CEJC 3(3) 2005 417–431

New transformation of cycloalkanone acetals by

peracids α, ω – dicarboxylic acids synthesis

Alexander O. Terent’ev∗, Sergey V. Chodykin

N.D. Zelinsky Institute of Organic Chemistry,

Russian Academy of Sciences,

119991 Leninsky Prospect 47, Moscow, Russia

Received 24 February 2005; accepted 13 April 2005

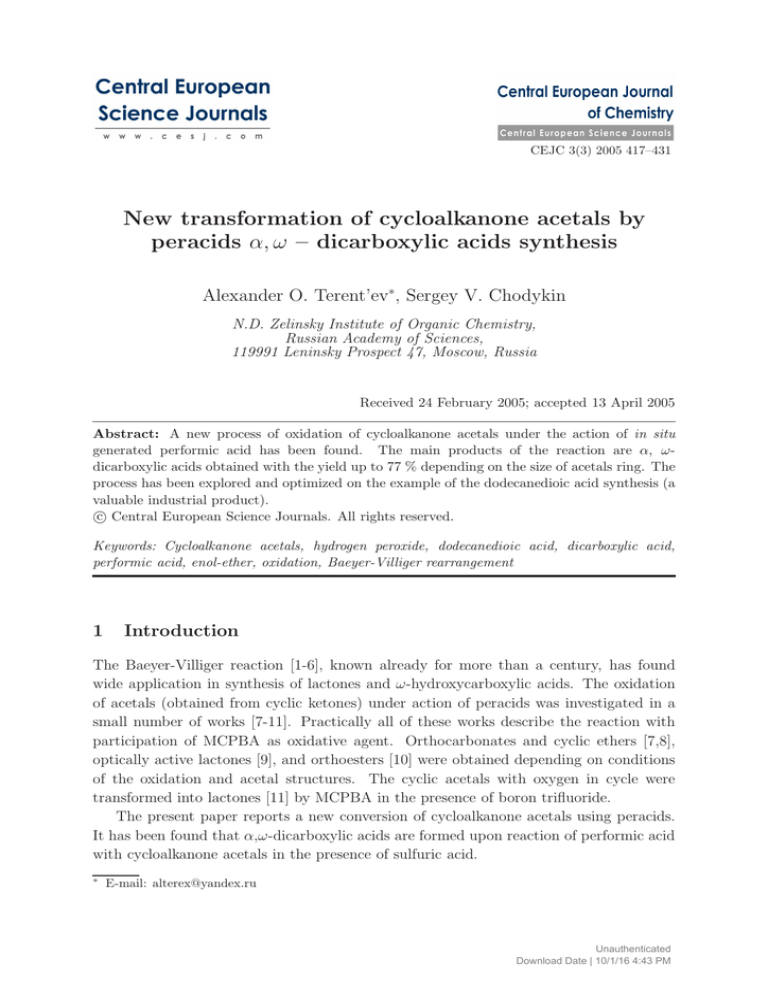

Abstract: A new process of oxidation of cycloalkanone acetals under the action of in situ

generated performic acid has been found. The main products of the reaction are α, ωdicarboxylic acids obtained with the yield up to 77 % depending on the size of acetals ring. The

process has been explored and optimized on the example of the dodecanedioic acid synthesis (a

valuable industrial product).

c Central European Science Journals. All rights reserved.

Keywords: Cycloalkanone acetals, hydrogen peroxide, dodecanedioic acid, dicarboxylic acid,

performic acid, enol-ether, oxidation, Baeyer-Villiger rearrangement

1

Introduction

The Baeyer-Villiger reaction [1-6], known already for more than a century, has found

wide application in synthesis of lactones and ω-hydroxycarboxylic acids. The oxidation

of acetals (obtained from cyclic ketones) under action of peracids was investigated in a

small number of works [7-11]. Practically all of these works describe the reaction with

participation of MCPBA as oxidative agent. Orthocarbonates and cyclic ethers [7,8],

optically active lactones [9], and orthoesters [10] were obtained depending on conditions

of the oxidation and acetal structures. The cyclic acetals with oxygen in cycle were

transformed into lactones [11] by MCPBA in the presence of boron trifluoride.

The present paper reports a new conversion of cycloalkanone acetals using peracids.

It has been found that α,ω-dicarboxylic acids are formed upon reaction of performic acid

with cycloalkanone acetals in the presence of sulfuric acid.

∗

E-mail: alterex@yandex.ru

Unauthenticated

Download Date | 10/1/16 4:43 PM

418

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

This oxidative process is of interest from two standpoints: as a new reaction in acetal chemistry and as a method of α,ω-dicarboxylic acid synthesis. The method has no

analogues. It can be applied in the synthesis of dodecanedioic acid [12-19], broadly used

for lubricants, anticorrosive composition, polyester covering and polyamide filaments,

and for the synthesis of tridecanedioic (brassylic) acid [20-22], a component of perfume

compositions.

2

Results and discussion

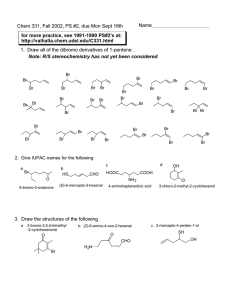

In continuation of our studies of acid-catalyzed reaction of acetals with hydrogen peroxide

[23], it was revealed that upon reaction of performic acid (generated in situ from HCOOH

and H2 O2 ) with 1,1-dimethoxycyclododecane (1a) in the presence of sulfuric acid dodecanedioic acid (2a) is formed as a major product. The by-product of the reaction is

12-hydroxydodecanoic acid (3a) (in a mix with its formate 3a’). Scheme 1.

Scheme 1 Oxidation of 1,1-dimethoxycyclododecane 1a.

The influence of the following factors on the yield of acids 2a and 3a (3a’) was

investigated: quantity of hydrogen peroxide in relation to acetal 1a, the type of H2 O2

solution (water or ether solution), the quantity of sulfuric acid, and temperature (Table 1).

