Drawings - City Of Beverly Hills

advertisement

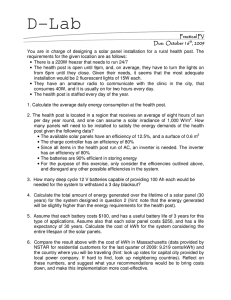

SHEET INDEX SOLAR PHOTOVOLTAIC (PV) BID NOTES: SHEET NO DESCRIPTION DATE PV001 SHEET INDEX, GENERAL NOTES, BID NOTES 2011-08-17 1. PV CONTRACTOR SHALL PROVIDE DRAWINGS FOR CITY OF BEVERLY HILL'S REVIEW FIFTEEN (15) DAYS AFTER BUILDING DEPARTMENT PERMIT FOR ROXBURY MEMORIAL PARK IS RECEIVED. THE PV CONTRACTOR DRAWINGS SHALL BE SIGNED AND STAMPED BY A CALIFORNIA LICENSED ELECTRICAL ENGINEER. 2. PV CONTRACTOR TO PROVIDE 3 YEARS OF MONITORING SERVICE FOR ENERGY. PV002 SYSTEM SPECIFICATION 2011-08-17 PV010 SINGLE LINE DIAGRAM 2011-08-17 PV101 PV SYSTEM LAYOUT - ROOF PLAN 2011-08-17 3. PV CONTRACTOR SHALL SUBMIT AND PROCESS ALL CALIFORNIA SOLAR APPLICATION AND FEE, PRIOR TO INSTALLATION OF THE SOLAR PV SYSTEM. 4. PV CONTRACTOR SHALL ADHERE TO ALL APPLICABLE CODES, ROOFING MANUFACTURERS RECOMMENDATIONS AND THE FOLLOWING CRITERIA. SECTION 263110 ROOF INTEGRATED CRYSTALLINE SOLAR SYSTEM (RICSS) 1.8 PROJECT CONDITIONS A. ENVIRONMENTAL REQUIREMENTS: 1. DO NOT INSTALL SYSTEM DURING RAIN, SNOW, OR WINDY CONDITIONS. 2. WORK ON A DRY ROOF ONLY. B. EXISTING CONDITIONS: ENSURE EXISTING CONDITIONS ARE STABLE, SOLID, AND READY TO ACCEPT NEW CONSTRUCTION. 1.9 WARRANTY A. PROVIDE CERTIFIED COPIES OF THE FOLLOWING MANUFACTURER'S PRODUCT WARRANTIES: 1. ROOFING MANUFACTURER'S WRITTEN 20 YEAR WARRANTY ON SINGLE PLY ROOFING AGAINST ALL DEFECTS IN MATERIALS OR WORKMANSHIP AND TO MAINTAIN WORK OF THIS SECTION IN WATERTIGHT CONDITION FOR 20 YEARS; WARRANTY SHALL INCLUDE CONNECTIONS TO ROOF DRAINAGE FITTINGS, SHEET METAL IN CONNECTION WITH ROOFING. 2. SOLAR PANEL MANUFACTURER'S 20 YEAR WARRANTY COVERING POWER OUTPUT OF PANELS AND 5 YEAR WARRANTY OF REBATED MATERIAL AND WORKMANSHIP. PART 1 - GENERAL PART 2 - PRODUCTS 1.1 SUMMARY 2.1 MANUFACTURERS A. SECTION INCLUDES: 1. SOLAR PHOTOVOLTAIC ROOF PANELS FULLY ADHERED TO ROOF MEMBRANE. 2. SOLAR ARRAY COMBINER BOXES. 3. SOLAR ARRAY DC DISCONNECT SWITCH. 4. DC TO AC INVERTER. 5. ISOLATION TRANSFORMER. 6. AC DISCONNECT SWITCH. B. RELATED SECTIONS: GENERAL NOTES 1. ALL CONSTRUCTION PROJECTS SHALL COMPLY WITH THE "BEST MANAGEMENT PRACTICES" OUTLINED IN "ATTACHMENT A," FOR "STORM 2. ALL ROOF ASSEMBLIES OR ROOF COVERING MATERIAL SHALL BE CLASS A FIRE RETARDANT. NO WOOD ROOF SHALL BE PERMITTED AS ROOF COVERING MATERIAL. 1. SECTION 075300 - ELASTOMERIC MEMBRANE ROOFING: THERMOSET MEMBRANE. 2. SECTION 075400 - THERMOPLASTIC MEMBRANE ROOFING. 1.2 DEFINITIONS A. ARRAY: A MECHANICALLY-INTEGRATED ASSEMBLY OF MODULES AND PANELS, TOGETHER WITH SUPPORT STRUCTURE AND FOUNDATION, TRACKING, THERMAL CONTROL, AND OTHER COMPONENTS, IF USED, TO FORM A DC POWERPRODUCING UNIT. B. ABBREVIATIONS USED IN THIS SECTION HAVE THE FOLLOWING MEANINGS: 3. FOR ALL NEW CONSTRUCTION AND WHEN REQUIRED BY THE CITY, A LICENSED SURVEYOR MUST CERTIFY THAT THE LOCATION OF THE FOOTING FORMS IS PER THE APPROVED PLANS BEFORE FOUNDATIONS CAN BE POURED. THE SURVEYOR MUST PROVIDE A PLOT PLAN SHOWING PRECISE DIMENSIONS TO THE PROPERTY LINES AND THE ELEVATION OF THE FORMS AS COMPARED WITH THE REFERENCE ELEVATION SHOWN ON 4. FOR ALL NEW CONSTRUCTION, AND WHEN REQUIRED BY THE CITY, A LICENSED SURVEYOR MUST CERTIFY THAT THE HEIGHT OF THE BUILDING IS IN ACCORDANCE WITH THE APPROVED PLANS. THE SURVEYOR MUST SHOW THE PRECISE HEIGHT OF THE BUILDING AS COMPARED WITH THE REFERENCE ELEVATION SHOWN ON THE APPROVED PLANS. 