate legends. Short-circuit current (withstand) rating of integrated unit. Features, characteristics, ratings, and factory settings of individual overcurrent protective devices. Specified modifications. Detail equipment assemblies and indicate dimensions, weights, loads, method of field assembly, components, and location and size of each field connection. Schematic and Connection Diagrams: For power, signal, alarm, and control wiring and for pressure-sensing tubing. INFORMATIONAL SUBMITTALS A. Qualification Data: For qualified testing agency. B. Seismic Qualification Certificates: For each type of product indicated, from manufacturer. 1. 2. 3. Basis for Certification: Indicate whether withstand certification is based on actual test of assembled components or on calculation. Dimensioned Outline Drawings of Equipment Unit: Identify center of gravity and locate and describe mounting and anchorage provisions. Detailed description of equipment anchorage devices on which the certification is based and their installation requirements. C. Product Certificates: For each type of product indicated, from manufacturer. D. Manufacturer's factory test reports of fully assembled and tested equipment. E. Source quality-control reports. F. Field quality-control reports. 1.7 CLOSEOUT SUBMITTALS A. Operation and Maintenance Data: For each type of product indicated to include in emergency, operation, and maintenance manuals. In addition to items specified in Section 017823 "Operation and Maintenance Data," include the following: 1. 2. Manufacturer's written instructions for setting field-adjustable timers, controls, and status and alarm points. Manufacturer's written instructions for testing, adjusting, and reprogramming microprocessor-based logic controls. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 2 MID-CABIN HANGAR ALTERATIONS 1.8 QUALITY ASSURANCE A. Testing Agency Qualifications: Member company of an NRTL. B. Source Limitations: Obtain fire-pump controllers and all associated equipment from single source or producer. C. Electrical Components, Devices, and Accessories: Listed and labeled as defined in NFPA 70, by a qualified testing agency, and marked for intended location and application. D. Comply with standards of authorities having jurisdiction pertaining to materials and installation. E. Comply with NFPA 20 , NFPA 70, and NEC 695. F. IEEE Compliance: Fabricate and test enclosed controllers according to IEEE 344 to withstand seismic forces defined in Section 260548.16 "Seismic Controls for Electrical Systems." 1.9 DELIVERY, STORAGE, AND HANDLING A. 1.10 A. Store controllers indoors in clean, dry space with uniform temperature to prevent condensation. Protect enclosed controllers from exposure to dirt, fumes, water, corrosive substances, and physical damage. PROJECT CONDITIONS Environmental Limitations: 1. 2. B. 1.11 Ambient Temperature Rating: Not less than 40 deg F and not exceeding 122 deg F unless otherwise indicated. Altitude Rating: Not exceeding 6600 feet unless otherwise indicated. Interruption of Existing Electric Service: Notify Construction Manager and Owner no fewer than Seven days in advance of proposed interruption of electric service, and comply with NFPA 70E. COORDINATION A. Coordinate layout and installation of controllers with other construction including conduit, piping, fire-pump equipment, and adjacent surfaces. Maintain required clearances for workspace and equipment access doors and panels. Ensure that controllers are within sight of fire-pump drivers. B. Coordinate sizes and locations of concrete bases with actual equipment provided. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 3 MID-CABIN HANGAR ALTERATIONS PART 2 - PRODUCTS 2.1 FULL-SERVICE CONTROLLERS A. Manufacturers: Subject to compliance with requirements, provide products by one of the following: 1. Aquarius Fluid Products, Inc 2. Joslyn Clark Corporation 3. Metron, Inc 4. Master Control Systems, Inc 5. Eaton Electrical Inc.; Cutler-Hammer Business Unit 6. ASCO Power Technologies, LP; Firetrol Products B. General Requirements for Full-Service Controllers: 1. 2. 3. 4. 