Final Exam: Functional Performance Testing

advertisement

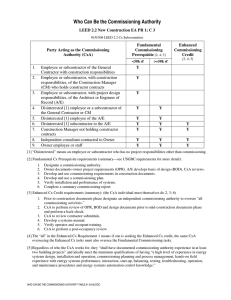

TECHNICAL FEATURE ©ASHRAE www.ashrae.org. Used with permission from ASHRAE Journal, June 2014 at www.atkinsglobal.com. This article may not be copied nor distributed in either paper or digital form without ASHRAE’s permission. For more information about ASHRAE, visit www.ashrae.org. Technical vs. Process Commissioning Final Exam: Functional Performance Testing BY DAVE MCFARLANE, MEMBER ASHRAE So far in this series on technical commissioning, we have examined commissioning functions and practices associated with the planning, design, and construction phases of a new building project. We have outlined the owner’s expectations in the Owner’s Project Requirements (OPR) document, and we have reviewed and approved the Basis of Design (BOD) document, which shows how the design meets the requirements of the OPR. In addition, we have created a plan that outlines the tasks everyone involved in the project must complete to ensure the project meets its OPR. We have also monitored the construction process to ensure that all equipment and systems were properly installed, and we have verified that all equipment and systems can be properly started and run. The next phase of technical commissioning—functional performance testing (FPT)—is the “final exam” a new building must pass before it can “graduate” and be turned over to a satisfied owner. This is the seventh in a series of bimonthly articles that explain the technical commissioning process for new buildings. Some of these articles’ content is based on ASHRAE Guideline 0-2005, The Commissioning Process (published 2005) and the National Environmental Balancing Bureau (NEBB) publication Procedural Standards for Whole Building Systems Technical Commissioning for New Construction (revised April 2013). In addition, some of the information in this article series has been adapted from an unpublished NEBB standard titled NEBB Standard Owner’s Project Requirements (OPR) Guideline (draft dated June 20, 2011); and from NEBB’s Procedural Standards for Building Enclosure Testing (March 2013). Dave McFarlane is principal project director at Atkins in Fort Myers, Fla. 14 A S H R A E J O U R N A L ashrae.org J U N E 2014 Importance of the Issue Log Up ’til now, at each step in the commissioning process either the commissioning authority (CxA) or the contractor has carefully documented issues of concern in the project issue log (which we have not discussed previously due to space limitations). But the issue log is more than just a chronicle of problems. It also should include the date the issue was first identified (and by whom), a description of possible solutions, who is responsible to correct the issue, and the date the issue was corrected (and by whom). The CxA must maintain the issue log, and a significant part of all commissioning-related meetings should be devoted to discussing possible resolutions, assignments, costs, and completion dates for the items in the log. These discussions are vital, because the CxA should resolve TECHNICAL FEATURE issues as they come up, during any phase of the construction process, before moving to the next phase. For example, FPT cannot begin until all equipment and systems are verified to start up and function properly during pre-functional testing. So when key startuprelated items are entered into the issue log but not corrected, FPT will probably fail and need to be repeated after the issues are corrected. So pay careful attention to the issue log, and make sure all issues are resolved before FPT begins. Role of Functional Performance Testing It’s important to note that ASHRAE Guideline 0-2005 requires functional performance testing. But the Guideline does not describe the number or type of tests to perform, nor does it define how stringent the tests must be or even who should conduct them. This article is an attempt to “flesh out” the Guideline in a practical manner, and from a technical commissioning perspective. This article also assumes that every issue in the issue log has been corrected, all pre-functional tests have been verified complete and successful, all building systems and components are properly installed and functional, and all valves and dampers open and close as required. At this point, you may ask, “OK, if everything is well designed, installed correctly, and fully functional—and all known issues have been corrected—what else is there to do?” This is an important question, as my experience indicates that a traditional process-commissioning CxA would give a very different answer than would a technical-commissioning CxA. I’ve found that a traditional process-commissioning CxA would likely answer: “You’re right. We’ve prepared the FPT forms, and the contractors have informed us that all of their testing was successful. We’ve verified that all of the commissioning forms have been completed, and we’ve randomly sampled the building’s equipment and systems to verify correct installation and proper