5. AN ACCURATE PLOT/SITE PLAN IS REQUIRED WITH EVERY PROJECT SUBMITTED FOR PLAN CHECK. THE PLOT/SITE PLAN SHALL BE DRAWN TO SCALE AND SHALL IDENTIFY ALL BUILDINGS AND IMPROVEMENTS ON SITE. THE PLAN MUST SHOW THE REQUIRED AND ACTUAL SETBACKS OF THE BUILDINGS FROM THE ADJOINING PROPERTY LINES OR PUBLIC RIGHT OF WAYS. THE PLOT/SITE PLAN SHALL ALSO INDICATE THE APPROXIMATE LOCATION OF THE BUILDINGS, STRUCTURES AND IMPROVEMENTS ON ADJOINING PROPERTIES WITHIN 15 FEET OF THE SUBJECT SITE. 6. TEMPORARY TOILET FACILITIES ARE REQUIRED DURING CONSTRUCTION. BEFORE THE START OF CONSTRUCTION OF ANY BUILDING OR STRUCTURE, AND BEFORE ANY REMODEL WHERE ALL TOILET FACILITIES ARE TEMPORARILY REMOVED, A TEMPORARY WATER-FLUSHED OR APPROVED CHEMICAL TOILET SHALL BE INSTALLED FOR USE BY THE WORKERS AND SHALLCOMPLY WITH ALL OF THE FOLLOWING REQUIREMENTS: I) SUCH TEMPORARY TOILET SHALL BE MAINTAINED THROUGHOUT THE CONSTRUCTION OF THE BUILDING OR STRUCTURE; II) IF A WATER-FLUSHED TOILET IS USED, SUCH TOILET SHALL BE CONNECTED TO THE SEWER, AND TILE PIPE WITHOUT A VENT MAY BE USED FOR THE INSTALLATION;III) SUCH TEMPORARY TOILET SHALL BE LOCATED WITHIN TWENTY-FIVE (25') FEET OF THE REAR PROPERTY LINE AND SHALL BE SET BACK AT LEAST TWENTY (20) FEET FROM ANY OTHER PROPERTY LINE UNLESS THE CITY BUILDING OFFICIAL APPROVES AN ALTERNATE LOCATION BECAUSE THE REQUIREMENTS OF THIS SUBSECTION PREVENT SERVICING THE TOILET OR ARE OTHERWISE INFEASIBLE; AND SUCH TEMPORARY TOILET SHALL NOT BE LOCATED ON PUBLIC PROPERTY WITHOUT THE APPROVAL OF THE DIRECTOR OF PUBLIC WORKS 1. A AMPERE (ALSO I) 2. AC ALTERNATING CURRENT 3. AM 1.5 AIR MASS 1.5 4. BOS BALANCE OF SYSTEM 5. DC DIRECT CURRENT 6. DEG. OR N DEGREE 7. IMAX MAXIMUM CURRENT 8. ISC SHORT CIRCUIT CURRENT 9. J JOULE 10. LBF FOOT-POUNDS 11. MIN MINIMUM 12. MPPT MAXIMUM POWER POINT TRACKING 13. N NEWTON 14. % PERCENT 15. PV PHOTOVOLTAIC 16. PSI POUNDS PER SQUARE INCH 17. SI SOLAR IRRADIANCE 18. V VOLT 19. VMAX MAXIMUM VOLTAGE 20. VOC OPEN CIRCUIT VOLTAGE 21. W WATT 1.3 SYSTEM DESCRIPTION A.DESIGN REQUIREMENTS: 7. AN APPROVED WEATHERPROOFING CONSULTANT MUST CERTIFY THE INSTALLATION OF WEATHERPROOFING ON ALL RETAINING WALLS WHICH ARE ADJACENT TO INTERIOR AREAS OF THE BUILDING. THE CONSULTANT WILL NOT BE REQUIRED IF THE INSTALLER IS CERTIFIED IN WRITING BY THE MANUFACTURER. 8. FOR ALL NEW CONSTRUCTION AND WHEN REQUIRED BY THE CITY, AN APPROVED WEATHERPROOFING CONSULTANT MUST CERTIFY THAT THE WEATHERPROOFING ELEMENTS OF THE BUILDING HAVE BEEN INSTALLED IN ACCORDANCE WITH THE APPROVED PLANS, ALL RELEVANT CODES, AND PER MANUFACTURERS SPECIFICATIONS. AT A MINIMUM, AN INSPECTION AND REPORT WILL BE REQUIRED BEFORE PLASTERING BEGINS AND BEFORE FINAL APPROVAL IS GRANTED. 