5. C. Comply with NFPA 20 and UL 218. Listed by an NRTL for electric-motor driver for fire-pump service. Combined automatic and non-automatic operation. Factory assembled, wired, and tested; continuous-duty rated. Service Equipment Label: NRTL labeled for use as service equipment. Method of Starting: 1. Pressure-switch actuated. a. b. c. d. 2. 3. 4. Water-pressure-actuated switch and pressure transducer with independent highand low-calibrated adjustments responsive to water pressure in fire-suppression piping. System pressure recorder, electric ac driven, with spring backup. Programmable minimum-run-time relay to prevent short cycling. Programmable timer for weekly tests. Magnetic Controller: Across-the-line type. Solid-State Controller: Reduced-voltage type. Emergency Start: Mechanically operated start handle that closes and retains the motor RUN contactor independent of all electric or pressure actuators. D. Method of Stopping: Automatic and non-automatic shutdown after automatic starting. E. Capacity: Rated for fire-pump-driver horsepower and short-circuit-current (withstand) rating equal to or greater than short-circuit current available at controller location. F. Method of Isolation and Overcurrent Protection: Interlocked isolating switch and non-thermal MCCB; with a common, externally mounted operating handle, and providing locked-rotor protection. G. Door-Mounted Operator Interface and Controls: 1. Monitor, display, and control the devices, alarms, functions, and operations listed in NFPA 20 as required for drivers and controller types used. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 4 MID-CABIN HANGAR ALTERATIONS 2. Method of Control and Indication: a. b. c. 3. Local and Remote Alarm and Status Indications: a. b. c. d. e. 4. 5. H. Controller power on. Motor running condition. Loss-of-line power. Line-power phase reversal. Line-power single-phase condition. Audible alarm, with silence push button. Non-automatic START and STOP push buttons or switches. Optional Features: 1. Extra Output Contacts: a. b. c. 2. 3. 4. 2.2 Microprocessor-based logic controller, with multiline digital readout. Membrane keypad. LED alarm and status indicating lights. One N.O. contact(s) for motor running condition. One set(s) of contacts for loss-of-line power. One each, Form C contacts for high and low reservoir level. Local alarm bell. Door-mounted thermal or impact printer for alarm and status logs. Operator Interface Communications Ports: USB, Ethernet, and RS485. CONTROLLERS FOR PRESSURE-MAINTENANCE PUMPS A. Manufacturers: Subject to compliance with requirements, provide products by one of the following: 1. Aquarius Fluid Products, Inc 2. Joslyn Clark Corporation 3. Metron, Inc 4. Master Control Systems, Inc 5. Eaton Electrical Inc.; Cutler-Hammer Business Unit 6. ASCO Power Technologies, LP; Firetrol Products B. General Requirements for Pressure-Maintenance-Pump Controllers: 1. 2. 3. 4. C. Type: UL 508 factory assembled, -wired, and tested, across-the-line; for combined automatic and manual operation. Enclosure: UL 508 and NEMA 250, Type 2 for wall-mounting. Factory assembled, wired, and tested. Finish: Manufacturer's standard color paint. Rate controller for scheduled horsepower and include the following: CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 5 MID-CABIN HANGAR ALTERATIONS 1. 2. 3. 4. 5. 2.3 Fusible disconnect switch. Pressure switch. Hand-off-auto selector switch. Pilot light. Running period timer. REMOTE ALARM PANELS A. General Requirements for Remote Alarm Panels: Comply with NFPA 20 and UL 218; listed by an NRTL for fire-pump service. B. Manufactures: Subject to compliance with requirements, provide products by one of the following: 1. Aquarius Fluid Products, Inc 2. Joslyn Clark Corporation 3. Metron, Inc 4. Master Control Systems, Inc 5. Eaton Electrical Inc.; Cutler-Hammer Business Unit 6. ASCO Power Technologies, LP; Firetrol Products C. General Requirements for Remote Alarm Panels: Factory assembled, wired, and tested. D. Supervisory and Normal Control Voltage: 120-V ac; dual source. E. Audible and Visual Alarm and Status Indications: 1. Driver running. 2. Loss of phase. 3. Phase reversal. 4. Supervised power on. 5. Common trouble on the controller. 6. Controller connected to alternate power source. F. Audible and Visual Alarm and Status Indications: Manufacturer's standard indicating lights; push to test. 1. Engine running. 2. Controller main switch turned to the off or manual position. 