operation.” If our project employed traditional process commissioning, it would be complete; and we would be ready to turn over the new building to its owner. But when faced with the same question, a technical commissioning CxA will likely answer: “Our commissioning team has done a great job so far! We’ve verified that the design satisfies the OPR. We’ve corrected every issue in the issue log, and we’ve personally confirmed that all equipment and systems have been properly installed and are fully functional. We’re now ready for the project’s final exam: real-world, functional performance testing of every building system. Our goal is to ensure that the building itself (not just the design) satisfies the OPR, so we must ensure that the occupants find the internal environment to be efficient, healthy, and comfortable. We’ve given all relevant contractors their FPT forms, and we’ll now work with them during FPT, observing and assisting as they perform every test.” This “test-and-verify-everything” perspective is a big difference between process commissioning and technical commissioning. Process commissioning permits contractors to serve as their own SMEs, and allows them to perform their own tests. However, technical commissioning requires the CxA to serve as the SME—and as such the CXA either performs or supervises all functional performance testing. Test Example: A Variable Air Volume Box To illustrate how the FPT process works, this article uses the example of a single variable air volume (VAV) box serving a single space. But note: Proper technical commissioning requires that the CxA measure and verify the correct operation of all control loops—not just a sample. It is true that the CxA is permitted to perform limited sampling during pre-functional testing (refer to the previous article in this series). But no sampling is allowed during FPT. Instead, all systems and equipment must be actively verified for real-world operation. You may ask, “What’s wrong with sampling? It can save time and potentially reduce overall costs.” The problem is sampling can work well for “homogenous” systems— such as a batch of well-mixed concrete: Every sample taken has a high probability of having the same chemical composition as any other sample. So if one sample meets specifications, the rest of the batch should also meet the specs. But mechanical systems are never homogenous. Why? Every system has probably been touched by multiple contracting firms and multiple technicians. Our sample VAV box, for example, has had electrical, piping, sheet metal, control, test-and-balance, and chemical-treatment contractors involved in its installation. Also, different employees of the same firm may build or install each of their components and systems differently. So it is likely that every VAV box will respond differently to control inputs. J U N E 2014 ashrae.org A S H R A E J O U R N A L 15 TECHNICAL FEATURE Temperature (°F) Temperature (°F) Temperature (°F) During the “final exam,” each control loop FIGURE 1 VAV box control sequence is too tight. of every system is checked to make sure its 80 control sequence actually does what it is 76 supposed to do. This is much more than simply testing to see if a valve opens in 72 response to a call for heat, or a reheat valve 68 closes in response to a call for cooling. In fact, from a technical commissioning perspective, those tests would have already 102030405060708090100110120 been performed during the operational perTime (Minutes) formance testing (OPT) phase. FIGURE 2 VAV box control sequence is too loose. Instead, the FPT phase calls for hands-on verification that every controlled device 80 performs all of the functions it is required to 76 perform, including: •• The performance of all required steps it 72 is supposed to perform. 68 •• A controller/actuator response speed that is appropriate for the application. 1020 3040 506070 8090100110120 •• A stable response. Time (Minutes) •• All events are controllable to the setpoint. •• All adjustments take place automatically FIGURE 3 Properly adjusted VAV box control sequence. through the building automation system. Figure 1 illustrates a control sequence that 80 is too tight. The figure shows a tempera76 ture that fluctuates hourly between 76°F and 68°F (24°C to 20°C). The problem is 72 that when the temperature drifts from its 68 setpoint, the controller causes the temperature to cycle unacceptably. If a thermostat controls this VAV box, the air flow damper 1020 3040 506070 8090100110120 Time (Minutes) and heating control valve responses are too rapid, which causes the cycling—and I can practically guarantee that the occupants will complain quickly enough—nor does the airflow increase at a rate that it’s too hot or too cold. sufficient to maintain the setpoint. But when called to resolve the problem, the building In this case, when occupants complain, the maintemaintenance staff may not be able to properly diagnose nance staff may simply see the temperature as too high it because the temperature is