1. CONTRACTOR IS RESPONSIBLE FOR PROVIDING THE PV SYSTEM, INCLUDING ATTACHMENT TO ROOF SYSTEM AND NECESSARY MODIFICATIONS TO MEET SPECIFIED REQUIREMENTS AND MAINTAIN VISUAL DESIGN CONCEPTS. 2. CONTRACT DRAWINGS ARE DIAGRAMMATIC AND ARE INTENDED TO ESTABLISH BASIC DIMENSION OF UNITS, SIGHT LINES, AND PROFILES OF UNITS. 4. PROVIDE DETAILS FOR ATTACHMENT AND ELECTRICAL CONNECTIONS. 5. 263110-2 6. SYSTEM. A.BASIS OF DESIGN PRODUCT: POWERPLY 400 BY LUMETA, INC. B. 2.2 SOLAR ROOF PANELS C.SOLAR PHOTOVOLTAIC PANELS CONSISTING OF MONOCRYSTALLINE PHOTOVOLTAIC CELLS OF CONVERSION EFFICIENCY HIGHER THAN 16%, FACTORY ENCAPSULATED USING ETHYLENE-VINYL ACETATE (EVA), WITH A NON-GLASS COVER MADE OF A DURABLE TRANSPARENT POLYMER TO REPEL DUST AND ENVIRONMENTAL POLLUTANTS. SOLAR PANEL SHALL BE OF THE SELF-ADHESIVE TYPE TO ROOF MEMBRANE, WITH ADHESION MECHANISM COMPATIBLE WITH THERMOPLASTIC [THERMOSET] [EXISTING] MEMBRANE ROOFING. SOLAR PV PANELS SHALL COMPLY WITH UL 1703 AND IEC 62125. D. WEIGHT LOAD OF SOLAR PANELS, INCLUDING ASSOCIATED MOUNTING STRUCTURES IF ANY, SHALL NOT EXCEED 2 LBS/SQUARE FEET IN ROOFING AREA UNDERNEATH SOLAR PANELS BEING INSTALLED. E. PHYSICAL CHARACTERISTICS: PANELS SHALL BE AS FOLLOWS: 1. LENGTH: 8 FEET (6 INCHES BETWEEN PANELS) 2. WIDTH: 4 FEET (6 INCHES BETWEEN PANELS) 3. WEIGHT PER PANEL: 80 LBS. 4. RATED DC POWER (WATTS): 380 WATTS (MINIMUM) 5. MAXIMUM POWER POINT VOLTAGE (VMPP - VOLTS): 79 6. MAXIMUM POWER POINT CURRENT (IMPP - AMPS): 4.9 7. OPEN-CIRCUIT VOLTAGE (VOC - VOLTS): 98.9 8. SHORT CIRCUIT CURRENT (ISC - AMPS): 5.2 2.3 BALANCE OF SYSTEM COMPONENTS A. SOLAR ARRAY COMBINER BOXES: UL LISTED, SERIES FUSING OR CIRCUIT BREAKERS FOR SOLAR ROOF PANEL SOURCE CIRCUITS IN NEMA 3 OR NEMA 3R ENCLOSURE AS REQUIRED. B. SOLAR ARRAY DC DISCONNECT SWITCHES: UL LISTED, HEAVY DUTY FUSED SAFETY SWITCHES ON THE OUTPUT OF THE SOLAR ARRAY IN NEMA 3 OR NEMA 3R ENCLOSURES AS REQUIRED. C.DC-TO-AC INVERTER: HIGH EFFICIENCY, UL LISTED, UTILITY INTERACTIVE, PHASE, VOLTAGE AND CURRENT MATCHED TO LINE AND LOAD, WITH MAXIMUM POWER POINT TRACKING (MPPT) ELECTRONICS, OVER- AND UNDER-VOLTAGE AND FREQUENCY PROTECTION IN ACCORDANCE WITH REQUIREMENTS OF UL 1741, HARMONIC CONTROL IN ACCORDANCE WITH IEEE 519, AND ANTI-ISLANDING PROTECTION AS REQUIRED BY IEEE 929. INVERTER SHALL HAVE AUTOMATIC START-UP, SHUT-DOWN, SELF-DIAGNOSIS, AND FAULT DETECTION. THE UNITS SHALL COMPLY TO FCC ELECTROMAGNETIC INTERFERENCE (EMI) PART 15, SUBPARTS A, B AND J (FCC PART 15), AND IEC 1727. D.ISOLATION TRANSFORMER: UL LISTED OR UL RECOGNIZED WHEN COMBINED WITH THE APPROVED INVERTER, HIGH EFFICIENCY, LOW IMPEDANCE, NOISE FILTERING, NEMA 3 OR NEMA 3R ENCLOSURE AS REQUIRED. E. AC DISCONNECT SWITCH: UL LISTED HEAVY DUTY FUSED SAFETY SWITCH ON THE OUTPUT OF ISOLATION TRANSFORMER IN NEMA 3 OR NEMA 3R ENCLOSURE AS REQUIRED. F. ELECTRIC SERVICE PANEL INTERCONNECTION: UL LISTED CIRCUIT BREAKER OR TAP, IN ACCORDANCE WITH NATIONAL ELECTRICAL CODE, LOCAL CODES AND LOCAL ELECTRIC UTILITY COMPANY REQUIREMENTS. CIRCUIT BREAKER OR TAP SHALL BE LOCATED IN EXISTING OR NEW ELECTRIC SERVICE PANEL ENCLOSURE AS REQUIRED. G.DC TO AC INVERTER: 1. SIZED TO PROVIDE MAXIMUM POWER POINT TRACKING FOR VOLTAGE AND CURRENT RANGE EXPECTED FROM PHOTOVOLTAIC ARRAY FOR TEMPERATURES AND SOLAR INSOLATION CONDITIONS EXPECTED FOR PROJECT CONDITIONS. 