Stabilising differential protection for an arc transformer

advertisement

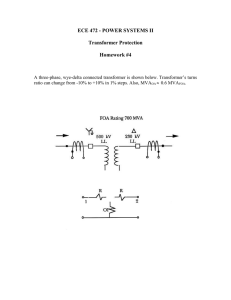

APPLICATION Stabilising differential protection for an arc transformer by A Perera and P Keller, Eskom System Operations and Planning Differential protection on transformers supplying arc furnaces is susceptible to maloperation. After extensive analysis it was discovered that the arcing process is not the cause of the maloperation. An arc transformer is located between the supply transformer and the furnace.The main factor causing the maloperation is the inrush current of the arc transformer. The large DC offset in the inrush current results in saturation of the supply transformer and its current transformers (CTs). In 1907 the first commercial arc furnace was commissioned in the United Sates of America. Since then this method of melting iron has become very popular around the world. This process has however introduced some challenges for the protection fraternity. In 2007 the protection on a transformer in Eskom feeding such an arc furnace was replaced with a modern digital relay. Shortly after this change was made this transformer started to trip on differential protection for no faults. These unwanted and unnecessary trips severely impacted the customer in terms of lost time of production. The procedure following a differential operation on a transformer in Eskom is to first inspect the transformer before it can be returned to ser vice. This resulted in substantial lost time of production. Network Fig. 1 shows the network diagram of the arc furnace installation. The transmission system has been replaced by an equivalent source. The Tx transformer is a 120 MVA 275/33 kV Ynd1 transformer. Its impedance is 8%. The arc transformer is an 80 MVA 30,3/0,6 kV DD transformer with an impedance of 7,16%. The two filter banks shown are 13 MVA 5th and 7th harmonic filters adding up to 26 MVA. The NEC is the zero sequence source for detection of earth faults on the 33 kV network. The arc furnace load is connected at 600 V. At this voltage level the system impedances are very low. Table 1 shows the impedances referred to the 600 V bus bar in primary ohms. A 70 MVA load at 600 V has an impedance of 0,00514 Ω. This impedance is almost an order of magnitude larger than the source impedance. The load current is about 75 kA. Figs. 2 to 7 show recordings from a digital fault recorder of the Tx transformer MV voltages, currents and power during the arcing process. The instantaneous wave forms were converted into RMSt traces for clarity for the following figures. The MV voltage of the Tx transformer is reasonably steady, while the current, and thus the power, is changing. The literature on arc furnace loads suggests this to be the case [1]. These variations are a function of the smelting cycle of the furnace, changing faster in the start of the smelting cycle, and slower towards the end when most of the pot is molten. The start up process for the arc furnace is as follows. The arc furnace transformer is energised The furnace is loaded with scrap metal and molten metal The arcing rods are lowered into the furnace to start the arcing process. There is a minute to two minutes time lag from the time the furnace transformer is energised to the start of the arcing process. This implies that all the transients of the energisation of the arc transformer should be settled by the time the arcing process starts. Figs. 5, 6 and 7 show captured waveforms of the arc furnace load as seen from the MV bus of the Tx-Transformer at the start of the arcing process when the arc is being struck. As can be seen from the waveform, the load is rich in harmonics and asymmetrical. In this particular record, the blue phase arc is only struck about 4 s into the process. Trip records Fig. 1: Network diagram. Relay recordings of two of the trips that energize - April 2011 - Page 54 Grid 275/33 kV Trf 33/0.6 kV Trf Total 0,000024 0,00024 0,0003222 0,000586 Table 1: Impedances referred to 600V Arcbus happened are shown in Fig. 8. Both of these were incorrect trips. Fig. 8 shows the first trip record. The peak value of the MV L2 current at the start of the event is 8 kA. The recording shows the L2 differential element picking up about 100 ms into the event at time marker T1. The blocking elements, wave block and 2nd harmonic block, prevents the differential element from issuing a trip. At time marker T2, about 420 ms from T1, the blocking elements drop off, and we see the relay issuing a restrained differential trip. Fig. 9 shows the 2nd trip record. The peak value of the MV L1 current for this event is 7,7 kA. The differential element picks up 20 ms into the event, but is blocked by the 2nd harmonic blocking element. It drops off and picks up again 20 ms later. Again it is blocked by the 2nd harmonic blocking element. However, 8 ms later the blocking drops off, and the relay issues a trip. There have been records on the relay where the relay picked up for similar looking wave forms but was blocked correctly. Theory To begin to understand why the differential relay may operate incorrectly it is firstly important to understand some theor y with regards to transformer protection and transformer behaviour under certain conditions. The following is a list of typical protection functions used to protect a power transformer: Differential protection (high or low impedance) Restricted Earth fault protection