The work production of shape memory alloy

advertisement

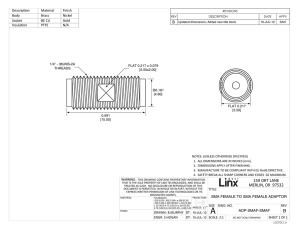

INSTITUTE OF PHYSICS PUBLISHING SMART MATERIALS AND STRUCTURES Smart Mater. Struct. 13 (2004) 552–561 PII: S0964-1726(04)76267-9 The work production of shape memory alloy Yong Liu School of Mechanical and Production Engineering, Nanyang Technological University, 639798, Singapore E-mail: mliuy@ntu.edu.sg Received 7 November 2003, in final form 2 February 2004 Published 26 April 2004 Online at stacks.iop.org/SMS/13/552 DOI: 10.1088/0964-1726/13/3/014 Abstract This paper is to evaluate the work production and thermal efficiency of shape memory alloy (SMA). NiTi wire under pure tension mode is chosen for the work production and several bias components are evaluated including a linear elastic component, a non-linear superelastic SMA wire and an SMA with well developed two-way memory effect (TWME). The calculated thermal efficiency shows good agreement with the reported experimental data. The estimation of the thermal efficiency is further discussed with respect to the latest results on SMAs, especially the transformation enthalpy change. Ways of increasing both the work production and the thermal efficiency of SMAs are further suggested. 1. Introduction The discovery of shape memory alloy (SMA) has inspired high enthusiasm in developing solid engines to convert low grade thermal energy to mechanical energy and further to electrical energy. As a result, various types of solid engine have been constructed or proposed, for example, by Banks [1], Smith [2], Ginell et al [3], Golestaneh [4], Wayman [5], Wang [6, 7], Johnson [8], Goldstein [9], Otsuka [10] etc. The underlying mechanism is a solid-state phase transformation that converts heat into motion through self-rearrangement of atoms in a piece of metal, known as shape memory effect. Heat supply is required to trigger the rearrangement of atoms (phase transformation) and to result in dimensional change of the metal. Since thermal energy is one of the least mechanically recoverable forms of energy, the advantage of such a mechanism of energy conversion is that the low grade thermal energy can be utilized conveniently and cleanly. Such thermal energy is abundant in nature, including especially solar thermal energy, geothermal energy and industrial exhaust warm water. However, as soon as people realized that the use of SMAs for energy conversion is limited by several intrinsic and extrinsic factors, the enthusiasm was cooled down. Among them, the energy conversion efficiency and the fatigue property are among the most important factors, that were also found to be interrelated [11]. Although there are still some trials today [12, 13], the number of publications in this field has reduced significantly in recent years. The 0964-1726/04/030552+10$30.00 © 2004 IOP Publishing Ltd most important theoretical works in this field were published more than a decade ago by, for example, Ahlers [14], Tong and Wayman [15], Golestaneh [16], Wollants et al [17–19], Mukherjee [20], Salzbrenner [21], McNichols and Cory [22], Jardine [23] and Duerig et al [11]. However, the published theoretical thermal efficiencies were found to vary from 2.8% to 29%, which are unacceptably widely scattered values for engineering practice. Some of the estimated values were later found to be either under-estimated or over-estimated. Re-examination of the previous works shows that the difference in the theoretical results is due largely to the different research approaches adopted and due partly to the selection of the input experimental data. Some of the previous works suggested that the thermal efficiency is intrinsically determined by the transformation enthalpy change, the equilibrium temperature between martensite and austenite phases and the specific heat of the material, while the change in shape recovery properties was not reflected in the calculation. This clearly contradicts the experimental observations. Another controversial parameter in estimating the thermal efficiency was the transformation enthalpy change. Some researchers have used the experimental values determined from fully annealed specimens, while in some other cases the effect of stress on the transformation enthalpy change was proposed by assuming that the entropy change during phase transformation is unaffected by the application of the stress. Meanwhile, confusion between chemical transformation enthalpy change Printed in the UK 552 Work production of shape memory alloy Figure 1. A schematic diagram illustrates the set-up for energy conversion using SMAs. The SMA wire under tension mode is used for converting thermal energy to mechanical work. The biasing component in chamber I can be either a simple weight, an elastic component, a superelastic SMA wire or an SMA wire identical to that in chamber II. Initial conditions: martensitic SMA II pre-strained to ε is balanced by a bias component at a stress level σ . and measured transformation latent heat has been found in the calculation, thus leading to unrealistic estimated results. Since our understanding of the SMAs has been improved tremendously during the last 10 years, it is time for us to re-evaluate the design of the solid engine and the thermal efficiency of SMAs by taking into account the latest progress in this field. Theoretical results will likely provide guidelines for the engineering practices towards more effective use of the materials. It is hoped that the present paper will re-evaluate the major factors affecting both the work production and the thermal efficiency of the solid engine and to provide guidelines for effective use of SMAs. Since NiTi SMAs have the best shape recovery property and much better fatigue resistance than other SMAs discovered so far, and since they have been used in most engine designs, the analysis will be performed based on the data of NiTi SMAs. The present work will begin by evaluating the work output of a proposed design of solid engine by using different biasing components, namely (1) a bias component of linear elasticity, (2) a superelastic SMA wire and (3) a SMA wire identical to that for work production. An SMA with two-way memory effect (TWME) will be further evaluated. The paper then proceeds to evaluate the thermal efficiency of the SMA and its influencing factors. Finally, ways of increasing both the work output and the thermal efficiency are suggested. 