VEHICLE TECHNOLOGY

AUSTRALASIA

ENGINEER

Issue 3 - October 2014

www.saea.com.au

TRANSPORT

EMISSIONS SIMULATION

The development of an Australian simulation tool for vehicle

emissions and fuel consumption software with high resolution in

time and space.

REDARC SUCCESS STORY

Commitment to both Innovation and Business

Excellence make a Powerful Combination.

MEMBER INTERVIEW

With Owen Johnstone, an Investigator with the

NSW Office of Transport Safety Investigations.

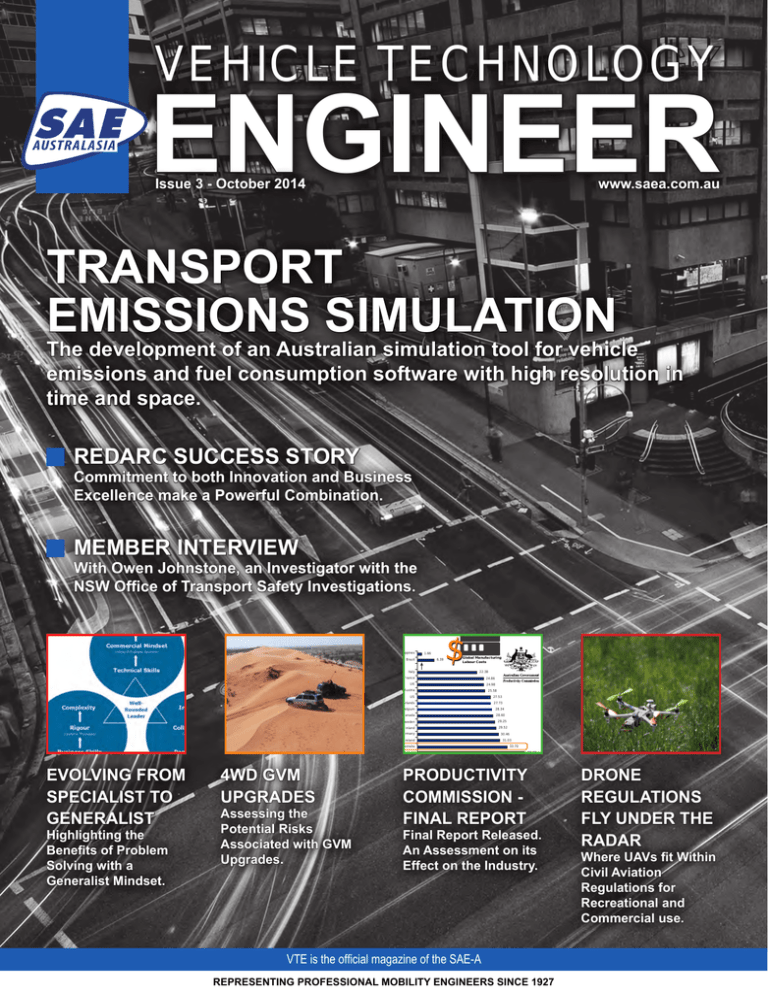

Philippines

1.66

Brazil

6.39

$

Italy

Global Manufacturing

Labour Costs

22.38

France

24.86

UK

24.98

Austria

25.58

US

27.53

Netherlands

27.73

Belgium

28.34

Canada

28.60

Sweden

29.25

Finland

29.52

Germany

30.46

Ireland

31.03

33.70

Australia

40.48

Switzerland

Denmark

41.03

0

EVOLVING FROM

SPECIALIST TO

GENERALIST

Highlighting the

Benefits of Problem

Solving with a

Generalist Mindset.

4WD GVM

UPGRADES

Assessing the

Potential Risks

Associated with GVM

Upgrades.

10

20

30

40

AU$, 2014

PRODUCTIVITY

COMMISSION FINAL REPORT

Note: Direct pay for time worked is wages and salaries for time actually worked.

Source: United States Department of Labor, Bureau of Labor Statistics (BLS), 2011.

Final Report Released.

An Assessment on its

Effect on the Industry.