As can be seen from Table 1, the greatest yields of 2a (64-72 %) were obtained when

the quantity of sulfuric acid was 15mmol and there was eightfold excess of H2 O2 (ether

solution); using an aqueous solution of H2 O2 , the yields of 2a were 6-10 % lower, most

likely due to partial hydrolysis of 1a into cyclododecanone 4.

Considering of this fact, a number of experiments on the oxidation of 4 were performed

in the presence of methanol in twofold excess with use of both water and ether solutions

of H2 O2 and H2 SO4 (15mmol) in eightfold excess. In result, the acid 3a was obtained

as the major product with a yield of 51-53 % and 2a as by-product at 39-43 %. These

results are in good agreement with an assumption that the decrease of the yield of 2a,

with use of aqueous H2 O2 , occurs due to hydrolysis of 1a to form 4.

It is necessary to use 8 eqv of H2 O2 in relation to 1a for full conversion of 1a into

acids 2a and 3a. Using H2 O2 in twofold excess, cyclododecanone 4 was isolated with

60 % yield (Table 1, footnote e ).

Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

H2 O2 ,

eqv b mmol

H2 SO4 ,

Temperature upon

addition of 1aa ,

◦C

Yield 2a,

(%)

Yield 3a,

(%)

5

5

5

8

8

8

8c

8c

2c

20 c

0.45

3.5

15

4

15

15

15

15

15

15

20

20

20

20

20

0

20

0

0

0

traces

45

57

56

58

62

64

72

traces

64

70 d

35 d

32

31

29

22

16

15

(17) e

14 f

419

a

Reaction conditions: 0.5 g (2.2 mmol) acetal 1a was added for 10-20 seconds to prepared

in situ solution of HCOOOH obtained from HCOOH (7 ml), H2 O2 solution, and H2 SO4 ,

maintaining the reaction temperature. Then the mixture was refluxed for 15-20 minutes.

Acetal conversion is 100 %. Owing to the significant dependence of the ratio of 3a (R=H)

and 3a’ (HC=O) due to the conditions of the reaction and workup, yields of 3a and for other

ω-hydroxycarboxylic acids 3b-g were determined after workup of the reaction mixture by a

solution of sodium hydroxide (formate hydrolysis) and the subsequent acidification.

b 30 % Water solution of H O .

2 2

c 6 % Ether solution of H O .

2 2

d Cyclododecanone (4) 6-7 %.

e The workup procedure is described in the Experimental section. The yield of 3a’ is shown.

Cyclododecanone (4) 60 % and 2-formyloxycyclododecanone (5) 11 %.

f A significant amount of tar.

Table 1 Influence of the reaction conditions on the yields of acids 2a and 3aa .

Additional increase (4-8 %) of the yield of 2a was reached by means of temperature

modification; 1a was added to a solution of performic acid at 0 ◦ C (instead of at 20 ◦ C),

then the mixture was heated to boiling.

After refluxing for 15-20 minutes, the qualitative reaction with KI did not indicate

peroxides, therefore further heating was unnecessary.

Oxidation of 1-methoxycyclododecene (6) by in situ generated performic, peracetic

and pertrifluoroacetic acids has been carried out to establish the possibility of elimination

of methanol from 1a with formation of 1-methoxycyclododecene (6) and subsequent oxidation of 6 into acids 2a and 3a. The same peracids were used for comparative oxidation

of 1a (Table 2).

The data in Tables 1 and 2 show that upon oxidation of 1a the yields of acid 2a were

always 7-29 % higher in comparison with the yields from 6. Performic acid oxidizes 1a

more effective than peracetic and pertrifluoroacetic acids.

The homologue row of cycloalkanone acetals 1b-g with different ring sizes was used as

an object of research during the following stage of our work. Acetals 1b-g were oxidized

in the similar conditions used for oxidation of 1a (see Table 2, footnote a ) (Scheme 2,

Table 3).

Unauthenticated

Download Date | 10/1/16 4:43 PM

420

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

Oxidizing agent

(oxidized substances)

Yield 2a,

(%)

Yield 3a,

(%)

HCOOOH (6)

CF3 COOOH (1a)

CF3 COOOH (6)

CH3 COOOH (1a)

CH3 COOOH (6)

43 (28b )

48

41

62

51

35 (58b )

41

24

23

35

a

Reaction conditions: 1a 0. 5 g (2.2 mmol), 6 0.5 g (2.55

mmol), acid (7 ml), H2 SO4 1.5 g (15 mmol), temperature of

the reaction mixture at addition of 1a or 6 0◦ C, overall reaction time 15-20 minutes, conversion of oxidized substances

100 %. 6 % Ether solution of H2 O2 (8 eqv, 17.6-20.4 mmol)

was used for in situ peracids preparation.

b Temperature of the reaction mixture at addition of 1methoxycyclododecene (6) was 30 ◦ C.

Table 2 Oxidation of 1-methoxycyclododecene 6 and 1,1-dimethoxycyclododecane 1a by performic, peracetic and pertrifluoroacetic acids prepared with use of ether solution of H2 Oa2 .

Scheme 2 Oxidation of cycloalkanone acetals 1b-g.

Acetal

1bb

1cb

1d

1e

1f

1g

1-3

b

c

d

e

f

g

n

1

2

3

4

7

9

R

Et

Me

Me

Me

Me

Me

H2 O2 (6 % ether solution)

Yield 2, (%) Yield 3, (%)

14

6

63

77

74

72

51

68

15

16

14

19

H2 O2 (30 % water solution)

Yield 2, (%) Yield 3, (%)

11

traces

44

57

69

65

61

61

17

21

21

23

a Reaction conditions: 1b-g 0.5 g (2.07-3.47 mmol), HCOOH (7 ml), H SO 1.5 g (15

2

4

mmol), temperature of the reaction mixture at addition of 1b-g 0 ◦ C, overall reaction

time 15-20 minutes, conversion of oxidized substances 100 %. Hydrogen peroxide (8 eqv,

16.5-27.8 mmol) was used for in situ HCOOOH preparation. The yields of acids 2b-2e

and 3b-3e are dependent upon methyl ethers.

b Significant amount of by-product is formed.