2. Design evaluations A simple design which uses the SMA wires under a tension mode is schematically illustrated in figure 1. This simple design is likely the best design in terms of fully exploiting the capacity of SMA wires. Polycrystalline SMA wire under tension mode should provide the best shape recovery characteristic, thus the highest kinetic output per unit volume if comparing with other loading modes, namely, compression, torsion and bending. One reason is that the martensite deformation and shape recovery is found to be asymmetric between tension and compression (see for example, [24– 27]) due to different deformation mechanisms. For textured polycrystalline SMAs, tension gives rise to a stress plateau during martensite reorientation and a higher recovery strain upon reverse transformation, while compression leads to a lower recovery strain [28, 29]. Another consideration is that Figure 2. Stress–strain curves of superelastic and martensitic SMAs. For a system incorporating an SMA and an elastic bias component, the stress in the elastic component at temperatures between As and Af can be described by line AM. The slope of the line is related to the modulus of the elastic component. The stress value at point M is the martensite stress in the initial condition and the stress value at point A is the austenite stress after heating to Af . The austenite stress varies depending on the modulus of the elastic component. Both stresses are functions of temperature. the material under compression load requires a larger diameter in order to avoid buckling. This will result in slow response due to low cooling rate, thus a low output power. In the case of shear deformation, the distribution of the shear strain across the diameter of the SMA wires or bars will significantly reduce the work output per unit volume of SMAs. As in this case, the strain in the central axis is zero, while that on the outer surface is limited by the maximum shape recovery strain achievable by different types of SMA. Similarly, in bending mode, one side of the SMA is under tension while the other side is under compression. In the central line, the strain is zero. Thus, both the deformation and shape recovery are unevenly distributed through the thickness of the materials, resulting in ineffective use of the materials. In figure 1, the temperature chamber is separated by a piston movable horizontally in one dimension. This onedimensional motion can be conveniently translated into a rotary motion through a proper design, which is, however, beyond the scope of the present paper. For convenience in description, we label the left-hand chamber chamber I and the right-hand chamber chamber II. The initial condition is that the SMA wire in chamber II is in martensitic state and is under tension to a strain slightly over the stress-plateau region in the martensite stress–strain curve as shown in figure 2. In chamber I, the resetting system could be a simple weight, a linear elastic component, a superelastic SMA wire of smaller diameter as compared to that of SMA II or an SMA wire of the same type as that in chamber II. In the first three cases, the temperature of chamber I is kept constant during the operation. Thus, the stress in the bias component is either a constant 553 Y Liu Figure 3. Schematic diagram showing the estimation of the work output of the SMA during one thermal cycle. Line AM is due to the constraint from an elastic bias component. The energy conversion device employs the SMA under tension mode as shown in figure 1. value or a function of strain. For the third design, the cross sectional area of the superelastic SMA in chamber I is chosen in such a way that its bias force will lead to the yield of the martensitic SMA II, and is yielded when SMA II is heated to the austenitic state. In the fourth design, the temperature in chamber I changes during operation, identical to that in chamber II. The stress–strain relations of SMA wire in both martensitic and austenitic states are schematically illustrated in figure 2 together with that of the elastic bias component. For convenience of discussion, we name the device incorporating two identical SMAs in both chambers the coupled SMA system. The unit work output that an SMA is able to produce is approximately shown by a square area between the stress– strain curves of martensite and austenite (figure 3) and can be estimated by wsma = ε1M ε2A σH dε − ε1M ε2A σL dε ≈ (σr − σ1M )(ε1M − ε2A ) (1) where σH and σL are stresses at high (> Af ) and low (<Mf ) temperatures, respectively. σ1M is the martensite detwinning stress and σr is the recovery stress when heated. When a bias elastic component is added, part of the work will be used to overcome the resistance due to the bias force. According to equation (1), in order to maximize the work output of SMA, one needs to maximize the combination of recovery stress and strain. Meanwhile, in order to maximize the work output of the solid engine, one needs to minimize the work done against the bias component. In the following, the work output of the device will be evaluated by using different bias components. 