Installation Instructions

advertisement

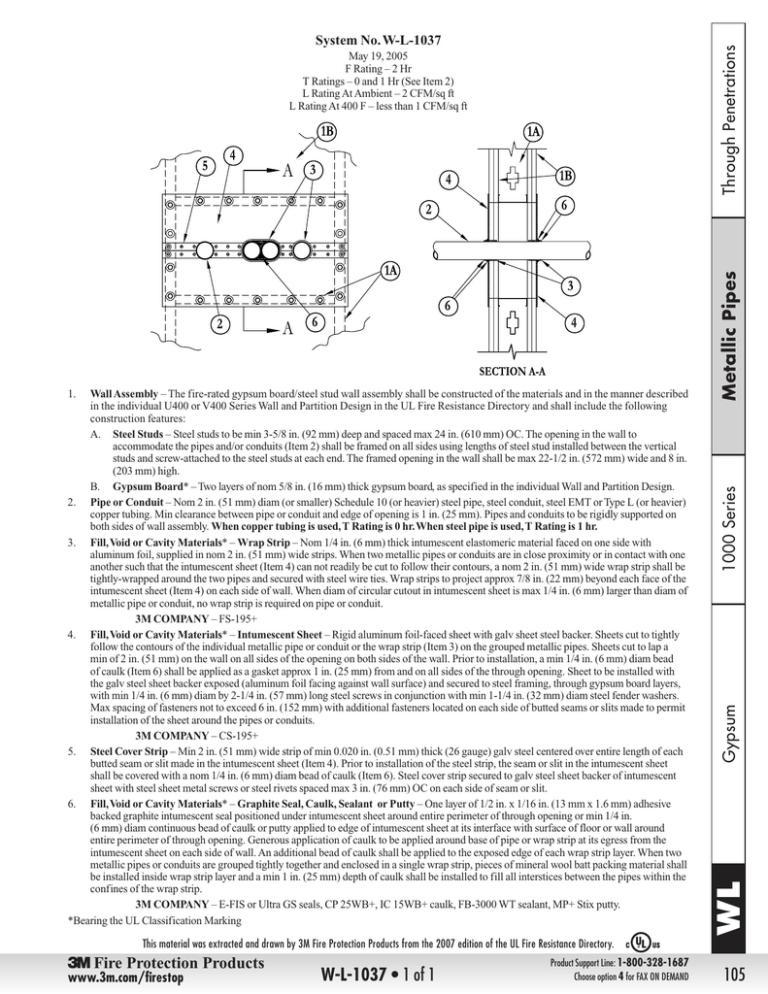

1000 Series Wall Assembly – The fire-rated gypsum board/steel stud wall assembly shall be constructed of the materials and in the manner described in the individual U400 or V400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the following construction features: A. Steel Studs – Steel studs to be min 3-5/8 in. (92 mm) deep and spaced max 24 in. (610 mm) OC. The opening in the wall to accommodate the pipes and/or conduits (Item 2) shall be framed on all sides using lengths of steel stud installed between the vertical studs and screw-attached to the steel studs at each end. The framed opening in the wall shall be max 22-1/2 in. (572 mm) wide and 8 in. (203 mm) high. B. Gypsum Board* – Two layers of nom 5/8 in. (16 mm) thick gypsum board, as specified in the individual Wall and Partition Design. 2. Pipe or Conduit – Nom 2 in. (51 mm) diam (or smaller) Schedule 10 (or heavier) steel pipe, steel conduit, steel EMT or Type L (or heavier) copper tubing. Min clearance between pipe or conduit and edge of opening is 1 in. (25 mm). Pipes and conduits to be rigidly supported on both sides of wall assembly. When copper tubing is used, T Rating is 0 hr. When steel pipe is used, T Rating is 1 hr. 3. Fill, Void or Cavity Materials* – Wrap Strip – Nom 1/4 in. (6 mm) thick intumescent elastomeric material faced on one side with aluminum foil, supplied in nom 2 in. (51 mm) wide strips. When two metallic pipes or conduits are in close proximity or in contact with one another such that the intumescent sheet (Item 4) can not readily be cut to follow their contours, a nom 2 in. (51 mm) wide wrap strip shall be tightly-wrapped around the two pipes and secured with steel wire ties. Wrap strips to project approx 7/8 in. (22 mm) beyond each face of the intumescent sheet (Item 4) on each side of wall. When diam of circular cutout in intumescent sheet is max 1/4 in. (6 mm) larger than diam of metallic pipe or conduit, no wrap strip is required on pipe or conduit. 3M COMPANY – FS-195+ 4. Fill, Void or Cavity Materials* – Intumescent Sheet – Rigid aluminum foil-faced sheet with galv sheet steel backer. Sheets cut to tightly follow the contours of the individual metallic pipe or conduit or the wrap strip (Item 3) on the grouped metallic pipes. Sheets cut to lap a min of 2 in. (51 mm) on the wall on all sides of the opening on both sides of the wall. Prior to installation, a min 1/4 in. (6 mm) diam bead of caulk (Item 6) shall be applied as a gasket approx 1 in. (25 mm) from and on all sides of the through opening. Sheet to be installed with