Relevance of Frequency and Duty-Cycle for Dynamic Flow Control

advertisement

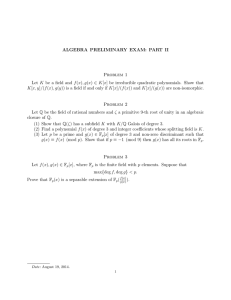

Relevance of Frequency and Duty-Cycle on the Dynamic Flow Control at High Lift Conditions J Ortmanns, P Scholz, CJ Kähler, R Radespiel Institut für Strömungsmechanik der TU Braunschweig Bienroder Weg 3, 38106 Braunschweig, Germany e-mail: j.ortmanns@tu-bs.de CEAS/KATnet CEAS/KATnet Conference, 20.06. – 22.06.2005, Bremen, Germany ABSTRACT The application of vortex generator jets for active flow control is a well known method. In the regime of high lift systems for instance longitudinal vortex structure can be generated to enhance the mixing process to prevent separation. The performance of this control method depends strongly on: 1) the velocity ratio λ = w/U∞ of the jet exit velocity and the free stream velocity, the actuator design, its size and shape with respect to the boundary layer thickness [1]. The pitch and the skew angle – α and β – relative to the flat plate and the free stream velocity, respectively. In the case of active flow control also the frequency f and the duty-cycle Δ have to be taken into account. To understand the significance of these two parameters a flat plate experiment with a turbulent boundary layer was mounted in a wind and a water tunnel and investigated experimentally with PIV. The global effect: the gain of momentum in the near wall region of the turbulent boundary layer (z = 1.5 mm = const.) is determined with an experimental set-up installed in the low noise, low speed wind tunnel Braunschweig (LNB) [2]. To get detailed information about the flow structures at different duty-cycle a second experiment was investigated in the water tunnel (WUB) [2]. z Experimental Setup x 1) 2D-PIV measurements in the xy-plane at z = 1.5 mm = const. in air (LNB), U∞ = 15 m/s and δ ≈15 mm (stripped at x/c = 0.05). A PCO 4000 camera was in use and the whole PIV system was connected with the frequency generator HAMEG 8131-2, which allows the adjustment of an arbitrary frequency f and duty cycle Δ, to get phase locked results. The pneumatic actuator is based on a commercial MH2 fast-switching valve from FESTO with a maximum switching frequency of 200 Hz (minimum response time of 2 ms ± 10 %) at an operating pressure range from 0.9 to +8 bar. The orifice design was a rectangular slot with an aspect ratio of h/b = 32 (h = 10 mm) and the skew angle was set to β = 45 deg. For main results see [1,3]. 2) For a detailed analysis of the structures generated by the actuator process for different duty-cycles the second measurement campaign was performed in water (WUB). In order to detect the 3D-effect of the actuation on the turbulent boundary the 2D-PIV measurements were performed at z = [0.65, 1.74, 4.65, 12.43, 25] mm. The boundary conditions were U∞ = 0.55 m/s and δ ≈ 15 mm (stripped at x/c = 0.05, XFoil), so a direct comparison of the results in air is not possible. However, the goal of the second experiment was to show how the turbulent boundary layer reacts on a dynamic perturbation in the temporal and spatial domain. For the dynamic of the blowing process a SIRAI micro solenoid valve was utilized, controlled by the frequency generator HAMEG 8131-2 and connected with the PIV system. The actuator was a hole of d = 1 mm and installed at α = 45 deg and β = 90 deg. x xy - plane Turbulator Width: 248 mm z Sketch of the measurement position in the turbulent boundary layer in the water tunnel experiment. u Flow visualization (laminar) actuator d = 1 mm, α = 45°, β = 90°. Results The results of the wind tunnel experiments are velocity distributions of the u- und v-component in the z-plane. The gain of momentum can be expressed by [4]: , where Δu is the velocity change with respect to the undisturbed flow, b the width for the 2D case and ΔI = ρ Δu ⋅ Δu ⋅ dy ρ the density. b Feed line pressure pV Slot actuator, α = 45 deg, β = 90 deg ∫ 0.2 0.2 0.1 0.1 0 steady f = 50 Hz f = 80 Hz f = 100 Hz f = 120 Hz -0.1 -0.2 0 25 50 x [mm] 75 The frequency has only a very little effect on the gain of momentum in the near wall region along x. The decreasing values for f ≤ 80 Hz supposed to be an effect of a higher flow drag of the valve (pV = 1.5 bar = const.). However, the characteristics of the curves are equal. Slot actuator, α = 30 deg, β = 90 deg 0.1 steady Δ = 10 % Δ = 25 % Δ = 50 % Δ = 75 % -0.1 0 25 50 x [mm] 75 100 The duty-cycle (f = 50 Hz = const.) has a more significant effect on the velocity distribution closed to the wall. For Δ = 50 % the curve progression is almost equal to the steady case, which results in a doubling of efficiency. Δ = 75 % even raises up to higher values. 2.0 bar 1,75 bar 1.5 bar 1.25 bar 1.0 bar 0.75 bar 0.5 bar 0 -0.1 -0.2 0 -0.2 100 Δ I/b [N/m] Duty-Cycle Δ Slot actuator, α = 45 deg, β = 90 deg Δ I/b [N/m] Δ I/b [N/m] Frequency f 0.2 0 25 50 x [mm] 75 100 As mentioned in earlier work, the velocity ratio λ = w/U∞ of the jet exit velocity and the free stream velocity has a basic effect of the actuator force. If λ is to weak, the mixing process based on the longitudinal vortex structures does not start. Is λ to strong on the other hand, the boundary layer will be break-through and the vortex structure is not induced right close to the wall. In the present case the curves of ΔI increase with increasing feed line pressure, so λ is selected in a moderate range. The feed line pressure pV is measured 3.5 m upstream of the valve; feed line length between valve and actuator is 1 m additionally. The feed line system is a FESTO QS 4 x 0.75 system. 0.4 Details 0.35 40 30 10 0 -10 20 10 0 -10 15 40 20 -20 ϕ = 36 deg 10 0 10 0 40 30 5 20 ϕ = 108 deg 10 0 -10 20 10 0 -10 5 20 -20 -10 ϕ = 72 deg 10 0 -10 20 10 0 -10 50 15 40 30 5 20 -20 ϕ = 144 deg 10 0 -10 20 10 = +0.1 m/s 0 -10 -20 25 25 25 15 40 5 -10 20 50 15 30 30 5 20 ϕ = 0 deg 50 50 50 15 40 30 5 20 -20 ϕ = 180 deg 10 0 -10 20 10 = -0.1 m/s (Spatial dimension in mm) 0 -10 -20 0.3 0.25 0.2 t [s] 15 z = 4.65 mm Convection velocity 0.15 0.1 0.05 -10 0 10 20 30 40 -20 2 0 00 50 y 50 25 25 Δ = 25 % Period 25 The velocity distribution in the z-planes were determined using phase locked 2D-PIV in a water tunnel experiment. The period was divided into 20 phase angles. To obtain details about the flow process, the undisturbed local velocity distribution was subtracted in each plane, respectively, and the 2D results were combined to a time dependent volume data set. By defining two arbitrary values (in the present case Δu = ±0.1 m/s) for an iso-surface plot, it is possible to detect the averaged dimensions and the deformations of the generated flow structure. The figures on the left hand side reveal the temporal evolution of flow structure in 3D-space for f = 3.4 Hz and Δ = 25 %. With respect to the blowing period (start: ϕ = 0 deg, end: ϕ = 90 deg) a phase shift can be observed. The evolution and deformation of the structure are dependent on the height in the velocity distribution. To define the dependences of the dynamic perturbation and the reaction of the main flow, it is necessary to take the temporal evolution into account. Therefore, the deformation was analyzed to estimate a characteristic length- and time-scale, see figure on the right hand side. x [mm] If the dynamic process is illustrated in a space-time-diagram f(x,t), it is possible to detect a characteristic length and period in which the dynamic is effectively present. Afterwards the dynamic effect vanishes and merges into the convection velocity. In the present case (Δu = +0.1 m/s): xdynamic ≈ 7.5 mm and tdynamic ≈ 0.11 sec. The deformation of the flow structures can indicate an acceleration or deceleration in the flow field by analyzing the gradient. SUMMARY The dynamic vortex generator process is able to prevent separation with a higher efficiency. The fundamental mechanism is the mixing process in the turbulent boundary, which transfers high momentum fluid towards the wall [1]. This gain of momentum can be estimated by analyzing the velocity distribution in a z-plane (e.g. z = 1.5 mm) parallel to the wall. Global results: The frequency f has no significant effect on the momentum transport (Δ = 50 % = const.) in the frequency range considered here. A change of the duty-cycle on the other hand has a strong effect: At Δ = 50 % (f = 50 Hz) the curve of ΔI(x) is almost equal to the steady case, which results in a increase of efficiency of 50 %. An increase of the duty-cycle to Δ = 75 % even raises up to higher values of ΔI. A remarkable fact is that the dynamic process needs a longer distance to evolve its strength. A detailed analysis of the deformation and interaction between the turbulent boundary and the dynamic perturbation structures results in an estimation of a characteristic length and period of dynamic process. References [1] J Ortmanns and CJ Kähler: Investigation of pulsed actuators for active flow control using phase locked stereoscopic Particle Image Velocimetry. 12th International Symposium on Application of Laser Techniques to Fluid Mechanics, Lisbon, Portugal 12 – 15 July, 2004. [2] http://www.tu-braunschweig.de/ism/institut/wkanlagen [3] P. Scholz, J. Ortmanns, C.J. Kähler and R. Radespiel: Influencing the Mixing Process in A Turbulent Boundary Layer by Pulsed Jet Actuators. to be published Sep. 2005 in “Notes on Numerical Fluid Mechanics and Multidisciplinary Design”. [4] P. Scholz, J. Ortmanns, C.J. Kähler and R. Radespiel: Performance Optimization of Jet Actuator Arrays for Active Flow Control. CEAS/KATnet Conference, 20. – 22.06.2005, Bremen, Germany.