2.1. Elastic bias component for resetting A schematic diagram of a complete thermal cycle of the energy conversion device is illustrated in figure 4. In the initial condition at T1 (<Mf ), the SMA II is in the martensitic state and 554 Figure 4. A schematic diagram illustrates the set-up for energy conversion using the SMA under tension. From condition 1 to 3, a complete thermal cycle is performed. The SMA wire in chamber II was initially in martensitic state (initial condition) and, when heated to above Af , transformed to austenitic state (condition 2). Meanwhile, the piston is moved to the right-hand side due to shape recovery of SMA II. Work is done by SMA II against force F0 and the resistance of bias component. Upon subsequent cooling to below Mf (condition 3), the system resets to its initial state. is deformed under tension to a strain ε1M by the bias component and is balanced at a stress σ1M . In condition 2, the SMA II is heated to a temperature T2 (>Af ) and is recovered to a strain ε2A under the constraint of the bias component and is balanced at a stress σ2A . ε2A can also be considered to be the residual strain under a constraint condition. Thus, the recovery strain is given by εr = ε1M −ε2A . See also figure 2 for the stress–strain relation. In condition 3, the SMA II is again cooled to T1 and the bias component deforms it to ε1M and is balanced at a stress σ1M . F0 is the external force to be overcome in order to produce work output. This external force is different from design to design. In order to maximize the work production, one needs to maximize this force through proper design within the allowable Work production of shape memory alloy range of recovery stress and strain. In the present work, we discuss the simplest case where F0 is assumed to be a constant. If, however, the force is a function of displacement, one needs to substitute the function into the deduced formula. In fact, for any distribution function of the force, the work output can be calculated by using an average force value multiplying the displacement. Further, the nature of this force is so designed that it exists only when there is a movement, i.e., F0 exists only in condition 2 in which the shape recovery of SMA II takes place but is negligibly small during resetting of the system (conditions 1 and 3). In order to generate motion, the maximum recovery force achievable by SMA II must be higher than the sum of F0 and bias force. After passing through a shape recovery process by overcoming the force F0 , the forces experienced by SMA II at T1 and T2 are F1 and F2 , respectively. The corresponding stresses experienced by SMA II in the balanced condition are σ1M and σ2A (σ2A > σ1M ). Under the application of F0 , the recovery stress needed to overcome the resistance is much higher than that in a balanced condition, i.e., σr > σ2A > σ1M . The stresses experienced by the elastic bias component are respectively σ1 and σ2 , and the corresponding strains are ε1 and ε2 . Based on figure 3, for a device using a linear elastic bias component, we have the estimated limit of the unit work output: wout ≈ (σr − σ1M )(ε1M − ε2A ) − 12 (σ2A − σ1M )(ε1M − ε2A ) (2) or wout ≈ [σr − 12 (σ1M + σ2A )](ε1M − ε2A ). (3) From the above equation, it is clear that, in order to increase the work output, σ2A should be reduced. Its lowest limit is σ1M and, in practice, it should always be σ2A > σ1M . However, if SMA II is trained to possess a stable TWME, F1 and σ1M can then be reduced to negligibly small within the TWME strain. In this case, wout ≈ [σr − 12 σ2A ](ε1M − ε2A ). (4) Thus, in order to increase the work output, one can reduce σ2A as much as possible. Based on figure 4, it can be envisaged that the actual work output of the device (Wout ) during one thermal cycle can be calculated by (5) Wout = F0 L 2 . Assuming F0 is negligibly small during resetting, the work production is zero during resetting. Thus, the total work output is (6) Wout = F0 L 2 = F0 (ε1M − ε2A )L 0 . Combining equations (3) and (6) results in Wout = F0∗ (ε1M − ε2A )L 0 ≈ [σr − 21 (σ1M + σ2A )](ε1M − ε2A )A0 L 0 . (7) Thus, (8) F0∗ ≈ [σr − 12 (σ1M + σ2A )]A0 where A0 is the initial cross sectional area of SMA wire and F0∗ is the average force. The amount of unit work production that an SMA can deliver is limited by its achievable combination of recovery stress and strain. Clearly, in order to increase the work output of the device, one needs to reduce the work compensated by deforming the bias component. One way is to reduce the force applied by the bias component as much as possible. Another way is to train the SMA to possess TWME. Using SMA having TWME, equation (8) becomes F0∗ ≈ [σr − 12 σ2A ]A0 . (9) 2.2. Superelastic SMA for resetting To further reduce the amount of work due to deforming the bias component, a superelastic SMA wire can be used as the bias component. Such superelastic wire should possess a low hysteresis and a flat stress plateau. Thus, the area below the AM line of figure 3 can be significantly reduced. The selection of the superelastic wire should consider at least the following two points. (1) The length of stress plateau associated with stress-induced martensitic transformation should be the same as (or longer than) that of the TWME strain (or the plateau strain associated with martensite detwinning if the SMA has only one-way memory effect). Satisfaction of this condition results in a constant bias force throughout the complete shape recovery process. (2) The diameter of the superelastic wire (or the cross section area) should be carefully selected so that the bias force is just enough to bring back the system to its original position in condition 3, and does not exert a significantbias force in condition 2. In such case, equations (8) and (9) still hold for the one-way memory effect and TWME, respectively. The only difference now is that the constraint stress in figure 2 is a constant, and it can be set to as close to σ1M as possible for the one-way memory effect and as low as possible for TWME. 2.3. Identical SMA for resetting This design is to use identical SMA wires for both actuation and resetting as illustrated in figure 5. The advantage of this design is that the work done against bias component is minimized. Meanwhile, the work output