IEEE Transactions on Energy Conversion, Vol. 5, No.1, March 1990

advertisement

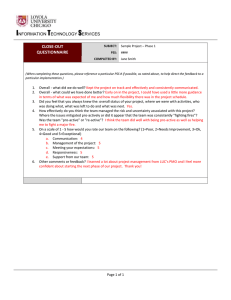

Transactions on Energy Conversion, Vol. 5, No.1, March 1990 IEEE 23 IMPROVED PGIER R.J. Fleming SMIEEE SYSTEM STABILIZERS M. M. Gupta SMIEEE Jun Sun Non-member Power Systems Research Group University of Saskatchewan This paper proposes three novel Abstract approaches to improve a conventional power system stabilizer (PSS) in a single machine to infinite bus system. These improved stabilizers use the conventional PSS in the usual manner plus modification of the terminal voltage feedback signal to the excitation system as a function of the accelerating power on the unit. This nonlinear action increases the power system stability greatly. Also, since these improved stabilizers are based on the conventional stabilizers they are simple to implement. X' d d-axis transient reactance of machine X' q q-axis transient reactance of machine T ' do d-axis transient open circuit time constant General s Laplace operator over a letter indicates derivative Keywords - Power system stabilizer (PSS), improved PSS, accelerating power, power system stability. 1 INTRODUCTION A single machine to infinite bus system is shown in Figure 1.1. NOMENCLATURE (p.u., except as indicated) System V ariables o torque angle (degree) W rotor speed (rad./sec. ) Fig. 1.1 field voltage accelerating power are: electrical power A single machine to infinite bus system The swing equations of this system in Figure 1.1 Ii= w (1) mechanical power (2) infinite bus voltage V reference input voltage ref V s stabilizer output V terminal voltage t R System Parameters D damping coefficient H inertia constant of the machine (secs. ) K A gain of excitation system T A time constant of excitation system r 9+jX £ transmission line impedance d-axis synchronous reactance of machine q-axis synchronous reactance of machine 89 SM 633-9 Ee A paper recommended and approved by the IEEE Energy Development and Committee of Long Beach, the IEEE/PES California, submitted January 27, June 21, Power Generation the IEEE Power Engineering presentation at 1989. July 1989; When the mechanical power P is not in equilibrium m W with the electric power P (o) and damping power e o during and following disturbances, the rotor speed w suffers electromechanical oscillations. The oscilla­ tions of concern to stability are in the 0.2 to 2.5 Hz frequency range [3]. usually, the damping coefficient D is small and these oscillations are strong and lightly damped. This causes the rise of periodic variations in electrical quantities and, possibly, the initiation of torsional shaft oscillations in a multistage turbo-generator unit. The most extreme result is dynamic instability due to negative damping. Even in stable situations, insufficient damping of these oscillations limits the ability to transmit power out of the plant [2,41. Society for 1989 Summer Meeting, 9 - 14, 1989. 'bnuscript made available for printing A proper stabilizing signal derived from the speed control loop and introduced into the excitation system can increase the damping torque of the machine at these oscillation frequencies; therefore, consider­ able attention and efforts have been directed toward using the excitation control systems to improve power system stability. Three novel approaches to improve conventional Based on the stabilizers are proposed in this paper. conventional stabilizer, these improved stabilizers introduce an auxiliary stabilizing signal, (6P ) , a which is a function of accelerating power into the terminal voltage feedback loop and make this feedback nonlinear. These improved stabilizers increase the power system stability greatly, while they are simple to implement. 