Attachment

advertisement

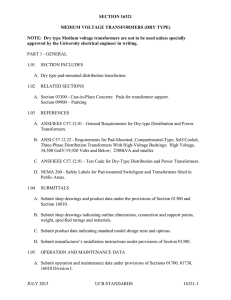

Contract Documents 170-4212 SECTION NUMBER 16321.3C - 3Ø PAD-MOUNT Technical Specifications for Pad-Mounted, Three-Phase, Distribution Transformers 2500 kVA And Smaller Revised 03/02/2016 1.0 GENERAL 1.01 SCOPE This section includes pad-mounted, three-phase, 60-Hz alternating current, oil-immersed, self-cooling, compartmental-type distribution transformers with separable bushing wells and insulated high voltage loadbreak bushing inserts suitable for operation on the District's 7620/13,200Y and 7200/12,470Y distribution system. The transformers shall be designed for outdoor installation on a concrete pad to provide underground power distribution to commercial, industrial, agricultural and institutional loads. All transformers ordered by the District shall comply with 2016 DOE efficiency standards. 1.02 REFERENCES 1.02.1 Unless otherwise noted, all specification references shall be the latest edition. Listed references for this document. A. ANSI C37.47, Specifications for Distribution Fuse Disconnecting Switches, Fuse Supports, and Current Limiting Fuses. B. ANSI/IEEE C57, Distribution, Power and Regulating Transformers, all related sections. C. ANSI/IEEE 386, Separable Insulated Connector Systems for Power Distribution Systems above 600V. D. ASTM Test methods for mineral oil and standards for mineral oil are included in section 5.01. E. ANSI Z535, Criteria for Safety Symbols. F. ASTM A240, Type 304 (18-8) stainless steel sheet stock. G. ASTM A276, Type 304 (18-8) stainless steel bar, angle, and flat stock. H. ASTM D3487, Physical, Chemical, and Electrical Properties of Mineral Oil. I. District Stock Page for the type & kVA of the transformers ordered. J. District Stock Page #24621800 for Bay-O-Net fuse assembly and drip guard. K. District Stock Page #24618068 for fuse cartridge, end plug and current sensing fuse. L. District Stock Page #24618659 for high amp fuse cartridge, end plug, high current sensing fuse for transformers rated 1000 kVA thru 2500 kVA. M. District Stock Page #24629004 for isolation link. 1.03 OPERATION AND MAINTENANCE DATA 1.04 Include procedures for sampling and maintaining fluid, cleaning unit, and replacing components. APPROVED MANUFACTURERS 1 Contract Documents 170-4212 The listed manufacturers are prequalified for production at the listed plants. Other production plants shall be accepted only after a factory audit is performed by the District engineering staff. These manufacturers shall provide the information required within the Contract Documents. Manufacturer ABB Central Moloney CG Power Cooper ERMCO GE Howard Factory Locations Jefferson City, MO Pine Bluff, AR Washington, MO Waukesha, WI Dyersburg, TN Monterrey, Mexico Laurel, MS 2.0 ELECTRICAL CHARACTERISTICS 2.01 SCOPE Lumberton, MS Nacogdoches, TX The three-phase, self-cooled, loop feed, pad-mount transformer shall conform to ANSI C57.12.26 60 hertz, 65º C rise, three-phase transformers shall be outdoor, pad-mounted, oil-immersed, type for determining performance, interchangeability, and safety of pad-mounted transformers. Transformers rated below 500 kVA shall be Category I and transformers rated 500 kVA and above shall be Category II as determined by ANSI C57.12.00 Section 7.1.2. 2.01.1 All transformers produced for the District shall meet or exceed the 2016 Federal Department of Energy (DOE) Efficiency requirements, listed in DOE Table below. Federal DOE Efficiency Rating Table. 2.01.1 kVA Rating Efficiency % kVA Rating Efficiency % kVA Rating Efficiency % 75 150 300 99.03 99.16 99.27 500 750 1000 99.35 99.40 99.43 1500 2000 2500 99.48 99.51 99.53 2.01.2 Each transformer shall include a core and winding loss, (no load & load loss) certification. 