PXI 2354 Winter 03 E

advertisement

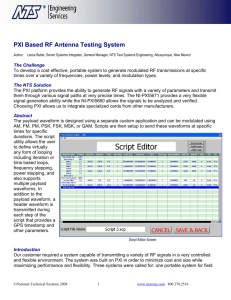

OpenSystems Publishing STANDALONE vs. MODULAR . . . BUILDING A MIXED SIGNAL TEST SYSTEM VOL. 3, NO. 3 Taking PXI into the realm of RF communications APPLICATION FEATURE: PROCESS CONTROL MACHINE MONITORING PRODUCT GUIDE: 2004 BUYER’S GUIDE W W W. P X I O N L I N E . C O M WINTER 2003 PRESORTED STANDARD U.S. POSTAGE PAID COLUMBUS, WI PERMIT NO. 73 PICTURED AEROFLEX 3000 SERIES RSC #2 @www.pxionline.com/rsc RSC #3 @www.pxionline.com/rsc t a b l e o f c o n t e n t s OpenSystems PublishingTM Vo l u m e 3 / N u m b e r FEATURES COLUMNS 7 PXISA UPDATES The president’s corner By Bob Stasonis PXI INDUSTRY REPORT ITC – Board testing revisited By Bob Stasonis 28 36 COVER PHOTO: The Aeroflex 3000 series is a PXI-based modular test suite for mobile phone and general-purpose wireless test. The series encompasses four PXI modules, the 3010 3 GHz RF synthesizer (single-slot 3U), the 3020 2.5 GHz RF signal generator (two-slot 3U), the 3030 3 GHz RF digitizer (two-slot 3U), and the 3060 2.5 GHz RF combiner (single-slot 3U). It also includes supporting applications for signal generation and signal analysis that meet the specific requirements for GSM/EDGE and UMTS/ WCDMA mobile phone testing. PXI Technology Review is published by: OpenSystems Publishing, LLC. 10 13 DEPARTMENTS PXI NEW PRODUCTS 3 / Winter 2003 OpenSystems PublishingTM pxionline www. .com 4 / PXI Technology Review / Winter 2003 SPECIAL FEATURE: Standalone vs. Modular Instrumentation bus history By Tim Carey, Aeroflex Inc. APPLICATION FEATURE: Process Control Machine Monitoring Off-the-shelf components combine to create a super solution By David Smith, Viewpoint Systems, Inc Pyrex glass press instrumentation system By Christopher D. Olson, Thomas B. Jozwiak, Gregory C. Cala, Data Science Automation, Inc. 24 31 32 INDUSTRY UPDATE: 802.11 Board Test Station Optimizing wireless measurements with the PXI platform By Wayne Larson, Larson Automation, Inc. PRODUCT FOCUS: Integrated Analog and Digital Devices Building a mixed-signal test system By Eric Starkloff, National Instruments 2004 BUYER’S GUIDE General: Accessories, Controllers, Systems, Packaging, Interfaces, Prototyping Instruments: Avionics, Interfaces, Power, Measurement, Stimulus, Switching, Other e-letters online WINTER E-LETTER Participate in a new PXI survey Read the latest industry related book review PXI is a trademark of the PXI Systems Alliance ©2003 PXI Technology Review RSC #5 @www.pxionline.com/rsc ISSN #1537-1069 Publication Agreement Number: 40048627 Canada return address: WDS, Station A, PO Box 54, Windsor, ON N9A 615 PXI Technology Review is published four times a year by OpenSystems Publishing LLC., 30233 Jefferson Ave., St. Clair Shores, MI 48082. Subscriptions are free, upon request in writing, to persons dealing with or considering PXI Technology Review. For others inside the US and Canada, subscriptions are $24/year. For 1st class delivery outside the US and Canada, subscriptions are $50/year (advance payment in US funds required). OpenSystems PublishingTM 13253 La Montana, Suite 207 Fountain Hills, AZ 85268 o f f i c e VP OF MARKETING & SALES ACCOUNT MANAGER SENIOR ACCOUNT MANAGER MARKETING REPRESENTATIVE PRINT/INTERNET MARKETING FOR REPRINTS & INSERTS Patrick Hopper (586-415-6500) phopper@opensystems-publishing.com Dennis Doyle (586-415-6500) ddoyle@opensystems-publishing.com Christine Long (586-415-6500) clong@opensystems-publishing.com An OpenSystems Publication ADVERTISING/BUSINESS OFFICE 30233 Jefferson Avenue St. Clair Shores, MI 48082 Tel.: 586-415-6500 POSTMASTER: Send address changes to PXI Technology Review s a l e s PXI Tom Varcie (586-415-6500) tvarcie@opensystems-publishing.com Andrea Stabile (586-415-6500) astabile@opensystems-publishing.com Call 586-415-6500 sales@opensystems-publishing.com SUBSCRIPTIONS: For new subscribers or to change an address, go to www.opensystems-publishing.com/subscription.html. Fax: 586-415-4882 EDITORIAL/PRODUCTION OFFICE 13253 La Montana, Suite 207 Fountain Hills, AZ 85268 Tel.: 480-967-5581 Fax: 480-837-6466 PUBLISHERS John Black, Michael Hopper, Wayne Kristoff TECHNICAL EDITOR Chad Lumsden clumsden@opensystems-publishing.com NEW PRODUCTS EDITOR Eli Shapiro newproducts@opensystems-publishing.com NEWS EDITOR news@pxionline.com VICE PRESIDENT, EDITORIAL DIGITAL AD TO COME Rosemary Kristoff rkristoff@opensystems-publishing.com SPECIAL PROJECTS EDITOR Bob Stasonis bstasonis@opensystems-publishing.com ART DIRECTOR Stephanie Sweet SENIOR WEB DESIGNER Konrad Witte WEB DESIGNER Andrew Felicetti CIRCULATION/OFFICE MANAGER Phyllis Thompson subscriptions@opensystems-publishing.com BUSINESS MANAGER Karen Layman 6 / PXI Technology Review / Winter 2003 SA Updates By Bob Stasonis T h e p r e s i d e n t ’s c o r n e r I In this column, I have written about the growth in the number of PXISA members and PXI instruments/tools, and the fervor of our members in developing new specifications for the architecture. Where are all of these instruments, chassis, and drivers going? What markets are using PXI successfully? Well, I donʼt have enough room here to talk about all areas of PXI success. So letʼs examine the market globally and then focus on one area of growth. Initially, PXI saw success in the data acquisition market. Lowto-medium-speed I/O and switching resources in a 7-slot 3U chassis was the norm. As the number of modules and chassis sizes grew, in terms of slot count and 6U instrument size, companies in other areas of test/measurement and automation saw PXIʼs usefulness and deployed it in ever-increasing numbers. In terms of greatest growth in PXI deployment, PCB functional and system-level board test is probably among the largest. PXI peripherals including high-speed digital pins, boundary scan interfaces, and high-accuracy RF products have become available in the last two years. Today, PXI is testing automotive electronics, consumer white goods, and more complex products, including cell phones. What is impressive to me is the rapid acceptance of PXI in the military and aeronautics test markets. This is a section of the electronics market that is traditionally very slow to change and for good reason. Reliability is critical. We do not need planes to fail in midair, and generals want assurances that a weapon fired harms the other side, so they tend to stick with what works. However, at last yearʼs Autotestcon, which is an IEEE testrelated conference that focuses on the mil/aero markets, I saw a fair number of companies, both large and small, either building PXI products or integrating other companiesʼ products for military and aeronautics applications. There were new companies on the trade show floor exhibiting PXI, and those who exhibited the previous year had a greater PXI catalog to show off. More importantly, sessions in the conference RSC #7 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 7 T h e p r e s i d e n t ’s c o r n e r focused on PXI, and the conference attendees asked questions and took information back to their companies and their bases. PXI was equally prominent at Autotestcon 2003. stretching stress, etc. One of these applications also uses a switching card with a TDR (Time Domain Reflectometer) for added cable diagnostics. The “tire kicking” that went on at Autotestcon in 2002 is now turning into real business. According to our members, a new trend in the military is to request newer technology to replace existing VXI-based systems. PXI is being quoted and winning some contracts. So where is PXI being deployed? In the fixed-base environment, PXI has found acceptance in the area of testing jet engines. The system is designed to interface with both engine and facility based signals to provide the technicians a complete view of their test environment while the engine is mounted in a test bed. In one example, the portable test set for the Maverick missile system is PXI-based. An extremely rugged chassis was designed, and commercial PXI cards were used to create a 70-pound portable chassis that would work in the heat of the Iraqi desert or the humidity of any jungle. This product is presently deployed in nine countries. In a very complex application, one PXISA member has deployed multiple systems for characterizing radar signals. The basic test scenario is to stimulate tracking/acquisition radar with typical “fly-by” targets, while at the same time, introduce recorded or synthesized countermeasures. The compact size of this PXI portion of the system was an important factor in its development. Another portable test system developed for the Navy tests the condition of various cables. It is implemented by utilizing a PXISA member companyʼs DMM that has the ability to measure leakage currents under variable DC voltage levels. The capacitance measurement function of this DMM also augments the leakage test with cable capacitance measurements as an indication of various faults, such as shorts, opens, Clearly, the military is seeing the value of PXI, in much the same way as the commercial markets. The rugged form factor and small size allow the architecture to easily integrate into a myriad of applications. In addition, the continued growth in the number of available instruments and chassis further assures PXISA members a chance to compete in this market. In closing, let me say that I have enjoyed leading the PXISA members over the past year as well as reporting our progress in this column. As I write this column, however, my term as president is drawing to a close. I wish the next president a healthy economy and the support and imagination of the many PXISA members. It should be a heck of a ride! Bob Stasonis was formerly a business development manager for Teradyneʼs Assembly Test Division. Throughout, the last 24 years, Bob has also held technical, sales, and marketing