PowerIT Vacuum Cast Coil Dry Type Distribution Transformers 50

advertisement

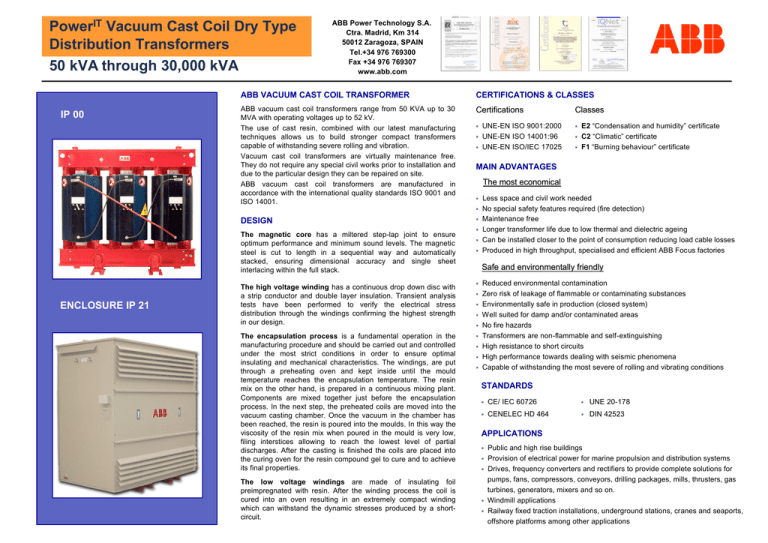

PowerIT Vacuum Cast Coil Dry Type Distribution Transformers 50 kVA through 30,000 kVA IP 00 ABB Power Technology S.A. Ctra. Madrid, Km 314 50012 Zaragoza, SPAIN Tel.+34 976 769300 Fax +34 976 769307 www.abb.com ABB ABB VACUUM CAST COIL TRANSFORMER CERTIFICATIONS & CLASSES ABB vacuum cast coil transformers range from 50 KVA up to 30 MVA with operating voltages up to 52 kV. The use of cast resin, combined with our latest manufacturing techniques allows us to build stronger compact transformers capable of withstanding severe rolling and vibration. Vacuum cast coil transformers are virtually maintenance free. They do not require any special civil works prior to installation and due to the particular design they can be repaired on site. ABB vacuum cast coil transformers are manufactured in accordance with the international quality standards ISO 9001 and ISO 14001. Certifications § § § The magnetic core has a miltered step-lap joint to ensure optimum performance and minimum sound levels. The magnetic steel is cut to length in a sequential way and automatically stacked, ensuring dimensional accuracy and single sheet interlacing within the full stack. ENCLOSURE IP 21 The high voltage winding has a continuous drop down disc with a strip conductor and double layer insulation. Transient analysis tests have been performed to verify the electrical stress distribution through the windings confirming the highest strength in our design. The encapsulation process is a fundamental operation in the manufacturing procedure and should be carried out and controlled under the most strict conditions in order to ensure optimal insulating and mechanical characteristics. The windings, are put through a preheating oven and kept inside until the mould temperature reaches the encapsulation temperature. The resin mix on the other hand, is prepared in a continuous mixing plant. Components are mixed together just before the encapsulation process. In the next step, the preheated coils are moved into the vacuum casting chamber. Once the vacuum in the chamber has been reached, the resin is poured into the moulds. In this way the viscosity of the resin mix when poured in the mould is very low, filing interstices allowing to reach the lowest level of partial discharges. After the casting is finished the coils are placed into the curing oven for the resin compound gel to cure and to achieve its final properties. The low voltage windings are made of insulating foil preimpregnated with resin. After the winding process the coil is cured into an oven resulting in an extremely compact winding which can withstand the dynamic stresses produced by a shortcircuit. § § § E2 “Condensation and humidity” certificate C2 “Climatic” certificate F1 “Burning behaviour” certificate MAIN ADVANTAGES The most economical § § DESIGN UNE-EN ISO 9001:2000 UNE-EN ISO 14001:96 UNE-EN ISO/IEC 17025 Classes § § § § Less space and civil work needed No special safety features required (fire detection) Maintenance free Longer transformer life due to low thermal and dielectric ageing Can be installed closer to the point of consumption reducing load cable losses Produced in high throughput, specialised