Table 3 Oxidation of 1b-g by HCOOOH prepared in situ from HCOOH and H2 Oa2

Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

421

Acids 2b and 2c were obtained with low yield from five- and six-membered cycloalkanone acetals 1b and 1c. The yield of heptanedioic acid (2d) from a seven-membered

cycloalkanone (1d) was 63 % and achieved a maximum of 77 % for octanedioic acid (2e)

by oxidation of eight-membered acetal 1e. Yields of dicarboxylic acids differ insignificantly for oxidation of acetals 1f and 1g with n ≥ 7.

The fact that upon oxidation of cyclododecanone 4, yields of 2a (34-43 %) are lower in

comparison with the yields of 2a (62-72 %) upon oxidation of 1a (in identical conditions),

leads one to believe that acid 2a is formed mainly from 1a instead of cyclododecanone 4

(product of hydrolysis of 1a). This assumption is confirmed by the fact that the yields

of dicarboxylic acid upon oxidation with aqueous H2 O2 are 3-20 % lower than oxidation

with the use of ether H2 O2 solution. In the aqueous H2 O2 , acetals hydrolyze partly to

ketones. This process leads to a decrease of the dicarboxylic acids yields.

As the yields of acid 2a upon oxidation of 1a by various peracids are higher than

from enol-ether 6 (Table 2), it is possible that at the first stage of the reaction the loss

of methanol from 1a with formation of 6 is not the basic route of the reaction. Probably

perester 7 is formed alongside of 6 (Scheme 3, stages ii).

R can be = H, Me, HC=O, O=C (H) O.

Scheme 3 Proposed mechanism for the oxidation of acetal 1a.

Unauthenticated

Download Date | 10/1/16 4:43 PM

422

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

Assumption of the formation of compound 7 from acetals was indirectly confirmed by

the experiment in which upon oxidation of 1,1-dihydroperoxycyclododecane 7’ in conditions identical to those for 1a, acids 2a and 3a were obtained with 62 % and 28 % yields,

respectively (Scheme 4).

Scheme 4 Oxidation of 1,1-bishydroperoxycyclododecane 7’.

An appreciable difference between the yields of 2b and 2c (oxidation of five- and sixmembered cycles respectively) and 2a, 2d-2g (oxidation of cycles of greater size) does

not allow one to assign the formation of enol-ethers 6 as a general reaction route at the

initial stage of the oxidation, as formation of enol-ethers for all oxidized acetals show.

After formation of compound 7, the reaction proceeds by two routes. The first route

is the formation of epoxide 8 (Scheme 3, stages iii), the second is the Baeyer-Villiger

reaction with formation of lactone 9 and subsequent acid hydrolysis to 3a (Scheme 3,

stage v). Epoxide 8 is similar in structure to the products of oxidation of the enol-ethers

observed in other works [24-27]. These products can be transformed by hydrolysis into

2-hydroxycycloalkanones under conditions of acid catalysis.

For definition of the structures of intermediate products, the reaction of 1a oxidation

has been stopped after 2 minutes by addition of water and methylene chloride to the reaction mixture. As a result, cyclododecanone 4, 2-formyloxycyclododecanone 5, dodecanedioic acid 2a, and 12-formyloxydodecanoic 3a’ were obtained. 2-Formyloxycyclododecanone

5 has also been isolated with a yield of 11 % upon oxidation of 1a with use of 2 eqv

H2 O2 (ether solution, Table 1, footnote e ).

The isolation of 2-formyloxycyclododecanone 5 as an intermediate product in the

incomplete oxidation of 1a is possible due to the hydrolysis of intermediate ether 10

and epoxide 8. This fact confirms the possible formation at stage iii (Scheme 3) 1-Osubstituted (hydroxy-, methoxy-, formyl- and performyl-) epoxides 8.

The data from works [24-27] in which the stage of enol-ether epoxidation was studied

and the fact that 2a is formed upon oxidation of 6 (Table 2) allows one to assume that

the formation of epoxide 8 is an initial stage of oxidative transformation of 6 from 2a

(Scheme 3, stage i).

Ethers 10 are rearranged by the Baeyer-Villiger reaction into 13-oxo-oxacyclotridec-2Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

423

yl-formate 11, which is oxidized (Scheme 3, stage vi) to form 2a. The similar mechanism

of 2-hydroxycycloalcanone transformation in dicarboxylic acids was discussed in the paper

[28].

The possibility of oxidative transformation of the O-CH-O fragment (11) into the

carboxylic group was proved by the oxidation of 1,1-dimethoxynonane (12). Nonanoic

acid (13) was obtained with 92 % yield.

Oxidation of 2-formyloxycyclododecanone 5 was carried out under the conditions of

the investigated reaction for confirmation of ester 10 transformation into acid 2a. As

a result, acid 2a was obtained with 91 % yield. Based on the Baeyer-Villiger oxidation mechanism [2-6] it is possible to believe that the performic acid reacts with 2formyloxycyclododecanone 5 to form ether 10 (R = H). Consequently, isolation of 2a

with high yield upon oxidation of 5 confirms the ability of ether 10 to be oxidized with

formation of acid 2a.

The enlargement of acetal ring size from 5 to 8 carbon atoms leads to a decrease in

the ω-hydroxycarboxylic acid 3 yields (products of hydrolysis of lactones - homologue

9). The Baeyer-Villiger rearrangement of perester 7 homologues is a major reaction in

the formation of thermodynamically favorable 6-,7-membered lactones. The decreasing

yield of acid 3 is due to the rearrangement of perester 7 homologues, becoming minor for

lactones with larger cycle.