2. CAPABLE OF ADJUSTING TO "SUN SPLASH" FROM ALL POSSIBLE COMBINATIONS OF CLOUD FRINGE EFFECTS WITHOUT INTERRUPTION OF ELECTRICAL PRODUCTION. 3. LISTED TO UL 1741. H.ISOLATION TRANSFORMER 1. UL LISTED OR UL RECOGNIZED WHEN COMBINED WITH THE APPROVED INVERTER, HIGH EFFICIENCY, LOW IMPEDANCE, NOISE FILTERING, NEMA 3 OR NEMA 3R ENCLOSURE AS REQUIRED. I. AC DISCONNECT SWITCH: UL LISTED HEAVY DUTY FUSED SAFETY SWITCH ON THE OUTPUT OF ISOLATION TRANSFORMER IN NEMA 3 OR NEMA 3R ENCLOSURE AS REQUIRED. J. KWH METER SOCKET AND METER MAIN: AS REQUIRED BY THE LOCAL ELECTRICAL UTILITY COMPANY, SHALL BE PHASE, VOLTAGE AND CURRENT MATCHED TO LOAD, L0K EMS AMPERES SHORT CIRCUIT CURRENT RATED OR HIGHER WITH UTILITY APPROVAL, UL LISTED, NEMA 3 OR NEMA 3R ENCLOSURE AS REQUIRED, INCLUDING REQUIRED OPENINGS AND LUGS. K. ELECTRIC SERVICE PANEL INTERCONNECTION: UL LISTED CIRCUIT BREAKER OR TAP, IN ACCORDANCE WITH NATIONAL ELECTRICAL CODE, LOCAL CODES AND LOCAL ELECTRIC UTILITY COMPANY REQUIREMENTS. CIRCUIT BREAKER OR TAP SHALL BE LOCATED IN EXISTING OR NEW ELECTRIC SERVICE PANEL ENCLOSURE AS REQUIRED. PART 3 - EXECUTION 9. FOUNDATION EXCAVATIONS SHALL BE INSPECTED AND APPROVED BY THE GEOTECHNICAL ENGINEER PRIOR TO REQUESTING CITY INSPECTION. THE GEOTECHNICAL ENGINEER SHALL PREPARE AND LEAVE A FIELD REPORT FOR THE CITY INSPECTOR. B. THE RICSS SHALL BE DESIGNED FOR FULLY ADHERED INSTALLATION OVER A COMPLETED SINGLE PLY ROOF MEMBRANE SPECIFIED IN SECTION 075300 AND 075400 (EXISTING SINGLE PLY ROOFING) . THE INSTALLATION OF THE SOLAR SYSTEM SHALL NOT RESULT IN PENETRATIONS TO THE UNDERLYING ROOF SYSTEM. THE SYSTEM SHALL COMPLY WITH IEEE 928 AND IEEE 1374. 10. REVISIONS AND DETAIL CHANGES PROPOSED ON A PROJECT AFTER THE BUILDING PERMIT IS ISSUED SHALL BE COORDINATED AND COMMUNICATED WITH THE CITY'S PROJECT PLAN REVIEW C.ROOF SYSTEM REQUIREMENTS: 1. ROOF MANUFACTURER AND INSTALLER APPROVAL REQUIRED FOR SOLAR PANEL INSTALLATIONS OVER EXISTING SINGLE-PLY ROOF SYSTEMS. EXISTING ROOFS SHOULD HAVE A LIFE EXPECTANCY CONSISTENT WITH WARRANTY PERIOD OF PV MODULES. REROOFING DURING THE WARRANTY PERIOD OF THE PV MODULES IS STRONGLY DISCOURAGED. ROOF SYSTEM SHOULD BE CLEAN AND FREE OF DEFECTS PRIOR TO INSTALLATION. 2. WALK PAD LAYOUT COMMENCING FROM ROOF ACCESS POINT TO AND AROUND ALL SERVICEABLE MECHANICAL UNITS AND PHOTOVOLTAIC SERVICEABLE COMPONENTS. 3. COORDINATE WALK PAD LOCATIONS WITH OWNER AND SOLAR SYSTEM PROVIDER. 4. THE SOLAR ROOF PANELS SHALL BE OF HIGH-EFFICIENCY CRYSTALLINE CELL TECHNOLOGY TYPE, RIGID, WITH A NON-GLASS COVER MADE OF A DURABLE TRANSPARENT POLYMER TO REPEL DUST AND ENVIRONMENTAL POLLUTANTS. 5. THE PANELS SHALL BE DESIGNED TO BE DIRECTLY ADHERED TO THE ROOF MEMBRANE ON WHICH IS BEING INSTALLED. EACH SOLAR PANEL SHALL BE CAPABLE OF GENERATING DC POWER. THE POWER DENSITY DEFINED AS DC WATT OUTPUT PER UNIT OF PANEL AREA SHALL BE GREATER THAN 10 WATTS/SQUARE FOOT, WHEN EXPOSED TO A RADIATION OF 1000 WATTS/SQUARE METER. 