Metasys System Extended Architecture Smoke Control UL 864

advertisement

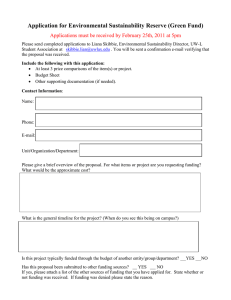

Metasys System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist Code No. LIT-1201754 Release 1.2 Issued February 10, 2005 Document Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Smoke Control UL 864 UUKL Compliance Checklist Overview . . . . . . . . . . . . . . . . 4 UL 864 UUKL Smoke Control Compliance Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 General UUKL Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Fire Fighter’s Smoke Control Station (FSCS) UUKL FSCS UUKL Requirements . . . . . 7 DX-9100 Applications UUKL Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Smoke Control Wiring UUKL Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Metasys System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 1 2 Metasys System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist Document Introduction This document summarizes the most common requirements to configure the Metasys system extended architecture to comply with Underwriters Laboratories®, Inc. (UL), UL 864 UUKL Smoke Control Listing. A UL 864 UUKL Smoke Control Compliance Survey form is followed by tables listing the requirements for UL 864 UUKL Listing compliance. The purpose of the enclosed UL 864 UUKL Smoke Control Compliance Survey is to provide a record of those elements of National Fire Protection Association (NFPA) 92A and UUKL that Johnson Controls, Inc. does or does not provide. Related Documentation If you are bidding, engineering, installing, or commissioning a Metasys system extended architecture requiring UUKL Smoke Control Listing compliance, follow the guidelines and procedures outlined in the documents listed in Table 1. Table 1: Related Documentation For Information On Refer to LIT No./Part No. Smoke Control Guidelines and Procedures Metasys System Extended Architecture Smoke Control System Technical Bulletin LIT-1201684 Smoke Control Wiring Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin LIT-1201753 Network Automation Engine (NAE) Installation NAE55/NIE Installation Instructions Part No. 24-10051-0 Smoke Control Applications Single Story Enclosed Shopping Mall Smoke Control with FSCS Override Metasys System Extended Architecture Application Note LIT-1201736 Multi-Story Building Smoke Control with FSCS Override - Metasys System Extended Architecture Application Note LIT-1201737 Warehouse Smoke Control with FSCS Override -Metasys System Extended Architecture Application Note LIT-1201738 Weekly Testing of Dedicated Smoke Control Dampers - Metasys System Extended Architecture Application Note LIT-1201743 Weekly Testing of Dedicated Stairwell Pressurization Fans - Metasys System Extended Architecture Application Note LIT-1201739 Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 3 Smoke Control UL 864 UUKL Compliance Checklist Overview UUKL is an identifier created by UL to identify those products Listed under UL 864 as part of a Smoke Control system. Products covered by this listing are intended to be installed in conjunction with Heating, Ventilating, and Air Conditioning (HVAC) equipment to form a system for controlling the flow of smoke in a building during a fire condition in accordance with NFPA Recommended Practice 92A. It is important that we document the system elements that are being provided. The UL 864 UUKL Smoke Control Compliance Survey can be used to provide that documentation. In the case where a project specification dictates compliance with the UUKL Listing, but contains elements of the system design that conflict with the Listing or are omitted, the completed UL 864 UUKL Smoke Control Compliance Survey can be given to the designer and/or the AHJ to obtain recognition and agreement on the extent of Listing compliance. This should occur prior to bid and/or proposal. Once agreement is reached with the AHJ, designer, and customer, the signed or initialed Smoke Control Compliance Checklist must become a permanent part of the project file. Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 4 UL 864 UUKL Smoke Control Compliance Survey Date of Survey Conducted By Project Location Branch Office Project Manager Specifications Building Codes UL Compliance Required By: Contract Applicable Building Codes and Standards Local (Branch) Person Providing and Verifying Information Initials Name Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 5 General UUKL Requirements Table 2 lists general requirements for UL 864 UUKL Listing compliance. Mark Yes/No for compliance and initial each item that was verified. Table 2: General UUKL Requirements Requirement Y/N NA Person Verifying Communication links between buildings are fiber-optic cable or copper cable buried in a conduit separate from power wiring. Each binary output object used for pressurization and exhaust control is configured with positive feedback. The feedback input monitors the associated controlled equipment status (for example, both open and closed, on and off). For smoke control dampers, there may be a pair of feedback binary inputs for two damper end