Similar observations have been reported in paper [29] where, under conditions of

the Baeyer-Villiger rearrangement, the yield of lactones decreased from 84 % to 6 %

by enlargement of the ring size from 6 to 8 carbon atoms. The authors [7,8] failed to

synthesize the expected products of the Baeyer-Villiger rearrangements under action of

MCPBA on cycloalkanone acetals with the cycle size more than six carbon atoms.

Probably, the formation of epoxides (similar to 8) occurs (Scheme 3, stage iii) in the

case of larger cycles (n=3, 4, 7-9; Scheme 2) instead of the thermodynamically unfavorable

reaction of cycle expansion similar to transformation of 7 to 9.

An attempt at the oxidation of acetals containing aryl fragments (derivatives of benzaldehyde, acetophenone, a-tetralone and phenylacetaldehyde) were not successful, tar

products were formed only.

In summary, a new transformation of cycloalkanone acetals by peracids has been

revealed and investigated. The main products of this reaction are α,ω-dicarboxylic and

ω-hydroxycarboxylic acids. The greatest yield of α,ω-dicarboxylic acids (72-77 %) is

achieved upon oxidation of acetals with a ring size of more than 7 carbon atoms and using

8-fold molar excess of H2 O2 in ether solution. The assumption about of the oxidation

mechanism has been made and is based on the structure of reaction products, with

dependence of quantity of these products on the reaction conditions, size of acetals rings,

and known literary data.

Unauthenticated

Download Date | 10/1/16 4:43 PM

424

3

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

Experimental part

1

H NMR and 13 C NMR spectra were recorded on a Bruker AC-200 and a Bruker WM-250.

Analytical TLC: Silufol UV-254, Silpearl as the sorbent, starch as the binder. Column

chromatography was performed on silica gel (63-200 mesh, Merk).

Melting points were determined using a Kofler hot stage.

The GLC analysis was carried out with ”Varian-3700” (FID, a glass column 2000×3

mm, 5 % Carbowax 20M on Inerton and 5 % XE-60 on Chromaton N-AW).

Cycloalcanones, formic, acetic and trifluoroacetic acids, 30 % water solution of hydrogen peroxide (all reagent grade) were used without additional purification. Solutions of

H2 O2 in Et2 O are prepared according to [30]. Solvents: petroleum ether, diethyl ether,

methylene chloride and methanol were distilled before use.

General procedure for acetals (1a-g, 12) synthesis

Trimethyl orthoformate 31.8 g (0.3 mol) and TsOH·H2 O 50 mg (1b-d) or 150 mg

(1a, 1e-g) were added to a solution of ketone (0.1 mol) in methanol 70 ml. The mixture

was boiled for 10-30 minutes (1b-d), 1-6 h (1a, 1e-g), K2 CO3 2 g (7.2mmol) was added

and the mixture was stirred for 15 minutes. Solids were filtered. Acetals were purified by

distillation.

1,1-Diethoxycyclopentane (1b): 9.5 g (60 %); b.p. 162-165 ◦ C; 162-166 ◦ C [31]. Prepared

in a similar manner using triethyl orthoformate.

1,1-Dimethoxycyclohexane (1c): 11.5 g (80 %); b.p. 60 ◦ C (20 Torr); 67 ◦ C (27 Torr)

[32].

1,1-Dimethoxycycloheptane (1d): 13.3 g (84 %); b.p. 74-76 ◦ C (10 Torr); 73 ◦ C (10 Torr)

[33].

1,1-Dimethoxycyclooctane (1e): 14.8 g (86 %); b.p. 92-94 ◦ C (10 Torr); 88 ◦ C (7.7 Torr)

[33].

1,1-Dimethoxycycloudecane (1f): 12.5 g (58 %); b.p. 93-95 ◦ C (1 Torr); 87-88 ◦ C (0.7

Torr) [33].

1,1-Dimethoxycyclododecane (1a): 18.5 g (81 %); b.p. 56-58 ◦ C (0.1 Torr); 63-64 ◦ C (0.2

Torr) [33].

1,1-Dimethoxycyclotridecane (1g): 15.1 g (62.4 %);

NMR 1 H 250 MHz (δ, CDCl3 ): 1.17-1.62 (m, 18H, CH2 ), 3.16 (s, 6H, CH3 ).

NMR 13 C 250 MHz (δ, CDCl3 ): 24.3, 25.1, 25.9, 26.3, 26.7, 30.3 (CH2 ), 47.6 (OCH3 ),

103.8 (C).

1,1-Dimethoxynonane (12): 14.1 g (75 %); b.p. 90-92 ◦ C (20 Torr); 91-92 ◦ C (20 Torr)

[34].

1,1-Bishydroperoxycyclododecane (7’) and 1-methoxycyclododecene (6) were prepared in

accordance with [35].

Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

425

General procedure for oxidation of acetals (1a-g), 1-methoxycyclododecene

(6), 1,1-bishydroperoxycyclododecane (7’), 1,1-dimethoxynonane (12),

2-formyloxycyclododecanone (5)

0.044-1.5 g (0.45-15 mmol) H2 SO4 and 5-20 eqv 30 % water or 6 % ether solution of H2 O2

were added to 7 ml HCOOH (CH3 COOH, CF3 COOH) at 0 or 20 ◦ C. This temperature

was maintained for 10 minutes. 1 eqv Oxidized substance (0.5 g) was added for 1020 seconds with stirring. The mixture was heated to boiling. In the case of H2 O2 in

ether solution, the ether was distilled off at boiling within 2-5 minutes, at which point

the temperature has risen up to 90-95 ◦ C. Heating was continued for approximately 20

minutes, sustaining moderate boiling. After this time the qualitative test with KI to

determine the presence of peroxide compounds was negative.