6. THE WEIGHT LOAD OF THE SOLAR SYSTEM ON THE UNDERLYING ROOF SYSTEM, INCLUDING ANY ASSOCIATED MOUNTING HARDWARE, SHALL NOT EXCEED 2 LBS/SQUARE FOOT. 7. THE INSTALLED SOLAR SYSTEM SHALL BE CAPABLE OF WITHSTANDING WIND LOADS OF UP TO 120 MILES PER HOUR. 8. THE WIRING INTERCONNECTING THE PV MODULES SHALL BE INSTALLED ON TOP OF THE ROOF MEMBRANE, USING A NON-PENETRATING METHOD OF SECUREMENT TO THE ROOF MEMBRANE. 11. ENGINEER/ARCHITECT (PRE). REVISIONS AND DETAIL CHANGES SHALL BE REVIEWED AND APPROVED BY THE PRE PRIOR TO REQUESTING AN INSPECTION. APPOINTMENTS ARE REQUIRED TO BE MADE WITH THE PRE TO REVIEW THE REVISED PLANS (ADDITIONAL REVIEW FEES MAY APPLY). 12. THE PROJECT ARCHITECT, ENGINEER, AND APPLICANT UNDERSTAND THAT THEIR POINT OF CONTACT IS THE CITY'S PLAN REVIEW ENGINEER/ARCHITECT (PREA) FOR THE DURATION OF THE PROJECT. ALL RELATED PROJECT PLAN REVISIONS, OR PROPOSED NEW STRUCTURES, (E.G. DETACHED GARAGE, GUEST HOUSE, ACCESSORY STRUCTURE, POOL, FENCE/WALLS, AND TO THE CITY'S PREA. THE ARCHITECT SHOULD CONTACT THE PREA USING THEIR DIRECT TELEPHONE NUMBER IN ORDER TO MAKE AN OFFICE APPOINTMENT. 13. ALL PLANNING DIVISION APPROVAL LETTERS, RESOLUTIONS, AND CODITIONAL APPROVALS SHALL BE MADE PART OF PLANS. THE FINAL SET OF PLANS SHALL BEAR THE STAMP AND SIGNATURE OF THE PLANNING DIVISION INDICATING COMPLIANCE AND CONFORMITY WITH THE CONDITIONS OF APPROVAL OF THE PROJECT, PRIOR TO APPLYING FOR THE BUILDING PERMIT. 14. A DIGITAL COPY OF "AS-BUILT" PLANS SHALL BE SUBMITTED TO THE BUILDING INSPECTOR PRIOR TO REQUESTING FOR FINAL INSPECTION. THE "ARCHITECT AND/OR REGISTERED PROFESSIONAL'S CERTIFICATION FORM" SHALL BE COMPLETED AND MADE PART OF THE PLANS AS A CONDITION OF THE BUILDING PERMIT ISSUANCE. 15. THE BUILDING INSPECTION RECORD MUST BE PLACED ON THE FIRST SHEET OF THE PLANS AS A CONDITION OF CITY APPROVAL. PLAN PREPARERS (ARCHITECTS, DRAFTSPERSONS, DESIGNERS AND ENGINEERS) SHOULD VISIT THE BUILDING AND SAFETY WEBPAGE TO DOWNLOAD A COPY OF THE BUILDING INSPECTION RECORD AND COPY IT TO THE FIRST SHEET OF THE PLANS FOR PERMANENT RECORD. FAILURE TO INCLUDE THE BUILDING INSPECTION RECORD ON PLANS SUBMITTED FOR APPROVAL WILL RESULT IN A CORRECTION GIVEN TO THE APPLICANT TO RETURN THE PLANS TO THE PREPARER TO INCLUDE THE DOCUMENT AS PART OF THEIR PLANS. PV SYSTEM NOTES: 1. THIS IS A 26,000 CEC WATT SOLAR ELECTRIC SYSTEM USING (65) LUMETA POWERPLY 400 MODULES. 2. THIS SYSTEM USES A UL-LISTED GRID INTERTIE INVERTER: (1) SATCON PVS-30 (208v). 3. NO BATTERY BACKUP OR UPS IS USED IN THIS SYSTEM. 4. THIS SYSTEM IS COMPRISED OF ADHERED PANELS ON THE ROOFS OF THE ROXBURY MEMORIAL PARK BUILDING. 5. THE ROXBURY MEMORIAL PARK BUILDING IS FULLY SPRINKLED. PER NEC 690.53, THE DC DISCONNECTS SHALL HAVE A SIGN AS SHOWN AT LEFT. 6. PER NEC 690.54, THE PHOTOVOLTAIC SYSTEM DISCONNECT SHALL HAVE A SIGN AS SHOWN BELOW. 7. APPLICABLE CODES INCLUDE: 2010 CALIFORNIA BUILDING CODE, 2010 CALIFORNIA ELECTRICAL CODE ARTICLE 690, BEVERLY HILLS BEVERLY HILLS GREEN BUILDING CODE, BEVERLY HILLS FIRE DEPARTMENT SOLAR PHOTOVOLTAIC INSTALLATION GUIDELINES. 