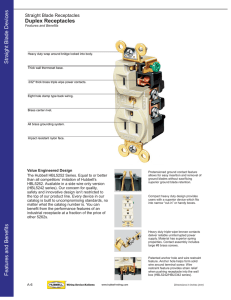

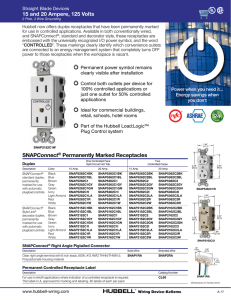

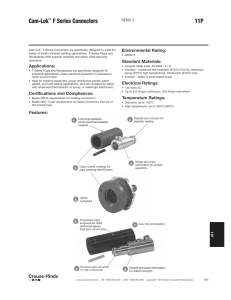

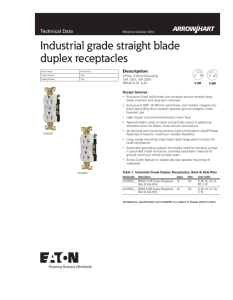

Catalog Page

advertisement