Document

advertisement

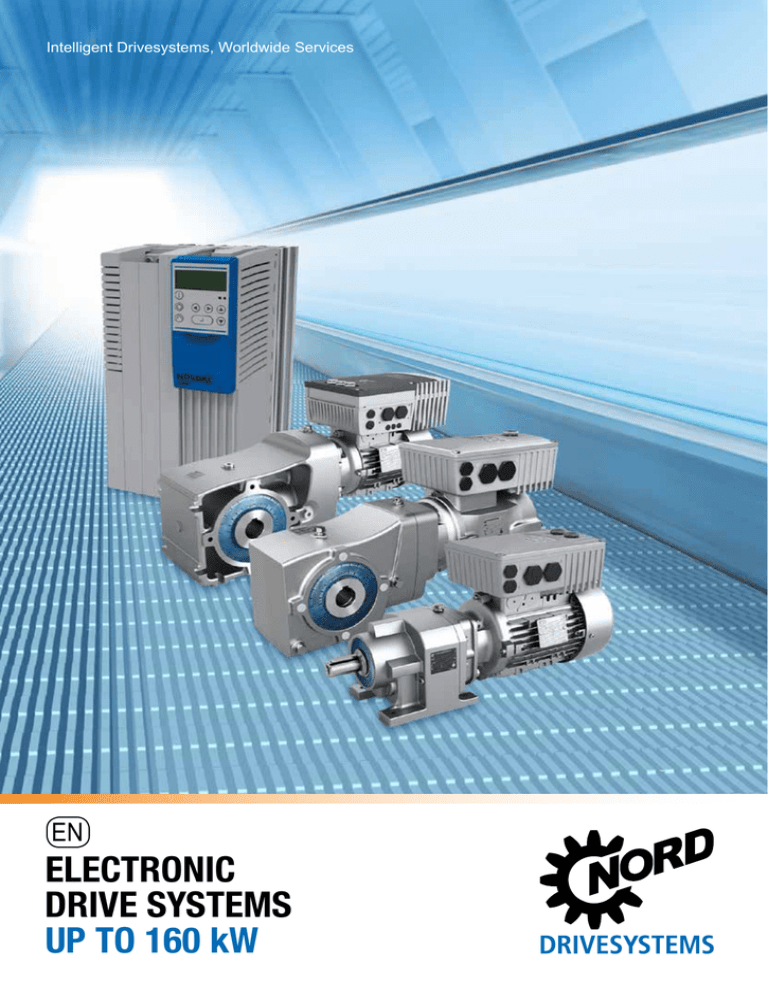

IntelligentDrivesystems, Drivesystems,Worldwide WorldwideServices Services Intelligent ALUMINIUM GEAR UNITS WITH SMOOTH MOTORS 0.37 – 1.1 kW EN ELECTRONIC DRIVE SYSTEMS UP TO 160 kW NORD DRIVESYSTEMS Group Headquarters and Technology Centre near Hamburg Innovative drive solutions for more than 100 industrial sectors Mechanical products Electrical products Electronic products Gear units Motors Frequency inverters and motor starters Gear unit production Motor production Inverter production 7 production locations with cutting edge technology producing gear units, motors, inverters etc. for complete drive solutions from a single source Subsidiaries in 36 countries on 5 continents provide local component stocks, assembly centres, technical support and customer service. More than 3,200 employees throughout the world create customised solutions 2 Electronic drive technology up to 160 kW NORD ELECTRONIC DRIVESYSTEMS, Aurich NORD ELECTRONIC DRIVESYSTEMS has developed and produced electronic drive technologies at its factory in Aurich since 1984. With our extensive know-how and large production capacity, we offer our customers optimum quality and short delivery times for frequency inverters and motor starters as part of a comprehensive modular range of drive components. www.nord.com 3 WHY DRIVE SOLUTIONS FROM NORD DRIVESYSTEMS ARE YOUR BEST CHOICE For more than 50 years we have provided our customers with extensive advice and planning security for the planning and implementation of standardised or customised drive solutions with electronic drive technology. n NORD provides everything from a single source. All components such as gear units, motors and drive electronics are optimally matched. n NORD provides competent local support throughout the world for the planning, design an integration of suitable drive technology. n NORD supplies pre-assembled drive systems which are simple and easy to install and maintain. n Satisfied customers from all over the world give you confidence in your decision for NORD. VERSATILE SK 500E CONTROL CABINET INVERTERS up to 160 kW FLEXIBLE SK 200E DECENTRALISED FREQUENCY INVERTERS up to 22 kW LOW COST SK 180E DECENTRALISED FREQUENCY INVERTERS up to 2.2 kW ECONOMICAL SK 135E MOTOR STARTERS up to 7.5 kW 4 Electronic drive technology up to 160 kW www.nord.com 5 VERSATILE SK 500E: CONTROL CABINET INVERTERS n Power range up to 160 kW n Protection class IP20 Process engineering Lifting equipment and cranes Material Handling Warehousing n Control cabinet installation n Alternative cooling concepts DRIVE SYSTEMS FOR ALL MOVEMENT APPLICATIONS 6 n High precision regulation with current vector control n Open or closed loop operation n 4-quadrant operation n Functional safety e.g. STO and SS1 n Integrated positioning and synchronisation mode (POSICON) Electronic drive technology up to 160 kW FLEXIBLE SK 200E: DECENTRALISED FREQUENCY INVERTERS Pumps / Fans Parcel distribution ATEX compliant Process engineering Baggage handling technology n Power range up to 22 kW n Protection class IP55, IP66 n Wall-mounted or motor-integrated n Brake rectifier n Plug-in EEPROM for easy parameter transfer n PLC functionality for functions close to the drive unit n Programming according to IEC 61131-3 n Scalable functions with simple parameterisation n Large overload reserve n Internal brake rectifier for motor brake control Ether ETHERNET ® www.nord.com POWERLINK 7 LOW COST SK 180E: DECENTRALISED FREQUENCY INVERTERS Material Handling Beverage industry Pumps / Fans Mechanical engineering ATEX compliant n Power range up to 2.2 kW n Protection class