0885-8969/90/0300-0023$01.00 © 1990 IEEE 24 COOVENTIONlIL STABILIZER 2 Limiter Figme 2.1 is a block diagram of a conventional It application. (PSS) stabilizer system power includes an output amplitude limited static exciter and an output limited stabilizer (PSS) with a transfer function G(s) • Vt + Vs r I I I Limiter __ - - - - ------, PSS improved � I I i---:----w E f 1----1--- I r----'--- �a=[Pe-Pm) 1---- stabilizing signal Limiter PSS 2.1 Fig. Block diagram of a PSS example system to which the applied as are Figure 2.1. The da.ta for the controllers shown in follows. Base MVA D = Xd x�, = 100 MVA, Xd 8.0 (p.u.), H Xq = 0.136 (p.u.), r P (MW) o 90.00 q 4.30 (secs.) 1.164 (p.u.) = 0.146 (p.u.), T d The operating Table I. Table I. = X � = = Fig. 3. � point � of ; = machine is in shown The Operating point of the machine Q o (MVAR) V 00 (p.u.) to 1.05 37.62 terminal voltage force the to chosen be should feedback 50 that the field voltage � will go down to f make electrical power go down to balance mechanical When � power as soon as possible. K(� ) < 0, a a should be negative to reduce the terminal voltage feedback in order to increase electrical power as soon as possible. According to the above principle, K(AP ) has been a PSS(A), chosen in three ways to improve performance: PSS(B), and PSS(C) respectively. 3.84 (secs.) 0.009 (p.u.) the Block diagram of improved stabilizer (deg.) 4 0.73 3.1 Stabilizer PSS(A) in Figure 3.1.1 shows K as a function of AP a graphical form. In this case, K switches between positive and negative values according to the sign of The effect is somewhat similar to bang-bang AP a' A small dead zone bound can be considered control. - 0, as indicated by the dashed lines in around AP a Figure 3.1.1. The key point of designing a PSS is to determine the best transfer function G(s) to provide the damping By using rotor speed 00 as a stabilizing needed. signal and using the phase compensation method [5] of design, G(s) for the machine was obtained as shown in K 0.0035 (3) • G(s) 4 s (1 + 4 s) x 0.15 (S (1 2 + + 9.88 S + 97.56) 0.05 s) 2 3 IMPROVED STABILIZER improved the between difference only The stabilizer and the basic stabilizer is that the stabilizing signal �P is introduced into the terminal a voltage feedback loop, where � is the difference a between electrical power and mechanical power and can Figure 3 is the block be measured approximately [6]. diagram of the improved stabilizer where the feedback from terminal voltage V is a function of � ' a t Because K(�P ) is a function of � ' the terminal a a voltage feedback becomes nonlinear feedback. The principle of designing K(� ) is as follows: a > P ' positive K(� ) > 0, this means P � a a e m When I 10.001 , (3) The first term in (3) is a reset term that is used to "wash out" the compensation effect with a time constant of 4 secs. The second term is a lead compensation pair that can be used to compensate the system phase lag [1,3]. IT,----­ />'P 0.0035 Fig. 3.1. 1 a K(/>,P ) for improved PSS(A) a Nonlinear computer simulations were carried out for both small and large disturbances to study the A 10 MW mechanical power performance of this system. step change and a 0.02 p.u. voltage reference step change are considered as small disturbances and a three-phase short circuit of 0.1 secs. duration on the infinite bus as a large disturbance. the program, simulation nonlinear the In resistances of the system components were included, saturation was represented in both axes as a function of the total air gap flux for a round rotor machine, one damping winding in the q-axis was included, and included representation machine rotor round the transient saliency. Figures 3.1.2, 3.1.3 and 3.1.4 are the responses comparing the improved PSS(A) with the conventional PSS and no PSS (only terminal voltage feedback) for disturbances large and small of cases the respectively. 