Resilient Seated Gate Valves

advertisement

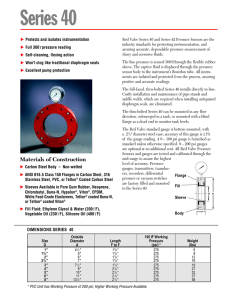

Resilient Seated Gate Valves Superior Design + Manufacturing Excellence = Long Term Reliability Tyco Resilient Seated Gate Valves Tyco UL listed and FM approved Resilient Seated Gate Valves conform to Underwriters Laboratories and Factory Mutual standard and to other international standards including: BS 5163, EN 1074, EN1171 and ISO 7259. It is one of the lightest most durable gate valves on the market today. Its materials and design make it easy to operate and built to last a lifetime. The fully encapsulated EPDM Ductile Iron Wedge ensures drop tight sealing. Valve components are either inherently corrosion resistant or protected with Fusion Bonded Polyester Resin Coating for a long, reliable service life and enhanced UV protection for exposed installations. Features Benefits // Lightweight ductile iron body and bonnet // Minimal weight and optimum strength, providing impact and surge pressure resistance // Ductile iron wedge gate, fully encapsulated with EPDM rubber // Reliable drop tight seal, no risk of long term corrosion // Fusion bonded polyester resin coating inside and out // Lifetime corrosion and operating protection - assured quality coating // Anti-friction wedge guides // Lower operating torque, ensures a higher life cycle // Permanent bar code product label // Each valve has a unique serial and batch number providing total product traceability // Replaceable or repairable stem seals // Seals can be removed and replaced or repaired under full operating pressure on all valves // Multiple configurations and operation modes // Outside screw and yoke, non-rising stem with post indicator cap and post indicators Why Choose Gate Valves From Tyco? Material selection is one factor... Tyco manufactured FM approved and UL listed gate valves incorporate high strength stainless steel stems, dezincification resistant copper alloy components, high grade elastomers and quality coating systems. …Valve design is another… There are no corrosion points in a Tyco gate valve. The Ductile iron gate is fully encapsulated in EPDM and any other component that are not inherently corrosion resistant are coated with a thermally applied Fusion Bonded Epoxy. The gate sealing design combines wedge and compression mechanisms to ensure low torque drop tight sealing. The stem seal arrangement incorporates five separate O-rings to provide a life time seal. ...Product testing and quality assurance ensures in-field performance Stringent Type Testing ensures Tyco gate valves meet the highest standard. Additionally every valve is hydrostatically tested before leaving the factory. A satisfactory shell test and seat test – in both directions, and maximum operating torque to seal – is a pre-requisite to acceptance and shipment. UL Listed and FM Approved OS&Y Gate Valve Type TMR 6 7 8 5 2 4 3 1 The Tyco OS&Y (rising stem) gate valve incorporates a unique design feature which provides a backup sealing device for the O ring stem seals in all OS&Y valves. This can be activated with the valve under full working pressure in the unlikely event of future leakage past the primary seals. and are shipped from the factory separately. DURING VALVE INSTALLATION THE TWO FASTENING NUTS SHOULD REMAIN FINGER TIGHT ONLY. It is normal for the two top nuts and gland remain in a relaxed state (loose) whilst the valve is