IP55, IP66, IP69K n Wall-mounted or motor-integrated n Leakage current <16mA for FI circuit breaker installation LOW COST VARIABLE SPEED DRIVE UNIT n High precision current vector control n Fulfil the maximum EMC requirements of EN n Energy-saving function for partial load operation n PLC functionality for functions close to the drive unit Ether 8 Electronic drive technology up to 160 kW ETHERNET ® POWERLINK ECONOMICAL SK 135E: MOTOR STARTERS Material Handling Belt conveyors ATEX compliant Agitators Roller conveyors n Power range up to 7.5 kW n Protection class IP55, IP66, IP69K n Wall-mounted or motor-integrated n Brake rectifier LOW COST FIXED SPEED DRIVE UNIT n Wear-free fully electronic starting with reversing function n Rapid commissioning via potentiometers n Internal brake rectifier for motor brake control n Internal motor protection www.nord.com 9 ELECTRONIC DRIVE TECHNOLOGY FOR EVERY APPLICATION Food and Beverage Requirements: n Corrosion resistant and suitable for the food industry n Easy to clean n Harsh Baggage handling Airports ambient conditions Requirements: n Simple commissioning n Maintenance-friendly n Few Intralogistics Parcel distributioncentres versions Requirements: n Direct integration of drive components into conveyor belts n Simple integration into existing largescale distribution centres n High Theatre technology availability if servicing is required Requirements: n Quiet noise drive system without external n Smooth, slow lifting of stage sets n Compliance with extensive safety regulations and legal requirements 10 Electronic drive technology up to 160 kW NORD application solution: n "nsd tupH" the unique NORD surface treatment system (complies with FDA Title 21 CFR 175.300) n Smooth surfaces (motor, gear unit and frequency inverter) simplify continuous cleaning processes n The entire drive solution is suitable for the extended temperature range (-25° C to +50° C) NORD application solution: n Complete pre-assembled and tested drive systems n Plug connectors instead of fixed wiring facilitate commissioning and maintenance n Many applications can be standardised with logistic drive units. NORD application solution: n Decentralised inverters n Simple drive technology with wall-mounted frequency wiring with Powerbus and communication bus n Plug-in EEPROM for easy parameter transfer for drive unit replacement NORD application solution: n Quiet operation with frequency inverters with high pulse frequencies and noise-reduced brakes n Closed circuit speed control for high precision speed regulation. n Integrated safety technology for safe control of movement and mechanical double brake www.nord.com 11 ELECTRONIC DRIVE TECHNOLOGY FOR EVERY APPLICATION Lifting equipment Construction hoists Requirements: n Compact lifting systems for mobile use n Sequence and positioning control in the elevator cab n Facilities for safe start (load take-up) and long downward movement Warehousing Requirements: n Rapid access to shelf areas n Operation of several aisles with a single shelf control device n Energy-efficient Material handling in the cement industry operation Requirements: n Positioning n Harsh in the loading area ambient conditions n Detection and elimination of mechanical blockages Pump operation Requirements: n Metering n Continuous n 12 flow Installation in existing concepts Electronic drive technology up to 160 kW NORD application solution: n Compact frequency inverters for control cabinet installation n Implementation integrated PLC of positioning control with POSICON and n Safe overload reserve and powerful brake chopper and integrated brake management. NORD application solution: n Dynamic n Curve