of the device is doubled. In figure 5, chamber I and chamber II are identical. During the operation, two chambers are to have different temperatures, i.e., when the temperature in chamber I is above Af , the temperature in chamber II should be below Mf , and vice versa. In the initial condition, the martensitic SMA I is deformed to a strain slightly over the stress-plateau and a residual strain ε0M exists. In chamber II the same SMA wire without pre-strain is connected. Temperature in both chambers is below Mf at the starting point. In this case, no stress exists, assuming also the same nature of the force F0 . When the SMA I is heated to above Af as illustrated in condition 2, its shape recovery will lead to the straining of SMA II to ε1M which is slightly less than ε0M due to deformation of austenitic wire I (ε0A ). In condition 3, the situation is reversed. SMA I is cooled to below Mf and SMA II is heated to above Af . In this case, shape recovery of SMA II leads to the straining of SMA I to ε1M and is balanced by a stress σ1M . A small residual strain (ε0A ) exists in SMA II due to austenite deformation. By reversing the temperatures in both chambers (condition 4), the situation 555 Y Liu In the coupled SMA system shown in figure 5, the actual work produced by a single SMA wire is estimated by ε2M Wsma = Wout + σ1M A0 L 0 dε. (10) 0 The work output Wout is given by equation (5). Equation (8) now has the form F0∗ ≈ [σr − 21 (σ1M + σ1M )]A0 = (σr − σ1M )A0 . (11) We can design the coupled SMA system in such a way that the recovery strain is within the range of the plateau strain. Based on various experimental observations, we can reasonably assume that the stress plateau is flat for the selected SMA wire in martensitic state, thus, the balance stress σ1M is constant throughout the recovery process, neglecting the minor complication at the beginning of the deformation. Thus, we further have the maximum work output of SMA wire in each chamber max ≈ (σr − σ1M )ε2M A0 L 0 . (12) Wsma From this simple equation, it is clear that in order to maximize the work output of SMA, a material approach is to increase the difference between the recovery stress and the martensite yield stress as well as to increase the shape recovery strain. The maximum work output of the coupled system is doubled max Wout ≈ 2(σr − σ1M )ε2M A0 L 0 . (13) By further using SMA wires with well developed TWME, the bias stress can be reduced to zero. In this case, the maximum work output of the coupled SMA system is equal to that of the maximum work output achievable by SMA wire. max max ≈ 2Wsma = 2σr A0 εr L 0 Wout Figure 5. A schematic diagram illustrates the coupled SMA system for work production by using two identical SMA wires under tension mode. In the initial condition, both SMA wires are in martensitic state, and one of them was pre-strained. Upon heating, the pre-strained wire I recovers and leads to the deformation of the SMA wire in chamber II (condition 2). By reversing the temperatures in the two chambers, SMA II recovers and deforms SMA I to the same strain magnitude (condition 3). Further reversing the temperatures (condition 4), the situation in condition 2 is repeated. During one complete thermal cycle, SMA wires in both chambers produce work against the external force F0 . is reversed and is identical to that of condition 2. After one complete thermal cycle, SMA wires in both chambers have produced work against the external force F0 . 556 (14) where σr is the recovery stress, A0 is the initial cross sectional area of the SMA wire, L 0 is the initial length and εr is the recovery strain that should have the same magnitude of ε0M . Thus, in order to increase the work output of the coupled SMA device, one needs to maximize the recovery stress and recoverable strain within the allowable range, and to increase both the cross-sectional area and the initial length of the SMA wires. For NiTi SMA, the recovery stress is up to 600 MPa and the achievable TWME strain is up to 5–6%. Due to the relatively small strain amplitude, we neglect the small difference between the true strain and engineering strain and use only the engineering strain in the following analysis. Increasing the cross sectional area does not necessarily imply increasing the diameter of the SMA wire. One can simply increase the number of wires in each chamber so that the total area of cross sections is increased. By doing so, the operational speed will not be significantly affected. The maximum F0 achievable is the recovery stress times the total area of the cross sections of all the SMA wires in one chamber. The work output per unit volume of SMA is wsma = σr A0 εr L 0 (J cm−3 ). V0 (15) The work output per unit mass of SMA material is wsma = σr A0 εr L 0 σr εr = (J g−1 ). V0 ρ ρ (16) Work production of shape memory alloy If reasonably taking 500 MPa for recovery stress and 5% for TWME strain, and the density of NiTi ρ = 6.45 g cm−3 , the unit work output of NiTi is estimated to be 3.88 J g−1 . In the ideal case, if we use 1 kg NiTi wire, the total work production of SMA is Wsma ≈ 3.88 J g−1 × 1000 g kg−1 = 3.88 kJ cycle−1 kg−1 . (17) If the frequency of thermal cycling f = 0.5 Hz, the work production for 24 h would be Wsma ≈ wsma × f × t = 3.88 J g−1 × 0.5 s−1 × 86 400 s day−1 = 167 616 kJ kg−1 day−1 . (18) The generated power is Psma = Wsma = 1.94 kW kg−1 . t (19) In order to increase the power, more SMA wires are needed to build a rather large device. Increasing the frequency by reducing the wire diameter and enhancing the heat convection is another option. Doubling the frequency will double the work output and power. Utilizing solar thermal energy in tropical areas in combination with low temperature of the seawater would be an ideal case. Geothermal energy in combination with cold air in frigid regions would be another ideal condition. Estimation based on a combination of recovery stress of 500 MPa and a recovery strain of 5% is reasonable. These values are already widely reported and can be achieved conveniently. Progress in the research of SMAs is likely to achieve a better combination of recovery stress and strain through further understanding the controlling factors and through developing new SMAs. A combination of 600 MPa recovery stress and 6% recovery strain will result in an estimated unit work output of 5.58 J g−1 . This ‘slight’ improvement in shape recovery characteristic will not only increase the output power of the SMA, but also increase the thermal efficiency that will be discussed in the following sections. 