installed and operated. Note however that The valve incorporates two the nuts below the gland hold primary O ring stem seals the yoke and guide in place which are designed to operate and these nuts should always for the lifetime of the valve. In remain fully tightened. the unlikely event that there is leakage past these O rings, Tightening the top nuts during valve installation a gland with additional seals is unnecessary as it will can be engaged by utilising create an additional torque the top nuts to provide a requirement to operate the backup stem sealing system. valve and may wear out Note that the gland and nuts the back up sealing device are not individually packed prematurely. 1: O ring stem seals 2: Guide 3: Additional seals 4: Additional seals 5: Gland 6: Yoke 7: Top nuts 8: Gland In applications where vibration may occur, a thread locking sealant can be applied to the top nuts to prevent them vibrating loose. Activation In the event of leakage through the primary seal use a spanner to tighten nuts gradually, applying an equal number of turns to each nut until leakage ceases. OS&Y Gate Valve Technical Data DN50 – DN300 (2"- 12") Size Range: Maximum operating pressure: UL - 300 Psi (20,87 bar) FM- 232 Psi (16 bar) Maximum test pressure: 348 Psi (24bar) Manufacturing Standard: UL / FM / EN1074 / ISO 7259 Flanges: EN 1092-2 / ISO 7005.2 or ASME B16.1 / ASME B16.42 Drilling: PN10 / PN16 or ANSI 125 / 150 Datasheet: TFP 1540 Valve Size " (DN mm) 50 65 80 100 150 200 250 300 Face to face (L) " (mm) 7.00 (178) 7.50 (190) 8.00 (203) 9.00 (229) 10.50 (267) 11.50 (292) 13.00 (330) 14.00 (356) Centre Height Open (CL1) " (mm) 15.55 (395) 16.14 (410) 18.9 (480) 22.56 (573) 29.53 (750) 37.64 (956) 46.25 (1175) 51.89 (1318) Centre Height Closed (CL2) " (mm) 13.07 (332) 13.31 (338) 14.96 (380) 17.72 (450) 23.31 (592) 29.45 (748) 34.96 (888) 39.57 (1005) OD1 2.375 (60.3) 2.875 (73.0) 3.500 (88.9) 4.500 (114.3) 6.500 (165,1) 8.625 (219.1) 10.750 (273.0) 12.750 (323.9) OD2 2.375 (60.3) 3.000 (76.1) 3.500 (88.9) 4.500 (114.3) 6.625 (168,3) 8.625 (219.1) 10.750 (273.0) 12.750 (323.9) FL-FL 29.8 (13.5) 35.3 (16) 41.9 (19) 57.3 (26) 97.0 (44) 154.4 (70) 264.6 (120) 330.8 (150) FL-GR 27.6 (12.5) 30.9 (14) 36.4 (16.5) 50.7 (23) 88.2 (40) 143.2 (65) 242.6 (110) 297.7 (135) GR-GR 25.4 (11.5) 26.5 (12) 30.9 (14) 44.1 (20) 79.4 (36) 110.3 (50) 220.5 (100) 275.6 (125) Grooved version OD " (mm) Weight Lbs. (Kg) Available End Connections Flange-Flange TMRX Flange-Groove Groove-Groove TMRT TMRG # Description Material 1 Wedge EPDM coated Ductile Iron 2 Wedge nut Cold forged copper alloy 3 Stem pin Stainless steel AISI 420 4 Sealing gasket EPDM-70 5 Sealing O rings NBR 6 Stem Guide Copper alloy 7 Stem O rings NBR 8 Compression washer Stainless steel AISI 420 9 Top Gland FBP coated Ductile Iron 10 Fixing Washers Copper alloy 11 Top nut Copper alloy 12 Hand wheel FBP coated Ductile Iron 13 Yoke FBP coated Ductile Iron 14 Stem Stainless steel AISI 420 15 Gland Stud Zinc Coated mild steel 16 Gland nut Zinc Coated mild steel 17 Gland washers Zinc Coated mild steel 18 Bonnet casting FBP coated Ductile Iron 19 Screw grouting Activated resin (removable) 20 Bonnet Screws Black Oxide Finished Carbon steel 21 Body casting FBP coated Ductile Iron Non Rising Stem Post Indicator Gate Valve Technical Data Size Range: DN100 – DN300 (4"- 12") Maximum operating pressure: FM - 232 Psi (16 bar) UL -300 