Dielectric behavior of transformer oil when - Constellation

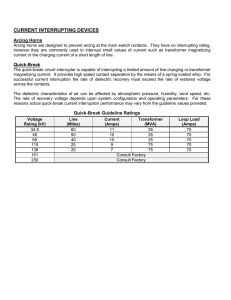

advertisement