3. Thermal efficiency In order to use the SMA more energy efficiently, we would like to heat the material to a temperature just high enough to generate enough force for work production and to cool it to a temperature just low enough to be re-deformed to the required strain amplitude. Obviously, these two critical temperatures are Af and Mf and, according to the Clausius–Clapeyron equation, both are functions of applied stress. One needs to pay attention to the accuracy of these temperatures determined by using different techniques under stress-free conditions. The most used technique is DSC in which the transformation temperatures are estimated by using a slope-line-extension method based on the experimental curves. Thus, the transformation temperatures determined by using DSC do not represent the actual starting and finishing temperatures. For the energy production, we like to have 100% martensite/austenite phase at target temperatures. This will increase the work output in terms of increasing displacement and force. Fully transformed SMA during operation may also help to increase the fatigue resistance since the martensite– austenite interface is likely the weakest place of the materials. Thus, it is recommended to include a few more degrees to the experimentally determined transformation temperatures in both operation and calculation. During heating part of the input thermal energy is converted into endothermic transformation latent heat denoted as HM→A , while during cooling part of the driving force is converted to the exothermic transformation latent heat, H A→M . The SMA only produces work through reverse transformation from martensite to austenite. It does not produce work upon cooling. Thus, input thermal energy (Hin ) is needed only to heat the SMA to above Af . This thermal energy transforms into work output (wout ), the work done against bias component (wbias ) and the wasted heat that does not produce any work (Hw ). (20) Hin = wout + wbias + Hw . In the case of the two-way memory effect, wbias = 0. The input thermal energy includes only the heat (HMf →Af ) needed to increase the temperature of the SMA from Mf to Af , and the transformation enthalpy change of the reverse endothermic σ . transformation HM→A σ Hin = HMf →Af + HM→A . (21) For simplicity, we only consider the heat needed by the SMA wire and do not take into account the heat required to heat up the chamber. The latter is an engineering problem and varies from design to design and, in practice, it should σ can be be minimized. For an adiabatic process, HM f →Af estimated from the specific heat of the SMA. The reported values of specific heat of NiTi vary significantly, being 0.46 J g−1 ◦ C−1 [11], 0.2 cal g−1 ◦ C−1 (0.8368 J g−1 ◦ C−1 , Shape Memory Applications), 0.49 J g−1 ◦ C−1 (AMT, Belgium) etc. Since 0.460 J g−1 ◦ C−1 is close to the mostly reported range from independent sources, it will be used in the present calculations. The value selected significantly influences the calculated results. During heating from Mf to Af , the total heat required is σ Hin = c p (Af − Mf ) + HM→A (J g−1 ). (22) According to the Clausius–Clapeyron equation, the stress and the transformation temperatures are interrelated: dσ H = −ρ dT εT0 (23) where σ is the stress imposed on the transforming constituent and ε, ρ and H are the amount of strain along the applied stress direction, the density of the alloy and the transformation enthalpy change, respectively. T0 (σ ) is the equilibrium temperature between two phases under stress and can be approximated by Af (σ ) + Ms (σ ) . 2 Equation (23) can also be written as σ − σ0 dσ H = = −ρ Ms (σ ) − Ms (σ0 ) εT0 dT Ms T0 (σ ) = (24) (25) 557 Y Liu transformation, the latent heat is required from the energy source. For NiTi, transformation latent heat is also a function of annealing temperature after cold work. Our research shows that it reaches the maximum value when annealed at about σ =0 600 ◦ C, where HM→A ≈ 25 J g−1 . It is about 20 J g−1 when annealed at 300 or 1000 ◦ C after cold work. Combining equations (16), (28) and (30), we have the expression of thermal efficiency −1 σr εr dσ wsma c p Af (0) − Mf (0) + = σ η= Hin ρ dT Af ε A (0) + M (0) + dσ −1 σ −1 f s dσ dT Af . (31) + dT Af 2ρ Figure 6. Schematic diagram showing the thermal cycle of one SMA component in the coupled SMA system shown in figure 5. Reverse transformation is under constrained stress while the forward transformation is under a stress-free condition due to the two-way memory effect. dσ where the constant ( dT ) Ms is the slope of the stress– temperature line. Its reported values vary from 4 to 20 MPa ◦ C−1 [11]. Rearranging equation (25), we have −1 dσ Ms (σ ) − Ms (0) = σ dT Ms −1 Mf (σ ) − Mf (0) dσ = σ dT Mf (26) −1 As (σ ) − As (0) dσ = σ dT As −1 Af (σ ) − Af (0) dσ . = σ dT Af According to figures 5 and 6, the SMA is under stress F0 during reverse transformation, while it is under a stressfree condition during forward transformation. Thus, the temperature difference between fully martensitic (Mf (0)) and fully austenitic (Af (σ )) states is expressed as −1 dσ Af (σ ) − Mf (0) = Af (0) − Mf (0) + σ. (27) dT Af Thus, Hin = c p Af (0) − Mf (0) + dσ dT −1 σ Af (0) + Ms (0) + dσ −1 Af (σ ) + Ms (0) dT Af = 2 2 dσ εT0 σ =− HM→A dT ρ dσ −1 (0) + M (0) + σ ε A f s dT Af dσ . =− dT Af 2ρ T0 (σ ) = (28) σ (29) (30) The minus sign in the above equation only tells us whether the latent heat is released or absorbed. In the case of reverse 558 Ms (0) = 40 ◦ C (313 K) Mf (0) = 30 ◦ C (303 K) As (0) = 60 ◦ C (333 K) Af (0) = 70 ◦ C (343 K) dσ = 10 MPa ◦ C−1 dT ρ = 6.45 g cm−3 σr = 500 MPa εr = 5% c p = 0.460 J g−1 ◦ C−1 . The estimated value of the thermal efficiency of NiTi wire under tension mode is η= Af σ + HM→A (J g−1 ) It needs to be noted that Af (σ ) − Mf (0) represents the operation temperature range of the solid engine. If the actual operation temperature range is wider than the range of Af (σ ) − Mf (0), one should use the actual temperature range to estimate the thermal efficiency. Both the transformation hysteresis and the transformation intervals are affected by various factors including especially alloying content and internal stress associated with processing routes. We take the following input values from the published data for an ideal case. Af (0) − Mf (0) = 40 ◦ C wsma 3.88 = ≈ 5.64%. Hin (J g−1 ) 68.76 (32) This value is much lower than that estimated by Tong and Wayman [15], Mukherjee [20] and Jardine [23]. The estimated value is, however, much higher than that the experimental result of Salzbrenner [21]. The very low efficiency (1.1–1.4%) reported by Salzbrenner is likely due to the wide operation temperature range between the low (25 ◦ C) and the high (190 ◦ C) setting temperatures. According to the condition given in Salzbrenner’s report (∼685 MPa recovery stress and ∼1.5% recovery strain), the thermal efficiency estimated by using equation (31) is 1.36%. If taking a value of 25 J g−1 for latent heat, the estimated thermal efficiency would be 1.2%. Work production of shape memory alloy Both values are within the range of the measured value (1.1– 1.4%) reported by Salzbrenner [21]. This shows that, to some extent, equation (31) gives a reasonable estimation of the thermal efficiency. Nevertheless, factors that affect the estimation of thermal efficiency will be further discussed in the next section. Taking a recovery stress of 600 MPa and a recovery strain of 6%, the thermal efficiency estimated by using equation (31) would be 7%. 4. Discussion of the estimated thermal efficiency In the estimation of thermal efficiency in both the present work and the works previously reported, one uncertainty is the effect of stress on the transformation enthalpy change. Wollants et al [17–19] suggested that the transformation enthalpy change is a function of stress and it increases with increasing stress. Such a suggestion was based on the assumption that the entropy change during phase transformation is independent of the applied stress. This assumption, however, needs to be further evaluated. Our recent understanding shows that the martensite variant formed under bias stress is aligned to the stress direction in a more orderly way than that formed under stressfree conditions. Thus, the entropy of such ‘stress-assisted’ martensite could be smaller than that of self-accommodated martensite. This may further result in the decrease of the entropy difference (S) between martensite and austenite. When the gradient of the stress–temperature line is fixed (being typically 7–10 MPa ◦ C−1 ), whether H increases or decreases under stress will depend on the value of S, that needs to be carefully examined. On the other hand, Salzbrenner and Cohen [30] have examined the enthalpy change of thermoelastic martensitic transformation by using CuAlNi single crystals having either a single transformation interface or multiple transformation interfaces. The results show that the observed latent heat of samples having a single transformation interface is higher than those having multiple interfaces. They further proposed that part of the chemical driving force was stored in the multi-interfaced samples in the form of elastic strain energy due to microstructural constraint. Thus, the experimentally determined transformation enthalpy change decreases under constraint. The stored elastic energy will likely promote the reverse transformation, thus, less chemical driving force is needed. In this context, to calculate the thermal efficiency, the stored elastic energy should be excluded from the chemical transformation enthalpy change. Experiments of Salzbrenner and Cohen [30] have provided a useful indication of the nature of the observed latent heat, while further research is needed to accurately determine the relation between the observed latent heat and the applied stress. During such research, one needs to pay special attention to whether the SMA is under stresscontrolled or strain-controlled mode, since this will affect the microstructural mechanism which in turn alters the origin of the observed latent heat change. The decrease in latent heat under constraint was also observed recently [31] by using pre-strained SMA wire embedded in epoxy. This is a partially strain-controlled mode and the authors attributed the decrease in latent heat to the incomplete phase transformation. As the sample has also had a shape change upon reverse transformation, the mechanism proposed by Salzbrenner and Cohen [30] may have been partially operative. Nevertheless, the effect of constrained stress on the transformation latent heat is not concretely concluded. Further investigation from both theoretical and experimental approaches is needed. Recent results [32, 33] have also shown that, after TWME training, the observed latent heat decreases. This result might be explained by the mechanism proposed by Salzbrenner and Cohen [30], i.e., part of the chemical transformation enthalpy was transformed into elastic energy as a result of training. Such elastic strain energy results in the preferential growth of martensite variants responsible for the observed TWME. The stored elastic energy will be released during reverse transformation, thus less chemical driving force is needed. This is responsible for