2.02 A. No Load Loss/Core Losses 20° C B. Load Loss/Winding Losses 85° C @ 50% nameplate load KVA SIZES The kVA ratings for this specification shall include the following transformer sizes: 75 kVA, 150 kVA, 300 kVA, 500 kVA, 750 kVA, 1000 kVA, 1500 kVA, 2000 kVA and 2500 kVA. 2.03 VOLTAGE RATINGS The configuration shall be Wye-Wye (Y-Y) or Wye-Delta (Y- Δ) connected with voltage ratings as follows: 2.03.1 Primary Voltage – 13,200GRDY/7,620 or 12,470GRDY/7,200 as specified in Bid Form. 2.03.2 Secondary Voltage 2.03.2.a 2.03.2.b 208Y/120V or 480Y/277V as specified in Bid Form. 240Δ /120V or 480Δ /240V as specified in Bid Form 2 Contract Documents 170-4212 2.03.3 2.04 Taps – transformer taps shall be provided for 1000 kVA, 1500 kVA, 2000 kVA, and 2500 kVA units. The taps shall be two (2) ea. – 2-1/2 above and two (2) ea. – 2-1/2 below rated voltage of 13,200 volts or 12,470 volts as specified in the Bid Form. TEMPERATURE RATING The transformer shall not exceed 65° C at continuous operation at rated kVA or 80° C hot-spot temperature rise. 2.05 CORE AND COIL The core shall be either five-legged or triplex with either aluminum or copper winding. 2.06 BASIC LIGHTNING IMPULSE INSULATION LEVELS The Basic Insulation Level (BIL) shall be 95 kV BIL for the high voltage and 30 kV for the low voltage terminals as described in ANSI C57.12.26.4. 2.07 SHORT CIRCUIT WITHSTAND The short circuit withstand capability shall be in accordance with IEEE Std. C57.12.00 and IEEE Std. C57.109 for Category I Transformers and Category II as shown below: Three-Phase (kVA) Withstand Capability per unit of base current (symmetrical) 45 - 75 40 35 112.5 - 300 500 25 For distribution transformers greater than 500 kVA the symmetrical short circuit shall be calculated using transformer impedance only. 2.08 IMPEDANCE VOLTAGE 3.0 3.01 The percent impedance voltage as measured on the rated voltage connection shall be in accordance to ANSI C57.12.26.5 CONSTRUCTION TANK The tank construction shall conform to ANSI C57.12.26.7 and as further described below. 3.01.1 The pad-mounted transformer shall consist of a moisture and dust tight tank with highvoltage and low-voltage cable terminating compartments as shown in Figure 3 of ANSI C57.12.26 – 1992. 3.01.1.a The bottom one and one half (1-1/2” inchs) of the rim, tank, supports and closure of the pad-mounted transformer shall be constructed of Type 304 (18-8) stainless steel. 3.01.1.b The transformer tank and termination compartments shall be assembled as an integral unit suitable for flush mounting on a concrete pad. 3.01.1.c The assembly shall block the entry of rain, blown or pump irrigation or snow melt water into termination compartments. 3.01.2 Tank Access 3.01.2.a The transformer tank shall have either a hand-hole or bolted cover and be capable of supporting 500 pounds of weight over the entire top, or a concentrated load of 200 pounds applied at any point. 3 Contract Documents 170-4212 3.01.2.b The hand-hole size shall be adequate to access the tank for internal maintenance or to replace the core and coils. 3.01.2.c A hand-hole cover, if exposed, shall be secured from inside the termination compartments. 3.01.2.d Either the hand-hole or bolted cover shall have a reusable water/dust tight gasket. 3.02 CABINET 3.02.1 Door openings shall be a minimum of 24” (inches). 3.02.2 Minimum Cabinet Provisions: 3.02.2.a 45 kVA through 150 kVA Transformers. For all transformers in this range, the manufacturer shall provide a minimum cabinet width. This width shall be 58” (inches) and the division of this width shall be determined by the manufacturer and as specified in ANSI C57.12.26, Figure 2 and ANSI C57.12.26 Figure 8. 