For determination of 2b-e and 3b-e yields upon oxidation of 1b-e acetals, formic

acid was evaporated, methanol (100 ml) was added and the mixture was heated for 2 h

in a water bath. The mixture was neutralized by a sufficient quantity of K2 CO3 and the

residue was filtered. The composition of the mixtures was analyzed by GLC with use of

esters 2b-e and 3b-e as standards previously isolated by column chromatography.

For determination of the yields of 2a, 2f, 2g, 3a, 3f, 3g and 13, carboxylic acid

was evaporated, >20 % solution of NaOH in water was added to initiate a strongly

alkaline reaction. The mixture was heated up within 1h in a water bath, then acidified

by hydrochloric acid. Target acids were extracted by 4×(Et2 O (25 ml) + CHCl3 (25 ml)).

The yields of acids 2a, 2f, 2g, 3a, 3f, 3g, and 13 were determined after column

chromatography using petroleum ether/diethyl ether (with the portion of diethyl ether

increasing from 50 % to 85 %).

Oxidation of 1a with use of 2 eqv of H2 O2 (6 % ether solution) (Table 1)

Oxidation of 1a was performed in accordance with the general procedure. The products

were isolated as follows. After the heating was stopped, the reaction mixture was cooled

to room temperature and diluted with water (40 ml) and methylene chloride (100 ml).

The organic layer was separated, washed by water 5×10 ml, dried under MgSO4 , filtered,

and evaporated. Cyclododecanone 4 (60 %), 2-formyloxycyclododecanone 5 (11 %),

dodecanedioic acid 2a (traces), and 12-formyloxydodecanoic acid 3a’ (17 %) were isolated

by column chromatography.

Oxidation of cyclododecanone 4

A number of experiments on the oxidation of 4 were performed in a similar manner to the

general procedure for oxidation of acetals (1a-g) using a twofold molar excess of methanol.

The acids 3a and 2a were obtained with 51-53 % and 39-43 % yields, respectively.

Oxidation of 1a with isolation of intermediate products

The oxidation of 1a was carried out according to the general procedure (1.5 g (15

mmol) H2 SO4 and 8 eqv 6 % ether solution of H2 O2 ) with heating of reaction mixture for 2 minutes, then quickly cooled to room temperature and diluted with water

Unauthenticated

Download Date | 10/1/16 4:43 PM

426

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

(40 ml) and methylene chloride (100 ml). the organic layer was separated, washed

by water 5×10 ml, dried under MgSO4 , filtered, and evaporated. Cyclododecanone 4

(12 %), 2-formyloxycyclododecanone 5 (15 %), dodecanedioic acid 2a (39 %), and 12formyloxydodecanoic acid 3a’ (24 %) were isolated by column chromatography.

Dodecanedioic acid (2a) [36].

M.p. = 124.5-125.5 ◦ C (toluene). (m.p. = 125 ◦ C) [36].

NMR 1 H, 250 MHz (δ, DMSO) 1.17-1.62 (m, 16H, CH2 ), 2.18 (t, 4H, CH2 COOH, J=7

Hz), 11.85-12.10 (br. s., 2H, COOH).

NMR 13 C, 62.9 MHz (δ, DMSO): 24.5, 28.6, 28.7, 28.9, 33.7 (CH2 ), 174.5 (COOH).

12-Hydroxydodecanoic acid (3b) [37].

M.p. = 81.5-83.5 ◦ C (toluene). (m.p. = 82-84 ◦ C) [37].

NMR 1 H, 250 MHz (δ, DMSO): 1.18-1.61 (m, 18H, CH2 ), 2.18 (t, 2H, CH2 COOH, J=7.3

Hz), 3.37 (t, 2H, CH2 OH, J=6.3 Hz), 3.50-4.50 (br. s., 2H, OH, COOH).

NMR 13 C, 62.9 MHz (δ, DMSO): 24.1, 25.1, 28.2, 28.41, 28.49, 28.55, 28.62, 28.7, 32.1,

33.2, 60.3 (CH2OH), 174.1 (COOH).

12-Formyloxydodecanoic acid (3a’) [38].

M.p. = 59-61 ◦ C. (m.p. = 61-62 ◦ C) [38].

NMR 1 H, 250 MHz (δ, DMSO): 1.15-1.69 (m, 18H, CH2 ), 2.19 (t, 2H, CH2 COOH, J=7.3

Hz), 4.10 (t, 2H, CH2 O, J=6.5 Hz), 7.98 (s, 1H).

Dimethylpentanedioate (2b) [39].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.83 (quint, 2H, CH2 CH2 COOMe, J = 7.5 Hz), 2.27 (t,

4H, CH2 COOMe, J=7.2 Hz), 3.54 (s, 6H, OCH3 ).

Methyl 5-hydroxypentanoate (3b) [40].

NMR 1 H, 200 MHz (δ, CDCl3 ): 1.43-1.75 (m, 4H, CH2 ), 2.29 (t, 2H, CH2 COOMe, J =

7.2 Hz), 2.55-2.65 (br. s., 1H, OH), 3.64-3.71 (m, 5H, CH2 OH, CH3 ).

Dimethylhexanedioate (2c) [39].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.55-1.64 (m, 4H, CH2 CH2 COOMe), 2.23-2.31 (m, 4H,

CH2 COOMe), 3.59 (s, 6H, OCH3 ).

Methyl 6-hydroxyhexanoate (3c) [41].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.4 (m, 2H, CH2 ), 1.45-1.72 (m, 4H, CH2 ), 2.22 (t, 2H,

CH2 COOMe, J = 7.2 Hz), 2.60-2.70 (br. s., 1H, OH), 3.62 (t, 2H, CH2 OH, J = 7 Hz),

3.66 (s, 3H, CH3 ).

NMR 13 C, 62.9 MHz (δ, CDCl3 ): 24.4, 24.5, 32.2, 33.7 (CH2 ), 51.5 (OCH3 ), 62.5

(CH2 OH), 174.2 (C=O).

Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

427

Dimethylheptanedioate (2d) [39].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.32 (m, 2H, CH2 CH2 CH2 COOMe), 1.58 (m, 4H,

CH2 CH2 COOMe), 2.25 (t, 4H, CH2 COOMe, J = 7.5 Hz), 3.60 (s, 6H, OCH3 ).

Methyl 7-hydroxyheptanoate (3d) [42].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.15-1.61 (m, 8H, CH2 ), 2.20 (t, 2H, CH2 COOMe, J =

7.2 Hz), 2.45-2.55 (br. s, 1H, OH), 3.48 (t, 2H, CH2 OH, J = 7.5 Hz), 3.65 (s, 3H, CH3 ).

NMR 13 C, 62.9 MHz (δ, CDCl3 ): 24.6, 25.2, 28.5, 32.1, 33.7 (CH2 ), 51.4 (OCH3 ), 62.3

(CH2 OH), 174.6 (C=O).

Dimethyloctanedioate (2e) [39].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.25-1.34 (m, 4H, CH2 CH2 CH2 COOMe), 1.57 (m, 4H,

CH2 CH2 COOMe), 2.25 (t, 4H, CH2 COOMe, J = 7.5 Hz), 3.61 (s, 6H, OCH3 ).

Methyl 8-hydroxyoctanoate (3e) [42].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.20-1.62 (m, 10H, CH2 ), 2.26 (t, 2H, CH2 COOMe, J =

7.2 Hz), 2.42-2.57 (br. s, 1H, OH), 3.62 (t, 2H, CH2 OH, J = 6.7 Hz), 3.65 (s, 3H, OCH3 ).

Undecanedioic acid (2f) [43].

M.p. = 108-109.5 ◦ C (H2 O) (m.p. = 110 ◦ C) [43].

NMR 1 H, 250 MHz (δ, DMSO): 1.10-1.62 (m, 14H, CH2 ), 2.18 (t, 4H, CH2 COOH, J = 7

Hz), 11.80-12.15 (br.s., 2H, COOH).

11-Hydroxyundecanoic acid (3f) [44].

M.p. = 68 ◦ C (H2 O) (m.p. = 65-67 ◦ C) [44].

NMR 1 H, 250 MHz (δ, CDCl3 ): 1.12-1.69 (m, 16H, CH2 ), 2.34 (t, 2H, CH2 COOH, J =

6.9 Hz), 3.60 (t, 2H, CH2 OH, J = 6.5 Hz), 3.70-4.40 (br. s., 2H, OH).

Tridecanedioic acid (2g) [45].

M.p. = 110.5-111.5 ◦ C (toluene) (m.p. = 113.0-113.5 ◦ C) [45].

NMR 1 H, 200 MHz (δ, DMSO): 1.10-1.65 (m, 18H, CH2 ), 2.17 (t, 4H, CH2 COOH, J=7.0

Hz), 11.85-12.15 (br. s., 2H, COOH).

NMR 13 C, 50.32 MHz (δ, DMSO): 24.5, 28.5, 28.6, 28.7, 28.9, 33.6 (CH2 ), 174.4 (COOH).

13-Hydroxytridecanoic acid (3g) [46].

M.p. = 76.5-78 ◦ C (toluene) (m.p. = 77 ◦ C) [46].

NMR 1 H, 200 MHz (δ, DMSO): 1.12-1.65 (m, 20H, CH2 ), 2.17 (t, 2H, CH2 COOH, J =

7.0 Hz), 3.36 (t, 2H, CH2 OH, J=6.3 Hz), 3.10-3.60 (br.s., 2H, OH).

NMR 13 C, 50.32 MHz (δ, DMSO): 24.1, 25.3, 28.6, 28.72, 28.77, 28.85, 28.92, 28.97, 29.1,

32.5, 33.7 (CH2 ), 60.3 (CH2 OH), 174.4 (COOH).

Unauthenticated

Download Date | 10/1/16 4:43 PM

428

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

2-Formyloxycyclododecanone (5).

NMR 1 H, 200 MHz (δ, CDCl3 ): 1.12-2.05 (m, 18H, CH2 ), 2.38-2.47 (m, 2H, CH2 ), 5.225.25 (m, 1H, CHOC (O) H), 8.09 (s, 1H, C (O) H).

NMR 13 C, 50.32 MHz (δ, CDCl3 ): 21.0, 22.3, 22.4, 22.7, 23.8, 26.0, 26.2, 27.7, 34.8, 40.3

(CH2 ), 78.0 (CHOC (O) H), 160.0 (CHOC (O) H), 205.3 (C=O).

MS: m/z (%) = 226 (M+ , 10), 198 (11), 181 (70), 163 (62).

Found (%): 68.61; H, 9.67. C12 H24 04 . Calculated (%): 68.99; H, 9.80.

Nonanoic acid (13).

NMR 1 H, 200 MHz (δ, CDCl3 ): 0.86 (t, 3H, CH3 , J=7.2 Hz), 1.18-1.42 (m, 10H, CH2 ),

1.49-1.72 (m, 2H, CH2 CH2 COOH), 2.31 (t, 2H, CH2 COOH, J=7 Hz), 10.95-11.10 (br. s.,

1H, COOH).

NMR 13 C, 50.32MHz (δ, CDCl3 ): 13.94 (CH3 ), 22.6, 24.6, 29.0, 29.1, 29.3, 31.7, 34.0

(CH2 ), 180.4 (COOH).

References

[1] Baeyer and V. Villiger: ”Einwirkung des Caro’schen Reagens auf Ketone”, Ber., V,

Vol. 32, (1899), pp. 3625–3633.

[2] C.H. Hassell: Organic reactions, Vol. 9, Ch.3, Wiley and Sons, New York-London,

1958.