3. Supervised power on. 4. Common trouble on the controller or engine. 5. Common pump room trouble. 6. Controller connected to alternate power source. G. Audible alarm, with silence push button. H. Pump REMOTE START push button. 2.4 ENCLOSURES A. Fire-Pump Controllers, ATS, Remote Alarm Panels, and Low-Suction-Shutdown Panels: NEMA 250, to comply with environmental conditions at installed locations and NFPA 20. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 6 MID-CABIN HANGAR ALTERATIONS 1. Indoor, Dry and Clean Locations: Type 1 (IEC IP10). B. Enclosure Color: Manufacturer’s standard “fire-pump-controller red”. C. Nameplates: Comply with NFPA 20; complete with capacity, characteristics, approvals, listings, and other pertinent data. D. Optional Features: 1. 2.5 Floor stands, 12 inches high, for floor-mounted controllers. SOURCE QUALITY CONTROL A. Testing: Test and inspect fire-pump controllers according to requirements in NFPA 20 and UL 218. 1. Verification of Performance: Rate controllers according to operation of functions and features specified. B. Fire-pump controllers will be considered defective if they do not pass tests and inspections. C. Prepare test and inspection reports. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine areas and surfaces to receive equipment, with Installer present, for compliance with requirements and other conditions affecting performance. B. Examine equipment before installation. Reject equipment that is wet or damaged by moisture or mold. C. Proceed with installation only after unsatisfactory conditions have been corrected. 3.2 CONTROLLER INSTALLATION A. Install controllers within sight of their respective drivers. B. Connect controllers to their dedicated pressure-sensing lines. C. Wall-Mounting Controllers: Install controllers on walls with disconnect operating handles not higher than 79 inches above finished floor, and bottom of enclosure not less than 12 inches above finished floor unless otherwise indicated. Bolt units to wall or mount on lightweight structural-steel channels bolted to wall. For controllers not on walls, provide freestanding racks complying with Section 260529 "Hangers and Supports for Electrical Systems." CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 7 MID-CABIN HANGAR ALTERATIONS D. Floor-Mounting Controllers: Install controllers on 4-inch nominal-thickness concrete bases, using floor stands high enough so that the bottom of enclosure cabinet is not less than 12 inches above finished floor. 1. 2. 3. 4. Install dowel rods to connect concrete base to concrete floor. Unless otherwise indicated, install dowel rods on 18-inch centers around the full perimeter of concrete base. For supported equipment, install epoxy-coated anchor bolts that extend through concrete base, and anchor into structural concrete floor. Place and secure anchorage devices. Use setting drawings, templates, diagrams, instructions, and directions furnished with items to be embedded. Install anchor bolts to elevations required for proper attachment to supported equipment. E. Seismic Bracing: Comply with requirements specified in Section 260548.16 "Seismic Controls for Electrical Systems." F. Temporary Lifting Provisions: Remove temporary lifting eyes, channels, and brackets and temporary blocking of moving parts from enclosures and components. G. Comply with NEMA ICS 15. 3.3 REMOTE ALARM PANEL INSTALLATION A. 3.4 Install panels on walls with tops not higher than 72 inches above finished floor unless otherwise indicated. Bolt units to wall or mount on lightweight structural-steel channels bolted to wall. For ATS not on walls, provide freestanding racks complying with Section 260529 "Hangers and Supports for Electrical Systems." POWER WIRING INSTALLATION A. 3.5 Install power wiring between controllers and their services or sources, and between controllers and their drivers. Comply with requirements in NFPA 20, NFPA 70, and Section 260519 "LowVoltage Electrical Power Conductors and Cables." CONTROL AND ALARM WIRING INSTALLATION A. Install wiring between controllers and remote devices and facility’s central monitoring system. Comply with requirements in NFPA 20, NFPA 70, and Section 260523 "Control-Voltage Electrical Power Cables." B. Install wiring between remote alarm panels and controllers. Comply with requirements in NFPA 20, NFPA 70, and Section 260523 "Control-Voltage Electrical Power Cables." C. Install wiring between controllers and the building's fire-alarm system. Comply with requirements specified in Section 283111 "Digital, Addressable Fire-Alarm System." D. Bundle, train, and support wiring in enclosures. E. Connect remote manual and automatic activation devices where applicable. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 8 MID-CABIN HANGAR ALTERATIONS 3.6 IDENTIFICATION A. Comply with requirements in NFPA 20 for marking fire-pump controllers. B. Identify system components, wiring, cabling, and terminals. Comply with requirements for identification in NFPA 20 and as specified in Section 260553 "Identification for Electrical Systems." 3.7 FIELD QUALITY CONTROL A. Testing Agency: Engage a qualified testing agency to perform tests and inspections. B. Manufacturer's Field Service: Engage a factory-authorized service representative to inspect, test, and adjust components, assemblies, and equipment installations, including connections. C. Perform tests and inspections. 1. D. Manufacturer's Field Service: Engage a factory-authorized service representative to inspect components, assemblies, and equipment installations, including connections, and to assist in testing. Acceptance Testing Preparation: 1. Inspect and Test Each Component: a. b. c. 2. Verify and Test Each Electric-Driver Controller: a. b. 3. 4. E. Inspect wiring, components, connections, and equipment installations. Test and adjust components and equipment. Test insulation resistance for each element, component, connecting supply, feeder, and control circuits. Test continuity of each circuit. Verify that voltages at controller locations are within plus 10 or minus 1 percent of motor nameplate rated voltages, with motors off. If outside this range for any motor, notify Construction Manager and Owner before starting the motor(s). Test each motor for proper phase rotation. Operational Test: After electrical circuitry has been energized, start units to confirm proper unit operation. Test and adjust controls and safeties. Replace damaged and malfunctioning controls and equipment. Field Acceptance Tests: 1. 2. Do not begin field acceptance testing until suction piping has been flushed and hydrostatically tested and the certificate for flushing and testing has been submitted to Construction manager , owner and authorities having jurisdiction. Prior to starting, notify authorities having jurisdiction of the time and place of the acceptance testing. CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 9 MID-CABIN HANGAR ALTERATIONS 3. 4. Engage manufacturer's factory-authorized service representative to be present during the testing. Perform field acceptance tests as outlined in NFPA 20. F. Controllers will be considered defective if they do not pass tests and inspections. G. Prepare test and inspection reports. 3.8 STARTUP SERVICE A. Engage a factory-authorized service representative to perform startup service. 1. 3.9 Complete installation and startup checks according to manufacturer's written instructions. ADJUSTING A. Adjust controllers and battery charger systems to function smoothly and as recommended by manufacturer. B. Set field-adjustable switches, auxiliary relays, time-delay relays, and timers. C. Program microprocessors for required operational sequences, status indications, alarms, event recording, and display features. Clear events memory after final acceptance testing and prior to Substantial Completion. D. Set field-adjustable pressure switches. 3.10 PROTECTION A. Temporary Heating: Apply temporary heat to maintain temperature according to manufacturer's written instructions until enclosed controllers are ready to be energized and placed into service. B. Replace controllers whose interiors have been exposed to water or other liquids prior to Substantial Completion. 3.11 A. DEMONSTRATION Engage a factory-authorized service representative to train Owner's maintenance personnel to adjust, operate, and maintain controllers, remote alarm panels, and to use a reprogram microprocessor-based controls within this equipment. END OF SECTION 213900 CONTROLLERS FOR FIRE-PUMP DRIVERS 213900 - 10