3.02.2.b Special Conditions for 225 kVA through 500 kVA Transformers. For all transformers in this range, the manufacturer shall provide a minimum secondary cabinet width of 32” (inches) and the minimum primary width shall be as specified in ANSI C57.12.26, Figure 2. Total Cabinet width shall not exceed 64” (inches) for transformers in this range. The minimum cabinet depth of transformers in this range shall be 20” (inches) and the minimum height of the cabinet shall be 55” (inches). 3.02.2.c 750 kVA through 2500 kVA Transformers. For all transformers in this range, the manufacturer shall provide a minimum cabinet depth. This depth shall be 24” (inches) as noted in ANSI C57.12.26, Figure 7, under note 4, Figure 4, Interface for 21.1kV. 3.02.2.d Transformer dimensions shall be noted as per the table Figure B on the attached Bid Data Sheet. 3.02.3 Access doors shall be removable and comply with the security provisions of ANSI C57.12.28. 3.02.3.a Door hinges and hinge pins shall be ASTM A276 stainless steel or equivalent corrosion-resistant metal, which may be lifted off by hand while in the open position. 3.02.3.b The doors shall have a stop for latching in the open position. 3.02.3.c The doors are to be arranged so that access to the high voltage compartment can be gained only after opening the low voltage compartment door. 3.02.3.d The edges of the access doors shall have a close-fitting mating surface in order to prevent illegal entry. 3.03 CABINET SECURITY 3.03.1 Cabinet locking and security provisions shall conform to ANSI C57.12.28 and include the following: 3.03.1.a All secondary access doors shall be secured by a recessed, captive, penta-head bolt that thread into a nut with a blind hole and padlock system. 3.03.1.b Inserting the padlock into the hasp shall not be possible until the bolt head is completely seated. 4 Contract Documents 170-4212 3.03.1.c The secondary door shall be a latched door and shall be latched at a minimum of three points. 3.03.1.d All primary access panels/doors shall be secured behind the secondary cabinet door with a minimum of one recessed, captive penta-head bolts that thread into a nut with a blind hole. 3.03.1.e A penta-head bolt shall be considered “captive” when the retention scheme will prevent it from being readily removed during normal operation of the door(s). The recess is to be non-rotating. Both the penta-head bolt and recess shall conform to Figure 1 of ANSI C57-12-28. 4.0 ACCESSORIES ALL TRANSFORMERS 4.01 GROUNDING 4.01.1 Grounding points shall be provided for the transformer cabinet and tank as follows: 4.01.1.a As per IEEE C57 12.26 with the following instructions: 4.02 4.01.1.a.1 Include one (1) ground pad/hole in the secondary compartment. 4.01.1.a.2 Transformers shall have two (2) ground points in the high voltage compartment. Pads or ground points are to be located near the base under the H2A and H2B terminals. 4.01.1.a.3 Transformers rated 500 through 2500 kVA shall have unpainted, copper-faced steel or stainless steel pads, 2” x 3-1/2”(inches) each with two (2) holes spaced on NEMA 1-3/4” (inches) centers and taped for 1/2” (inch) – 13 NC thread ground pads in both the primary and secondary sections. 4.01.1.a.4 On transformers rated 500 kVA through 2500 kVA when using the copper plated option the minimum thickness of the copper facing shall be 0.015” (inch). 4.01.1.a.5 Minimum threaded depth of ground pad or ground nut holes shall be 1/2” (inch). PRESSURE RELIEF 4.02.1 All transformers shall have a pressure relief device equivalent to “Qualitrol 202-032-01”. 4.02.1.a Pressure relief valve shall be located per ANSI C57.12.22. 4.02.1.b The pressure relief valve shall be accessible for operation after bushing CT’s and conductors have been installed on the secondary bushings. 4.03 OIL FILL, DRAIN & TEST PLUG 4.03.1 A minimum 3/4” (inch) NPT plug for filling and pressure testing transformer shall be provided in the secondary terminating compartment. 