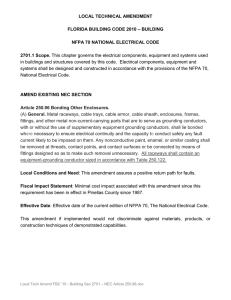

Chapter 10

advertisement