positions with GenRad, Schlumberger, and WK Test (formerly Wayne Kerr). He has written numerous papers and articles on the subject of electronic test. Bob is presently the vice president of marketing for the American Society of Test Engineers (ASTE), and co-chairperson for the Boston IEEE Instrumentation & Measurement Society. Bob earned his B.S.E.E. from the University of Hartford in Connecticut. Bobʼs e-mail address is stasonis@comcast.net RSC #8 @www.pxionline.com/rsc 8 / PXI Technology Review / Winter 2003 PXI Systems Alliance (PXISA) 2515 Camino Del Rio South Suite 340 San Diego, CA 92108 Tel.: 619-297-1213 Fax: 619-297-5955 E-mail: fbode@vxinl.com Web site: www.pxisa.org RSC #9 @www.pxionline.com/rsc Special Feature Standalone vs. Modular Instrumentation bus history By Tim Carey Instrumentation bus technology has evolved quite a bit throughout the past 30 years. For standalone generalpurpose instruments, the main bus technology during this time has been General Purpose Interface Bus (GPIB) and, to a lesser degree, RS-232, with more recent emergence of Ethernet, Universal Serial Bus (USB), and IEEE-1394 (Firewire). For modular instruments, the main choice has been VXI based upon an evolution of VME and PXI, an evolution of PCI and CompactPCI with PXI emerging as the front runner. In this article, Tim compares standalone and modular instruments and describes why his company ultimately chose PXI. Standalone vs. modular Because of its track record of decades of reliability and compatibility, the standalone GPIB bus has earned an unrivaled position at the top of the test and measurement world. Since its inception in 1975, there have been approximately 5-10 million instruments deployed with a GPIB interface. Anyone would be hard-pressed to find a measuring instrument for system applications that is not equipped for the GPIB bus. Due to this fact, any modifications made to this standard must be compatible with current technologies to be beneficial to GPIB users. This requires the HS488 extension proposal, which is currently presented for adoption by the American IEEE TC-8 committee, to adhere to current compatibility issues. The goal of HS488 is to ensure that new technologies are compliant with instruments that operate with both the HS488 and GPIB protocols. Modular bus technologies have evolved from VME into VXI, and more recently, from PCI into CompactPCI and now PXI. PXI was designed to bridge the gap between desktop PC systems and high-end VXI and GPIB bus systems. While standard PCs offer a very lowcost option for instrumentation systems, they fail to meet many of the needs of industrial and embedded applications. VXI and GPIB systems meet the specific needs of instrumentation users, but are often too large and expensive. While PXI extends CompactPCI, it also maintains complete interoperability so the user can deploy any CompactPCIcompliant product in a PXI system and vice versa. PXI extensions also leverage off other standard technologies, such as Windows software, VXI timing and triggering, VXIplug&play instrument drivers, and international environmental testing standards to deliver a powerful and affordable system. Modular bus technology offers many advantages over older bus standards. However, it must overcome an enormously installed worldwide base of users. Figure 1 to the right shows the instrumentation bus milestones during the last 30 years. PXI is an ideal architecture for rapid product and custom solution development. This stable architecture has become an essential requirement to remain competitive and to satisfy market needs in fast evolving communications development and manufacturing applications. Table 1 shows a comparison of standalone and modular test platforms. PXIʼs modular architecture leverages a single user interface and a common chassis that enables much higher bus speeds and lower system cost. Modular instruments donʼt need multiple power supplies, cooling, built-in controllers, or front panels. Taking PXI into the realm of RF communications As part of its strategy to provide customers with flexible and cost-effective test systems, Aeroflex has launched Standalone Speed Timing and Synchronization Product Availability Modular GPIB VXI PXI 1 Mbyte (488.2) to 8 Mbytes (HSS488) 40 Mbytes to 80 Mbytes (VME64) 132 Mbytes None Defined >10,000 >1,000 ~1,000 Form Factor Large Medium Small/Medium Standard Software Framework None VXIplug&play NO YES Modular EMI Shielding Optional Defined Module Specific System Cost High Medium-High Low-Medium Table 1 10 / PXI Technology Review / Winter 2003 Figure 1 the Aeroflex 3000 series, a PXI-based modular test suite for mobile phone and general-purpose wireless testing. This test suite is shown in Figure 2. Aeroflex has made it a high priority to market high-performance RF test capability on the PXI platform. With a long history in systems development, Aeroflex is extending its vast systems and RF experience into the PXI instrumentation market. Now, both high-performance and low-phase-noise capability are available in PXI. Aeroflex engineers designed the PXI modules to cater to the broadest possible range of mobile terminal markets, including private mobile radio, cellular, WLAN, cordless telephone, and military radio systems. The Aeroflex 3000 series encompasses four PXI modules and complementary software applications for RF signal generation and RF signal analysis. Signal analysis software applications address Figure 2 RSC #11 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 11 Special Feature Standalone vs. Modular the specific needs of GSM/EDGE and UMTS/WCDMA mobile phone testing, whereas signal generation applications additionally provide a broad range of other standards and generic system personalities. The new PXI modules include: 3 GHz RF synthesizer 2.5 GHz RF signal generator 3 GHz RF digitizer 2.5 GHz RF combiner RF performance breakthroughs for PXI Aeroflex used the digital RF synthesizer as a test bed for proving the viability of using PXI for RF instrumentation. Aeroflex based the RF synthesizer on the companyʼs patented fractional N synthesizer technology. It provides a low-noise local oscillator input to other modules. The 3010 digital RF synthesizer is an industry first for PXI. The 1.5-3.0 GHz frequency synthesizer offers low phase noise and frequency agility in a single-width 3U module. The 3020 digital RF signal generator provides modulation and waveform generation, RF leveling, and frequency tuning from 250 MHz to 2.5 GHz, with the 3010 providing the low-phase-noise LO input. In addition to the groundbreaking 3010 and 3020, Aeroflex launched the 3030, a compact RF digitizer with higher performance than any similar PXI product. The 3060 RF combiner, designed for use in RF test systems in conjunction with the 3020 RF signal generator and 3030 RF digitizer, is the first PXI module of its kind designed specifically for RF component and radio terminal system test. Aeroflex has carefully defined each module to maximize reuse for the development of future modules. Taking PXI into the realm of RF wireless testing broadens the choices for system developers, and accelerates the adoption of PXI in a major test market. Tim Carey is a senior product marketing engineer with Aeroflex Test Solutions, Stevenage, England division. Tim is responsible for PXI product management at the company. For more information, contact Aeroflex directly. Aeroflex Inc. 35 South Service Road Plainview, NY 11803-4193 Tel.: 516-694-6700 Fax: 516-694-4823 E-mail: info-test@aeroflex.com Web site: www.aeroflex.com RSC #12 @www.pxionline.com/rsc 12 / PXI Technology Review / Winter 2003 Application Feature Process Control Machine Monitoring Off-the-shelf components combine to create a super solution By David Smith An aerospace valve manufacturer was looking for a better solution for their automated long-term durability testing of valves destined for remote locations. They needed a method of presenting mixed signal stimulus to their valves so as to exercise them in a very precise and repetitive manner. Viewpoint Systems was able to provide a PXI solution that not only met, but also exceeded their needs. Introduction The aerospace valve manufacturer needed to apply a mixed signal stimulus (analog and digital) to its valves with microsecond accuracy for periods of milliseconds to minutes. An ideal solution would scale to allow control of a large number of valves at one time. This solution should be easy to set up and flexible enough to handle a variety of different valve product requirements. The solution was to combine Viewpointʼs DIO-64 event analyzer/controller board with National Instrumentsʼ analog output card and integrate them into a tightly coupled arbitrary output system. The DIO-64 provided the overall system timing and digital output functions and specifically drove the update clocks on the NI analog output card, as shown in Figure 1. Viewpoint Systems had been working with this valve manufacturing company for more than four years on a wide variety of testing solutions. Viewpoint Systems understood the need to provide a clean and simple solution to this problem. The challenge A test required the application of digital pulses and a series of analog voltages Figure 1 to the UUT at precise points in time. The test called for a timing resolution of 1 µsec, but the period between the various changes was relatively longer (>100 µsecs). The actual times and output states are usually known ahead of time, but the test required repetition of the sequence a given number of times, typically tens of thousands of times. Note that there was no requirement for generating a continuous analog waveform. The ideal solution would scale in the number of digital and analog channels available to drive the UUT valves. It would also scale across UUTs, allowing testing of a number