4.03.2 All transformers shall have an oil drain valve installed at the bottom edge in the secondary compartment. 4.03.2.a The valve shall be 3/4” (inch) minimum diameter, gate activated, with an oil sampling valve on the side of the valve. 4.03.3 4.04 A suitable means for indicating correct liquid level at 25º C shall be provided in the secondary termination cabinet. See section 8.04 below. ACCESSORIES FOR TRANSFORMERS RATED 1000 through 2500 kVA 5 Contract Documents 170-4212 4.04.1 In addition to standard accessories, each transformer rated 1000 through 2500 kVA shall be equipped with the following: 4.04.1.a Oil level gauge 4.04.1.b Dial thermometer with maximum top oil temperature indicator complete with magnetic reset. 5.0 4.04.1.c Tank pressure-vacuum gauge. TRANSFORMER OIL 5.01 MINIMUM OIL REQUIREMENTS 5.01.1 Transformer oil shall meet ASTM D3487 Type II mineral oil. Test and Method Value Dielectric Strength (ASTM D1816) kV minimum 1 mm gap 25 kV 2 mm gap 45 kV Dissipation Factor (power factor) (ASTM D924) 25 ºC, % Maximum 0.05 100 ºC, % maximum 0.40 Interfacial Tension (ASTM D971) mN/m minimum 38 Color (ASTM D1500) ASTM units maximum 1.0 Visual Examination (ASTM D1524)) Bright & Clear Neutralization Number (acidity) (ASTM D974) 0.015 Mg KOH/g maximum Water Content (ASTM D1533) Mg/kg maximum (ppm) 20 Oxidation Inhibitor Content (ASTM D2668) 0.3 Type II oil, % maximum 0.08 Type II oil, % minimum 5.01.2 The oil level at 25º C shall be permanently indicated by an identifiable stencil or marking on the interior of the transformer tank. 5.01.3 6.0 6.01 Oil shall be tested and contain “less than 1 PPM of PCB” and shall be so designated on the nameplate. 5.01.4 The type of oil shall be listed on the name plate. BUSHINGS HIGH & LOW VOLTAGE HIGH-VOLTAGE SEPARABLE CONNECTORS The high voltage separable connectors shall conform to ANSI C57.12.26. The bushings shall be arranged to include provisions for Loop Feed dead front configuration. 6.01.1 Configuration – the configuration of the high voltage bushing wells shall conform to ANSI C57.12.26, Figure 2, Minimum Dimensions for Loop-Feed Transformers. 6.01.2 High Voltage Bushing Wells shall be 2-1/2” (inch) shank diameter with tri stud mounting in a 4.69” (inch) bolt circle conforming to the following provisions. 6 Contract Documents 170-4212 6.01.2.a 6.01.2.b Three phase transformers shall be equipped with a single piece molded epoxy externally clamped 15/25/28 kV Class high voltage bushing wells with a semiconductive collar. The bushing well shall be rated equivalent to 200 Amp with removable stud and gasket. The bushing well shall be equal to or better than Cooper catalog number 2603973B02R. 6.01.2.a.1 The bushing wells are to be externally mounted and clamped with a three (3) stud corrosion inhibited coated steel clamp with flange and studs. Clamp and flange system shall be equal to or better than Cooper catalog number 2085399A01 6.01.2.a.2 Each bushing well clamp flange shall include ten (10) bail tab holes. 6.01..2.a.3 A 5” (inch) 14 AWG bare copper wire pigtail with 0.375” (inch) eyelet shall be attached to one of the studs and connected to the grounding insert tab. Pad-mounted transformers shall have 200 Amp, 15 kV Class Loadbreak Bushing Inserts installed complete with dust covers, equivalent to Cooper Catalog No. LBI215. 6.01.2.c.1 6.02 A wire shall be wrapped around the dust cover and secured to the bail tab holes. LOW-VOLTAGE BUSHINGS The secondary low voltage compartment shall be in accordance to ANSI C57.12.26 and as more fully described below: 6.02.1 Low voltage bushing arrangement - The low-voltage bushing shall be in accordance to ANSI C57.12.26, Figure 8.a, staggered “Low-Voltage Terminal Arrangements and Specific Dimensions”. 