Psi (20,7 bar) Maximum test pressure: 348 Psi (24bar) Manufacturing Standard: FM / EN1074 / EN 1171/ ISO 7259 Flanges: EN 1092-2 / ISO 7005.2 or ASME B16.1 / ASME B16.42 Available Drilling: PN10 / PN16 or ANSI 125/ 150 Datasheet: TFP 1545 Aggressive media version also available for salt water applications. Valve Size " (DN mm) 100 150 200 250 300 Face to face (L) " (mm) 9.00 (229) 10.50 (267) 11.50 (292) 13.00 (330) 14.00 (356) Centre Height (CL1) " (mm 13.07 (332) 17.17 (436) 20.47 (520) 24.41 (620) 26.38 (670) OD type 1 4.500 (114,3) 6.500 (165,1) 8.625 (219,1) 10.750 (273,1) 12.750 (323,9) OD type 2 4.500 (114,3) 6.625 (168.3) 8.625 (219,1) 10.750 (273,1) 12.750 (323,9) Flanged-Flanged 70.5 (32) 103.6 (47) 169.7 (77) 240.3 (109) 295.4 (134) Flanged-Grooved 55.1 (25) 83.8 (38) 134.5 (61) 202.8 (92) 262.4 (119) Grooved-Grooved 48.5 (22) 75.0 (34) 123.5 (56) 180.8 (82) 235.9 (107) Grooved version (OD) " (mm) Weight (Kg) Available End Connections Flange-Flange TMPX Flange-Groove TMPT 15 12 2 10 11 13 16 14 14 18 17 5 3 5 Groove-Groove 9 4 6 20 2 1 19 8 7 NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 TMPG # Description Material 1 Wedge Nut Bronze 2 Stem QTY. DESCRIPTION Wedge Nut . . . . . . . . . . 1 3 Bonnet Screw Stem . . . . . . . . . . . . . . 1 Bonnet Screw . . . . . . . 4 ......1 Sealing Gasket 4 Sealing Gasket Bonnet . . . . . . . . . . . . . 1 Sealing O-Ring . . . . . . 1 5 Bonnet Sealing O-Ring . . . . . . 1 Stem Ring . . . . . . . . . . 1 ........1 Stem Bearing 6 Sealing O-Ring Dust Guard . . . . . . . . . 1 Top Cap . . . . . . . . . . . . 1 7 Sealing O-Ring Cap Screw . . . . . . . . . . 1 Sealing O-Ring . . . . . . 2 8 StemFlange Ring . . . . . . 1 Indicator Indicator Top Screw . . . 2 ...........1 Bushing 9 Stem. Bearing Sealing O-Ring . . . . . . 1 Screw Grouting . . . . . . 1 10 Dust . .Guard ...........1 Wedge Body . . . . . . . . . . . . . . . 1 Stainless Steel MATERIAL Bronze Black Oxide Carbon Steel Stainless Steel Black Oxide Carbon Steel EPDM EPDM FBE Coated Ductile Iron NBR FBE Coated Ductile Iron NBR Stainless Steel Bronze NBR EPDM FBE Coated Ductile Iron NBR Black Oxide Carbon Steel NBR Stainless FBE CoatedSteel Ductile Iron Black Oxide Carbon Steel Nylon Bronze NBR Activated Resin EPDM EPDM Coated Ductile Iron FBE Coated Ductile Iron 11 Top Cap FBE Coated Ductile Iron 12 Cap Screw Black Oxide Carbon Steel 13 Sealing O-Ring NBR 14 Indicator Flange FBE Coated Ductile Iron 15 Indicator Top Screw Black Oxide Carbon Steel 16 Bushing Nylon 17 Sealing O-Ring NBR 18 Screw Grouting Activated Resin 19 Wedge EPDM Coated Ductile Iron 20 Body FBE Coated Ductile Iron Indicator Post Tyco Fire Protection Products offers a range of Factory Mutual approved adjustable vertical indicator posts for use with DN100 to DN300 non rising spindle resilient seated PIV gate valves in buried applications. Indicator posts are normally provided for use with clockwise closing valves however may be ordered for use with anticlockwise closing valves where required. Buried valves are commonly used in fire protection systems to control water supply to automatic sprinklers, water spray deluge, foam-wafer deluge or standpipe systems. Vertical Indicator posts are utilized to allow above ground actuation of gate valves, whilst also providing a visual indication of the open or shut status of the valves. They also provide a means for locking the valves to avoid unauthorized