VTE is the official magazine of the SAE-A

REPRESENTING PROFESSIONAL MOBILITY ENGINEERS SINCE 1927

DRONE

REGULATIONS

FLY UNDER THE

RADAR

Where UAVs fit Within

Civil Aviation

Regulations for

Recreational and

Commercial use.

BE PART OF THE

WINNING FORMULA.

BECOME A VOLUNTEER.

11 – 14

DECEMBER

2014

CALDER PARK

RACEWAY

CALDER FWY,

CALDER PARK,

VICTORIA

Formula SAE-Australasia is the region’s premier design, construction

and on track performance competition for engineering students.

Linked to the international SAE Formula program, this event attracts

entries from all major Australian and key international universities.

CALLING VOLUNTEERS FOR FRIDAY,

SATURDAY OR SUNDAY

To learn more visit:

www.saea.com.au/formula-sae-a

Be part of this exciting event as a volunteer official.

Complete the volunteer form here:

www.saea.com.au/formula-sae-a/volunteer-at-fsae-a

Volunteering offers you an opportunity to see new ideas and

technologies at work and to share the experience of the 500+

passionate, innovative students - all with their eye on the prize.

For more information contact Paul Muscat:

EM: formulasae@sae-a.com

PH: (03) 9676 9568

Formula volunteers receive:

• Polo shirt

• Sun hat

• Gourmet lunch each day

• Commemorative 2014 Formula SAE-A program

By volunteering you are helping students advance their careers into

the Australian engineering community.

YOUNG ENGINEERS

CONTENTS

CONTENTS

TRANSPORT

EMISSIONS SIMULATION

EVOLVING FROM

SPECIALIST TO

GENERALIST

$

23

17

6

MEMBER

INTERVIEW

30

6

IND. NEWS

WHERE TO NOW FOR THE

AUTOMOTIVE SUPPLY CHAIN?

34

34

EVENTS & TRAINING

Vehicle Technology Engineer Workshop������������������������������������������ 8

Volvo Technical Innovations Evening��������������������������������������������������� 9

Formula SAE-A ���������������������������������������������������������������������������������������������������� 11

Engineering Consultants������������������������������������������������������������������������������ 12

INDUSTRY NEWS

Salt Water Powered Supercar���������������������������������������������������������������� 15

15

4WD GVM

UPGRADES

FROM THE SAE

From the President����������������������������������������������������������������������������������������������� 2

From the Executive Director������������������������������������������������������������������������� 3

SAE-A Industry Programs Working Group������������������������������������� 3

SAE-A Software and IT Update���������������������������������������������������������������� 4

Member Interview with Owen Johnstone���������������������������������������� 6

New Members������������������������������������������������������������������������������������������������������������ 7

TRANSPORT EMISSIONS SIMULATION

The Development of an Australian Simulation Tool for

Vehicle Emissions and Fuel Consumption ������������������������������� 16

EVOLVING FROM SPECIALIST TO GENERALIST

Highlighting the Benefits of Problem Solving with a

Generalist Mindset��������������������������������������������������������������������������������������������� 22

TECHNICAL

Drone Regulations Fly Under the Radar�������������������������������������� 26

4WD GVM Upgrades��������������������������������������������������������������������������������������� 29

Small Overlap Frontal Crash Test������������������������������������������������������� 32

AUTOCRC

INDUSTRY PARTNERS

FAPM������������������������������������������������������������������������������������������������������������������������������� 34

HWL Ebsworth Lawyers�������������������������������������������������������������������������������� 36

AutoCRC���������������������������������������������������������������������������������������������������������������������� 38