Overcurrent (IDMT and instantaneous) protection Earth fault protection Winding and oil temperature protection Buchholz protection Overfluxing protection All these functions complement each other to provide comprehensive protection APPLICATION Fig. 2: Tx Transformer MV voltage during arcing. Fig. 3: Tx Transformer MV current duringarcing. under load and through fault conditions, while still permitting good sensitivity to be achieved. This bias characteristic is shown in Fig. 11. The differential relay normally has a restrained function and an unrestrained function. The purpose of the unrestrained function is to operate for high values of differential currents. This function is not supervised by any other conditions and will operate unconditionally if the differential currents reach a certain level. There strained differential function caters for differential currents of lower magnitude, but must still remain stable for false differential currents caused by CT mismatches, inrush currents, CT saturation during through faults etc. For this reason the differential relay is supervised by the bias current and often restrained by some other quantity. Simulations and problem identification RTDS simulations Fig. 4: Load snap shot. Fig. 5: Tx Transformer MV voltage during arc striking. Fig. 6: Transformer MV current during arc striking. Fig. 7: Transformer MV power during arc striking. for the transformer. We will elaborate a little with regards to the differential protection function. Differential protection theory Fig. 10 shows the application of differential protection. Currents that flow through the transformer will result in zero current in the differential relay, and currents that flow into the transformer from both sides will result in large currents through the relay. Due to the transformer ratio the currents on the two sides of the transformer will be different and the CT ratios should be selected to compensate for this. The differential relay must be stable even if the transformer is operated at a tap position other than its nominal tap, and also if a mismatch in the CTs exists. To cater for these two factors a bias is introduced that allows the differential relay to be stable To tr y and solve the problem of the differential relay mal-operating, it was studied using a real time digital simulator (RTDS). The network was modeled using available data for the Tx transformer, the arc transformer, the Tx transformer HV and MV CTs to which the differential relay is connected. There was insufficient data to model the transformer protection CT secondar y circuit. Where data was not available, i.e. the B-H curve of the transformers, CT secondar y circuit etc, engineering judgment was used to estimate the data. The RTDS arc furnace load model was used to model the load. The same make and model of protection relay, with the relevant settings was connected to the RTDS. The primary objective of the tests was to tr y and recreate a relay mal-operation. The assumption when the network was simulated on the RTDS was that the nature of the currents that the arc furnace load creates, and their interactions with the transformers and the CTs, were leading to the currents that confused the differential relay. However after a few simulations it was evident that this was not the case. Adjusting the parameters of the RTDS arc furnace load and fine tuning the estimated data for the transformers did not produce the wave forms that resembled the relay trip records. Further, the RTDS simulations showed that faults on the arc furnace bus do not create the expected wave forms, nor does it make the relay mal-operate. The simulations showed that closing of the Tx transformer MV breaker created waveforms that resembled the waveforms seen in the relay trip records. However, we were not able to recreate a trip event at the RTDS. One of the limitations of the RTDS transformer model was that the initial fluxes of the magnetic circuits could not be set. At the start of the simulation the fluxes would start from zero. To evaluate the results of certain initial residual flux in the transformer and the CTs we would have energize - April 2011 - Page 56 to have a certain sequence of events that leave the transformer in that state, and then continue the simulation from that point onwards to obtain the results. This is a time consuming process, especially if one is uncertain as to what the initial fluxes should be. Thus we did not have enough time to evaluate the impact of residual flux. As can be seen in Fig. 8 and Fig. 9, two of the criteria used to block the restrained differential function are 2nd and the 5th harmonic blocking. When the protection was changed a few years back, and the relay started mal-operating, one of the suggestions to fix the problem was to reduce the 2nd harmonic blocking level. However, there was a concern about setting this too low for the fear of blocking the relay for an internal fault. The RTDS transformer model allows simulation of transformer internal faults. This feature was used to investigate the 2nd harmonic current level for internal faults. It was found that even with the most sensitive setting the differential protection correctly detected and tripped for internal faults. Digsilent simulations Simulations and the relay trip records seem to indicate that the onset of the problem is when the arc transformer is energized. Armed with this knowledge, Digsilent power factory software