8. TERMINALS ON BOTH THE LINE AND LOAD SIDES MAY BE ENERGIZED IN THE OPEN POSITION." 1.4 SUBMITTALS A.PRODUCT DATA: 1. SUBMIT PRODUCT DATA FOR SYSTEM COMPONENTS. 2. INCLUDE INFORMATION FOR PHYSICAL CHARACTERISTICS, SIZES, PATTERNS, AND METHOD OF INSTALLATION. B. SHOP DRAWINGS: SUBMIT SHOP DRAWINGS SHOWING PLANS, SECTIONS, ELEVATIONS AND DETAILS. 1. ROOF PLAN WITH PANEL LAYOUT. 2. INCLUDE LOCATIONS AND TYPES OF ALL DRAINS, VENTS AND MECHANICAL EQUIPMENT. 3. SHOW ROOF STRUCTURES AND SCREENS, DIMENSIONED FOR SIZE AND LOCATION. 4. PROVIDE SITE PLANS AND ELEVATIONS SHOWING ADJOINING SHADING STRUCTURES, INCLUDING TREES, ADJACENT BUILDINGS AND STRUCTURES. INDICATE LOCATION, HEIGHT, AND TYPE OF STRUCTURE. 5. ELECTRICAL SINGLE LINE DIAGRAM. 6. ELECTRICAL EQUIPMENT ROOM LAYOUT DRAWING TO SCALE. C.SUBMIT THE FOLLOWING INFORMATIONAL SUBMITTALS: 1. CERTIFICATIONS SPECIFIED IN QUALITY ASSURANCE ARTICLE. 2. QUALIFICATION DATA: A. CONTRACTOR'S AND MANUFACTURER'S QUALIFICATIONS VERIFYING MINIMUM 12 MONTHS OF COMMERCIAL EXPERIENCE. B. INCLUDE LIST OF 3 COMPLETED PROJECTS HAVING SIMILAR SCOPE OF WORK IDENTIFIED BY NAME, LOCATION, DATE, REFERENCE NAMES, AND PHONE NUMBERS. 3. MANUFACTURER'S INSTRUCTIONS: A.MANUFACTURER'S PRINTED INSTALLATION INSTRUCTIONS. B. INDICATE BY TRANSMITTAL THAT COPIES OF INSTRUCTIONS AND RECOMMENDATIONS HAVE BEEN DISTRIBUTED TO INSTALLER. 4. CONTRACTOR'S FIELD REPORTS: WRITTEN RESULTS AND FINDINGS OF CONTRACTOR'S FIELD SERVICES SPECIFIED AS PART OF FIELD QUALITY CONTROL. D. CLOSEOUT SUBMITTALS 1. PROJECT RECORD DOCUMENTS: A.RECORD ACTUAL LOCATIONS OF PANELS, JUNCTION BOXES, COMBINER BOXES, DISCONNECT SWITCHES AND ISOLATION TRANSFORMER. PROVIDE COMPLETE WIRING AND CIRCUIT DIAGRAMS. 2. SUBMIT EVIDENCE INDICATING COMPLIANCE WITH STATE AND LOCAL BUILDING CODES. 3. OPERATION AND MAINTENANCE DATA: SUBMIT MANUFACTURER'S PRINTED, RECOMMENDED OPERATION AND MAINTENANCE DATA AND CLEANING INSTRUCTIONS. 4. WARRANTY: SUBMIT SPECIFIED PRODUCT WARRANTY. E. LEED DATA (IF REQUIRED BY OWNER): PROVIDE SPECIAL SUBMITTALS CONFORMING TO SECTION 018113 - SUSTAINABLE DESIGN REQUIREMENTS FOR THE FOLLOWING: 1. LEED CREDIT EA 2.2: PROVIDE CALCULATIONS INDICATING THAT 10 PERCENT OF TOTAL ENERGY COSTS ARE SUPPLIED BY ON-SITE RENEWABLE ENERGY SYSTEMS. 1.5 QUALITY ASSURANCE A. SINGLE SOURCE RESPONSIBILITY: TO ENSURE QUALITY OF APPEARANCE AND PERFORMANCE, OBTAIN EQUIPMENT FOR SYSTEMS FROM SINGLE RICSS MANUFACTURER. B. INSTALLER QUALIFICATIONS: CERTIFIED IN WRITING BY EQUIPMENT MANUFACTURERS AS QUALIFIED FOR INSTALLATION OF SPECIFIED SYSTEMS. MUST HAVE 12 MONTHS INSTALLATION EXPERIENCE ON COMMERCIAL PROJECTS, AND PROPER LICENSING. C.REGULATORY REQUIREMENTS: 1. COMPLY WITH IEEE 928, IEEE 929, IEEE 1374, IEC 1277, NFPA 70 ARTICLE 690 - SOLAR PHOTOVOLTAIC SYSTEMS AND ARTICLE 705 - INTERCONNECTED ELECTRIC POWER PRODUCTION SOURCES, THE NATIONAL ELECTRICAL SAFETY CODE (IEEE C2), OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION (OSHA) REGULATIONS (29 CFR 1910), INTERNATIONAL BUILDING CODE (ICC IBC), STATE AND LOCAL CODES. D. CERTIFICATIONS: SUBMIT SYSTEM COMPONENT MANUFACTURER'S CERTIFICATION THAT PRODUCTS FURNISHED FOR PROJECT MEET OR EXCEED SPECIFIED REQUIREMENTS. 