VEHICLE TECHNOLOGY

ENGINEER

PH: (03) 9676 9568

FX: (03) 9646 7793

EM: info@sae-a.com.au

WEB: www.saea.com.au

ABN 95 004 248 604

ISSN 00360651

Published by: Society of Automotive Engineers - Australasia

Unit 30, 3 Westside Ave, Port Melbourne, VIC, 3207

Editor

Gavin Kroon

editor@sae-a.com.au

Business Enquiries

SAE-A Executive Director

Natalie Roberts

executive@sae-a.com.au

Subscription & SAE-A

Membership Enquiries

Rose De Amicis

rose@sae-a.com.au

President

Adrian Feeney

president@sae-a.com.au

VTE INDUSTRY PARTNERS AND SPONSORS

AutoCRC Enquiries

PH: (03) 9948 0450

FX: (03) 9948 0499

EM: enquiries@autocrc.com

www.autocrc.com

FAPM Enquiries

PH: (03) 9863 2400

FX: (03) 9820 0164

EM: info@fapm.com.au

www.fapm.com.au

The editor, publisher, printer, the Society of Automotive Engineers – Australasia (SAE-A) and their employees, directors, servants, agents and associated or related entities (Publishing Entities) are

not responsible for the accuracy or correctness of the text, pictures or other material comprising the contributions and advertisements contained in this publication or for the consequences of any

use made of the products, services and other information referred to in this publication. The Publishing Entities expressly disclaim all liability of whatsoever nature for any consequences arising from

the use or reliance on material contained in this publication whether caused to a reader of this publication or otherwise. The views expressed in this publication do not necessarily reflect the views of

the Publishing Entities. The responsibility for the accuracy or correctness of information and other material is that of the individual contributors and the Publishing Entities do not accept responsibility

for the accuracy or correctness of information or other material supplied by others. To the extent permissible by law, the Publishing Entities exclude all liability pursuant to the Competition and

Consumer Act 2010 (Cth) or other applicable laws arising from statute or common law. Readers should make their own inquiries prior to the use of, or reliance on, any information or other material

contained in this publication, and where necessary seek professional advice. All rights reserved. Reproduction in whole or part without the written permission of SAE-A is strictly prohibited.

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

1

7TH: WA. Volvo Truck, Facility Tour

FROM THE SAE-A

7

6

9

23

14

22 23 24 25 26 27

UPCOMING EVENTS

28 29 30 31

23RD: VIC. Denso, Facility Tour

29TH: Mobility Engineering

Excellence Awards

OCTOBER

Truck, Facility Tour

7TH: WA. Volvo

JANUARY

7

September is already upon us and it

has been one of the busiest years for a

long time at SAE-A. I won’t recap on all

the events that have been co-ordinated

by our National Office in 2014, instead

I want to focus on what is happening

between now and the end of the year. For

me, the two most important and perhaps

defining events for SAE-A are the annual

Excellence Awards and Formula SAE-A.

The Excellence Awards is an opportunity for all to celebrate the success and

ingenuity of our peers and to offer them

a forum to publicise their achievements.

This year, in line with our stated aim

to reach out to all forms of mobility, not

just automotive, the Awards will feature

submissions from the non-automotive

sectors. To this end I encourage any

company or organisation who feels that

they may have a suitable project worthy

of consideration to contact Paul Muscat at

the Head Office to discuss their submission. I also encourage all members (and

non-members of course) to join us on the

evening, you will enjoy yourselves and

perhaps will see the benefit of a submission in future years.

Formula SAE-A is also fast approaching

and with the event moving to its new

home at Calder Park, this year will be

bigger, better and more comfortable for

both participants and spectators alike. If

you have never been to this event, please

come along and see the results of the

student’s year of hard work and creativity

as they develop their organisational and

engineering skills in a real world environment. Don’t just come and watch however,

why not get involved as a volunteer? We

have roles for all levels of skill and we will

ensure you are appropriately trained and

assisted in whatever task we allocate to

you.

VEHICLE TECHNOLOGY ENGINEER

11 12 13

15TH: Ford, Proving Ground Tour

29

Adrian Feeney

2

15

9TH: VIC. Bombardier, Facility Tour

FROM THE

PRESIDENT

SAE is a member based organisation, so

why not become more involved?

