CORY March 4, 1999 Mr. Peter Cooke Chair, Executive Board

advertisement

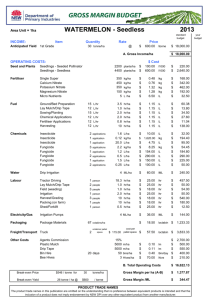

CORY POTASH CORPORATION OF SASKATCHEWAN INC. P.O. BOX 1320, SASKATOON. PHONE: (306) 382-0525 FAX: (306) 384-9132 SK, CANADA S7K 3N9 March 4, 1999 Mr. Peter Cooke Chair, Executive Board Canadian industry Program for Energy Conservation 75 Jntemational Boulevard Suite 400 Toronto, Ontario M9W 6L9 Dear Mr. Cooke: As part of our corporate undertaking to become an Industrial Energy Innovator, PCS Potash, Cory Division is submitting its energy conservation Annual Report for 1998 and Action Plan for 1999. These reports will indicate our energy reduction performance for 1998, and provide a brief description of significant energy conservation projects planned for 1999. Yours sincerely, D. :Matthews Chief Metallurgist PCS Potash, Cory Division C.C. M. Davyduke R. Bubnick M. Woolley, PCS Technical Services PCS Potash POTASH CORPORATION CANADIAN Industrial INDUSTRY Energy 1998 Annual CORY OF SASKATCHEWAN INC. P.O. BOX 1320, SASKATOON, PHONE: (306) 382-0525 FAX: (306) 384-9132 PROGRAM Innovators FOR ENERGY SK, CANADA CONSERVATION S7K 3N9 (CIPEC) Program Report PCS Potash, Cory Division is submitting our 1998 energy use and emissions data as a continuing step in our formalized energy efficiency target or goal-setting and review process. The annual energy use and emission data from 199 1 up to the end of 1998 have been included as well to indicate our division’s past performance. In addition, all projects pertaining to energy conservation in 1998 are described briefly. Where possible, energy savings and emissions reductions incurred by these projects are estimated. LBac;eline Year The baseline year selected for our division is 1991. Table 1 shows the annual electrical and natural gas energy use data per tonne of product from the baseline year to the end of 1998. This table also shows the estimated greenhouse gas emissions for our division during the same years. These emission estimates are based on emission factors for combustion and process sources provided by Environment Canada. The average concentration ratio for our process has been included in this table as well (Note: concentration ratio = tonnes of ore / tonnes of final product). - Natural Gas m3/t kg SOJ product kg NO$ tonne product tonne 223.5 105.1 372.2 412132 199.0 92.1 2.95 457905 188.5 1994 3.04 466242 1995 3.22 1996 Concentration Ratio Product Tonnes 1991 2.95 318020 1992 2.96 1993 Year Electrical kWh/t kg COJ tonne VOCI product tonne product .23 1 2.868 .00455 328.7 .202 2.554 .00399 92.5 321.0 .203 2.419 .00401 184.6 96.8 325.7 .212 2.369 .00419 530196 167.6 98.5 315.3 .216 - 2.151 3.22 625477 160.9 97.8 308.6 .215 2.065 .00423 1997 3.07 625498 157.1 94.5 299.6 .207 2.017 .00410 1998 3.23 676329 151.6 95.6 297.1 .209 1.946 .00414- - kg 1998 Enerw Conservation iO427 Performance The overall energy use at PCS Potash, Gory Division in 1998 was 5.5 kWh/t lower for electrical consumption and 1.1 m3 /t higher for natural gas. This is a 3.50% reduction in electrical consumption and a 1.16% increase in natural gas use. The net result is a reduction of 0.8% in greenhouse gas emissions per unit of production. The actual performance exceeded our target of a 0.5% reduction in energy consumption for 1998. 1998 Enerw Conservation Proiects In this section, the energy conservation projects that have been undertaken at our division in 1998 are briefly described. Where possible, estimates of the energy savings and emissions reductions for each particular project are shown. Two of the projects that had originally been planned for 1998 had to be delayed due to higher priority items that came up during the year. The delayed projects were: 1) Refined Circuit Heat Exchanger 2) Slimes Thickener Replacement These projects were started in 1998 but will not be completed until 1999. 