fairly close to the setpoint or too low. So to resolve overcooling, they reduce air much of the time. So the maintenance staff leaves, havflow; to resolve overheating, they throttle back valves. ing done nothing—except to accuse the occupants of But neither of those solutions is the proper fix. being oversensitive. Figure 3 reflects proper system calibration, adjustment, Figure 2 illustrates a different challenge: A controller and tuning: When the setpoint is adjusted, the VAV airflow that does not respond quickly enough. The problem is damper and the reheat control valve respond correctly, the when the room temperature is below its setpoint, the temperature reaches the control setpoint within a reasonreheat valve or air flow damper does not change quickly able time interval, and afterward the temperature is stable. enough to meet the setpoint; and when the temperature In this case, most occupants would feel comfortable, as is above its setpoint, the heating valve does not close OPRs often call for a temperature of 72°F (22°C), ±2°F (1°C). 16 A S H R A E J O U R N A L ashrae.org J U N E 2014 Advertisement formerly in this space. Advertisement formerly in this space. TECHNICAL FEATURE So for the “final exam” for our sample VAV box involves verifying that: •• Control sequences generate the appropriate temperature control responses; •• Control sequences adjust the temperature to the setpoint; •• All sequences yield stable results; •• All sequences occur automatically through the control system; •• The box reacts properly to a power failure; and •• Room occupancy/CO2 sensors are properly set to open the air inlets in order to maintain proper CO2 levels and room temperature. Under the process commissioning model, I have seen a contractor simply set a thermostat to full heat and then to full cool; and that was submitted as the FPT. But this kind of test does not measure response time or stability, which is why such “tests” are unacceptable for technical commissioning. Space limitations do not permit me to describe the FPT requirements and processes for all of the systems and components for an entire project. Suffice it to say that the CxA must perform functional performance tests on every control loop in the project, which encompasses all of a building’s major systems and equipment, including boilers, chillers, air handlers, cooling towers, pressurization systems, and so forth. controllers with pneumatic differential-pressure sensors, thermostats, and control valves. In one of the processes I oversaw, an explosion could result if the chemical mixture got too hot. If the temperature were too cold, the proper reaction would not occur. In another process, the final result was a material that could be either too brittle or too soft, depending on chemical flow rates. Advertisement formerly in this space. Importance of Control Loop Adjustments In the 1970s, I worked as a chemical process engineer. Part of my job was to ensure pumps started and valves opened and closed as required. We used tuned control loops to maintain chemical flows, pressures, and temperatures within tight constraints. This was before the advent of computerized controls, so we used J U N E 2014 ashrae.org A S H R A E J O U R N A L 19 TECHNICAL FEATURE My coworkers and I became adept at checking and tuning control loops, which measured and controlled three parameters, together known as PID: 1. The proportional (P) parameter, which measures present error; 2.The integral (I) parameter, representing the accumulation of past errors; and 3.The derivative (D) parameter, predicting future errors. We were required to maintain our control loops within specific ranges; and our PID tuning resulted in quick adjustments. We controlled temperatures, pressures, and flow rates to the appropriate setpoints and stability requirements—thus yielding materials that met the quality standards. Today, computerized controls are commonplace in HVAC systems, but the same tuning of control loops is still essential. That’s because technical commissioning is about minimizing energy consumption as well as improving occupant comfort. However, the tuning of control loops is normally not performed during traditional process commissioning. It is common for the manufacturer’s “standard” control loops to be left in place until there’s a complaint. I would be a rich man if I had a dollar for every time I heard a control technician say, “We don’t need to adjust the PID loops; they’re preset at the factory.” PID Loop Testing Process It is important to ensure that a system’s control loops are properly tuned. But because PID loop tuning is done so infrequently, it may be necessary for the CxA to brush up on how it’s done, in order to help the controls contractor properly test the equipment and systems they’ve installed. As previously noted, proper technical commissioning calls for the CxA to oversee the measurement and verification of all control loops. This objective is accomplished by making minor system setpoint changes and then data-logging the