the galv steel sheet backer exposed (aluminum foil facing against wall surface) and secured to steel framing, through gypsum board layers, with min 1/4 in. (6 mm) diam by 2-1/4 in. (57 mm) long steel screws in conjunction with min 1-1/4 in. (32 mm) diam steel fender washers. Max spacing of fasteners not to exceed 6 in. (152 mm) with additional fasteners located on each side of butted seams or slits made to permit installation of the sheet around the pipes or conduits. 3M COMPANY – CS-195+ 5. Steel Cover Strip – Min 2 in. (51 mm) wide strip of min 0.020 in. (0.51 mm) thick (26 gauge) galv steel centered over entire length of each butted seam or slit made in the intumescent sheet (Item 4). Prior to installation of the steel strip, the seam or slit in the intumescent sheet shall be covered with a nom 1/4 in. (6 mm) diam bead of caulk (Item 6). Steel cover strip secured to galv steel sheet backer of intumescent sheet with steel sheet metal screws or steel rivets spaced max 3 in. (76 mm) OC on each side of seam or slit. 6. Fill, Void or Cavity Materials* – Graphite Seal, Caulk, Sealant or Putty – One layer of 1/2 in. x 1/16 in. (13 mm x 1.6 mm) adhesive backed graphite intumescent seal positioned under intumescent sheet around entire perimeter of through opening or min 1/4 in. (6 mm) diam continuous bead of caulk or putty applied to edge of intumescent sheet at its interface with surface of floor or wall around entire perimeter of through opening. Generous application of caulk to be applied around base of pipe or wrap strip at its egress from the intumescent sheet on each side of wall. An additional bead of caulk shall be applied to the exposed edge of each wrap strip layer. When two metallic pipes or conduits are grouped tightly together and enclosed in a single wrap strip, pieces of mineral wool batt packing material shall be installed inside wrap strip layer and a min 1 in. (25 mm) depth of caulk shall be installed to fill all interstices between the pipes within the confines of the wrap strip. 3M COMPANY – E-FIS or Ultra GS seals, CP 25WB+, IC 15WB+ caulk, FB-3000 WT sealant, MP+ Stix putty. *Bearing the UL Classification Marking Gypsum 1. WL May 19, 2005 F Rating – 2 Hr T Ratings – 0 and 1 Hr (See Item 2) L Rating At Ambient – 2 CFM/sq ft L Rating At 400 F – less than 1 CFM/sq ft Metallic Pipes Through Penetrations System No. W-L-1037 This material was extracted and drawn by 3M Fire Protection Products from the 2007 edition of the UL Fire Resistance Directory. 3Fire Protection Products www.3m.com/firestop W-L-1037 • 1 of 1 Product Support Line: 1-800-328-1687 Choose option 4 for FAX ON DEMAND 105