6.02.1.a The secondary compartment and bushings shall support 265 pounds of conductor weight for each NEMA eight, (8) hole spade. 6.02.1.b The secondary compartment and bushings shall support 350 pounds of conductor for each NEMA twelve (12) hole spade. 6.02.2 Low-voltage terminals shall be porcelain, thermoplastic, or high temperature epoxy insulated and be of integral (one piece) construction consisting of a single-piece, rectangular spade-type terminal. The minimum ampacity rating of the secondary bushing(s) shall be 125% (percent) of the transformers name plate rating. 6.02.3 Low-voltage terminals shall be copper rated for either aluminum or copper terminal connectors/conductors. 6.02.3.a Transformers rated 45 kVA through 500 kVA. The terminal shall be a copper spade bushing complete with 4-hole square external clamp. 1. The external (secondary) terminal shall be an eight (8) hole terminal (spade type) and be similar to ANSI C57.12.26, Figure 9b. 2. The eight (8) hole terminal shall be capable of supporting 265 pounds of conductor weight. 3. The internal terminal connection shall be either a 1-1/2” (inch) threaded stud/post or two (2) hole pad. 7 Contract Documents 170-4212 4. When using the threaded stud/post the configuration shall be nut, lead nut and jam nut. Other configurations are not acceptable. 5. When using the two (2) hole pad the configuration shall use both holes with required nut and bolt connections. 6. The bushing shall be rated at a minimum of 1600 amps continuous. 6.02.3.b Transformers rated 750 kVA through 2500 kVA. Terminal shall be copper spade bushing complete with 4-hole square external clamp. 1. The internal connection shall be an minimum four (4) hole terminal and the external (secondary) terminal shall be a twelve (12) hole paddle externally supported. 2. The twelve (12) hole terminal shall be capable of supporting 350 pounds of conductor weight. 3. The terminal shall be in accordance to ANSI C57.12.26, Figure 9c. 4. The terminal shall be rated at 4515 amps continuous. 6.02.4 Low-Voltage Bushing Supports. 6.02.4.a 45 kVA through 300 kVA transformers may be supported as shown in Figure A or B below when required to achieve 265 lbs. of support. 6.02.4.b 500 kVA through 2500 kVA transformers shall have bushing supports that will not interfere with NEMA sized pad holes and shall not block the bushing end from possible extension per Figure A or B below: Minor modifications to the drawings are acceptable as long as the intent is followed. 8 Contract Documents 170-4212 FIGURE A 9 Contract Documents 170-4212 FIGURE B 6.02.5 Low-Voltage Connections – The low-voltage spades shall be bi-metallic for use with either copper or aluminum conductors. Manufacturer’s design of bushing to windings shall be described and submitted as part of Bidder’s Data. 10 Contract Documents 170-4212 7.0 FUSING 7.01 FUSING TYPE, STYLE & RATING 7.01.1 The transformer shall be protected with a Bay-O-Net assembly, fuse cartridge, current sensing fuse, end plug, drip guard and an internal isolation link, completely assembled and installed. See the following stock pages for approved catalog numbers: 7.01.1.a District Stock Page #24621800 for Bay-O-Net assembly and drip guard. 7.01.1.b District Stock Page #24618068 for fuse cartridge, end plug and current sensing fuse. 7.01.1.c District Stock Page #24618659 for high amp fuse cartridge, end plug and high current sensing fuse for transformers rated 1000 kVA to 2500 kVA. 7.01.1.d District Stock Page #24629004 for isolation link. 7.01.2 The Bay-O-Net fuse shall be unobstructed and readily removable from the fuse holder using a standard hot stick. 