1.6 PRE-INSTALLATION CONFERENCE 3.1 EXAMINATION A. VERIFY ITEMS PROVIDED BY OTHER SECTIONS OF WORK ARE PROPERLY SIZED AND LOCATED. B. VERIFY THAT THE DC TO AC INVERTERS HAVE GROUND FAULT PROTECTION. C. VERIFY THAT ROOF TEMPERATURE IS A MINIMUM OF 60 DEGREES F FOR PROPER ADHESIVE PERFORMANCE. D. THE ROOF DECK SHALL BE STRUCTURALLY SOUND, CLEAN, DUST FREE, SMOOTH AND FLAT. REQUIRED ROOF PITCH IS 0.25:12 MINIMUM TO 2:12 MAXIMUM. 3.2 SPECIAL CAUTION TO BE OBSERVED IN WORKING WITH THE PANELS A. THE RICSS CONTAINS LIVE ELECTRICAL COMPONENTS ENCLOSED AND PROTECTED WITHIN. DO NOT CUT OR DRIVE SCREWS INTO ANY PART OF THE SOLAR ROOF PANEL AND SYSTEM WHERE SOLAR PANELS OR WIRING ARE PRESENT WHICH INCLUDES, BUT IS NOT LIMITED TO THE SOLAR PANELS, THE INTER-PANEL WIRING ASSEMBLY AND THE ROOFTOP SOLAR ARRAY WIRING. B. AVOID ELECTRICAL HAZARDS WHEN INSTALLING, WIRING, OPERATING AND MAINTAINING THE SOLAR ROOF PANEL AND ALL OTHER ELECTRICAL EQUIPMENT. C. THE PANELS GENERATE DC ELECTRICITY WHEN EXPOSED TO SUNLIGHT OR OTHER LIGHT SOURCES. D.DO NOT TOUCH THE EXPOSED COPPER WIRE LEADS WHILE THE PANEL IS EXPOSED TO LIGHT OR DURING INSTALLATION. USE PROPERLY INSULATED TOOLS ONLY. E. WORK ONLY UNDER DRY CONDITIONS WITH A DRY PANEL AND TOOLS. F. THE SOLAR ROOF PANELS ARE SLIPPERY WHEN WET. USE EXTREME CAUTION AND PROPER ROOF SAFETY PRACTICES WHEN WORKING ON OR NEAR THE PANELS. G.DO NOT STAND OR STEP ON THE PANELS. H.DO NOT DROP PANELS OR ALLOW OBJECTS TO FALL ON THE PANELS. DO NOT PLACE EQUIPMENT ON THE PANELS. I. COVER SOLAR PANELS WITH AN OPAQUE MATERIAL BEFORE MAKING WIRING CONNECTIONS TO REDUCE THE RISK OF ELECTRIC SHOCK OR SPARKS. J. DO NOT LEAVE PANELS UNSECURED. KEEP THE PANEL FRONT AND BACK SURFACE FREE FROM FOREIGN OBJECTS. K. DO NOT INSTALL PANELS WHERE FLAMMABLE GASES OR VAPORS ARE PRESENT SINCE SPARKS MAY BE PRODUCED. L. DO NOT DRILL OR CUT HOLES IN THE PANEL SOLAR MODULES OR WIRING. AVOID SHARP EDGES. M.ARTIFICIALLY CONCENTRATED SUNLIGHT SHALL NOT BE DIRECTED ON THE PANEL. N.USE THE PANEL FOR ITS INTENDED USE ONLY. DO NOT DISASSEMBLE THE PANEL OR REMOVE ANY PART OR LABEL INSTALLED BY THE MANUFACTURER. 3.3 INSTALLATION A.MAKE A SOLAR PANEL ROOF LAYOUT DRAWING TO INCLUDE CONDUIT RUNS, JUNCTION BOXES, COMBINER BOXES AND ELECTRICAL HOMERUN TO THE DC DISCONNECT SWITCH AND INVERTER. B. INSTALL PANELS OVER SINGLE-PLY ROOF IN ACCORDANCE WITH MANUFACTURER'S RECOMMENDATIONS. FOR EXISTING MEMBRANE ROOFS WITH EXPECTED LIFE LONGER THAN 15 YEARS, INSPECT ROOF TO ENSURE EXISTING ROOF SYSTEM MEETS REQUIREMENTS OUTLINED IN THIS SECTION. C.CLEAN THE ROOF DECK SURFACE OF DIRT, DEBRIS AND FOREIGN MATERIALS. D.LAY OUT THE PANELS AS INDICATED AND IN ACCORDANCE WITH IEEE C2 AND ASCE/SEI 7-05. E. INSTALL CONDUIT, JUNCTION BOXES AND COMBINER BOXES ON THE ROOF DECK PER STANDARD COMMERCIAL PRACTICES AND CODES. F. BEFORE INSTALLING SOLAR PANELS, FEED A MANDREL THROUGH CONDUIT TO ENSURE THAT CONDUIT IS CLEAR OF ROOFING