was used to further investigate this phenomenon. This investigation was done in parts; first, the inrush currents on energisation of the arc transformer were investigated. Then, the primary DC time constants and the interactions of primar y and secondar y time constants were investigated. Finally, the effect of the arc transformer inrush on the Tx transformer and the Tx transformer CTs were investigated. Arc transformer inrush. Fig. 12 shows a relay recording of the arc transformer inrush current as seen by the Tx transformer MV CTs. The current values are referred to primary values. For the following discussion we shall assume that during this short time period, the Tx transformer MV CTs faithfully reproduce the primary currents. Fig. 8: Trip record 1. Fig. 9: Trip record 2. APPLICATION Fig. 10: Differential protection. Fig. 14 shows the results of the same simulation, this time the initial flux of the arc transformer was changed to as follows; fluxA = -0,25, fluxB = -0,5 and fluxC = 0,8 p.u. The correlation between the recording and the simulation is now much better. The initial flux values were arrived by trial and error. The differences in the current traces are probably due to the estimated B-H curve of the arc transformer being different from the actual, and errors in the initial flux estimation. This simulation shows that the residual flux of the arc transformer will change the inrush current of the transformer. Network primary time constant Fig .11: Diff-Bias characteristic. Fig. 12: Arc transformer inrush (relay recording). Fig. 13: Simulation of inrush (initialflux zero). To investigate the primary network time constant and the interaction of the primary and the secondar y time constants the network shown in Fig. 15 was simulated. The results are for an A to ground fault on the bus labeled “Terminal”. Fig. 16 shows the primar y fault currents of two simulations with two different network R/X ratios. The green trace is the results with a network R/X ratio of 0,1, and the red trace is for an R/X ratio of 0,025. The network with a smaller R/X ratio has a longer DC time constant. Take note of the network and the Tx transformer impedances mentioned in Table 1. The Tx transformer impedance is an order of magnitude l a r g e r t h a n t h e s y s t e m i m p e d a n c e. Transformer impedance is almost a pure inductance and it follows that the R/X ratio of the source impedance seen from the MV bus of the Tx transformer will have a small R/X ratio. To study the effect of arc transformer inrush the network shown in Fig. 1 was simulated. A relay record that was triggered by the energisation of the arc transformer that did not result in a trip was used to fine tune the unknown values. Using the MV voltages as a reference, the initial flux of the arc transformer was set to match the relay MV currents. Fig. 17 show the results of this simulation. The simulated values were rescaled to primary values so that they can be compared to the recording. The 1st peak value of the L2 current is 5 kA. Once the simulation objects were tuned, the relay trip record shown in Fig. 8 (which resulted in an incorrect trip) was used to test the simulation. Fig. 14: Simulation of inrush (initialflux set). From Fig. 12 we can see that the MV breaker was closed 0,3 ms after the MV blue (L3) voltage peak. The largest inrush current is on the white (L2) phase. The 1st peak value of this current is 5 kA. Fig. 13 shows the results of a simulation of closing the breaker at the same point on wave as the recording. The currents in Figs. 12 and 13 do not correlate well. While the peak value of the L2 current (the green trace on both the plots) is 5 kA, the other two currents do not match. Figs. 18 and 19 show the simulated and the measured MV and HV L2 currents as well as the simulated primary currents. All traces have been scaled so that they can be plotted on the same graph. From Fig. 18 we can see that all the currents start at the same value. 20 ms into the event the simulation and the recording deviate. About 100 ms into the event, we can see the simulated MV CT measuring errors, which is different to the recording. About 600 ms into the event simulated CT and the recording are about the same value, which is different from the actual primary value. energize - April 2011 - Page 57 This may indicate that the MV CT time constant that is modelled is incorrect. Fig. 19 shows the HV values. Here the simulations reasonably match the recording. We see that about 250 ms into the event the CTs are not correctly transforming the primar y current, and the MV and the HV CTs are behaving differently, which this leads to a false differential current. Fig. 20 shows the simulated magnetising currents drawn by the Tx transformer. The DC current in the inrush of the arc transformer is saturating Tx transformer causing it draw more magnetizing current. This magnetising current will cause a genuine differential c u r r e n t. T h e n o m i n a l m a g n e t i s i n g current of the Tx transformer is about 3 A. This corresponds to the initial values of Fig. 20. Therefore at the worst point (1,2 s) the differential current is about 100 A. However, as this is magnetising current, the 2nd harmonic content of this current would be high, blocking the operation of the differential relay. This simulation assumed initial fluxes of the Tx transformer to be zero. Even though we were unable to simulate conditions that resulted