of valves simultaneously. A typical generated waveform is illustrated in Figure 2 (top is digital, bottom is analog). The period of the waveform is 10msecs for easier visibility, but the test requirement was that the period be adjustable from 10 msecs to 100 seconds. RSC #13 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 13 Application Feature Process Control Machine Monitoring relative to other system events AND limit the amount of space required for the analog output buffers. Simply changing the timestamps in the DIO-64 data can modify the timing of the waveform. No change is necessary in the analog output data buffer. Figure 2 The traditional approach The first solution involved a system that integrated typical digital outputs, analog outputs, and timer/counter cards. At second glance, something seemed wrong with this approach. The combination of precise timing and long (relatively) duration introduced a whole new set of problems with this type of solution. The waveform definition for the output waveforms was extremely large (number of samples in a 100-second waveform at 1 Msample/sec), requiring significant onboard or host memory resources. This approach adversely impacted the processing power and bus bandwidth available to the rest of the test system. Viewpoint’s solution Our proposed solution involved combining the DIO-64 event analyzer/ controller card with a simple analog output card. The idea was to integrate readily available components into a high-end solution. By choosing hardware that supported multi14 / PXI Technology Review / Winter 2003 board triggering and clocking (like the PXI trigger bus), the hardware was combined with little additional wiring or components. The DIO-64 would provide all the digital output capabilities and the clocking signal for the analog output board. The key ingredient One of the primary advantages of using the DIO-64 as an output device is that the user can define the output waveform in its simplest form, with no need to generate large buffers of redundant data. This feature can also apply to other hardware in the system. By clocking the analog output waveform from a signal in the DIO data, the application can precisely position the analog updates Viewpoint Systemsʼ DIO-64 dynamic digital I/O cards exploit the PXI bus extensions, allowing simple solutions to tricky data acquisition problems. It is common to route clocks and triggers over the PXI trigger bus, and the DIO64 does this as well. The DIO-64 is unique in its ability to be able to direct up to three digital output bits over the PXI trigger bus. This feature allows DIO-64 applications to send clocks or triggers to other PXI devices at arbitrary points in time – perfectly synchronized with the rest of the digital output data. In this case, DIO-64ʼs Port A, bit 13, is directed over the PXI trigger bus to the analog output card. Putting it all together The application that drove this test solution was fairly simple. The test technician specified the output waveforms in terms of time and digital/analog output values. Inserting a new point simply meant adding a new row of information. Changing the position in time of an event was as simple as modifying the timestamp for that particular row. The application also managed the number of times to repeat each sequence. Refer to Figure 3. The application downloaded a list of analog values to the analog output hardware where a DIO-64 digital output bit was used to clock out these values. The ...dynamic digital I/O cards exploit the PXI bus extensions, allowing simple solutions to tricky data acquisition problems. Conclusion Figure 3 application then downloaded the digital sequence to the DIO-64 hardware and started the test. At the appropriate time, the DIO-64 then applied the next digital output scan and clocked the analog output. It couldnʼt have been simpler! Refer to Figure 4. The decisions that led to a test system solution had significant impact on the systemʼs usability, performance, and maintainability. It is important to look at all these factors when weighing alternative designs. The brute force approach to this solution would have consumed large amounts of processor time generating the data buffers, would have required significant memory resources, and would have consumed a large amount of bus bandwidth. The final solution, however, allowed for the test waveforms to be described simply. The application transferred this test waveform description almost directly to the hardware, and once the process was initiated, the application was free to handle other test activities. The hardware generated the output sequences with minimal interaction with the application. Detailed specifications on Viewpoint DIO64 Systemsʼ event analyzer/controller board, along with additional application solutions, are available at www.ViewpointSystems.com/dio64. The DIO-64 offers input and output and can share clocks with National Instrumentsʼ cards. Figure 4 This approach scales well. The 64 digital channels available on the DIO-64 are anticipated to be more than enough for the test system. Adding additional analog output cards can scale the number of analog channels available. The additional cards can be clocked in the same manner. The customer’s reaction The customer felt very good about this solution. It consisted of just a few components: it had a very slight impact on the system; and the customer understood the solution to the point that they were comfortable maintaining and enhancing it. David Smith is vice president and an owner of Viewpoint Systems. His responsibilities include product development, custom system integration, and project leadership. David holds a B.S. in computer engineering from Rochester Institute of Technology. For more information, contact Viewpoint Systems directly. Viewpoint Systems, Inc. 800 W. Metro Parkway Rochester, NY 14623 Tel.: 585-475-9555 Fax: 585-475-9645 Web site: www.viewpointUSA.com RSC #15 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 15 Application Feature Process Control Machine Monitoring Pyrex glass press instrumentation system By Christopher D. Olson, Thomas B. Jozwiak, Gregory C. Cala A Pyrex glassware manufacturer desired to upgrade their 24 x 7 process monitoring on high-temperature production glass presses. The original C-based system was difficult to maintain and modify, and was developed with technology that is now obsolete. Equipment deterioration and obsolescence dictated a change from the present system with enhanced features. This is where Data Science Automation (DSA) came into the picture. The solution DSA developed a contemporary system based on National Instrumentsʼ (NI) LabVIEW, PXI, and DAQ to acquire digital and analog signals from displacement sensors, pyrometers, etc., for event and process monitoring, and to replicate the original GUI to simplify the end userʼs transition. An industrial PXI solution was suitable to sustain the harsh, high-temperature environment and 24-hour operation. In addition to real-time analysis and display of process characteristics, the data is collected for archival to a networked Oracle database. to present the data in a similar manner. LabVIEW allowed DSA to develop front panel controls and indicators that closely resembled the old systems but with all the built-in features to design a useful user interface. The system permits selection from several existing job files (recipes) that specify target values, ranges, etc., for various pieces of glassware. These recipes have been well established from the years of production of several different types of glassware. Production rates will range from 20-50 parts per minute. Manufacturing new designs and storage of the new recipes is easily accomplished through a spreadsheet recipe interface. See Figure 2. Using various SCXI modules, DSA was able to seamlessly interface with these signals on the individual presses for acquiring, analyzing, and presenting press data to the operator, in addition to archiving to the customerʼs existing database. The customer was using service-proven, heavy-duty LVDTs to acquire position and velocity measurements from the hydraulic press ram system. There was no desire to change LVDT manufacturers based on the past success in this demanding environment. The integrated PXI-1010 chassis with integral SCXI module capability enabled selection of compatible LVDT modules for signal conditioning and acquisition of the required data without having to change LVDT models or manufacturers. This allowed DSA to do a direct comparison between old and new systems for verification without introducing additional unknowns with another sensor. System monitoring In addition to the position and velocity measurements, temperature measurements are acquired through optical pyrometers, since direct connection to the mold surface with a thermocouple is impossible. Direct connection of the pyrometers system outputs to the analog inputs of the PXI system allows The PXI solution utilizes a mixture of analog and digital inputs to monitor the glass press process and to compare the analyzed values to stored parameters for several types of glassware. It is critical to the quality of the glass for the operator to have immediate access to the analyzed data for adjustment of the process, if necessary, as shown in Figure 1. This is especially true during change of production runs. Running outside of these specified parameters will lead to possible loss of product and delays in the production cycle. Since the operators are accustomed to viewing the results with the current system, the new solution would have 16 / PXI Technology Review / Winter 2003 Figure 1 display to the operator in the control room and to a remote panel display on the production floor for analysis. This is a direct benefit to the operators during initial setup of production