AIR-CONDITIONING AND REFRIGERATION EQUIPMENT BASED

advertisement

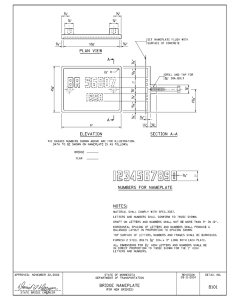

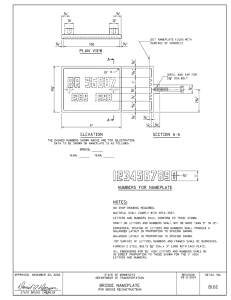

AIR-CONDITIONING AND REFRIGERATION EQUIPMENT BASED ON THE 2014 NEC Article 440 applies to electrically driven air-conditioning and refrigeration equipment. The rules in this article add to or amend the rules in Article 430 and other articles [440.3(A)]. A key term to understand is “rated-load current.” This is the current resulting when the motor-compressor operates at rated load and rated voltage. Each manufacturer has the motor for a given air conditioning or refrigeration unit built to its own specifications. Cooling and other characteristics of these motors are different from those of nonhermetic motors. Other articles As noted, Article 440 builds on Article 430. But, depending upon the equipment or occupancy, other articles apply. These are identified in Table 440.3(D). Not all air-conditioning and refrigeration equipment motors fall under Article 440: Air-conditioning and refrigeration equipment that don’t have hermetic refrigeration motorcompressors, such as furnaces with evaporator coils, must comply with (respectively) Article 422 for appliances, Article 424 for electric space heating, and Article 430 for motors [440.3.(B)]. Room air conditioners, household refrigerators and freezers, drinking water coolers, and beverage dispensing machines are listed as appliances, and their installation must also comply with Article 422 for appliances [440.3(C)]. Nameplate The manufacturer of multi-motor and combination-load equipment must affix a visible nameplate marked with the maker’s name, rating in volts, number of phases, and minimum conductor ampacity. It must also provide the maximum rating of the branch-circuit short-circuit and ground-fault protective device [440.4(B)]. When determining the rating of the disconnecting means, the branch-circuit conductors, the controller, and the branch-circuit short-circuit and ground-fault protection for a hermetic refrigerant motorcompressor, use the rated-load current marked on the nameplate of the equipment [440-6(A). Always check the nameplate data before installing and/or connecting the motor. It is a good practice to photograph this nameplate as part of the project documentation. Use the nameplate data to calculate the minimum conductor ampacity per 440.33. Choose the branch circuit short-circuit and ground-fault protective device rating per 440.22(B). Disconnecting means For a hermetic refrigerant motor-compressor, the ampere rating must be at least 115 percent of the nameplate rated-load current or branch-circuit selection current, whichever is greater [440.12(A)(1)]. For cord-connected room air conditioners, household refrigerators and freezers, drinking water coolers and beverage dispensers, an attachment plug and receptacle can serve as the disconnecting means [440.13]. A disconnecting means for air-conditioning or refrigeration equipment must be located within sight from and readily accessible from the equipment [440.14]. The disconnecting means can be mounted on or within the air-conditioning equipment, but it must not be located on panels designed to allow access to the equipment, or where it will obscure the equipment nameplate. Note these two 440.14 exceptions: Ex 1: A disconnecting means does not have to be within sight from the equipment, if all the following conditions are met: The disconnecting means is lockable (as described in 110.25). The equipment is essential to an industrial process in a facility that has written safety procedures. Where the conditions of maintenance and supervision ensure only qualified persons service the equipment. Ex 2: An accessible attachment plug and receptacle can serve as the disconnecting means. The receptacle for the attachment plug does not have to be readily accessible. Overcurrent protection If the equipment nameplate specifies “Maximum Fuse Size,” you must use a one-time or dual-element fuse [110.3(B)]. If the nameplate says “Maximum Protection Size,” circuit breakers or fuses can be used. For single motor-compressors, the short-circuit and ground-fault protective device must not be more than 175 percent of the motor-compressor current rating. If the protective device sized at 175 percent isn’t capable