NAILS OR SCREWS. G.INSTALL AND CONNECT THE BALANCE OF SYSTEM (BOS) EQUIPMENT (COMBINER BOX, DC DISCONNECT SWITCH INVERTER, ISOLATION TRANSFORMER, AC DISCONNECT SWITCH AND UTILITY INTERCONNECTION EQUIPMENT) IN ACCORDANCE WITH IEEE 929 AND IEC 1173. H.INSTALLATION OF INTEGRATED PV PANELS: 1. INSTALL MODULES OVER ROOF MEMBRANE, IN ACCORDANCE WITH THE SOLAR PANEL MANUFACTURER'S INSTRUCTIONS. ATTACH THE SOLAR PANEL TO THE ROOF MEMBRANE USING PANELS' SELF-ADHESIVE MECHANISM, IN ACCORDANCE WITH THE RECOMMENDATIONS OF PANEL MANUFACTURER, ROOF MEMBRANE MANUFACTURER AND APPROVED SUBMITTALS. 2. INSTALL MODULES IN LOCATION AND ORIENTATION AS INDICATED ON SUBMITTAL DRAWINGS. 3. INSTALL MODULES IN ACCORDANCE WITH NFPA 70. I. INSTALLATION OF WIRE WAYS AND/OR CONDUIT FOR DC WIRING 1. INSTALL WIRE WAYS ON THERMOPLASTIC MEMBRANE, USING THE SELF-ADHESIVE MECHANISM ATTACHED TO WIRE WAYS. 2. INSTALL WIRE WAYS IN LOCATION AND ORIENTATION AS INDICATED ON SUBMITTAL DRAWINGS J. COMPLETE THE WIRING TERMINATION IN THE FOLLOWING ORDER: 1. GROUND ELECTRODE CONDUCTOR. 2. INVERTER. 3. COMBINER BOX. 4. JUNCTION BOX. 5. MODULES. K. INSPECT, TEST AND STARTUP THE SOLAR POWER SYSTEM IN ACCORDANCE WITH THE PANEL SOLAR PANEL MANUFACTURER'S INSTALLATION MANUAL AND IN ACCORDANCE WITH IEEE 1373. 3.4 FIELD QUALITY CONTROL A. AN AUTHORIZED REPRESENTATIVE OF THE MANUFACTURER SHALL INSPECT THE INSTALLATION PERIODICALLY DURING CONSTRUCTION AND AT COMPLETION TO ASSURE THAT THE SYSTEM IS INSTALLED IN COMPLIANCE WITH THESE SPECIFICATIONS. B. UPON COMPLETION, IN ADDITION TO CODE REQUIRED TESTING OF ELECTRICAL COMPONENTS AND SYSTEM, MEGGER TEST EACH CIRCUIT, AND FURNISH A REPORT OF THE TESTS TO THE ARCHITECT. 3.5 ADJUSTING A. TEST AND ADJUST ELECTRICAL COMPONENTS AND OPERATING FUNCTIONS IN ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS TO ENSURE SMOOTH OPERATION. 3.6 CLEANING A. CLEAN PANEL SURFACES AND ELECTRICAL COMPONENTS IN COMPLIANCE WITH MANUFACTURER'S RECOMMENDATIONS. 3.7 START UP A. SYSTEM START UP: FURNISH THE SERVICES OF A TRAINED REPRESENTATIVE OF THE SOLAR PANEL MANUFACTURER TO INSTRUCT THE OWNER PERSONNEL IN OPERATION AND ROUTINE MAINTENANCE OF THE SOLAR PANEL SYSTEM. 3.8 PROTECTION B. PROTECT FINISHED WORK FROM DAMAGE DUE TO CONTINUING CONSTRUCTION ACTIVITIES. A. CONDUCT PRE-INSTALLATION CONFERENCE AT PROJECT SITE. B. REVIEW REQUIREMENTS OF CONTRACT DOCUMENTS AND SUBMITTALS. C.REVIEW ANCHOR AND WEATHER-TIGHT INSTALLATION REQUIREMENTS. D.ESTABLISH AGREEMENT, COORDINATION, SAFETY AND RESPONSIBILITIES. 1.7 DELIVERY, STORAGE, AND HANDLING north A. STORE IN AN AMBIENT TEMPERATURE OF 40.1 DEGREES F TO 80.1 DEGREES F. B. DELIVER IN ORIGINAL UNOPENED CONTAINERS OR WRAPPINGS. PROTECT FINISHED SURFACES AS NECESSARY TO PREVENT DAMAGE. C. PLACE MATERIALS ON PALLETS AND FULLY PROTECT FROM MOISTURE. LEAVE PROTECTIVE PACKAGING IN PLACE UNTIL PANELS ARE INSTALLED. D. HANDLE TO AVOID BENDING OF SOLAR MODULES. E. REPLACE DAMAGED UNITS. north SPECIFICATION - PV SYSTEM north SPECIFICATION - INVERTER north north north 4' 1'-6" TYP 4' 4' 6" TYP 4' 1 north ROOF PLAN Scale: 1/4"=1'-0" north