4 Modify Crushing Circuit The mill feed crushing circuit was modified to eliminate two pumps (200 HP and 300 HP), an impactor (200 HP) and the rod mill (500 HP). This equipment was replaced with one large crusher (500 HP). This will result in a net savings of 700 HP. In addition, the circuit changes will also improve heat recovery resulting in a saving of 3 Giga.loules/hour. The average natural gas savings per tonne of product amounts to 0.4 m3/tonne and 1.8 kWh/tonne. The estimated reduction in annual emissions per tonne of product amounts to 0.011 kg SOJtonne and 1.0 kg COz/tomre for the five months that the new circuit was in operation. B) Refinery Lighting Incandescent lighting in the refinery was replaced with higher efficiency and better illuminating metal halide light fixtures. In 1998, 200 incandescent fixtures were removed and replaced with 50 metal halide fixtures. The incandescent light fixtures removed were 200 Watts and the metal halide fixtures used to replace them were 175,250, or 400 Watts. The amount of energy conserved in 1998 is calculated based on 200 incandescent 200 Watt fixtures being replaced with 50 metal halide 275 Watt light fixtures. The estimated annual energy saved for 1998 per tonne of product is approximately 0.13 kWh/torme. The estimated reduction in annual emissions per tonne of product amounts to 1.7 x 1Om3 kg SOz/tonne and 0.11 kg COJtonne. Cl Install A New Boiler A new steam boiler was installed to provide additional heating for increased production. The new boiler is a more efficient design than the existing boilers and will increase energy efficiency. The new boiler was just started up at the end of the year so most of the impact of this project will be noticed in 1999. D) Replace 50 Ton Air Conditioning Unit - The mill control room, labs, and motor control centers are cooled by a large air conditioner. The existing unit was old and in poor condition. A new 50 ton air conditioner was installed that is of a more efficient design and will reduce energy consumption. The average electrical savings per tonne of product amounts to 0.1 kWh/tomre. The estimated reduction in annual emissions per tonne of product amounts to 0.001 kg S02/tonne and 0.6 kg C02/tomre. El Communications Articles promoting energy conservation, and describing our performance in the Industrial Energy Innovators program, were included in the newsletters sent out from the Cory division. Summary This report has been submitted as a continuing part of PCS Cory Division’s goal setting and review process. The baseline year data is used as a reference against which energy use is measured. Further to this report, an Action Plan for 1999 outlining targets for the year will be submitted, as well as the long and short term energy conservation measures proposed. POTASH CORPORATION CANADIAN Action OF SASKATCHEWAN INC. P.O. BOX 1320, SASKATOON, PHONE: (306) 382-0525 FAX: (306) 384-9132 INDUSTRY PROGRAM FOR ENERGY SK, CANADA S7K 3N9 CONSERVATION Plan for 1999 PCS Inc., Cory Division is submitting our energy conservation Action Plan for 1999. This report also includes our 12 month energy use reduction goals and estimates of the energy sayings associated with the various actions that are being proposed. .. Enerey Reduction Goals For the 12 month reporting period of 1999, our goal for reduction in electrical energy use is 0.5% of 1998 electrical usage in kWh/tonne of product, and our natural gas energy reduction goal is 0.5% of the natural gas consumption in 1998 in m3/torme of product. The following table provides a summary of the energy reduction results starting from the baseline year of 199 1. kg SO2 /tonne kg VOC /tonne product product 2.868 0.0046 2.554 0.0040 2.419 0.0040 2.369 0.0042 2.151 0.0043 2.065 0.0042 1997 157.1 70.3% 94.5 89.9% 299.6 0.207 2.017 0.0041 1998 151.6 67.8% 95.6 91.0% 297.1 0.209 1.946 0.004 1 Please note that our natural gas consumption per tonne of product increased in 1994 and 1995 due to changes in product mix. We have significantly increased our production of Granular products and these products have to be dried a second time after being compacted which results in an extra 8 m3/tonne of natural gas per tonne