of carrying the starting current of the motor-compressor you can use the next size larger protective device, but in no case can it exceed 225 percent of the motor-compressor current rating [440.22(A)]. If the equipment incorporates more than one hermetic refrigerant motor-compressor, or a hermetic refrigerant motor-compressor and other motors or other loads, the equipment must have a visible nameplate containing the maximum rating of a branch-circuit short-circuit and ground-fault protective device [440.22(B)]. Conductor sizing Branch-circuit conductors to a single motor-compressor must have an ampacity not less than 125 percent of the motor-compressor rated-load current or the branch-circuit selection current, whichever is greater [440.32]. Example for sizing overcurrent protection and conductor size: What size conductor and overcurrent device are required for an 18A motor compressor with 75 degree C terminals? (a) 12 AWG, 30A (b) 10 AWG, 50A (c ) a or b (d) 10 AWG, 60A Answer: (a) 12 AWG, 30A Step 1: Determine the branch-circuit conductor [Table 310.15(B)(16) and 440.32]: 18A x 1.25 = 22,50A 12 AWG, rated 25A at 75 degree C [110.14(C)(1)(a)(3), Table 310.15(B)(16)] Step 2: Determine the branch-circuit protection [240.6(A) and 440.22(A)]: 18A x 1.75 = 31.50Am next size down = 30A If the 30A short-circuit and ground-fault protection device is not capable of carrying the starting current, you can size the protective device up to 225 percent of the equipment load current rating. 18A x 2.25 = 40.50A, next size down 40A. You can use a 30A or 40A overcurrent device to protect a 12 AWG conductor for an air-conditioning circuit. See 240.4(G) for details. It is very common for a motor-compressor unit to have a nameplate that specifies the maximum overprotection size and the minimum circuit ampacity. Room air conditioners The requirements of Article 440, Part VII apply to a cord-and-plug-connected room air conditioner of the window or in-wall type that incorporates a hermetic refrigerant motor-compressor rated not over 40A, single-phase [440.60]. Branch-circuit conductors for a cord-and-plug-connected room air conditioner must have an ampacity not less than 125 percent of the rated-load current [440.32]. If the room air conditioner is the only load on a circuit, the marked rating of the air conditioner must not exceed 80 percent of the rating of the circuit overcurrent device [440.62(B)]. The total rating of a cord-and-plug-connected room air conditioner must not exceed 50 percent of the rating of a branch circuit where lighting outlets, other appliances, or general-use receptacles are also supplied [440.62(C)]. An attachment plug and receptacle or cord connector can serve as the disconnecting means for a room air conditioner, if [440.63]: (1) The manual controls on the room air conditioner are readily accessible and within 6 ft. of the floor, or (2) A readily accessible disconnecting means is within sight from the room air conditioner. If a flexible cord is used to supply a room air conditioner, the cord must not exceed 10 ft. for 120V units, or 6 ft. for 208V or 240V units [440.64]. Single-phase cord-and-plug-connected room air conditioners must be provided with a factory-installed leakage current detector, or with an arc-fault circuit-interrupter (AFCI) [440.65]. Just chillin’ You can avoid panics and be able to just chill at the end of the project, if you keep two basic concepts in mind. First, remember that Article 440 covers a special case motor, so it modifies Article 430 requirements rather than serving as an alternative to (or replacement for) them. Second, the equipment nameplate is crucial. Always check that early in the project and again before making connections. You need a perfect match with the application; the nameplate information is the basis for correctly sizing the supply. For each motor, the manufacturer has worked out all of the details and supplied the correct protection, conductor sizing, and other information on the nameplate. So when wiring an air conditioner, trust the information on the nameplate and don’t try to over-complicate the situation. The math for sizing the overcurrent protection and conductor minimum ampacity has already been done for you. Source: Mike Holt, NEC Consultant, Mike Holt Enterprises, December 16, 2015