and efficient ABB Focus factories Safe and environmentally friendly § § § § § § § § § Reduced environmental contamination Zero risk of leakage of flammable or contaminating substances Environmentally safe in production (closed system) Well suited for damp and/or contaminated areas No fire hazards Transformers are non-flammable and self-extinguishing High resistance to short circuits High performance towards dealing with seismic phenomena Capable of withstanding the most severe of rolling and vibrating conditions STANDARDS § CE/ IEC 60726 § UNE 20-178 § CENELEC HD 464 § DIN 42523 APPLICATIONS § § § § § Public and high rise buildings Provision of electrical power for marine propulsion and distribution systems Drives, frequency converters and rectifiers to provide complete solutions for pumps, fans, compressors, conveyors, drilling packages, mills, thrusters, gas turbines, generators, mixers and so on. Windmill applications Railway fixed traction installations, underground stations, cranes and seaports, offshore platforms among other applications PowerIT Vacuum Cast Coil Dry Type Distribution Transformers 50 kVA through 30,000 kVA ABB Power Technology S.A. Ctra. Madrid, Km 314 50012 Zaragoza, SPAIN Tel.+34 976 769300 Fax +34 976 769307 www.abb.com ABB 2 STANDARD ACCESSORIES SPECIAL ACCESSORIES 5 7 1. 2. 3. 4. 5. 6. 7. 6 Bidirectional wheels Lifting rings Hooks for pulling Earthing terminals Rating plate Temperature sensors Off load tap changer § § § § § § § § § § 1 4 § § Antivibration pads Space heater Electrostatic screen Current transformer Delta connection encapsulated Plug in bushings HV switch Surge arrestors On load tap changer Temperature control device Optional Ventilated enclosure Forced cooling VOLTAGE CLASS 12KV IPXX VOLTAGE CLASS 12 KV IP00 RATED POWER No load losses Load losses 75ºC Load losses 120ºC Impedance Noise level, accoustic power Length (A) Width (B) Height (H) Weight Distance between wheels (E) Wheels diameter (ø) Width of wheels (G) KVA W W W % dB mm mm mm Kg mm mm mm 50 350 1230 1400 4 58 1000 770 1080 520 520 125 40 100 440 1760 2000 4 59 1020 770 1130 620 520 125 40 160 610 2380 2700 4 62 1200 770 1130 845 520 125 40 250 820 3080 3500 4 65 1290 850 1180 1230 670 125 40 315 1100 3780 4300 4 68 1290 850 1320 1310 670 125 40 400 1150 4310 4900 4 68 1380 850 1350 1660 670 125 40 500 1350 5630 6400 6 69 1380 850 1480 1570 670 125 40 630 1370 6690 7600 6 70 1530 900 1520 2060 670 125 40 800 1000 1250 1600 2000 2500 3150 1800 2000 2500 2800 3600 4300 6000 8010 8900 11130 12460 16200 18900 22500 9000 10000 12500 14000 18000 21000 25000 6 6 6 6 6 6 6 71 73 74 76 78 81 83 1470 1590 1650 1800 1830 2040 2250 900 900 1000 1000 1000 1250 1250 1750 1750 2000 2100 2430 2500 2680 2170 2620 3100 4020 4630 5500 6900 670 670 820 820 820 1070 1070 125 125 200 200 200 200 200 40 70 70 70 70 70 70 50 350 1320 1500 6 58 1050 780 1100 505 520 125 40 100 500 1850 2100 6 59 1200 780 1150 650 520 125 40 160 750 2550 2900 6 62 1380 780 1180 865 520 125 40 250 880 3340 3800 6 65 1450 850 1220 1150 670 125 40 315 1150 4050 4600 6 66 1450 850 1320 1250 670 125 40 400 1200 4840 5500 6 68 1500 900 1350 1470 670 125 40 500 1500 6160 7000 6 69 1470 900 1500 1575 670 125 40 630 1650 6860 7800 6 70 1590 900 1520 1910 670 125 40 800 1000 1250 1600 