movement and precise positioning movement facility with torque control n Integrated energy management. NORD application solution: n High precision positioning with POSICON and encoder feedback n Tried and tested drive technology for a wide temperature range n The PLC, which is integrated in the frequency inverter, can detect and eliminate blockages with reversing operation. NORD application solution: n Integrated positioning n Closed n Bus circuit control and PI process controller communication and sensors www.nord.com 13 NORD DRIVESYSTEMS DRIVES WITH INTEGRATED PLC Thanks to integration of a PLC into the frequency inverter: n Application-specific special functions close to the drive unit can be efficiently programmed and parameterised in the same way as all other frequency inverter functions. n The integrated PLC converts the combination of a NORD frequency inverter and a motor-gear unit combination into a complete system solution. Use of manufacturer-independent "PLCopen Motion Control" function blocks reduces complexity and therefore reduces application development costs. n The NORD system solution is extended with functions for IEC 61131-3 programming (Structured Text and Instruction List) by use of the NORD CON software tool. Direct access to the parameters as well as the analogue and digital inputs and outputs of the frequency inverter, for example for pre-processing of signals is possible. n Complete implementation of sequence and movement control, for example positioning applications are possible without the use of a central control unit. NORD DRIVE SOLUTIONS WITH INTEGRATED PLC ARE INDUSTRY 4.0 READY "NORD 4.0 READY" means that NORD drive units are networked, autonomous and scalable. The key to this is the frequency inverter with its powerful processors and comprehensive equipment, interfaces and functions. These not only monitor themselves and the motor, but also their effect on the load situation within the plant segments and beyond. Sensors / Process data Actuators 14 Electronic drive technology up to 160 kW NORD CON SOFTWARE TOOL NORD CON is a software tool for: n Parameterisation n Programming n Diagnosis n Control This tool enables the offline production and testing of PLC programs independently from the inverter. NORD CON is available for all SK 500E series inverters (control cabinet technology), as well as SK 180E and SK 200E series inverters (decentralised technology). NORD CON PLC Editor and Oscilloscope function PRE-ASSEMBLED DRIVE SYSTEMS Application-specific plug connections and control elements, e.g. for commissioning and service mode. Application example: Transfer unit with movement control and pre-processing of sensor signals for the field bus connection with integrated PLC www.nord.com 15 NORD DRIVESYSTEMS Group Headquarters and technology centre in Bargteheide, near Hamburg Innovative drive solutions for more than 100 branches of industry Mechanical products Parallel, helical in-line, right angle bevel and worm gear drives Electrical products IE2/IE3/IE4 motors Electronic products Centralised and decentralised frequency inverters, motor starters 7 production locations with cutting edge technology for all drive components Subsidiaries in 36 countries on 5 continents provide local stocks, assembly centres, technical support and customer service More than 3,200 employees throughout the world create customised solutions. www.nord.com/locator Getriebebau NORD GmbH & Co. KG Getriebebau-Nord-Straße 1 22941 Bargteheide, Germany T +49 (0) 4532 / 289 - 0 F +49 (0) 4532 / 289 - 22 53 info@nord.com, www.nord.com Member of the NORD DRIVESYSTEMS Group S5300 Part No. 6091302 / 0916 Headquarters: