It is now commonly accepted that biodegradability is

advertisement

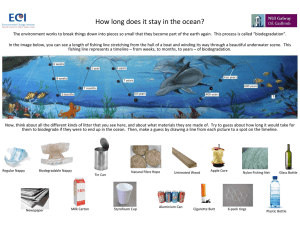

NAME : Stephane A Page, Donald B Cherry, C Clair Claiborne COUNTRY : Switzerland, USA REGISTRATION NUMBER : DLGw24813 GROUP REF. : A2 PREF. SUBJECT : 2 QUESTION N° : 2 It is now commonly accepted that biodegradability is considered to be a highly desirable property in dielectric insulating liquids used in transformers since major environmental concerns over the toxic effects and collateral damages of uncontained transformer oil spills have quite extensively been reported. The definition of biodegradation is the process by which organic substances are broken down by the enzymes produced by living organisms. Whenever any substance is placed in the environment, it begins to undergo degradation due to the action of relevant substrate utilizing microorganisms. Every substance, irrespective of its complexity and toxicity, is subject to this process. The term biodegradability is generally associated with reduced environmental impact in the event of a spill and less toxicity to living organisms. When used in the present context, it is referenced to a time frame. That is, for a transformer oil to be referred to as biodegradable, a specific time limit must be used as a reference. There are two major types or classifications of biodegradability, primary and ultimate. Both types are measured as a percentage change in relation to a period of time under standard conditions. Primary biodegradation measures the loss of a product by alteration of the chemical structure resulting in a change in the chemical nature of the product, not the partial or total degradation or breakdown of the material into CO2 and water. CEC L-33-A-93 and EPA OPPTS 835.3110 – developed by the Coordinating European Council (CEC) and by the U.S. Environmental Protection Agency (EPA), respectively – are test methods for primary biodegradation that determine the rate and extent of aerobic aquatic biodegradation under laboratory conditions. Biodegradability tests based on the CEC method described above indicate that mineral oils have poor biodegradability, i.e., typically between 15 and 35%, and as low as 10%. While silicone oils are essentially non-biodegradable per the same method, the latter shows that vegetable-based oils (or natural ester-based liquids) undergo typically about 90 to 100% biodegradation in the specified period of time (21 or 28 days). Synthetic ester-based liquid biodegradability is typically about 80% and can be as high as 90% per the same CEC method. Figure 1 – Biodegradation rates of different dielectric insulating liquids used in transformers measured as per the CEC L-33-A-93 test method after 21 days [1] Ultimate biodegradation, called mineralization, is the percentage of the substance that undergoes complete degradation, i.e., how long it takes to achieve a specific percentage of complete degradation. When this happens it is referred to as Ultimate or Complete Biodegradation – which is the degradation achieved when a substance is totally utilized by microorganisms resulting in the production of carbon dioxide, methane, water, mineral salts, and new microbial cellular constituents. ISO Method 14593, ASTM D5864 and Method OECD 301B – the Modified Sturm Test developed by the Organization for Economic Cooperation and Development (OECD) – determine ultimate biodegradation through the measurement of CO2 released. A material is classified as readily biodegradable when 60% or more of the test material carbon is converted to CO2 in a 10 day window over a maximum period of 28 days, as determined using these test methods. ISO Method 10708, OECD Methods C, D, F, and Method EPA 560/6-82-003, number CG-2000 – the Shake Flask Test adapted by the U.S. Environmental Protection Agency (EPA) – determine biodegradation through the measurement of Biochemical Oxygen Demand (BOD). The pass criteria for these tests is the same, i.e., at least 60% of the oil has to be degraded within a 10 day window over a maximum 28-day period. Both natural and synthetic ester-based dielectric insulting liquids are typically readily biodegradable. Figure 2 – Biodegradation rates of different dielectric insulating liquids used in transformers measured as per the OECD 301B test method [2] The key point when specifying biodegradability is to ensure that a required percentage is set in reference to a specific test method. Prior agreement to these parameters will serve to prevent confusion or misinterpretation of the reported test results. [1] R. Asano and S. A. Page, “Reduced environmental impact and improved safety and performance of power transformers with natural ester dielectric insulating fluids”, Paper PR-13, 9th Petroleum and Chemical Industry Conference Europe, Electrical and Instrumentation Applications, Prague, Czech Republic, June 2012 [2] Cigré Brochure 436, Experiences in Service with New Insulating Liquids, October 2010