8.0 8.01 7.01.3 For 1000 kVA and greater, the Bay-O-Net assembly contacts will be silver plated. PAINT / COATING SYSTEM/NAMEPLATE/LABELS PAINT FINISH & COATING 8.01.1 A corrosion-resistant finish for the carbon steel pad-mounted transformer shall meet or exceed the requirements of ANSI C57.12.28. 8.01.2 The outside shall be properly prepared, primed and coated. 8.01.3 The color shall be Munsell Color No. 7GY3.29/1.5 pad-mount green. 8.01.4 Each tank shall be given a phosphatizing bath or sand blasted, or grit blasted then primed with epoxy or vinyl primer which is no less than 2.0 mils dry thickness. 8.01.4.a All surfaces on the tank shall be primed, including under and around all access points and doors. 8.01.5 The exterior finish primer coat shall be semi-gloss polymer, scratch resistant, free of runs and sags, no less than one (1) mil dry thickness. 8.01.6 The total measured thickness of the coated exterior surface shall not be less than three (3) mils dry thickness. 8.01.6.a Baked enamel or heat fused powder paint are acceptable as long as the three mil dry thickness is achieved. 8.02 NAMEPLATE 8.02.1 An aluminum name plate with name plate information engraved shall be securely attached to each transformer. 8.02.2 Nameplate information shall be in accordance to IEEE Std C57.12.00 paragraph 5.12.2 “Nameplate A”. 8.02.3 The nameplate shall be mounted inside the termination cabinet at the top on the secondary side. 11 Contract Documents 170-4212 8.02.4 8.03 A second aluminum name plate with the transformer size, manufacturer, serial number and other data shall be attached securely to the secondary door interior. DISTRICT SUPPLIED & APPLIED LABELS 8.03.1 The District shall provide and install the exterior warning and interior danger stickers. 8.03.2 The District will provide and install kVA rating label on the front exterior of the closure for all 3Ø pad-mounted transformers. 8.03.2.a The manufacturer shall not ink, stencil, paint or label the front of the cabinet with a kVA rating. KVA labeling from the manufacturer shall be on the name plate only. 8.03.2.b See 8.04 below for all required labeling to be included by the manufacturer. 8.04 MANUFACTURER LABEL REQUIREMENTS 8.04.1 The manufacture shall provide and install all other ANSI and District required transformer labels and stickers. 8.04.2 These shall include but not be limited to the following:. 8.04.2.a Bushing labels and markings (both high and low voltage). 8.04.2.b When using the fill plug for oil level indication the plug shall be labeled with either oil level line or arrow as the oil level indicator on the tank face. 8.04.2.c The required oil fill level shall never be higher than the bottom of the oil fill plug. 8.04.2.d Bayonet fuse labels verifying the brand of Bay-O-Net fuse holders and catalog number of current sensing fuse. 8.04.2.e A sticker or glued on tag attached to the back of the tank with manufacturer information. 9.0 9.01 QUALITY ASSURANCE / TEST TESTS All transformers manufactured under this specification shall be tested according to ANSI C57.12.00 Table 17 and ANSI C57.12.90. Tests required are listed as Routine and Design in Table 19 Section 8 of C57.12.00 and shall be performed as listed in C57.12.90 with the exception of load and no load losses. Actual loss data shall be prepared in accordance with the Bid Form. 10.0 10.01 TRANSPORTATION AND HANDLING MANUFACTURER Responsibilities The manufacturer shall prepare transformers for shipping/transportation as described below: 10.01.1 The manufacturer shall ship transformers completely assembled and filled with the proper amount of transformer oil. 10.01.2 The manufacturer shall ship/transport the transformers according to the following: 10.01.2.a The District requires that all transformers shipped during the months of October through March shall be in covered transportation (tarped on a flatbed or van) to protect the transformers from dirt and grime. 