the decrease of the observed latent heat. The decrease in the latent heat after TWME training was also reported independently by another group [34]. In some cases, the decrease was very significant; the latent heat peak nearly disappeared after TWME training. Taking these observations into account, for SMA possessing well developed TWME, equation (30) is no longer valid; the actual thermal efficiency can be much higher than that estimated by using equation (31). In this case, equation (31) can be further written into a more general form σr εr wsma ρ = dσ −1 σ Hin c p Af (0) − Mf (0) + dT σ + HTWME Af (33) σ is the transformation latent heat of SMA where HTWME possessing well developed TWME. According to previous σ is influenced by both internally discussion, HTWME developed stress and externally applied stress. Taking the value of 17.86 J g−1 reported by Da Silva [33] for NiTi with TWME, the estimated efficiency would be increased from 5.64% (equation (31)) to 6.55% (equation (33)). Considering the result of Miller and Lagoudas [34] and taking an estimated value of 10 J g−1 for the latent heat after TWME training, the resulted thermal efficiency will be further increased to σ 7.55%. Clearly, selection of the value of HTWME significantly affects the estimated thermal efficiency. By further reducing the transformation temperature range (Af (0) − Mf (0)) to 20 ◦ C while other conditions remain unchanged, the thermal efficiency could be increased to as high as 9.2%. If further increasing the recovery stress to 600 MPa and recovery strain to 6%, the estimated thermal efficiency would be 10% for a transformation range of 40 ◦ C and 11.93% for a transformation range of 20 ◦ C. Reducing transformation hysteresis by adding Cu is often accompanied by the decrease in recovery stress. Edwards and Perkins [35] have reported that the recovery stress (σr ) is closely related to the yield stress of austenite (the stress for inducing martensite, σ A→M ). η= σr |ε,T ≈ 0.9σ A→M |ε,T . (34) According to this formula, one can increase the recovery stress by reducing the grain size, forming precipitates, adding solid solution etc. However, the effect on the shape recovery strain should be investigated as well. Table 1 lists the calculated thermal efficiencies of NiTi under several selected conditions including the effect of shape 559 Y Liu Table 1. Calculated thermal efficiencies of NiTi with TWME for several assumed conditions. Recovery stress (MPa) Recovery strain (%) Af − Mf (◦ C) H M→ A (J g−1 ) Thermal efficiency (%) 300 300 300 300 500 500 500 500 600 600 600 600 685 685 5 5 5 5 5 5 5 5 6 6 6 6 1.5 1.5 40 40 40 20 40 40 40 20 40 40 40 20 165 165 Equation (30) 17.86 10 10 Equation (30) 17.86 10 10 Equation (30) 17.86 10 10 Equation (30) 25 3.96 4.65 5.51 7.05 5.64 6.55 7.55 9.2 7.04 8.78 9.96 11.93 1.36 1.2 recovery property, latent heat and transformation temperatures. In the optimal condition, the thermal efficiency is higher than 10%. Certainly, reaching such a high value in engineering practice is technically challenging. NiTi-based SMAs are excellent materials but still have their limits. Developing new SMAs with low specific heat and better shape recovery property is very meaningful. We need to bear in mind that, during the calculation, the thermal energy needed to heat the chamber was not considered. Thus, the actual energy conversion efficiency of the device is lower than the estimated value of thermal efficiency. One needs to pay great attention to the design of the device for higher energy conversion rate. Nevertheless, since the solar thermal energy is so abundant in nature, it is likely a feasible way to convert solar heat to mechanical or even electrical energy by using SMAs. Collection and concentration of the solar energy is needed in order to heat the SMA more effectively. The most attractive aspects of such devices are their cleanliness, simplicity in design and low production and maintenance cost. For a solid engine utilizing the temperature difference between that below the sea surface and that above the seawater, once it begins to operate, in principle, it may be like a ‘perpetual machine’ as long as there is a sun in the sky and as long as there is water in the sea. Another important aspect for successful application of a solid engine is the stability of SMAs especially the stability of the shape recovery stress and strain, which is under extensive investigation by various groups. A further interesting consideration is the utilization of the latent heat released during the forward martensitic transformation provided that such latent heat is a significant amount. Since the work production practice is a continuous operation involving a large number of thermal cycles rather than a single thermal cycle, if we are able to utilize the exothermic latent heat through proper design, we can further increase the thermal efficiency. This can be understood from the formula below. σ σ Hin∗ = c p (Af − Mf ) + HM→A − H A→M (J g−1 ). (1) Use SMA in tension mode. This will fully utilize the capacity of SMA through a uniform distribution of the deformation and recovery strain. For especially textured SMAs (wires, plates, sheets, rods, thin foils), tension deformation leads to higher shape memory strain than that of compression and torsion. In addition, it also has lower martensite detwinning stress, thus less energy dissipation upon martensite deformation. (2) Use textured SMAs rather than non-textured since textured SMAs possess an optimized shape recovery strain along specific directions. If a textured SMA sheet or thin foil is used, tension along the rolling direction provides much better performance than tension along the transverse direction. This is due to the deformation and shape recovery anisotropy due to texture distribution, see for example [36–38]. (3) Train the SMA to have TWME so that the work done on deforming the bias component is minimized. A coupled SMA system