Applications Guide - Duobias-M-200 Technical

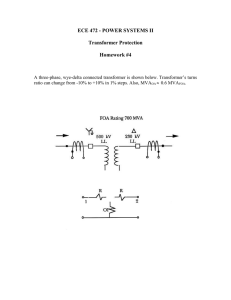

advertisement