25 The maximum overshoot Mp and settling time Ts (for boun d) of rotor speed i n the case of a 10 MW mec hanical power step change are listed in Table II. 1% Rotor Speed OVershoot and Settling Time Table II. ROTOR SPEED Ul OVershoot Settling time Ts (sees.) Mp (p.u.) EXCITATION CONTROL No PSS 0.3280 0.2239 0.2064 PSS Improved PSS(A) 3.3 Improved PSS(C) Figure 3.3.1 f unc ti on K (6P ) a slope The osci ll ati on frequency without the PSS is about The improved PSS(A) damps t he oscillation Hz. much more than the PSS. O.0035 for an overshoot the decreases PSS(A) imp ro ved This means that somewhat further than the PSS. the improved PSS(A) is not so sensitive to large power disturbances. This can also be shown in the responses of large di stur ban ce s . 3. However, the settl ing time decreases from 1.350 (sees.) to 0.525 (sees.). This indica tes that the improved PSS(A) is quite effective for small power disturbances. Improved PSS(B) Figure 3.2.1 shows K as a linear function of aP . a K 0.15 -:l---- lip a -----"V"+ ::::.� -:: O OO O. 15 � " lIP a �l�----:O�.�OO I ----------� The 2. slope the by 2.1 3.2 is improved PSS(C) whic h is the combi nation of improved PSS(A) when liP is small and improve d PSS(B) when aP a a is large. 2.525 1.350 0.525 can be obtained The fo ll owing conclusions comparing the improved PSS(A) with the basic PSS. 1. From these results, it is found that the improved PSS(B) decreases overshoot significantly, however, the settling time is almost the same as f or the PSS. This me an s the improved PSS(B) is effective for large power power small to sensitive not but disturbances the of combination a Therefore, disturban ce s. advantages of PSS(A) and PSS(B), giving PSS(C) is developed below. 1-0.0035 Fig. 3.3.1 K(llP ) for impr oved PSS(C) a It can be predicted that the improved PSS(C) must be effective for lar ge as well as small power distur­ ban ces and it must decrease both the overshoot as well as the set tl in g time. These advantages are cl early shown in Figures 3.3.2, 3.3.3 and 3.3.4 and Table IV. Table IV is given to compare maximum overshoot and settling time (for 1% bound) of rotor speed Ul in the Also, case of a 10 MW mechanical power step c ha nge. it is found that the improved PSS(C) does not have a significan t effect on the static deviation of terminal voltage in the case of step change. Table IV. Rotor Speed Overshoot an d Set tling Time ROTOR SPEED Ul Fig. 3.2.1 K(llP ) for improved PSS(B) a The dashed line in Fig. 3.2.1 represents the small By using this function of = O. a K, i t is clear that the larger absolute values of llP a w ill have more effect on terminal voltage feedback, therefore, improved PSS(B) must have more effect on large disturbances. error bound around llP Figures 3.2.2, 3.2.3 and 3.2.4 are the responses comparing the improved PSS(B) with the PSS in the cases of small and large disturbances respecti vel y. Table is III given to compare maximum overshoot and settling time (for 1% bound) of rotor speed the case of 10 MW me chani cal power step change. Table III. w in Rotor Speed OVershoot and Settling Time ROTOR SPEED Ul OVershoot EXCITATION CONTROL PSS Improved PSS(B) Mp (p .u . ) 0.2239 0.1665 Overshoot Mp (p.u.) EXCITATION CONTROL PSS 0.2239 0.1664 Improved PSS(C) 4 Settling time Ts (secs.) 1.350 0.600 CONCLUSIONS From the simulation results, it is concluded that these three kinds of improved stabilizers can improve power system stability much more than the conventional PSS which has been used widely in power systems since While the impro ve d PSS is based on the 1970's. conventional PSS and only a llP stabilizing signal i s a introduced into the terminal voltage feedback loop, i t Comparing is simple to imple men t the improved PSS. the three kinds of improved stabilizers, the improved PSS(C) is the best one since it is e f fec tive for both small and large dist urb ance s, and is also effective to improve both overshoot and settling time of rotor speed deviations. Settling time Ts (sec s. ) 1.350 1.225 ------ ---- ------ -- 26 0.35 .