operation. The Tyco Indicator Post features a telescoping stem that can be adjusted to its final position in the field. The appropriate Indicator Post type for a particular application depends on the size of the valve and trench depth. The Indicator post is available in 4 different lengths. See TFP 1545. # Description Material 1 Cotter Pin Carbon Steel 2 Screw Pin M16 Zinc coated carbon steel 3 Hex Cap Screw M16 Zinc coated carbon steel 4 Hex Nut M16 Zinc coated carbon steel 5 Upper Pipe FBP coated carbon Iron 16 6 Lower Pipe FBP coated carbon Iron 13 7 Eye Bolt M12 Zinc coated carbon steel 8 Target “SHUT” Aluminum 15 18 9 Screw M6 Zinc coated carbon steel 12 27 10 Hex Nut M6 Zinc coated carbon steel 19 28 Aluminum 11 17 10 20 9 7 11 Target “OPEN” 14 29 12 Stem Nut Bronze 13 O Ring NBR 8 14 Wench 1/2 FPB coated Ductile Iron 21 15 Operating Stem Bronze 22 16 Hex Socket Set Screw Stainless Steel 17 Post Cap FBP coated Ductile Iron 18 Screw M6 Zinc coated carbon steel 19 Pipe Plug 1/2" NPT Zinc coated carbon steel 20 Carrier Plate Carbon Steel 21 Hex Cap Screw M12 Zinc coated carbon steel 22 Flat Washer 12 Zinc coated carbon steel 31 5 6 23 4 3 30 23 Extension Rod FBP coated Carbon Steel 24 Connect Cap FBP coated Ductile Iron 2 25 O Ring NBR 1 26 Bottom Flange FBP coated Ductile Iron 24 27 Ferrule Zinc coated carbon steel 28 Window Plastic 29 Gasket NBR 30 Hex Socket Set Screw Stainless Steel 31 Hex Socket Set Screw Stainless Steel 25 26 NO 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 3 3 11 12 10 10 Handwheel . . . . . . . . . . 11 Eye Bolt M16 . . . . . . . . # Description Material 1 Connect Cap FBE Coated Ductile Iron 2 Cotter Pin Carbon Steel 3 Post Body FBE Coated Ductile Iron 4 Carrier Plate Carbon Steel 5 Hex Nut M6 Zinc Coated Carbon Steel 6 Pipe Plug 1/2" NPT Zinc Coated Carbon Steel 13 7 Screw M6 Zinc Coated Carbon Steel 14 8 Stem Nut Bronze 9 Operating Stem Bronze 10 Handwheel FBE Coated Ductile Iron 11 Eye Bolt M16 Zinc Coated Carbon Steel 12 Flat Washer 16 Zinc Coated Carbon Steel 13 Hex Socket Set Screw Stainless Steel 14 O-Ring NBR 15 Eye Bolt M12 Zinc Coated Carbon Steel 16 Screw M6 Carbon Steel 9 7 8 15 6 17 20 18 5 19 17 Ferrule Carbon Steel 16 3 18 Window Plastic 21 4 19 Gasket NBR 20 Target “OPEN” Aluminum 21 Target “SHUT” Aluminum 22 Extension Rod FBE Coated Carbon Steel 1 1 FBE Coated Ductile Iron Zinc Coated Carbon Steel 21 Target "SHUT" . . . . . . . . 22 Extension Rod . . . . . . . 1 1 Aluminum FBE Coated Carbon Steel Wall Indicator 22 2 1 Supervisory switch The Indicator Post incorporates a 1/2" NPT tapped port to accommodate the installation of a supervisory switch which can be used to electrically monitor the open position of the valve. ­A Potter Model PCVS-2 Control Valve Supervisory Switch, which is FM approved, UL listed and CE marked, is recommended as a suitable device Safer. Smarter. Tyco Global Strength. Local expertise. At your service www.tfppemea.com ENSCHEDE Kopersteden 1, P.O. Box 198, 7500 AD Enschede, The Netherlands, Tel. +31 (0)53-428-4444 www.tfppemea.com SINGAPORE Tyco Fire Protection Products, 2 Serangoon North Avenue 5, #07-01, Singapore 554911 Tel. +65-6577-4360, Fax: +65-6481-8791 www.tyco-fire.com TYFENGATE1112 WORLDWIDE HEADQUARTERS Tyco Fire Protection Products, 1400 Pennbrook Parkway, Lansdale, PA 19446, Tel: +1 215-362-0700, (Toll Free) Tel: +1 800-558-5236, Fax: +1 800-877-1295 www.tyco-fire.com