runs because it allows them to monitor and adjust critical parameters at the press without having to return to the control room. Timing events and tracking of 8/16 mold-set data is accomplished by continuously monitoring digital channels from the press PLC system. By monitoring these channels, data can be tracked as the mold progresses through the 8/16 stations. Timing and sequencing information is acquired and analyzed along with the analog data for display to the operators. The operator has the choice of viewing the acquired data in various modes based on mold location, parameter, or by summary screen. In addition to the parameters being displayed to the operator in the control room, critical values such as mold temperatures, ram velocity, and event timing need to be displayed for the operators directly by the glass press. These display features are achieved by the analyzed data being output to easy-to-see panel meters which are located directly next to the press. During the changeover to another piece of glassware, the operator will monitor this critical subset of parameters at the press for adjustment of the process. Once the operators are satisfied with the quality of the glassware being made, they can better monitor the production from the local control room and select more detailed displays of the press activity by way of selectable front panel screens. An example is shown in Figure 3. The production line is located in a different area of the facility than the engineering and administrative offices. Leveraging off of the built-in features of LV, supervisors can view and even control the application with the built-in Web server. If a supervisorʼs support is required on the off-shift, they can remotely access the same control with a Web browser, as shown in Figure 4. The data is acquired, analyzed, and presented to the operator and additionally logged to the local hard drive. At sched- Figure 2 Figure 3 uled intervals, the data is inserted to a networked Oracle database utilizing the LabVIEW database connectivity toolset. Once the data has been archived in the companyʼs enterprise system, all personnel with access to the database can use it for reporting, production analysis, report generation, etc. This is the first phase of the project. The next phase will be to instrument the other four glass presses with the same type of solution. All the stations will be networked so data and recipes can be shared between them if necessary. In addition to all presses having their own DAQ sys- tem, one spare unit will also be used as a replacement should the need arise. The spare unit will be on the shelf and powered up so it will be up to date with the information stored on the production presses. Should the customer desire to include additional channels (i.e., pressure, temperature, etc.), the PXI/SCXI chassis can easily accommodate several modules for expandability. In conclusion Data Science Automation, Inc. was able to use the modularity of the National Instrumentsʼ PXI chassis to deliver an industrial solution with the functionality PXI Technology Review / Winter 2003 / 17 Application Feature Process Control Machine Monitoring Figure 4 needed by the customer. The ability of the NI product line to seamlessly connect to the customerʼs service-proven sensors was critical to this solution. By selecting the LabVIEW development environment, DSA was easily able to reproduce the capability of the existing system and introduce the needed new functionality that the customer required. The application is now structured in a modular type architecture that will allow for easier future enhancement. The customer also benefits from the easy-to-follow application code as compared to the proprietary C-based code that was a challenge to understand and modify. Equally as valuable is the knowledge that the components are industry standard and available off the shelf for replacement if necessary. Christopher D. Olson is a measurement and automation engineer. Thomas B. Jozwiak is a measurement and automation consultant. Gregory C. Cala is vice president of operations. RSC #18 @www.pxionline.com/rsc 18 / PXI Technology Review / Winter 2003 Christopher D. Olson Thomas B. Jozwiak For more information, contact Data Science Automation directly. Gregory C. Cala Data Science Automation, Inc. Southpointe Plaza I 400 Southpointe Boulevard Suite 210 Canonsburg, PA 15317 Tel.: 724-745-8400 Fax: 724-745-8461 Web site: www.dsautomation.com RSC #19 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 19 20 / PXI Technology Review / Winter 2003 PICKERING RSC #21 @www.pxionline.com/rsc 22 / PXI Technology Review / Winter 2003 RSC #23 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 23 Industry Update 802.11 Board Test Station Optimizing wireless measurements with the PXI platform By Wayne Larson Larson Automation has developed an 802.11 board test station. This tester fully integrates the chip-set standard manufacturing test plan with engineering tools to control the test station and the Device Under Test (DUT) from a simple drill-down GUI interface. This system is used for production testing, engineering evaluation, or for manufacturing a debug station. In this article, Wayne explains how Larson Automation conducted testing on the PXI platform. One of the compelling reasons to move to the PXI platform is to take advantage of the instrumentation connected to the test controllerʼs bus. In addition, portions of the measurements are performed in the host CPU. This simplifies custom measurement techniques, and optimizes each portion of the measurement cycle. An automated test system can be simplified to include a test controller, stimulus instruments, measurement instruments, and the DUT. There are also requirements for communication, triggering, and synchronization between the blocks. Figure 1 shows a functional schematic of a test controller, but for simplicity, does not include the electrical and mechanical interfaces. An automated test station performs a series of measurements, much like a manual test station. Each measurement is a process of discreet steps. In Figure 2, we have represented these as: System setup: The DUT is powered up, instrument paths are set for the input and output signals, and any configuration on the DUT is performed as required for the measurement. Stimulate DUT: The instrument that supplies the stimulus is commanded to apply the proper signal to the input of the DUT, as required for the measurement. Collect raw data: The DUT is in the proper state for measuring and transforming the supplied stimulus as required. The measurement instrument is used to collect the raw data. Figure 1 For a box instrument, it may not be accessible as part of the overall measurement. Additionally, the user may choose to let the instrument perform the entire process. For example, this may be the process of triggering a measurement on a spectrum analyzer. The spectrum analyzer will sweep a band-pass filter over a frequency range and record the value of the A/D converter. This converter is subject to a voltage measurement with relation to the power applied. Process information: This step converts the raw data into useable information. It also transforms the data that was collected by the sensor, scales it into a log format, removes any internal instrument error, and applies the proper frequency scale for the x-axis. Ultimately, it produces a trace on the screen that represents power vs. frequency. Perform measurement: The requested information is extracted from the processed data. It may be the peak power of the trace, the power at a certain frequency, or the frequency of the highest power point. Transfer data to controller: The measurement result is transferred to the test controller. A traditional box instrument will perform this over a GPIB bus, Ethernet, RS-232, or some other medium of data transfer. Figure 2 24 / PXI Technology Review / Winter 2003 Most automated measurement systems are derived from manual test methods. Engineers typically use discreet box instruments to make the measurements that they are interested in. Traditional box instruments have the advantage of specialized displays and measurement routines to process and display the information they are best suited to handle. Each standalone instrument is typically optimized to measure a particular parameter such as: Power vs. frequency (spectrum analyzer) Frequency (frequency counter) Total RF power (power meter) Down-converted I and Q vs. time (vector signal analyzer) The disadvantage, from a test station point of view, is the serial method of processing required. For each measurement, the engineer needs to connect the appropriate instrument, stimulate the DUT, collect the raw information, process and analyze it, and then send it over an instrumentation bus (usually GPIB) in a non-optimized, relatively slow shared bus to the test controller. Using the approach of multiple discreet measurement instruments adds a fair amount of complication for routing signals to the different instruments and increases the difficulties communicating to the test controller. New issues arrive in the synchronization, timing, and triggering as well. This operation is shown in Figure 3. The user must repeat the measurement cycle for each instrument. The timing diagram is represented in Figure 4. Each measurement requires setup of the stimulus and routing of the proper signal to the proper measurement instrument independently. The next example will measure peak power, frequency Figure 3 accuracy, power in band, EVM, and will verify the integrity of the data packet. By rethinking the measurement strategy to take advantage of the PXI instrumentation architecture, the user can streamline this process significantly. Using the PXI instrument model, the RF analyzer is a combination of an RF down-converter that