Sustainbility

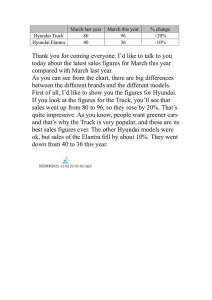

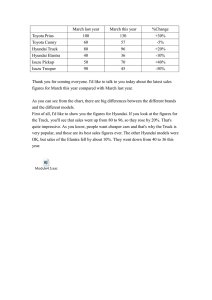

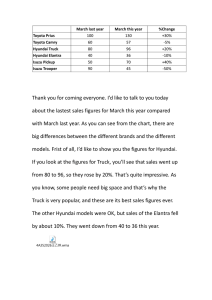

advertisement