in an incorrect differential trip at the RTDS, the simulations done on DigSilent show that the hypothesis about the cause of the differential trip is reasonable i.e. the Arc transformer inrush current causes the Tx Transformer differential relay to mal-operate. Proposed solutions Since the start of the nuisance tripping of this transformer, many solutions have been tried. Among these solutions were: Replacementof the MV CTs to match the HV CTs. The MV CTs were of the class 10P20 and the HV CTs are Class X. The MV CTs were replaced with Class X CTs and the magnetising curves were matched. Some setting changes were also tried. These included: Reducing the level of the 2nd harmonic blocking. The minimum level on the relay internal transformer faults. I n c r e a s i n g t h e B i a s / D i f f c u r v e, essentially making the differential relay less sensitive. Enabling cross blocking between the different phases. Replacement of the relay with a relay from another manufacturer. None of the above stopped the nuisance tripping. Present solution 2nd harmonic blocking level. The 2nd harmonic blocking level has been decreased to a minimum level of 5%. Simulations done on the RTDS confirmed that for faults in the transformer the 2nd harmonic levels are below this level and the differential relay will not be blocked. Overcurrent blocking An additional over current blocking of the APPLICATION Setting the pick-up level of the O/C block function. Fig. 21: O/C blocking logic diagram. Fig.15: Simple network. Fig. 22: Directional element of O/Cfunction. Fig16: Effect of the R/X ratio on DC decay. Fig. 17: Simulated vs Measured MV CT currents(tuned). Fig. 18: Simulated vs Measured MV CT currents(Check). Fig. 23: Matlab calculations of magnitude and phase. restrained differential function for a preset time has been introduced as shown in Fig. 21. This element is directionalised with the voltage on the MV side of the transformer. A positive sequence voltage and current is used to establish the directionality and a 50 Hz rms quantity is used to establish a current magnitude. The over current level is set above the full load of the arc transformer, ensuring that no blocking will occur under normal load conditions. Setting the directional element of the O/C block function. Fig. 19: Simulated vs Measured HV CT currents(Check). Fig. 20: Tx Transformer magnetising current. The directional element of the O/C block function uses positive sequence quantities of the MV voltage and the MV current. The O/C pick-up level is set very sensitive to ensure that the function is active under inrush conditions as the positive sequence quantities might be very small. During the inrush condition the circuit is predominantly inductive and the current should lag the voltage by 90°. The MV CT is starred towards the transformer, thus inrush currents that flow towards the furnace will effectively be defined as “reverse”. The operation of the directional element can be seen in Fig. 22. RCA is the relay characteristic angle and ROA is the relay operating angle. energize - April 2011 - Page 58 The O/C level element uses 50 Hz rms quantities. A true rms measurement is not available in the relay. The level element is set to 75% of the MV CT ratio (2000:1). This relates to a primar y current equal to 1500 A. The full load currentof the arc transformer is equal to 1400 A. The setting is above the full load current of the arc transformer. This function should thus not pick-up for load conditions. During the arcing process the relationship between the voltage and current should be predominantly resistive, which means that the directional element should also not be picked-up. Actual recordings of the load confirmed this. The directional element in conjunction with the O/C level element ensures that the blocking of the restrained differential function will only occur under inrush conditions. Internal transformer faults will not enable this blocking function. Fig. 23 show the values calculated by Matlab for the magnetising inrush from the relay recorded currents. The graphs are the actual currents, positive sequence current magnitude, and the positive sequence current angle with the positive sequence voltage as the reference. As expected, before the breaker is closed the current is leading the voltage (filter bank current). During the initial stages of the inrush the current is lagging. Around 1,2 s the positive sequence magnitude is zero and after this the positive sequence current changes to capacitive current again. Acknowledgement This paper was presented at the 2010 SAPSP Conference and is reprinted with permission. Results This solution was extensively tested in the lab before implementation. The test results were: For the actual trip records from the relay this solution prevented the relay from operating. For simulated cases with high inrush currents the blocking function was picked up. For simulated cases with low inrush currents the blocking function did not pick up. This is not a concern as low inrush currents should not cause the Tx Transformeror the CTs to saturate. The differential relay operated for simulated internal faults, as created at the RTDS. References [1] RTDS technologies, “RealTime Digital SimulatorPower System Users Manual (page 19-1)”, November 2006. [2] Alstom, “NetworkProtection & Automation Guide – Chapter 6”, July 2002. Contact Paul Keller, Eskom, Tel 011 871-2013, paul.keller@eskom.co.za