of product. Specific Enerw Actions for 1999 The energy conservation projects that are scheduled for this year are listed in this section of the report. The types of projects for this section may include improved maintenance or operating practices, energy metering and tracking of energy costs, investment in new technology, and replacement of inefficient equipment. Specific policy, learning, communications, or promotion related activities are included in this section as well. The first two projects listed are carried over from last year as they were not completed before the end of 1998, but will be completed and operational by April 1999. 4 Refined Circuit Heat Exchanger The Refmed leaching circuit is currently heated by the addition of live steam to the leach tanks. The use of live steam for heating this circuit results in a loss of condensate from the boilers. Installation of a shell and tube heat exchanger will return condensate to the boiler room which reduces the requirement for addition of cold makeup water to the boiler feed and improves boiler efficiency. This project will reduce the Refmed circuit heat load by 3 GigaJoules/hour resulting in an overall saving of 0.4 m3 natural gas per tonne of product. (Note: This project was started in 1998 and will be completed and on-line by April 1999.) The estimated reduction in annual emissions per tonne of product will be 4 x 10’ kg SOJtonne and 0.7 kg COz/tomre. B) Slimes Thickener Replacement The existing Slimes thickener will be removed and replaced with a smaller more efficient unit. The new thickener will have less surface area to minimize radiant heat loss, and will be better insulated. This project will reduce the Soluble circuit heat load by 7 GigaJoules/hour, resulting in an overall saving of 1.2 m3 natural gas per tonne of product. (Note: This project was started in 1998 and will be completed and on-line by April 1999.) The estimated reduction in annual emissions per tonne of product will be 1.1 x 1Oq5 kg SOJtonne and 2.2 kg C02/tonne. Cl Crystallizer Particle Size Enhancement The growth rate of crystals and crystal size distribution have a direct impact on the amount of usable production that can be achieved from a crystallizer circuit In order to increase production and improve recovery the crystallizers are being modified to produce larger crystals and increase efficiency. These modifications will result in more product from the same amount of energy input. The average savings per tonne of product amounts to 0.5 m3/tonne natural gas and 0.7 kWb/tonne electrical. The estimated reduction in annual emissions per tonne of product amounts to 0.9 x los2 kg S02/tonne and 1.5 kg COz/tonne. W Refinery Lighting Incandescent lighting in the refinery is being replaced with higher efficiency and better illuminating metal halide light fixtures. In 1999,200 incandescent fixtures will be removed and replaced with 50 metal halide fixtures. The incandescent light fixtures removed are 200 Watts and the metal halide fixtures used to replace them will be 175,250, or 400 Watts. The amount of energy conserved in 1999 is calculated based on 200 incandescent 200 Watt fixtures being replaced with 50 metal halide 275 Watt light fixtures. The estimated annual energy saved for 1999 per tonne of product is approximately 0.13 kWh/tonne. The estimated reduction in annual emissions per tonne of product amounts to 1.7 x low3kg S02/tonne and 0.11 kg COJtonue. El Communications Articles promoting energy conservation, and describing our performance in the Industrial Energy Innovators program, will be included in the newsletters sent out from the Cory division. -Summary This Action Plan has been presented as an intermediate step in our goal setting and review process. As indicated in the Action Plan requirements, we have stated our specific 1999 energy reduction goals, and listed specific energy efficiency actions for the year. At the end of 1999 we will submit our Annual Report to CIPEC to review our performance, and present our Action Plan for 2000.