covers the frequency and bandwidth desired, and a digitizer that performs the desired measurements at a base-band frequency. This architecture is similar to modern standalone RF instruments. The processing of the signals is performed in the host processor using digital signal processing techniques. Digital filters are applied to the waveform rather than switching in the proper electrical filter. I and Q demodulation is an algorithm instead of a vector demodulator that is optimized for a unique frequency. This step allows the user to acquire one set of raw data from a digitizer and process it for whatever parameter is desired. This simplifies a number of things: Figure 4 PXI Technology Review / Winter 2003 / 25 Industry Update 802.11 Board Test Station It reduces the overall cost of the system It reduces the overall test time significantly It reduces the complexity of the switching, synchronization, timing, and triggering interface Figure 7 As a side advantage, all measurements naturally correlate to each other because they are based on the same raw data. If the oscillator occasionally loses lock, all measurements would be either locked or unlocked. A block diagram is shown in Figure 5. Figure 8 Modulation power Starting with the raw data again, the user can process the data slightly differently, and extract the magnitude vs. time information. This display is useful to determine power ramp uptime, overshoot, peak power, and power ramp downtime. The representation of this function is shown in Figure 9. Baseband conversion Figure 5 It is clear from the sequencing diagram in Figure 6 that the process is much more efficient and quicker. There are also 11 functional blocks, as opposed to 30 as shown in Figure 4. What is not initially obvious is the speed advantage of having the instrumentation and the test controller share a PCI bus. An example of the digitizer output vs. time is shown in Figure 7. RF spectrum The RF down-converter is tuned to the center frequency of the 802.11b channel, and the test system is set up to make the measurement. The burst is captured by the digitizer. This is a simple packet that covers less than 300 µsecs. Starting with the raw data, the user can perform a standard FFT to show the power with respect to frequency for a standard spectrum analyzer display. The user can utilize this to calculate power in band. This process is shown in Figure 8. The raw data is processed by digitally down-converting the data to baseband, and representing it as I and Q data streams. The user then extracts the exact carrier frequency and, thus, the frequency error, and resamples the data at the clock rate. This step releases the BPSK/QPSK demodulated data stream as I and Q chips, as represented in Figure 10. Calculate EVM From the I and Q bit stream, the user can calculate the error for each chip as an error vector, and can consolidate this information into an Error Vector Magnitude (EVM) value for the packet. Figure 11 shows how this can be plotted on a constellation diagram with the center of the circles representing the ideal location. Decode frame/decode data Starting from the I and Q bit stream again, the user can continue to decode the information contained in the frame. Figure 6 26 / PXI Technology Review / Winter 2003 A breakdown of the frame can be seen in Figure 12. The user performs a Barker Correlation, descrambles the data, locates the Start Frame Delimiter (SFD), and checks the header CRC to ensure proper decoding. The rest of the header information can be used to determine how to decode the payload. The user can then work down the protocol stack to decode the actual information contained in the payload. Figure 9 Figure 10 These steps can all be performed on one small data acquisition sample (<1 msec). Data is captured once, and analyzed in many different ways. The test time is dependent upon the processing speed of the computer and the amount of analysis desired. In addition, configuration can easily be done through software. Bringing this idea one step further is the concept of a synthetic test station. This is where integration of basic components takes place to support different devices or protocols. By changing the down-converter frequency range, it is possible to convert a test station to support 802.11a from one designed to support 802.11g. With the plethora of wireless protocols and standards being introduced all the time, this technology helps preserve an investment in test equipment and test development for future projects. Wayne Larson is president of Larson Automation. For more information, contact Larson Automation directly. Figure 11 Larson Automation, Inc. 48511 Warm Springs Blvd., Suite 209 Fremont, CA 94539 Tel.: 510-656-4100 Web site: www.LarsonAutomation.com Figure 12 PXI Technology Review / Winter 2003 / 27 Industry Report By Bob Stasonis ITC – Board testing revisited T Throughout the more than 30-year existence of the Automatic Test Equipment (ATE) industry, there has been a pendulum effect in terms of technology focus. At certain times in the industry, the focus was on creating new ways to address the testing needs of component manufacturers. At other times, innovation in the testing of Printed Circuit Boards (PCBs) and subassemblies has been in the forefront. In this column, Iʼll relate some of the technologies that I saw at the 2003 International Test Conference (ITC). Overall, the show floor was more of a “meet & greet” type of exhibit. In other words, the hardware and software on display was minimal. However, there were enough staff from each company to talk to the attendees and assess their needs. ITC has long been a barometer of how technology swings. Now in its 33rd year, the papers presented at this IEEE sponsored conference showcase the research and status of test strategies and standards. The theme for 2003 was “Breaking Test Interface Bottlenecks.” The faculty and attendees came from many countries in Europe and Asia, as well as ITCʼs home in North America. Since the conference location changes every two years, this yearʼs ITC was held in Charlotte, North Carolina. ITC will be in Charlotte again next year, and will then move to Austin, Texas in the fall of 2005. The Web site address for ITC is www.itctestweek.org. Conference overview The ITC of the previous 10 years was very component testcentric. The exhibitors and the papers in the conference were very focused on getting that extra picosecond of resolution out of a microprocessor, ASIC, or memory test system. However, last year, the ITC inaugurated a Board Test Workshop at the end of the conference. The attendance was so positive that the committee added a board and system test track to the main conference in 2003. I attended ITC to look at the technology on the show floor and to listen to the presenters give their vision of the future from a board test standpoint. I also presented and participated in several well received sessions. I think youʼll agree with me that there is a resurgence in development for board testing, driven by the board technology itself, and the desire to provide lower cost solutions for testing. From the standpoint of PXI, there was a strong showing that the architecture is poised to play a part in this technology resurgence. Trade show floor – less is less… The trade show portion of ITC has seen a precipitous decline in terms of vendors throughout the last few years. In terms of component testing, with one exception, the major players were noticeably absent. Only Advantest had an exhibit, albeit a virtual one. There were no hardware products/samples at the show, only pictures and software demos. Companies like Agilent, Teradyne, and NP Test were represented by speakers at the conference, and their logos were conspicuously placed outside the exhibit hall and in the conference guide. 28 / PXI Technology Review / Winter 2003 The PXI Systems Alliance was also represented on the show floor. Goepel, JTAG, National Instruments, and Pickering had their products on exhibit. In terms of board test, they were the primary exhibitors involved in the market. While the primary focus of the conference is still IC test and design, ITC had a separate board and systems test track. If I were to summarize the track in three topics, they would be: Functional test Electrical access BIST (Built-In Self Test) There was virtually no discussion of the traditional test strategies: In-circuit test, Automated Optical Inspection (AOI), or Automated X-ray Inspection (AXI). It should be noted, however that ITC tends to focus on the theoretical aspect of testing and not on strategies or implementation. There was some discussion on a technique called flying probers, but this was discussed under the premise of limited access. In the area of functional testing, PXI was a well received topic. National Instruments presented a 90-minute tutorial about the PXI architecture and its application in board testing, and more than 60 people attended. Ninety minutes was not enough to explain the architecture, and the strongest comment received was that it needed to be longer. Only a third of the audience raised their hands when asked if they knew what PXI meant. It was obvious that some education on this subject was needed. There was not enough time to give real world details as to how PXI is being implemented in electronics manufacturing, but Iʼm sure the debate for next yearʼs ITC conference committee will be to expand this session. There was also a panel on the use of PXI in functional testing, hosted by Glenn Woppman, president of ASSET Intertech. The panel consisted of Stan Craft of Microcraft (a systems integrator), Eric Starkloff of National Instruments (a PXI manufacturer), E. Smitt of Lockheed Martin (a PXI user), Jim Webster of BAE Systems (an opposing view), and me. Actually, Jim was not as much of a naysayer as one might think. Rather, his position was “You say PXI is so great, prove it!” The panel proceeded to show how and where PXI works well from a broad set of perspectives. I think the major opinion that the audience took home was that PXI is one tool they can draw on for a variety of applications. However, the importance of understanding your end productʼs specifications and test requirements is far more important than any particular test architecture. One attendee commented that the panel was so harmonious in their message that the session was akin to a “PXI love fest.” In the area of BIST, there were several sessions. However, Intelʼs presentation appeared to have the most interest. The Three Reusable Integrated Bist-u-Technologies (TRIBuTE) program will be part of Intel microprocessors in a few years. The three on-die BIST designs will provide internal self-test information as well as verify the external bus structures of the motherboard the processor is mounted on. TRIBuTE will greatly offset the test limitations brought on by the lack of electrical access and bus speeds that can be degraded by external probing. Access to this circuitry is via either BIOS ROM or a Boundary Scan Test Access Port (TAP). Boundary Scan – the future of board testing? Speaking of Boundary Scan, the IEEE 1149.X specification dominated the conference with nine papers in the main conference and an additional seven papers in the Board Test Workshop. Clearly, lack of electrical access is driving increased interest in this specification. Fortunately for PXI users, there are several members who are producing 1149.x compliant test products. In my research for this column, I asked several of these companies for market input on where the various aspects of 1149 are being implemented. ...there is a resurgence in development for board testing, driven by the board technology itself, and the desire to provide lower cost solutions for testing. In the mid 1990s, there was an extension to the 1149 spec to address the issue of analog component testing. The 1149.4 mixed-signal test specification defined a compliant device with a series of Analog Boundary Modules (ABMs). These ABMs can be integrated into an analog chip design and used to monitor the status of an analog net, inject stimulus, make measurements, and return test results to the TAP for external assessment. They can also be implemented as a separate device that monitors analog nets and other devices. Additional pins were added to the JTAG interface to allow for analog instrumentation. Other than the addition of the TBIC (Test Bus Interface Circuit), 1149.4 is compliant with the 1149.1 protocol. According to several manufacturers of 1149.1 tools, you can use existing Boundary Scan test products to “brute force” 1149.4 test code. More information on the 1149.4 specifications can be found on the IEEE Web site at www.grouper.ieee.org/groups/1149/4/. For those readers who are a little unfamiliar, the 1149.x specification, which was also known as the Joint Test Action Group (JTAG) interface, was first introduced in 1990. The initial specification, known as1149.1, defined a serial interface with compatible digital devices that allowed the JTAG interface to take control of a device, run internal self tests, and verify interconnections between devices, all done without electrical access to the individual pins. The standard was accepted slowly, as JTAG compliance required specialized chips and additional interconnections as device geometries got smaller and smaller. With the efficiencies of scale in IC manufacturing that have been realized over the last decade, the additional cost of 1149.1 became negligible, and it actually lowered the cost of testing complex PCBs. How many 1149.1 devices are available? Heiko Ehrenberg, CEO of Goepel Electronics stated, “Almost every mid to high complex digital component today has Boundary Scan (1149.1) capabilities built in. CPUs, DSPs, microprocessors, some communication chips, PLDs, FPGAs, and similar devices almost all come with 1149.1 built in. Additionally, almost all devices in a BGA or similar package come with Boundary Scan, since this is the only economical way to test for connectivity on such devices on the board and system level. Even some more complex memory devices are now available with a limited 1149.1 implementation.” If you search the Internet, youʼll find that the devices are available, there is a broad range of tools available for both designing in 1149.1, and there are hardware and software tools for developing test programs. RSC #29 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 29 PXI Industry Report The main problem is that there are not a lot of 1149.4 products being implemented. I only found one 1149.4 compliant device available from National Semiconductor (STA400). Is it the same issue that 1149.1 experienced early on? After all, no one wants to add additional cost and use up valuable resources for something that can only be used for testing unless absolutely necessary. Ray Dellecker, United States marketing manager for JTAG Technologies put it this way, “We believe that 1149.4 acceptance and implementation are limited by the usual chicken-and-egg situation. Except there are three camps, not two: users, IC vendors, and tools providers. The 1149.4 spec has been out for years, but no one has done anything commercial with it. That is why we developed our new evaluation kit and announced it at ITC. We are looking for potential users who would like a convenient means of experimenting with the capabilities of 1149.4 on a sample board, and in the process begin to develop ideas for commercial application. As these ideas solidify, we will be able to ascertain the needs of the marketplace and respond accordingly.” Dave Bonnett, technical product manager for ASSET Intertech appears to agree with Ray. “We feel that the market will find 1149.4 acceptance as more tools for development and testing become available. The markets that will eventually embrace the 1149.4 architecture will be in the area of high reliability. Medical and military/aeronautics systems need the visibility into as much of their designs as possible. In this case, itʼs not just diagnostic capability, itʼs prognostics – finding weak signals before they cause problems. In areas of high liability, such as the automotive industry, 1149.4 should also find acceptance.” Daveʼs predictions for the automotive industry are already being looked into. A paper from Lancaster University in the UK showed how 1149.4 compliant chips could monitor the status of analog circuitry in mission-critical options on the automotive horizon. For example, drive-by-wire and brake-by-wire are new applications that will require extensive diagnostics to ascertain impending failures and implement options for the driver so they will not be stranded or fatally injured. The nature of the automotive industry dictates that this diagnostic ability must be implemented at the lowest possible cost. More work needs to be done, but it appears that 1149.4 may find its first home under the hood of your new SUV in the near future. In 2003, a new extension of the 1149 spec was added. The 1149.6 specification defines a new set of commands and circuitry that allow for characterization and diagnosis of highspeed serial interfaces. With the proliferation of high-speed digital interfaces, including Gigabit Ethernet, Firewire, USB 2.0, and other SERializer/DESerializer (SERDES) devices, the need to better test the integrity of these data paths is clear. For more detail, go to the IEEE Web site at www.grouper.ieee.org/ groups/1149/6/. In the area of 1149.6 compliance, all of the companies interviewed for this article agree that this standard will be accepted 30 / PXI Technology Review / Winter 2003 much faster than the past two 1149 specifications. Ray Dellecker said, “We see 1149.6 taking off more rapidly than 1149.4, primarily because the need for it is well understood. In fact, the working group that produced the spec was prodded by potential end users, and that means its practical application is more assured. Because of this market push, we are actively developing tools to support the standard.” Dave Bonnet added, “1149.6 is being driven by several major networking hardware companies. I expect that we will see 1149.6 compliant devices in less than two years. As the market embraces this spec, we will provide tools to assist them.” Finally, Heiko Ehrenberg stated, “Goepel will support the standard by offering compliant hardware and software tools in the future. I expect adoption of this standard to be much faster than for 1149.4. However, again I see the implementation of 1149.6 capabilities initially in custom ASICs, later on maybe in off-the-shelf devices such as SERDES and high-speed communication chips. I expect first applications to appear in late 2004, early 2005.” Conclusion Overall, the ITC was a good experience from a technology standpoint. Major companies, universities, and a lot of imaginative entrepreneurs are developing new ways to address the issues of testing advancing technology, safety, and costs. Next year, the ITC will focus on end-to-end test flow, from IC to board and on to system testing. I expect to see lots of new trends then as well. I hope you can make it to Charlotte, North Carolina next October! For more information, contact Bob Stasonis at: bstasonis@opensystems-publishing.com Companies quoted in this column: ASSET Intertech 2201 N. Central Expressway, Suite 105 Richardson, TX 75080 Tel.: 888-694-6250 Fax: 972-437-2826 www.asset-intertech.com GOEPEL Electronic GmbH Goeschwitzer Str. 58/60 07745 Jena Germany www.goepel.com JTAG Technologies Inc. 1006 Butterworth Court Stevensville, MD 21666 Tel.: 877-FOR-JTAG Fax: 410-604-2109 www.jtag.com Product Focus Integrated Analog and Digital Devices Building a mixed-signal test system By Eric Starkloff As computing and communications technologies converge, consumer devices are becoming more complex. At the same time, the semiconductor industry is combining more analog and digital technologies on a single chip, creating unique testing challenges. For these mixed-signal test systems, system developers need modularity and flexibility of both the analog and digital test components. PXI is designed to meet these needs through its modular design, making it an ideal platform Stimulus for mixed-signal test. Open standard and modular hardware deliver Analog the challenge of traditional instrumentation. Modular instrumentation, however, can take the best of both worlds. If the system requirements change as time goes on, users can add modules to expand channel counts or to address changes in signal levels or frequency needs. If the analog channels have varying bandwidth requirements, users can select modules with different bandwidths, tailoring their systems to exact Arbitrary waveform generators Response High-speed digitizers Function generators Simultaneous-sampling data acq The only requirement of a mixedFrequency synthesizers RF signal analyzers signal system is that it integrates analog Digital waveform generators Digital waveform analyzers and digital components. Typically, this Digital definition applies to systems where the Digital test modules Digital test modules analog and digital components integrate Pulse/pattern generators together to test the same device. With Logic sources the open standard of PXI, engineers and scientists can integrate multiple comTable 1 paniesʼ products together into a single system. With more than a thousand products in PXI, and with interoperability with CompactPCI, requirements. By choosing modular components to fit the system developers can mix any number of devices from one specific requirements of the applications, users only pay for or more vendors into one system. Table 1 lists common analog what they need, thus controlling costs and addressing the issue and digital stimulus and response devices. The PXI platform of shrinking budgets. These technologies can be used to create delivers a greater degree of test system flexibility and hardware faster, more flexible mixed-signal systems to solve applicareuse than is possible in fixed-functionality systems. For mixedtions that previously required expensive proprietary solutions signal test systems, the PXI modular architecture is a flexible or simply remained unsolved. platform for integration. Eric Starkloff is the PXI and moduSystem flexibility for mixed-signal test lar instrument marketing manager at Traditional instrumentation, along with modular instrumentaNational Instruments. He joined the comtion, trends toward mixed-signal test. For example, mixed-sigpany in 1997, and currently is responnal oscilloscopes are more common than ever. A mixed-signal sible for leading the project management oscilloscope is ideal for systems that only require a few chanteams for PXI, modular instruments, VXI, nels of analog and digital with static requirements. Increasingly, GPIB, and test software. Eric holds a though, engineers need different frequency ranges or different B.S. in electrical engineering from the University of Virginia channel counts for driving new requirements. If the device at Charlottesville. For more information, contact National under test changes, the requirements could change dramatiInstruments directly. cally. With traditional instrumentation, a mix of requirements for the same system or a change in those requirements over National Instruments time, means that users must purchase new instruments. With 11500 N Mopac Expwy the fixed functionality of traditional instrumentation, if the Austin, TX 78759 users need more analog channels, they have to buy new instruTel.: 800-811-0742 ments to replace the current ones. If the analog channels need Fax: 512-683-9300 different bandwidths, they pay for the highest bandwidth on E-mail: info@ni.com all the channels, regardless of whether they all need it. This is Web site: www.ni.com PXI Technology Review / Winter 2003 / 31 Web Site waveform generators RSC #3201 @www.pxionline.com/rsc ROM EMULATORS RSC #3202 @www.pxionline.com/rsc RSC #3203 @www.pxionline.com/rsc 32 / PXI Technology Review / Winter 2003 www.acqiris.com www.acromag.com www.adlinktech.com www.advmeas.com www.advancedmsinc.com www.aerocomm.com www.utmc.aeroflex.com www.aim-online.com www.alfautomazione.com www.alphitech.com www.amfax.co.uk www.ancot.com www.asset-intertech.com www.bbtechno.com www.bi2s.com www.bloomy.com www.bustronic.com www.chtech.com www.calbay.com www.centralp.com www.chromaate.com www.chromausa.com www.conduant.com www.daqtron.com www.dsautomation.com www.ekf.de www.elma.com www.gage-applied.com www.generalstandards.com www.geotestinc.com www.gespac.com www.goepel.com www.ghs.com www.huntron.com www.icon-tech.com.au www.inesinc.com www.inesinc.com www.intertesttech.com www.invisar.com www.ittcannon.com www.kaparel.com www.lecroy.com www.macpanel.com www.marconi.com www.marekmicro.de www.maxt.com www.menmicro.com www.microbus.com www.ni.com www.navatek.com www.nextron.com.tw www.pickering.co.uk www.pxit.com www.qmt.ch www.quantum-controls.com www.rohde-schwarz.com www.sbs.com www.schroff.us www.strategic-test.com www.team-solutions.com www.teradyne.com www.thermotron.com www.tracewellsystems.com www.tripleease.com www.ttitestron.com www.ueidaq.com www.vieng.com www.vi-tech.com www.viewpointusa.com www.vpc.com General Memory Flash Extenders Connectors Attenuators BUYER’S GUIDE: GENERAL Acqiris Acromag, Inc. Adlink Technology America, Inc. Advanced Measurements, Inc. Advanced Microcomputer Systems, Inc. AeroComm Inc. Aeroflex UTMC AIM USA ALFAUTOMAZIONE Srl Alphi Technology Corporation Amfax Ltd Ancot Corporation ASSET InterTech B & B Technologies, Inc. Bi2S Bloomy Controls, Inc. Bustronic Corporation C & H Technologies, Inc. Cal-Bay Systems, Inc. Centralp Automatismes Chroma ATE, Inc. Chroma Systems Solutions, Inc. Conduant Corporation DAQTron, Inc. Data Science Automation, Inc. EKF-ELECTRONIK GmbH ELMA Electronic, Inc. Gage Applied Technologies General Standards Corporation Geotest Gespac GOEPEL electronics GmbH Green Hills Software, Inc. Huntron ICON Technologies INES GmbH Innovative Electronik Systems Inc International Test Technologies Invisar, Inc ITT Cannon Kaparel Corporation LeCroy Corporation MacPanel Company Marconi Integrated Systems MarekMicro MAX Technologies, Inc. MEN Micro Elektronik GmbH Microbus Inc National Instruments Navatek Eng. Corp. Nextronics Engineering Corp. Pickering Interfaces Ltd Px Instrument Technology Ltd Qualimatest S.A. Quantum Controls, Inc. Rohde & Schwarz SBS Technologies, Inc. Schroff Strategic Test Team Solutions, Inc. Teradyne, Inc. Thermotron Industries Tracewell Systems, Inc. Triple E TTI Testron United Electronic Industries VI Engineering, Inc. VI Technology Viewpoint Systems Virginia Panel Corporation Accessories Test Interface waveform generators Company Name √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ Boundary Scan Debugging Interfaces Prototyping √ Wireless Remote Access PXI-to-PXI PCI-to-PXI PCI-to-PCI PMC PCMCIA PC•MIP Pkg. Modules Enclosures IP Modules Drivers Front Panels Backplanes App. SW GPIB Serial Turnkey Systems √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ 2004 BUYER’S GUIDE: GENERAL √ Test Integration System Tools Development SCSI Serial Remote PXI Controllers Prototyping √ √ √ √ PXI Technology Review / Winter 2003 / 33 DATA ACQUISITION RSC #3401 @www.pxionline.com/rsc DIGITAL I/O RSC #3402 @www.pxionline.com/rsc RSC #3403 @www.pxionline.com/rsc 34 / PXI Technology Review / Winter 2003 Acqiris www.acqiris.com Adlink Technology America, Inc. www.adlinktech.com Advanced Power Designs Inc. www.VxIbus.com Aeroflex UTMC www.utmc.aeroflex.com Agilent Technologies www.agilent.com AIM USA www.aim-online.com Alphi Technology Corporation www.alphitech.com Analogic Corporation www.analogic.com Ascor, Inc. www.ascor-inc.com B & B Technologies, Inc. www.bbtechno.com Ballard Technology www.ballardtech.com Bustec www.bustec.com C&H Technologies, Inc. www.chtech.com Chroma ATE, Inc. www.chromaate.com Chroma Systems Solutions, Inc. www.chromausa.com Conduant Corporation www.conduant.com Corelis, Inc. www.corelis.com Cytec Corp www.cytec-ate.com Datum www.datum.com D-TACQ Solutions Ltd. www.d-tacq.co.uk Digalog Systems, Inc. www.digalogpxi.com Exacq www.exacq.com Excalibur Systems, Inc. www.mil-1553.com Gage Applied Technologies www.gage-applied.com General Standards Corporation www.generalstandards.com Geotest www.geotestinc.com Gespac www.gespac.com GL Communications, Inc. www.gl.com GOEPEL electronics GmbH www.goepel.com Innovative Electronik Systems Inc www.inesinc.com Innovative Integration www.innovative-dsp.com Janz Automations Systeme AG www.janzag.de JTAG Technologies B.V. www.jtag.com Kineticystems Company, LLC www.kscorp.com LeCroy Corporation www.lecroy.com MarekMicro www.marekmicro.de Meilhaus Electronic GmbH www.meilhaus.com MEN Micro Elektronik GmbH www.menmicro.com Murrelektronik, Inc. www.murrinc.com National Instruments www.ni.com Pickering Interfaces Ltd www.pickering.co.uk PX Instrument Technology Ltd www.pxit.com Racal Instruments, Inc. www.racalinst.com Radical Systems Engineering www.radicalsystems.com SBS Technologies, Inc. www.sbs.com Signametrics Corporation www.signametrics.com Spectrum GmbH www.spec.de Strategic Test www.strategic-test.com Summit Microelectronics www.summitmicro.com Sundance DSP www.sundance.com Team Solutions, Inc. www.team-solutions.com Teradyne, Inc. www.teradyne.com Tracewell Systems, Inc. www.tracewellsystems.com United Electronic Industries www.ueidaq.com Viewpoint Systems www.viewpointusa.com ZTEC Instruments, Inc. www.ztec-inc.com CAN Fieldbus √ GPIB √ Ethernet √ Interfaces Boundary Scan √ Synchro-Digital BUYER’S GUIDE: INSTRUMENTS Avionics MIL-1553 Web Site ARINC GENERATORS Company Name √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ Optical: Video Switching I/O Other Switch Matrix Multiplexers RF High-Current General Microwave LVDT/RVDT Stimulus Other √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ 2004 BUYER’S GUIDE: INSTRUMENTS √ Pulse Gen. Pattern Gen. Motor Gen. Measurement Function Gen. Generators Frq. Synth. DAC Amplifiers Digitizers/O-Scope Signal Cond. Power Mtr. DSP DMM Data Acq. Counters ADC Analyzers Time Interval Power Supplies DC Sources Power PXI Technology Review / Winter 2003 / 35 New Products By Eli Shapiro ANALYZERS: OTHER Ascor, Inc. Web site: www.ascor-inc.com Model: 7205 RSC No: 15798 A PXI block down converter • Extends RF signal analyzers to 6 GHz • Eliminates external switching • 10 MHz reference input • Plug and Play software interface • Two-slot PXI size • +15 dBm input power • 0 to 2.7 GHz passthrough ANALYZERS: TIME INTERVAL Geotest Web site: www.geotestinc.com Model: GTX2220 RSC No: 15785 A 1.3 GHz time interval counter • Provides all features of standalone counters, including frequency, period, totalize, and time interval in the PXI form factor • Uses reciprocal counting techniques • 10 digits/sec of resolution for frequencies from 1 Hz to 1.3 GHz; determines any frequency to seven digits in 1ms • 2300 measurements/sec capability APPLICATION SOFTWARE National Instruments Web site: www.ni.com Model: TestStand v3.0 RSC No: 15807 A ready-to-run test management environment for organizing, controlling, and executing automated prototype, validation, and manufacturing test systems • Graphical sequence editor environment • Adapters for tests written in any programming language • Multithreaded sequence execution engine • ASCII, HTML/Web, and XML report generation • Access, Oracle, and SQL Server database connectivity • Create, edit, execute, and debug sequences • More than 30 built-in step types • Develop custom test steps for unique requirements • Advanced sequenc- RSC #36 @www.pxionline.com/rsc 36 / PXI Technology Review / Winter 2003 E-mail: newproducts@opensystems-publishing.com RSC #15798 ing, branching, and flow control • Source code control system integration Model: VDM 7.0 RSC No: 15810 A vision development module for machine vision and scientific imaging applications • Consists of IMAQ Vision and NI Vision Builder • High-level machine vision and image processing functions as well as display tools • Processing and analysis of grayscale, color, and binary images • Highspeed pattern matching for locating objects of various size and orientation, even in poor lighting • Blob analysis for calculating 49 parameters, including the area, perimeter, and location of objects • Image calibration for correcting lens distortion and camera angle • Support under LabVIEW RT • Interactive vision prototyping environment that generates LabVIEW diagrams or builder files for LabWindows/CVI and Visual Basic • Offline inspection with automated scripting and batch processing • Image display with zooming, panning, extracting, and scrolling • Measurements such as distances, areas, and locations returned • Visual image management with the image browser • Performance benchmarking with the performance meter • Compatible operating systems: Windows 2000/NT/XP/ME/9x BOUNDARY SCAN GOPEL electronic GmbH Web site: www.goepel.com Model: SYSTEM CASCON 4.1 RSC No: 15797 A boundary scan software suite • Version includes Scan Vision II, a next generation graphical viewer product based on Router Solutions’ CAMCAD package • Processes design data from many different CAE systems, extracting required information for viewing schematic and layout features • Scan Vision supports applications such as: graphical indication of a fault location, graphical presentation of fault coverage, interactive cross probing between schematic, layout, and net list, hierarchical design browsing, interactive guarding for Flash programming or test pattern generation, and interactive logic probing in layout and schematic in conjunction with the SYSTEM CASCON graphical multi mode debugger • Extension of the CASLAN programming language with an interface for external 32-bit DLLs • BGA package generator supports interactive generation of boundary scan and non-boundary scan device models • Backwards compatible and supports all boundary scan controllers by GOEPEL electronic based on VXI, PXI, PCI, USB, PCMCIA, GPIB, Parallel, RS-232, and Fast Ethernet GENERAL PURPOSE SWITCH Digalog Systems, Inc. Web site: www.digalogpxi.com Model: P6608 RSC No: 15801 A 32-channel, general-purpose relay board • 32 Form A relays • 1A maximum current • 100VDC or 100VAC maximum switching voltage • 512-state scan list • PXI triggers • Onboard debounce timer • Programmable scan advance delay • Drivers provided for Windows 9x/ME/NT/2000/XP • Programming: Visual Basic, Visual C/C++, LabView, LabWindows/ CVI, and CVI function panels GENERATORS: PULSE Geotest Web site: www.geotestinc.com Model: GP1550H RSC No: 15784 A series of dual-channel, GPIB-programmable pulse generators for use as 100 percent form-fitting replacements for HP8160A pulse generators • Fully compatible with the HP8160A, including output specifications and the GPIB command set IP MODULES/CARRIERS MAX Technologies, Inc. Web site: www.maxt.com Model: PXI-400 RSC No: 15794 A multi-protocol, 3U, intelligent PXI carrier board • Supports up to two 8/32-MHz IndustryPack modules • StrongArm RISC processor at 200 MHz • 1 to 2 Mbytes of SRAM and 16 Mbytes of shared memory, expandable to 64 Mbytes • Onboard firmware • Runs multiple protocols simultaneously • Received messages are time-tagged with 32-bit microsecond precision • IRIG-B RSC #15797 input support • Multiple carrier boards can be time synchronized LVDT/RVDT STIMULUS AND MEASUREMENT Geotest Web site: www.geotestinc.com Model: GX5152 Series RSC No: 15786 A series of PXI Digital Stimulus-Response (DSR) cards for bus emulation and highspeed digital test • The 6U GX5152 is the master, which includes the DSR timing set and can control up to 15 GX5153 DSR slaves to expand the dynamic digital I/O channels up to 512 • Timing set within the DSR master features major cycles running at 100 MHz, and minor cycles running at 50 MHz • Provides strobes that control the master and any slave instruments to generate or capture data • Features a trigger signal, 10nsec edge placement resolution, and five memory SIMMS for a memory depth of up to 8 Mbits • Variety of I/O modules available; TTL, LVDS, and programmable levels MAINFRAMES/CARD RACKS/ENCLOSURES Geotest Web site: www.geotestinc.com Model: GX7100 Series RSC No: 15803 A 3U/6U, 14-slot combination PXI chassis • Accommodates seven 3U PXI or CompactPCI instruments and seven additional 3U or 6U PXI or CompactPCI instruments • Expandable to accommodate additional PXI/CompactPCI instruments using MXI-3 • Built-in peripherals include: hard disk, floppy disk, and CD-ROM or CD-RW drives • Accommodates instruments from any vendor • Desktop and rackmount configurations • Front-loading mechanism similar to VXI • UUT interfacing options MarekMicro Web site: www.marekmicro.de Model: PXI Chassis RSC No: 15805 A series of PXI 2.1 compliant chassis • Rackmount and desktop PXI chassis with 8, 14, 18, and 21 slots • Optimized cooling and reduced noise • Based on MarekMicro’s PXI backplane technology RF SWITCH Geotest Web site: www.geotestinc.com Model: GX6062 RSC No: 15787 A high-density RF multiplexer in 6U PXI form factor • 12 groups of 1:4 multiplexers that can be software controlled to provide various multiplexer configurations, while maintaining the instrument’s full 200 MHz of bandwidth • Provides differential RF switching and may be configured as 12 x 1:4, 6 x 1:9, 2 x 1:29, 1 x 1:59, as well as other configurations • Suited for Automated Test Equipment (ATE), parametric measurements, engineering verification, high-density switching systems, and RF communications SCANNERS/MULTIPLEXERS Geotest Web site: www.geotestinc.com Model: SMX4032 RSC No: 15773 A 32-channel PXI relay scanner/multiplexer • Onboard microcontroller • Can be configured on the fly to handle 2, 4, and 6-wire guarded measurements • Very low thermaloffset leakage and capacitance • Up to four differential switching groups of 10:1 • Fast switching and settling times • Measure relay actuation time • Test for contact failure • Auto-scanning mode • Trigger input and output • Triggered scanning operation • Power and control isolation • Self cleaning • Channel ID • Programmable actuation and delay times TEST SYSTEMS Geotest Web site: www.geotestinc.com Model: MTS-206 RSC No: 15806 A rugged, portable tester for the Maverick Missile System • Field testing of the AGM-65 missile, missile sections, LAU-117 & LAU88 launchers, and launcher-missile clusters • PXI architecture • Full parametric test with optional diagnostics • Controlled by an integrated LCD display and touch screen • Menu-driven • Automatic cable selection TURNKEY SYSTEMS MEN Micro Elektronik GmbH Web site: www.menmicro.com Model: 190007 RSC No: 15799 A 19” PXI desktop enclosure for 6U cards • IEEE-1101.10 compliance • 14-slot, 3U PXI backplane • 650W, open-frame power supply • Three DC fans, temperature controlled • 6U PXI system controller installed, with Pentium III processor at up to 1.26 GHz or Pentium 4 processor at 2.2 GHz, 256 Mbytes DRAM, and a 2.5”, 20-Gbyte hard disk • Windows installed on request RSC #15805 RSC #15787 FOR MORE INFORMATION on these and other new products, check our Web site at www.pxionline.com. RSC #37 @www.pxionline.com/rsc PXI Technology Review / Winter 2003 / 37 RSC #38 @www.pxionline.com/rsc 38 / PXI Technology Review / Winter 2003 RSC #39 @www.pxionline.com/rsc RSC #40 @www.pxionline.com/rsc RSC #40 @www.pxionline.com/rsc