[3] V.N. Belov, L.A. Hejfits and S.I. Varezub: Reactions and methods of research of

organic compounds, Vol. 10, GCHI, Moscow, 1961.

[4] Methoden der Organischen Chemie (Houben-Weyl), 4th ed., Georg Thieme Verlag,

Stuttgard, 1963, pp. 707.

[5] G.R. Krow: “Oxygen insertion reactions of bridged bicyclic ketones”, Tetrahedron,

Vol. 37, (1981), pp. 2697–2724.

[6] M. Renz and B. Meunier: “100 Years of Baeyer-Villiger Oxidations”, Eur. J. Org.

Chem., (1999), pp. 737–750.

[7] W.F. Bailey and M.-J. Shih: “Oxidation of Ketals to Orthocarbonates: A Double

Baeyer-Villiger Reaction”, J. Am. Chem. Soc., Vol. 104, (1982), pp. 1769–1771.

[8] W.F. Bailey and J.J. Bischoff: “Formation of Cyclic Ethers in the Double BaeyerVilliger Oxidation of Ketals Derived from Cyclic Ketones”, J. Org. Chem., Vol. 50,

(1985), pp. 3009–3010.

[9] T. Sugimura, Y. Fujiwara and A. Tai: “Asymmetric Baeyer-Villiger reaction:

Diastereodifferentiating peracid oxidation of chiral acetal in the presence of Lewis

acid”, Tetrahedron Lett., Vol. 34, (1997), pp. 6019–6022.

[10] Y. Gaony: “Oxidation of 2,7-Dioaxabicyclo[2.2.1]heptanes with m-Chlorperbenzoic

acid. 2,7,8-Trioxabicyclo[3.2.1]octanes”, J. Chem. Soc. C., Vol. 23, (1968), pp. 2934–

2941.

[11] P.A. Grieco, T. Oguri and Y. Yokoyama: “One-step conversion of protected lactols

into lactones”, Tetrahedron Lett., Vol. 5, (1978), pp. 419–420.

Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

429

[12] D.D. Davis and D.L. Sullivan: “Process for the preparation of dodecandioic acid by

oxidation of cyclododecene”, US Pat. 5026461; Chem. Abstr., Vol. 115, (1991), pp.

114024.

[13] K. Schermanz, M. Schoeftner, E. Kloimstein, J. Schaller, E. Perndorfer, K. Reiter

and R. Nehofer: “Preparation of α, ω-alkanedioic acids by ozonolysis, hydrogenation

and oxidation of cycloalkenes”, Eur. Pat. Appl., EP 432541, (1991); Chem. Abstr.,

Vol. 115, (1991), pp. 114023.

[14] Standard Oil Development Co.: “Dicarboxylic acids from saturated monocarboxylic

acids”, GB 706650, (1954); Chem. Abstr., Vol. 48, (1954), pp. 8818.

[15] Esso Research and Engineering Co.: “1,12-Dodecandioic acid”, GB 878241, (1959);

Chem. Abstr., Vol. 56, (1962), pp. 8570.

[16] N.E. Drysdale, T.W. Stambaugh and J.V. Tarbell: “Solventless dimeric cyclic ester

distillation process”, US Pat. 5236560, (1993); Chem. Abstr., Vol. 119, (1993), pp.

252569.

[17] O. Shohachi, N. Katsuyuki and M. Yoshiyuki: “1,12-Dodecane dioic acid”, Jap. Pat.

7429164, (1974); Chem. Abstr., Vol. 82, (1975), pp. 139366.

[18] L. Marosi and W. Schlenk: ”Langkettige Carbonsäureester: Schmelzpunkte Regeln

für das Auftreten des Vertikaltyps der Kristallstruktur, Inkremente des großen

Netzebenenabstandes”, Justus Liebigs Ann. Chem., (1973), pp. 584–598.

[19] R. Bhattacharaya, S.R. Saletore and J.L. Simonsen: “A synthesis of Behenolic acid”,

J. Chem. Soc., (1928), pp. 2678–2681.

[20] H. Stetter and W. Dierichs: “Eine neue Methode zur Darstellung Langkettiger

Carbonsäuren, II. Mitteil.*): Vereinfachtes Verfahren zur Darstellung langkettiger

Carbonsäuren”, Chem. Ber., Vol. 85, (1952), pp. 290–292.

[21] M.D. Potter and E.P. Taylor: “The reaction of Sodiomalonic Esters with a Halogenocarboxylic Acid”, J. Chem. Soc., (1951), pp. 3513–3513.

[22] S. Ravi, D. Padmanabhan and V.M. Mamdapur: “Macrocyclic musk compounds:

Synthetic approaches to key intermediates for exaltolide, exaltone and dilactones”, J.

Indian. Inst. Sci, Vol. 81, (2001), pp. 299–312.

[23] A.O. Terent’ev, A.V. Kutkin, M.M. Platonov, Y.N. Ogibin and G.I. Nikishin: “A

new method for the synthesis of bishydroperoxides based on a reaction of ketals with

hydrogen peroxide catalyzed by boron trifluoride complexes”, Tetrahedron Lett., Vol.

44, (2003), pp. 7359–7363.

[24] A.A. Frimer: “Synthesis of α-Hydroxyacetals”, Synthesis, (1977), pp. 578–579.

[25] Hassner, R.H. Reuss and H.W. Pinnick: “Hydroxylation of Carbonyl Compounds via

Silyl Enol Ethers”, J. Org. Chem., Vol. 40, (1975), pp. 3427–3429.

[26] R.B. Moffett and G. Slomp, Jr.: “Reaction of Peracids with ∆20(21) -Steroid Enol

Acetates”, J. Am. Chem. Soc., Vol. 76, (1954), pp. 3678–3682.