controlled event. For the VAV box example, the controlled event is the space temperature, so the CxA must ensure these five data points are logged: •• Space temperature; •• Damper position; •• Reheat valve position; •• Discharge air temperature; and •• Airflow volume from the box. For each loop, the tests involve subjecting the 20 A S H R A E J O U R N A L ashrae.org J U N E 2014 controller to small but definitive changes from the wall thermostat setpoint and measuring the results. In our VAV box example, the system is started and run at a setpoint of 72°F (22°C) until stable. Next, the setpoint is adjusted to 75°F (24°C), which should cause the box to begin heating, and the system’s response is measured by readings taken every minute. In a typical VAV box, the damper position should throttle back, the airflow should be reduced to the heating (or minimum) setpoint, and the reheat valve should open. The CxA then makes sure the required data points are logged, ensures that the temperature has adjusted to 75°F (24°C), and verifies that the system’s response time conforms to either the OPR or to acceptable responses as described in the Commissioning Plan. Finally, the setpoint is lowered to 69°F (20°C), which should cause the box to begin cooling. As before, the system’s response is measured via readings taken every minute. In a typical VAV box, the damper position should open to the maximum or cooling airflow, the airflow should increase, and the reheat valve should close. As previously, the CxA also makes sure the required data points are logged, ensures that the temperature has adjusted to 69°F (20°C), and verifies that the response time conforms to either OPR or Commissioning Plan standards. If performance is unsatisfactory in any way, the CxA collaborates with the contractor to investigate the problem, determine the cause, and adjust the control loops as needed. Testing all control loops is another difference between FPT in technical and process commissioning. A typical process commissioning approach calls for the CxA to sample 10% to 15% of a building’s control loops and by extrapolation conclude that all systems work properly. In contrast, under technical commissioning the CxA verifies that 100% of a building’s control loops work properly. Identifying and Resolving Problems As noted in the previous article in this series, project contractors have the ultimate responsibility for their own quality control. Therefore, all contractors need to perform their own tests before the CxA either conducts or witnesses FPT. For our sample VAV box, multiple contractors would be involved in a successful testing process. It’s worth noting that each contractor should have verified their work during pre-functional testing. However, that is an insufficient level Advertisement formerly in this space. TECHNICAL FEATURE of testing in the world of technical commissioning—if for no other reason than the amount of time that often elapses (weeks or months) between pre-functional testing and FPT. While our sample VAV box may have passed prefunctional testing, conditions can change in the weeks or months before FPT. For example, the box will fail FPT if there is an insufficient flow of hot water to the reheat coil; and there are many reasons why the flow might be reduced Advertisement formerly in this space. during the time that passes since pre-functional testing, including: •• A plugged strainer (responsibility: chemical treatment contractor); •• A manual valve having been closed (mechanical piping contractor); •• Improper testing and balancing (testing, adjusting, and balancing contractor); •• The control valve failing to open (controls contractor); or •• The VAV box fan failing to start properly (electrical contractor). In a previous article, I noted how a project’s contract documents should permit the owner to financially penalize a contractor for testing beyond a specified limit; and retests required during FPT would fall under the financial-penalty stipulations. But contractors can avoid those penalties by ensuring their systems work properly before the CxA shows up on site to oversee the final tests. Fully Tested = Fully Confident Functional performance testing is the “final exam” that verifies all of a building’s systems work in the real world. After all project issues are resolved and functional performance testing is complete, the technical-commissioning CxA can look the owner in the eye and confidently state: “Your building works as you’ve intended. We’ve verified that your project requirements have been fully satisfied. Through careful and detailed hands-on testing, we’ve made certain that the building functions as designed. All known issues have been corrected, and we’ve personally verified that 100% of the building’s equipment has passed every test. “Congratulations! Your building has been through a comprehensive technical commissioning process. And we know this because we’ve overseen or conducted all of the tests in person.” 22 A S H R A E J O U R N A L ashrae.org J U N E 2014