Rotary Power Flow Controller (RPFC) Characteristics Analysis

advertisement

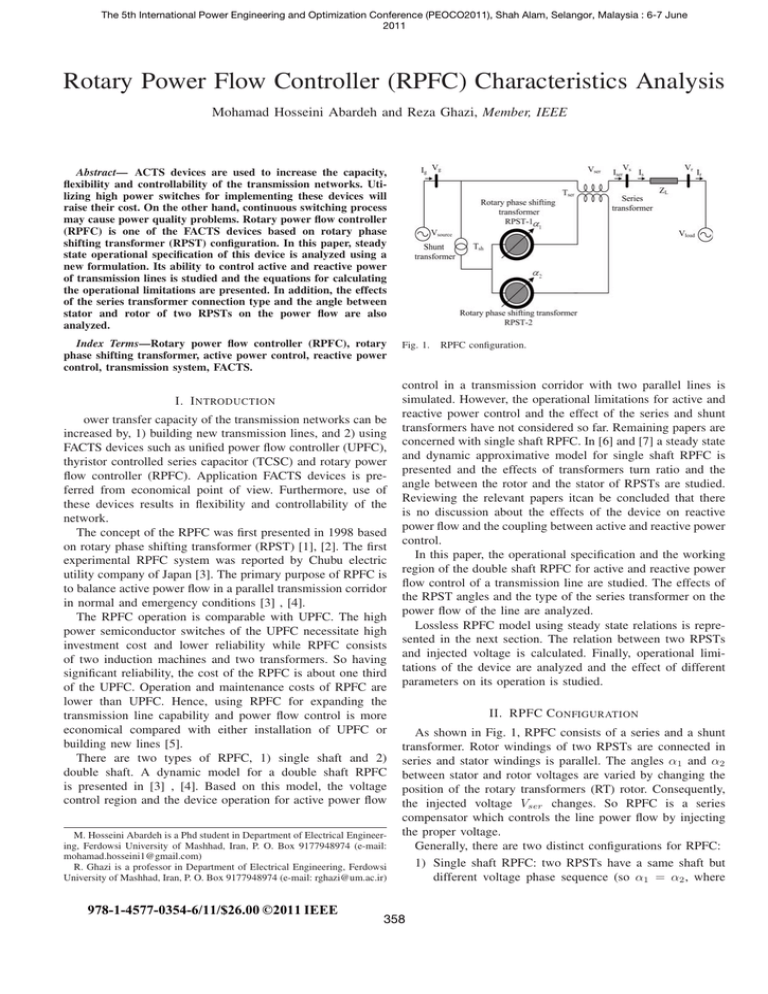

The 5th International Power Engineering and Optimization Conference (PEOCO2011), Shah Alam, Selangor, Malaysia : 6-7 June 2011 Rotary Power Flow Controller (RPFC) Characteristics Analysis Mohamad Hosseini Abardeh and Reza Ghazi, Member, IEEE Abstract—FACTS devices are used to increase the capacity, flexibility and controllability of the transmission networks. Utilizing high power switches for implementing these devices will raise their cost. On the other hand, continuous switching process may cause power quality problems. Rotary power flow controller (RPFC) is one of the FACTS devices based on rotary phase shifting transformer (RPST) configuration. In this paper, steady state operational specification of this device is analyzed using a new formulation. Its ability to control active and reactive power of transmission lines is studied and the equations for calculating the operational limitations are presented. In addition, the effects of the series transformer connection type and the angle between stator and rotor of two RPSTs on the power flow are also analyzed. Index Terms—Rotary power flow controller (RPFC), rotary phase shifting transformer, active power control, reactive power control, transmission system, FACTS. I. I NTRODUCTION Power transfer capacity of the transmission networks can be increased by, 1) building new transmission lines, and 2) using FACTS devices such as unified power flow controller (UPFC), thyristor controlled series capacitor (TCSC) and rotary power flow controller (RPFC). Application FACTS devices is preferred from economical point of view. Furthermore, use of these devices results in flexibility and controllability of the network. The concept of the RPFC was first presented in 1998 based on rotary phase shifting transformer (RPST) [1], [2]. The first experimental RPFC system was reported by Chubu electric utility company of Japan [3]. The primary purpose of RPFC is to balance active power flow in a parallel transmission corridor in normal and emergency conditions [3] , [4]. The RPFC operation is comparable with UPFC. The high power semiconductor switches of the UPFC necessitate high investment cost and lower reliability while RPFC consists of two induction machines and two transformers. So having significant reliability, the cost of the RPFC is about one third of the UPFC. Operation and maintenance costs of RPFC are lower than UPFC. Hence, using RPFC for expanding the transmission line capability and power flow control is more economical compared with either installation of UPFC or building new lines [5]. There are two types of RPFC, 1) single shaft and 2) double shaft. A dynamic model for a double shaft RPFC is presented in [3] , [4]. Based on this model, the voltage control region and the device operation for active power flow M. Hosseini Abardeh is a Phd student in Department of Electrical Engineering, Ferdowsi University of Mashhad, Iran, P. O. Box 9177948974 (e-mail: mohamad.hosseini1@gmail.com) R. Ghazi is a professor in Department of Electrical Engineering, Ferdowsi University of Mashhad, Iran, P. O. Box 9177948974 (e-mail: rghazi@um.ac.ir) 978-1-4577-0354-6/11/$26.00 ©2011 IEEE 978-1-4577-0353-9/11/$26.00 ©2011 IEEE Fig. 1. RPFC configuration. control in a transmission corridor with two parallel lines is simulated. However, the operational limitations for active and reactive power control and the effect of the series and shunt transformers have not considered so far. Remaining papers are concerned with single shaft RPFC. In [6] and [7] a steady state and dynamic approximative model for single shaft RPFC is presented and the effects of transformers turn ratio and the angle between the rotor and the stator of RPSTs are studied. Reviewing the relevant papers itcan be concluded that there is no discussion about the effects of the device on reactive power flow and the coupling between active and reactive power control. In this paper, the operational specification and the working region of the double shaft RPFC for active and reactive power flow control of a transmission line are studied. The effects of the RPST angles and the type of the series transformer on the power flow of the line are analyzed. Lossless RPFC model using steady state relations is represented in the next section. The relation between two RPSTs and injected voltage is calculated. Finally, operational limitations of the device are analyzed and the effect of different parameters on its operation is studied. II. RPFC C ONFIGURATION As shown in Fig. 1, RPFC consists of a series and a shunt transformer. Rotor windings of two RPSTs are connected in series and stator windings is parallel. The angles α1 and α2 between stator and rotor voltages are varied by changing the position of the rotary transformers (RT) rotor. Consequently, the injected voltage Vser changes. So RPFC is a series compensator which controls the line power flow by injecting the proper voltage. Generally, there are two distinct configurations for RPFC: 1) Single shaft RPFC: two RPSTs have a same shaft but different voltage phase sequence (so α1 = α2 , where 358