2000 2500 3150 2100 2300 2900 3100 4200 5000 7000 8370 9790 12020 14240 17550 20700 24300 9400 11000 13500 16000 19500 23000 27000 6 6 6 6 6 6 6 71 73 74 76 78 81 83 1530 1620 1680 1830 1890 2040 2220 900 900 1000 1000 1000 1250 1250 1750 1750 2080 2150 2480 2550 2720 2100 2445 2930 3860 4460 5565 6645 670 670 820 820 820 1070 1070 125 125 200 200 200 200 200 40 40 70 70 70 70 70 VOLTAGE CLASS 24KV IP00 RATED POWER No load losses Load losses 75ºC Load losses 120ºC Impedance Noise level, accoustic power Length (A) Width (B) Height (H) Weight Distance between wheels (E) Wheels diameter (ø) Width of wheels (G) KVA W W W % dB mm mm mm Kg mm mm mm RATED POWER Length (A) Width (B) Height (H) Distance between wheels (E) Wheels diameter (ø) Width of wheels (G) Weight § § § § § § Copper winding LV/LV transformers Layer windings for special application Class H transformers Double primary voltage Double secondary winding § § § § § Temperature rise below 100 K Encapsulated LV LV connections at the bottom Frequency 50 Hz, 60 Hz and 13 2/3 Hz Special connections groups Sealed LV winding 100 1310 1020 1430 520 125 40 770 160 1490 1080 1440 520 125 40 990 250 1580 1110 1510 670 125 40 1380 315 1580 1110 1650 670 125 40 1480 KVA mm mm mm mm mm mm Kg 50 1410 1150 1400 520 125 40 650 100 1560 1200 1450 520 125 40 800 160 1740 1260 1490 520 125 40 1030 250 1810 1290 1550 670 125 40 1360 315 1810 1290 1650 670 125 40 1460 ROUTINE TESTS § § § § § § 50 1290 1020 1380 520 125 40 670 400 1670 1140 1680 670 125 40 1830 500 1670 1140 1810 670 125 40 1740 630 1820 1190 1850 670 125 40 2270 800 1760 1170 2080 670 125 40 2420 1000 1880 1210 2100 670 125 70 2870 1250 1940 1230 2350 820 200 70 3390 1600 2110 1280 2470 820 200 70 4310 2000 2140 1290 2800 820 200 70 5010 2500 2350 1360 2890 1070 200 70 5880 3150 2560 1430 3070 1070 200 70 7370 VOLTAGE CLASS 24KV IPXX RATED POWER Length (A) Width (B) Height (H) Distance between wheels (E) Width of wheels (G) Wheels diameter (ø) Weight § MANUFACTURING OPTIONS KVA mm mm mm mm mm mm Kg § Measurement of windings resistances Transformation ratio measurement and connection checking Load loss and short-circuit impedance measurements No load loss and current measurement Separate source voltage-withstand test Induced over voltage withstand test Partial discharges measurements TYPE TESTS § § § Temperature rise test Lightning impulse test Noise level test 400 1860 1300 1680 670 125 40 1680 500 1830 1290 1830 670 125 40 1820 630 1950 1330 1850 670 125 40 2160 800 1890 1310 2080 670 125 40 2390 SPECIAL TESTS § § § § § § 1000 1980 1340 2100 670 125 40 2740 1250 2040 1360 2430 820 200 70 3220 1600 2210 1410 2520 820 200 70 4220 2000 2270 1430 2850 820 200 70 4840 2500 2420 1480 2940 1070 200 70 5940 3150 2600 1540 3110 1070 200 70 7110 (always performed under customer request) Measuring zero-sequence impedance Measuring insulation resistance Measuring of harmonics of the no-load current Measuring of the parallel capacity of winding and the tag d Anti-corrosion protection measurement Short circuit test These test are carried out in accordance with the relative IEC, IEEE/ANSI and/or UNE standards and the internal test procedures at the disposal of our clients. Our test laboratory is certified according to the standard UNE-EN-ISO/IEC 17025:2000