12 Contract Documents 170-4212 10.01.2.b The manufacturer shall have the option from April through September to ship the transformers in covered transportation (tarped on a flatbed or van) or washing the road dirt and grime off all surfaces prior to delivery. 10.01.2.c Any transformer exceeding 5,500 pounds shall be shipped on a flatbed trailer and tarped or washed as described in 10.01.2.e below. 10.01.2.d Transformers greater than 750 kVA shall be shipped on a flatbed trailer, as describe above and shall be arranged to be unloaded from the side by forklift (Van shipment of transformers exceeding 5,500 lbs or 750 kVA shall not be accepted). 10.01.2.e If any transformer is shipped uncovered, the bill of lading will clearly state the driver will be responsible to wash any and all road grime from the transformers. 10.01.3 The manufacturer shall observe District’s warehouse delivery schedule as described in Contract Documents or as stated on the quote. 10.01.4 Any shipping damage shall be repaired or corrected to the satisfaction of the District. 10.02 DISTRICT RESPONSIBILITIES 10.02.1 The District will provide equipment and personnel to unload transformers using methods to prevent damage. 10.02.2 The District will promptly inspect shipments to assure that transformers comply with requirements, quantities are correct, and transformers are undamaged. 13 Contract Documents 170-4212 BID DATA SHEET PAD-MOUNTED TRANSFORMER, THREE-PHASE A separate Bid Data Sheet must be completed for each kVA size and voltage rating. Each Bid shall include a statement that the manufacturer has reviewed the dimensions included in Section 3.02.2 and that those dimensions will be complied with. When notified the apparent low Bidder will provide complete dimensional drawings within 10 working days of notification. Each Bid shall include a statement that the manufacturer has reviewed both the high and low bushing requirements in sections 6.01 & 6.02 and that the correct bushings/connectors shall be provided. Describe and submit the coating system on separate sheets. Manufacturer:__________________________________________ Date: __________________ Contract Number:__________________________ Bid Item Number:__________ Size: _____________kVA High Voltage (ANSI Desig.) _____________kV Low Voltage (ANSI Desig.) _____________Volts Impedance Voltage: _____________% Maximum L.V. Short Circuit Current _____________kA Maximum L.V. Short Circuit Current is at: L-L L.V. Windings (Interlaced or Non-interlaced): ________________ Short Circuit Impedance: _____________% Total Weight: _____________Pounds Oil: _____________Gallons H.V. Winding Metal, Type: ________________ L.V. Winding Metal, Type: ________________ Core Metal, Type: (Grain oriented, Amorphous) ________________ Minimum Primer Thickness: ______________Mils 2 mil required Minimum Paint Thickness: 1 mil required Total Primer/Paint thickness shall not be less than 3 mils. Corrosion Protection 14 or L-N ______________Mils Contract Documents 170-4212 Verify that the entire bottom 1-1/2” (inches) is Type 304 (18-8) stainless steel ________________ Secondary Bushing Current Rating (@ max hot spot rating) _______________Amps Core Loss: Winding Loss: _______________Watts _______________Watts See section 3.02.2 Minimum Cabinet Provisions: The vendor shall verify the dimensions shown in the drawing and required in the table below. Table Bid Form; Transformer Dimension with Table (Dimensions must be included for each Bid Item and shall be listed in inches only.) Using the nomenclature listed above provide the following dimensions. Overall Cabinet Width HV Cabinet Width LV Cabinet Width Overall Cabinet W 15 Cabinet Depth Base Depth Tank W with or without fins