switches. Any mismatch of a command and status of the binary output occurring longer than the allowed response time must create a trouble light indication at the FSCS. For fans there is positive indication of airflow. Non UL-Listed control equipment must be isolated from the UL-Listed network. The Weekly Testing of Dedicated Stairwell Pressurization Fans application is used on all dedicated smoke control systems. Automatic smoke control sequences take precedence over HVAC automatic and manual commands. Manual FSCS takes precedence over all else. Automatic activation of any smoke control sequence of operation has priority over any non-smoke control manual commands and any automatic environmental control strategy, when an auto smoke control sequence is initiated. High and low temperature protection devices and return and exhaust air-duct smoke detectors are bypassed. Response time for individual smoke control fans to reach commanded state is no more than 60 seconds. Response time for individual smoke control dampers to reach commanded state is no more than 75 seconds. Fire alarm system manual pull stations do not initiate automatic smoke control sequences. Smoke detectors are used to initiate a smoke control strategy only as detailed in the Metasys System Extended Architecture Smoke Control System Technical Bulletin (LIT-1201684). All Application Specific Controls (ASCs) that monitor or control smoke control equipment are UUKL Listed. Electrical disconnects, overloads, duct static pressure limits, and supply air duct smoke detectors are not overridden by manual or automatic smoke control strategies. Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 6 Fire Fighter’s Smoke Control Station (FSCS) UUKL FSCS UUKL Requirements Table 3 lists general requirements for UL 864 UUKL Listing compliance for FSCSs where required. Mark Yes/No for compliance and initial each item that was verified. Table 3: FSCS UUKL Requirements Requirement Y/N NA Person Verifying FSCS is UUKL Listed and provides manual control of the smoke control system, a UUKL Listed annunciator panel is used as FSCS. Custom annunciator FSCS is connected to a UUKL Listed Smoke Control NAE55. FSCS provides positive indication of the operation of all smoke control equipment (for example, both open and closed, on and off). FSCS provides audible and visible trouble indication when any smoke control equipment does not respond to automatic or manual commands. FSCS simultaneously displays the status of all smoke control systems dampers, fans FSCS has manual control over all smoke control systems. FSCS can override (partially or in full) any operation in progress, including programmed actions, non-smoke control manual overrides. FSCS has highest priority over all smoke control systems. A building diagram or equivalent at FSCS clearly indicates the type and location of all smoke control equipment. FSCS indicates the actual status (not the command status) of systems and equipment used for smoke control. This includes the current position of each damper used in an active smoke control sequence and the status of airflow status of every fan. FSCS activates an audible signal if the operation proof sensor (binary feedback point) failed to provide positive feedback that fan or damper reached its intended position. Only one FSCS on Metasys system is used for smoke control applications unless approved by the AHJ. The FSCS manual activation or deactivation of any smoke control device has priority over any automatic smoke or environmental sequence of operation. Any return air duct smoke detectors in duct work of each HVAC fan system used for smoke control exhaust or purge only reports an alarm condition to the FSCS or fire alarm annunciator located at the FSCS and does not stop the fan. All hardware supervision alarms, such as binary feedback alarms on fans and dampers, as well as system alarm points turn on FSCS alarm horn. Annunciation on the FSCS of change of state of smoke control equipment is no more than 10 seconds after reaching commanded state. Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 7 DX-9100 Applications UUKL Requirements Table 4 lists general requirements for UL 864 UUKL Listing compliance for DX-9100 hardware with fire alarm panel applications. Mark Yes/No for compliance and initial each item that was verified. Table 4: DX-9100 Applications UUKL Requirements Requirement Y/N NA Person Verifying If the Digital Inputs (DIs) are used for smoke control, the fuse on the DI circuit of that DX-9100 is monitored by a jumper wire across a DI, mapped to the NAE/NIE/Site Director. If the fuse goes into trouble then the alarm is activated in the NAE and a trouble light for the affected equipment energizes at the FSCS. If Analog Outputs (AOs) are used for smoke control, the fuse on the AO circuit of that DX-9100 is monitored by doing the following. They are fused and the fuse is monitored. To do this, set one AO for voltage and define an Analog Input (AI) for voltage. Connect a Control Output (CO) set for 50.0 to the AO that is ranged for 0-100. This gives the AO a 50 percent signal or a 5 volt