Fire Alarm Systems for Life Safety Code Users

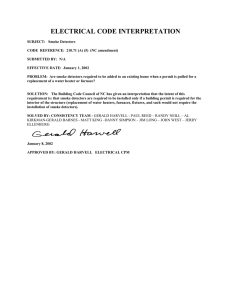

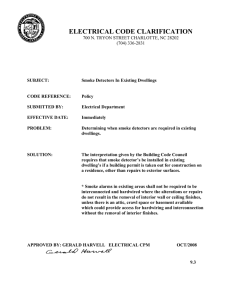

advertisement