-:- 0.10 � � .,; .,g, 0.15 g 0 0' --: 0.10 ." : � 0.00 o f: 0 25 020 0.05 , 1.5 1.062 '3' 2 2.5 3 time (sees. ) 35 • .. 5 S' ri. 0> c 10.8 (I 0. 5 � � $! :: ..,9; " .2 "0 > g 1.5 2 2.5 3 time (sees . ) 3.5 .. ..5 1.0415 5 MW +--H:±W�""_----­ -0.1 -03 0.' 05 1.S 2 2.5 3 time (sees. ) 3.5 .. ".S -0. 1.065 .! ... . 5 5 time (sees.) 1 -0.1 "U % � -0.2 eo -O.l I 0.5 o 1.5 r 2 I 2.5 , 3 3.5 time (secs.) 1 . 07 L065 g J 05 1 1.5 1 2'S �3�5 time (secs.) Fig. 3.2. .3 Responses for the ca se of 0.02 p voltage reference step cha ng e 2.50 1 ) 3.5 4.5 .. 5 1.0'� 1.050 5 ./5 2 t ime (s ecs. 1.070 � a I.� 5 1.060 .,g u o I o.!) 1.'s. � 2:5 .3 t ime (s ee s. ) Fig. .3.3.3 Responses fo r ' .5 5 the case of 0.02 vol ta ge reference step change 30 -0 ...?.. 0.0+++'9____________ ." II . -1.0 p e - - +0 -'0'. , -', � 1.0 � " 0.9 g "0 � O.G 0.5 I 2.5 i 5i ,VS time (sees.) rig. 3.1.4 Respons es for the cose of 0 th ree phase shod circuit of 0.1 (sec . 1.5 liS duration on infinite bus PSS(A) PSS no PSS ) � 2iS i time (sees. ) ., '" I 2 1 , .2 -: o o.s (sees. ) 1.0 3'5 _ 0. T7s-2.-�2r:s-;,-4., �� 5 .-.';_; � time (sees. ) :;- 1.0 3o.g . 0> .£ 0.8 � 0.7 0.6 O.s. 4'5 0.15 c . -1.0 -2. 0 0 -3. e -30 --,'-; -,'-�,r.5--�' --'3��5 -'--":5--' time � -!'!. .,; 1. o.o+++'9r--g- -2.0 o 0.5 � o.o +-�--==_--- 2.0 - 3.0 o time (secs.) 0.' u � g :- - 5 -, '� --,", ,r' --,r,--3,--,l:5� -,-.�- 0.2 :\ - T­ . . .... . 0 Fig. 3.3.2 Responses for the cose of 10 MW mec han i ca l power step chonge mechanical power step change 3.0· -2.0 0" 1.0.15 ..2 voltage reference step chenge � a. ';;' 0.9 t1> .2 0.8 � 0.1 c -4 1.050 1.065 time (sees.) " .� 3.5 1.052 � 1.060 1.050 -1.0 "0 3 lOSe. "0 , 45 g. o.o+++b-t-�""'::"=-�--- -•. 1.0SI5 .2 C � 2iS � 3�5 1.060 -.------. � 1.0 0 2.5 5 s- .� 1.'S 1.051 +-�--.--.-,__-,-,__,___,--.__, 1.5 2 2.5 J l.S. • ..s. o 0.5 time (s ee s. ) 0 g '.0 o 2 - --.----- 3 -0.4 Fi g. 3.1.3 Responses for the case of 0.02 p.l' e .�- == ..�-� - =�- - .=-. -=.-�---=.-.= . -. ---, ,--- -----,. - .--o 0.5 1 1.5 1.075 � 0.5 -0.1.5 .E � g .� - +-..:..2�·;;--'"'-·=�-- -0.10 � " � 1. 70 (I e 5 -0.2 s- '.0 � U -0.1 � 5 1.070 1050 � time (s:ecs.) • U o.o+-"'=�=___________ :' . � L eo -0.1 11.055 "0 , 0' LOSD "0 U S 02 0.1 o.o 0.00 -0.05 Fig. 3.2.2 ResponsE's for the case of 10 �W meehanical po w er step change 1. 7 s- , 3.1.2 Responses for the cose of 10 0.' � � 2 1.052 +-�--.--.-.--,--'_-r-.-.__' rig. ; U , � ] � u 2 "0 � o 1.051 t1> 1.056 g ��==---- 1.060 ---;; 0.05 .. +--.-.--,--,----.--.,-0:--.-.-, -o 0.10 u " 1.062 1.05� l? -0.15 5 1.060 .2, . . 0.00 -0.1(1 0.5 !,:, 0.15 1* +-I'+�f=li+',,-",""''''�---- 0. 30 0.30 � � 0,25 0.20 0.35 0. 35 --:- "0 C '§ 5 � 0 rig. - 1 J'S e (sees.) 3.2.4 Re spons e s tor the case of a three phase short circuit of 0.1 (sec.) --05 ; 15 j �--� ' 2 .!l- ti m du rat ion on infinite bLoS PSS(8) PSS 0.7 0.6 0.5 0.4. o 05 ---,-- I 1 1 5 :1 I 2.5 ,�-� .3 time (s ees. ) .3 5 .. - -T ".5 rig. 3.3.4 Responses for tne case of a three phas e short circuit of durati on on inf inite bus 0.1 (se.:.) PSS(C) PSS 27 REFERENCES [1] Anderson, P.M. and Fouad, A.A., Power System Iowa State Control and Stability, Chapter 8, Un1versity Press, Ames, Iowa, 1977. [2] Fleming, R.J., "Machine Interactions Mu1timachine Generating Plants", proceedings CEA Meeting, Toronto, March 25, 1970. [3] Larsen, E.V. and Swann, D.A., "Applying Power System Stabilizers", IEEE PAS-100, No. 6, pp. 3017-3046, June 1981. [4] Watson, W. and Coultes, M.E., "Static Exciter Stabilizing Signals on Large Generators Mechanical Problems", IEEE Winter Meeting, pp. 204-211, New York, Jan. 30 - Feb. 4, 1972. [5] Li, L. , "The Application of Power System Stabilizers in a Multimachine Generating Plant", E.E., M.Sc. Thesis, Dept. of Univ. of Saskatchewan, 1986. [6] Bayne,J.P., Lee,D.C., Watson,W., "A