output. This output is hardwired back to the AI defined for voltage with a range of 0-100 and a low limit of 20. If the AO fuse blows, the voltage will go to 0 and the AI will go into low alarm. This alarm must be monitored as a critical alarm. Each DX-9100 used for smoke control has a Metasys system poll priority of 1 or 2. All fans controlled by the DX-9100 have an airflow status switch. Any mismatch of command and status of the fans reports a critical alarm at FSCS. An IFC-640/1010/2020/3030 is connected to the Metasys system via the BACnet® Gateway to initiate automatic smoke control actions. If the fire alarm control panel alarms are not displayed on an annunciator at the FSCS, all alarm input DIs are monitored and report critical alarms at the NAE when they close (turn On), such as a fire alarm control panel smoke detector alarm point. Locate the annunciator panel at the FSCS to enable the operator to monitor all alarms in the fire alarm system. The buttons on the face of the DX-9100 are not used to override smoke control points. Any DX-9100 for smoke control is locked in a Listed enclosure, such as the EN-EWC25-0 to prevent unauthorized access. All alarm input DIs are monitored and report critical alarms at the NAE/NIE/Site Director when they close (turn On). Any signal circuits connected to the XP9102 do not leave the room in which the XP9102 is mounted unless transient protection is applied as detailed in the Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin (LIT-1201753). If signal circuits leaves the room, transient protection is applied as detailed in the Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin (LIT-1201753). Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 8 Smoke Control Wiring UUKL Requirements Table 5 lists requirements for UL 864 UUKL Listing compliance for Smoke Control Wiring. Mark Yes/No for compliance and initial each item verified. Table 5: Smoke Control Wiring UUKL Requirements Requirement Y/N NA Person Verifying Communication links between buildings are fiber-optic cable or copper cable buried in a conduit separate from power wiring. If N1 or N2 signal circuits leave the room, transient protection is applied as detailed in the Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin (LIT-1201753). When using DX-9100 product line for smoke control, the DX-9100-8990F base must be used. If the XP-9102 is used and the signal circuit leaves the room in which the XP-9102 is installed, the protection is shown in the Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin (LIT-1201753) . The Metal Oxide Varistor (MOV) must be a Johnson Controls® Code No. SMOKE-MOVEKIT-0. The transzorbs in the Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin (LIT-1201753) are installed on the base frame products. Only terminals in use and signal circuits leaving a room where a controller is installed have transient protection. The transzorb must be a Johnson Controls Code No. SMOKE-TRNKIT-0. MOVs are installed on the AHU, UNT, and VAV products as shown in the Metasys System Extended Architecture Smoke Control Wiring Technical Bulletin (LIT-1201753) . Only terminals in use, and I/O wiring leaving a room where a controller is installed, or wire more than 20 feet in length have transient protection. The MOV is a Johnson Controls Code No. SMOKE-MOVKIT-0. For faston versions use Johnson Controls Code No. AS-MOVKIT-0 Verify that a Tripp Lite® ISOBAR8ULTRA surge protector or a Tripp Lite ISOBAR12ULTRA surge protector protects all 120 VAC power sources. If fiber-optic cable is used, verify that it meets the requirements listed in the Metasys System Extended Architecture Smoke Control System Wiring Technical Bulletin (LIT-1201753) If copper cable is used, verify that it meets the requirements listed in the Metasys System Extended Architecture Smoke Control System Wiring Technical Bulletin (LIT-1201753). Verify that copper cable connected to media converters does not leave the room in which the media converter is installed. Verify that all RJ45 cables are protected from electrical surges through the use of the American Power Conversion (APC) Protect Net (Model PNET1) surge protector at each end of the RJ45 cable. Verify that only the Smoke Control NAE, MS-NAE5510-0U, is used for smoke control in a UUKL smoke control system. If an RS-485-to-RS485 repeater is used to isolate UUKL from non-UUKL devices on an N2 Bus, verify that it is installed in a UL-Listed enclosure. Verify that the power-limited and non-power limited wiring from the repeater is seperated. Refer to the Metasys System Extended Architecture Smoke Control System Wiring Technical Bulletin (LIT-1201753). The transzorb must be a Johnson Controls Code No. SMOKE-TRNKIT-1. Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist 9 Controls Group 507 E. Michigan Street Milwaukee, WI 53202 10 Metasys® is a registered trademark of Johnson Controls, Inc. All other marks herein are the marks of their respective owners. © 2005 Johnson Controls, Inc. Metasys® System Extended Architecture Smoke Control UL 864 UUKL Compliance Checklist Published in U.S.A. www.johnsoncontrols.com