provides an optimal work output and thermal efficiency. (4) Reduce the endothermic transformation latent heat through TWME training and utilize the exothermic latent heat if it is significant. (5) Carefully select the operation temperature range. Upon cooling the temperature should be just low enough to form 100% martensite, and it is just high enough to form 100% austenite upon heating (with slight offset). This will increase the work output and thermal efficiency and likely increase the service life of SMAs as well. (35) Thus, for continuous thermal cycling, the thermal efficiency can be written as wsma (36) η= σ σ c p (Af (σ ) − Mf (σ )) + HM→A − µH A→M 560 where µ is a coefficient representing the utilization rate of the exothermic latent heat. It is related to design. When µ = σ 0, H A→M is not utilized, and equation (36) becomes (31) σ is fully (for design shown in figure 5). When µ = 1, H A→M utilized. Utilization of latent heat is technically challenging. It is considerable only when the amount of latent heat is significant. If one is able to reduce the amount of latent heat through various means, e.g. TWME training, utilization of the exothermic latent heat is less important. As long as high thermal efficiency is required, designs using SMA helical springs as actuation media should be avoided. The reason is that, in the helical spring, the SMA wire is under mainly shear deformation. Both recovery stress and recovery strain are not evenly distributed across the diameter of the wire and their average values are rather small as compared to the same SMA under pure tension. Thus, the unit work output of SMA is low and much more material is needed to achieve the same amount of work production as that of SMA under tension. Although an SMA helical spring may have longer operation life due to less deformation amplitude, it is not practical for real work productions due to the very low thermal efficiency. In summary, in order to use SMA effectively, the following considerations are recommended. 5. Conclusions The present research evaluates the work production of solid engine and the thermal efficiency of shape memory alloy. SMA under tension mode is recommended and evaluated. Work production of shape memory alloy Reducing the energy dissipation due to deformation of the bias component through proper design can effectively increase the work output of the solid engine. A coupled SMA system using identical SMA wires having TWME for both actuation and resetting is recommended for achieving higher work output and thermal efficiency. Analysis shows that the thermal efficiency is strongly related to the shape recovery property of SMA; it increases with increasing shape recovery stress and strain. The calculated thermal efficiency is in good agreement with the reported experimental data. When estimating the thermal efficiency, attention should be paid to the difference between chemical transformation enthalpy change and the measured latent heat which is lowered after TWME training. References [1] Banks R 1975 Energy conversion system US Patent Specification 3 913 326 [2] Smith W K 1978 Compound memory engine US Patent Specification 4 086 769 [3] Ginell W S, McNichols J L and Cory J S 1979 Mech. Eng. 101 28 [4] Golestaneh A A 1981 Solid state engine using Nitinol memory alloy US Patent Specification 4 302 939 [5] Wayman C M 1981 Solid state thermal engine US Patent Specification 4 246 754 [6] Wang F E 1981 Energy conversion system US Patent Specification 4 275 561 [7] Wang F E 1984 Energy conversion system US Patent Specification 4 472 939 [8] Johnson A D 1985 Two-way shape memory alloy heat engine US Patent Specification 4 490 976 [9] Goldstein D 1990 Heat engine based on shape memory alloys US Patent Specification 4 938 026 [10] Otsuka G K 1995 Shape memory alloy heat engine US Patent Specification 5 442 914 [11] Duerig T W, Stöckel D and Keeley A 1990 Engineering Aspects of Shape Memory Alloys ed T W Duerig, K N Melton, D Stöckel and C M Wayman (London: Butterworth-Heinemann) pp 181–94 [12] Kutlucinar I V and Saul A M 2001 Heat converter engine using a shape memory alloy actuator US Patent Specification 6 226 992 [13] Tobushi H, Okumura K, Shimeno Y and Takata K 2001 Trans. Mater. Res. Soc. Japan 26 171–4 [14] Ahlers M 1975 Scr. Metall. 9 71–4 [15] Tong H C and Wayman C M 1975 Metall. Trans. A 6 29–32 [16] Golestaneh A A 1978 J. Appl. Phys. 49 1241–4 [17] Wollants P, De Bonte M and Roos J R 1979 Z. Metallk. 70 H.2, S.113–7 [18] Wollants P, De Bonte M, Delaey L and Roos J R 1979 Z. Metallk. 70 H. 5, S.298–304 [19] Wollants P, Roos J R and Delaey L 1980 Scr. Metall. 14 1217–23 [20] Mukherjee K 1980 Scr. Metall. 14 405–10 [21] Salzbrenner R 1984 J. Mater. Sci. 19 1827–35 [22] McNichols J L and Cory J S 1987 J. Appl. Phys. 61 972–84 [23] Jardine A P 1989 J. Mater. Sci. 24 2587–93 [24] Liu Y, Xie Z L, Van Humbeeck J and Delaey L 1998 Acta Mater. 46 4325–38 [25] Xie Z L, Liu Y and Van Humbeeck J 1998 Acta Mater. 46 1982–2000 [26] Gall K and Sehitoglu H 1999 Int. J. Plast. 15 69–92 [27] Gall K, Sehitoglu H, Chumlyakov Y I and Kireeva I V 1999 Acta Mater. 47 1203–17 [28] Liu Y 2001 Smart Materials ed A R Wilson and H Asanuma; Proc. SPIE 4234 82–93 [29] Liu Y 2002 IUTAM Symp. on Mechanics of Martensitic Phase Transformation in Solids ed Q-P Sun (Dordrecht: Kluwer) pp 37–44 [30] Salzbrenner R and Cohen M 1979 Acta Metall. 27 739–48 [31] Zheng Y J, Schrooten J, Cui L S and Van Humbeeck J 2003 Acta Mater. 51 5467–75 [32] Xu H and Tan S 1995 Scr. Metall. Mater. 33 749–54 [33] Da Silva E P 1999 Scr. Mater. 10 1123–9 [34] Miller D A and Lagoudas D C 2001 Mater. Sci. Eng. A 308 161–75 [35] Edwards G and Perkins J 1975 Shape Memory Effects in Alloys ed J Perkins (New York: Plenum) pp 445–9 [36] Mulder J H, Thoma P E and Beyer J 1993 Z. Metallk. 84 501–8 [37] Inoue H, Miwa N and Inakazu N 1996 Acta Mater. 44 4825–34 [38] Liu Y, Xie Z L, Van Humbeeck J and Delaey L 1999 Acta Mater. 47 645–60 561