Power System stabiliser Stabilising Signal For Thermal Units Based on Derivation Of Accelerating Power", IEEE Trans. PA5-96, Vol. 77, N, Nov;t>ec 1977, pp. in of 1777-1783. Ronald J. Fleming (SMIEEE, P.Eng.) was born in Saskatchewan, Canada, in 1930. He received his education in Saskatchewan, completing his ph.D. in 1968 in electrical engineering. He served as process instrument engineer with Atomic Energy of Canada Ltd. for two years and has been active as a consultant and research contractor in the area of electric power system control for several years. He has been on the faculty of the Department of Electrical Engineering at the University of saskatchewan since 1958, teaching and doing research in the area of power system modelinq and control. He has been participatinq in the research activities of the Power Systems Research Group and was Head of the Electrical Engineering Department from 1984 to 1988. He is currently a professor in the Electrical Engineering Department. Madan M. Gupta rec�ived the B.Eng. (Honors) in 1961, M.Sc. 1n 1962, both in electronics­ and the colllltli ll1 cations engineering, from BITS Pilani, India. He received the ph.D. degree for his studies in adaptive control systems in 1967 from the University of Warwick, U.K. From 1962 to 1964, he electrical-colllltli ll1 cations served as a engineering lecturer in at the He joined the faculty University of Roorkee, India. of the College of Engineering at the University of Saskatchewan in 1967 as a sessional lecturer, becoming a full professor in July 1978. His present research interests are in the areas on non-invasive methods in medical diagnosis, medical imaging, intelligent robotic systems, cognitive information, neural networks, and computer vision. He is co-author with A. Kaufmann, of the books Introduction to Fuzzy Arithmetic: '1heory and Applications (Van Nostrand Reinhold, 1985) and Fuzzy Mathematical Models in Engineel'ing and Jlllanagement Science (NOl'th-Holland, in press) and is the editor of the books Fuzzy Automata and Decision Processes (1977), lIdvances in Fuzzy Set 'ltteary and Applications (1979), Appl'oximate Reasoning in Decision Analysis (1982), Fuzzy Information, Knowledge Representation, and Decision Analysis (1983), Appl'oximate Reasoning in Expert Systems (1985), Fuzzy <DIpJting (1988), Fuzzy Logic in Knowledge-based Systems Decision and Control (1988), all with North-Holland, and .Adaptive Methods for Control Systems Design (IEEE Press, 1986). He is the subject editor for the Encyclopedia of Systems and Control (Pergamon Press, Oxford, 1987) and has authored or co-authored over 200 research papers. He is an advisory editor for the International Journal of Fuzzy Sets and Systems (IFSA) and other journals in the field. His recent research interest lies in the theory and design of new sensors, new devices and intelligent systems using biological and cognitive processes as a basic (for possible applications in health sciences, space exploration, manufacturing processes and robotics) . Jun Sun was born in Shanghai, China, on May 2, 1946. She graduated in electrical engineering from Tsinghua University, Beijing, China, and received the M.Sc. degree in electrical engineering from Chongqing University, Chongqing, China, and the M.Sc. degree in electrical engineering Saskatchewan, Saskatoon, 1987 respectively. from the canada, in University 1968, of 1982 and From 1968 to 1979 she was with the North-East Power Company, China, working in the Power Plant In 1982 Electrical Adjustment and Test Department. she joined the faculty of Chongqing univers�ty, Chongqing, China, and was a lecturer of electr�cal In 1985 she joined th� EI�ctr1cal engineering. of Engineering Department of the un1ve�s1ty . Saskatchewan, Saskatoon, canada, and now 1 S work1ng towards a ph.D. degree in the area of excitation control of power systems.