[27] T.H. Kritchevsky and T.F. Gallagher: “Partial Synthesis of Compounds Related to

Adrenal Cortical Hormones. XIV. Preparation of the Dihydroxyacetone Side Chain;

17α-Hydroxyprogesterone and “Substancese L and P””, J. Am. Chem. Soc., Vol. 74,

(1951), pp. 184–189.

[28] K. Sato, M. Aoki and R. Noyori: “A “Green” Route to Adipic Acid: Direct Oxidation

of Cyclohexens with 30 Percent Hydrogen Peroxide”, Science, Vol. 281, (1998), pp.

1646–1647.

Unauthenticated

Download Date | 10/1/16 4:43 PM

430

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

[29] P.S. Starcher and B. Phillips: “Synthesis of Lactones”, J. Am. Chem. Soc., Vol. 80,

(1958), pp. 4079–4082.

[30] I. Saito, R. Nagata, K. Yuba and T. Matsuura: “Synthesis of α-silyloxyhydroperoxides

from the reaction of silyl enol ethers and hydrogen peroxide”, Tetrahedron Lett., Vol.

24, (1983), pp. 1737–1740.

[31] A. Napieraj, S. Zawadski and A. Zwierac: “New Routes to Diethyl 1Alkenylphosphoramidates“, Tetrahedron, Vol. 56, (2000), pp. 6299–6306.

[32] G.A. Olah, S.C. Narang, D. Meidar and G.F. Salem: “Catalysis by solid superacids;

81 . Improved Nafion-H2 perfluorinated resinsulfonic acid-catalyzed preparation of

dimethyl acetals and ethylenedithioacetals, and hydrolysis of dimethyl acetals”,

Synthesis, (1981), pp. 282–283.

[33] W.W. Zajaci and K.J. Byrne: “Relative Reactivities of Cycloalkanone Dimethyl

Ketals to Hydrogenolysis by Dichloroaluminum Hydride”, J. Org. Chem., Vol. 35,

(1970), pp. 3375–3377.

[34] Hori, T. Hayashi and H. Midorikawa: “Synthesis with Dithiocarbamate Derivatives

III. A New Route to Aldehydes”, Synthesis, (1974), pp. 705–707.

[35] A.O. Terent’ev, A.V. Kutkin, M.M. Platonov, I.I. Vorontsov, M.Yu. Antipin, Yu.N.

Ogibin and G.I. Nikishin: “Synthesis of peroxide compounds by the BF3 -catalyzed

reaction of acetals and enol ethers with H2 O2 ”, Izv. Akad Nauk, Ser.Khim., Vol. 3,

(2004), pp. 650–656; Russ. Chem. Bull., Vol. 3, (2004), pp. 681–687 (Engl. Transl.).

[36] E.K. Starostin, A.A. Mazurchik, A.V. Ignatenko and G.I. Nikishin: “ Synthesis of

α-Haloadipic Acids from 1,2-Cyclohexanedione”, Synthesis, (1992), pp. 917–918.

[37] S.B. Mirviss: “Synthesis of ω-unsaturated acids”, J. Org. Chem., Vol. 54, (1989), pp.

1948–1951.

[38] S. Muñoz, J. Mallén, A. Nakano, Z. Chen, I. Gay, L. Echegoyen and G.W. Gokel:

“Ultrathin Monolayer Lipid Membranes from a New Family of Crown Ether-Based

Bola-Amphiphiles”, J. Am. Chem. Soc., Vol. 115, (1993), pp. 1705–1711.

[39] R. Ballini and G. Bosica: “α-Nitrocycloalcanones as a Source of α, ω-Dicarboxylic

Acid Dimethyl Esters”, Tetrahedron, Vol. 53, (1997), pp. 16131–16138.

[40] B.A. Marples, C.G. Saint and J.R. Traynor: “Regiochemistry of Nucleophilic Opening

of β-Substituted Styrene Oxides with Thiolate Anions: Model Experiments in the

Synthesis of Leukotriene Analogues”, J. Chem. Soc. Perkin Trans.1, (1986), pp. 567–

574.

[41] E. Bosone, P. Farina, G. Guazzi, S. Innocenti and V. Marrotta: ”New Synthesis

of Methyl 7-oxoheptanoate: an Useful Intermediate for the Preparation of 2-(6Methoxycarbonylhexyl)-cyclopent-2-en-1-one”, Synthesis, (1983), pp. 942–944.

[42] R. Ballini, M. Petrini and V. Polzonetti: “Amberlist A21 as New and Efficient Surface

Catalyst for cleavage of 2-Nitrocycloalkanones”, Synthesis, (1992), pp. 355–357.

[43] A.J. Hubert: “A Novel Method for the Catalytic Partial Hydrogenation of Diolefins to

Mono-olefins. Preparation of Cycloalkenes”, J. Chem. Soc. C, (1967), pp. 2149–2152.

[44] J. Inanaga, K. Hirata, H. Saeki, T. Katsuki and M. Yamaguchi: “A Rapid

Esterification by Means of Mixed Anhydride and its Application to Large-ring

Lactonization”, Bull. Chem. Soc. Jpn., Vol. 52, (1979), pp. 1989–1993.

[45] K. Saotome, H. Komoto and T. Yamazaki: “The synthesis of α, ω-disubstituted higher

alkanes from α,α,α,ω-tetrachloroalkanes”, Bull. Chem. Soc. Jpn., Vol. 39, (1966), pp.

480–484.

Unauthenticated

Download Date | 10/1/16 4:43 PM

A.O. Terent’ev, S.V. Chodykin / Central European Journal of Chemistry 3(3) 2005 417–431

431

[46] K.B. Wiberg and R.F. Waldron: “Lactones. 2. Enthalpies of Hydrolysis,

Reduction, and Formation of the C4 -C13 Monocyclic Lactones. Strain Energies and

Conformations”, J. Am. Chem. Soc, Vol. 113, (1991), pp. 7697–7705.

Unauthenticated

Download Date | 10/1/16 4:43 PM