6TH: Vehicle Technology Engineer

Workshop #2

9

1

2

4

5

6

2014

NOVEMBER

2015

23

22ND Dec - 6TH Jan:

SAE-A Close of National Office

DECEMBER

Technology Engineer

6TH: Vehicle

FEBRUARY

Workshop #2

3

9TH: VIC. Bombardier, Facility Tour

11TH - 14TH: Formula SAE-A

5

15

5TH: Vehicle Technology Engineer

TH

Workshop

#3

15

: Ford, Proving

Ground Tour

29

APRIL

JANUARY

1

4

5

2

11 12 13

14

10 11 12 13 14

15 22 23 24 25 26 27

28 29 30 31

10TH - 15TH: Australian Automotive

Formula SAE-A

11TH - 14TH: Week

23RD: VIC. Denso, Facility Tour

29TH: Mobility Engineering

Excellence Awards

22ND Dec - 6TH Jan:

SAE-A Close of National Office

MARCH

6

22ND Dec - 6TH Jan:

- APACClose

18

SAE-A

of National Office

- Cars of Tomorrow

- Formula SAE-A @ the GP

2015

MAY

FEBRUARY

3

6

YE: Design To Win

5

1

ST

1

5TH:: SAE-A

VehicleAGM

Technology Engineer

Workshop #3

JUNE

MARCH

Technical Accident

Investigation

10 &11 12 13

Reconstruction Course

14

15

10TH - 15TH: Australian Automotive

Week

- APAC 18

- Cars of Tomorrow

- Formula SAE-A @ the GP

22ND Dec - 6TH Jan:

SAE-A Close of National Office

KEY:

APRIL

National Event

Division Event

YE: Design

To Win

Upcoming

Events

MAY

JUNE

Event dates yet to be finalised

1

Vehicle Technology

Engineer

(VTE) Magazine

Technical

Accident

1ST: SAE-A AGM

Investigation &

Reconstruction Course

Mobility Engineering Excellence Awards

Date:

October 29th, 2014

Time: 6.30pm -11.00pm

Venue: Leonda by the Yarra, 2 Wallen Rd, Hawthorn, Vic

Contact: info@sae-a.com.au

Register:

www.stickytickets.com.au/sae-a

KEY:

National Event

Event dates yet to be finalised

Division Event

Vehicle Technology Engineer (VTE) Magazine

Vehicle Technology Engineer Workshop #2

Date:

November 6th, 2014

Time: 8.00am - 6.00pm

Venue: Swinburne University, Hawthorn Campus

Contact: info@sae-a.com.au

Register: www.stickytickets.com.au/sae-a

VIC: Ford Proving Ground Tour

Date:

November 15th, 2014 Time: 9.00am -2.30pm

Venue: Ford You Yangs Proving Ground

Transport Leaving From: cnr Salmon St. And Bayside Ave, Port Melbourne

Contact: info@sae-a.com.au

Register: www.stickytickets.com.au/sae-a

Division Contacts

Division Coordinator:

Rose De Amicis

info@sae-a.com.au

Victoria:

Doug Monaghan

vic@sae-a.com.au

Queensland:

Lachlan Tomlin

qld@sae-a.com.au

Young Engineers:

Gavin Kroon

youngengineers@sae-a.com.au

Contact Rose De Amicis on (03) 9676 9568 to become involved in your division.

AUSTRALASIA

October 2014

FROM THE SAE-A

FROM THE

EXECUTIVE

DIRECTOR

Natalie Roberts

Time flies when you’re having fun [or is it

when you are busy]. In August, I hit my

first milestone date at SAE-A, being 12

months since I started. During this time,

substantial changes have occurred within

the organisation and the industry.

In this issue of the VTE-M, [M for magazine], you can read about what SAE-A

is doing via the Industry Programs

Working Group [IPWG] to assist automotive professionals as they transition. The

SAE-A’s focus is on the needs of the engineering professional at the individual level.

The aim of the IPWG is to place engineers

into roles that add value to the employer

and where the automotive professional

can utilise their skills, knowledge and

experience. This will be done by identifying and communicating opportunities.

Contact me if you would like to volunteer

your time to assist in this program.

The work of the IPWG will be fundamental to empowering engineers and

professionals to make their next career

decision and will add long term benefits to

Australian industry through the retention

of a highly skilled workforce.

In other news... SAE-A is revamping our

entire IT, web and membership systems

and has adopted cutting edge technologies to bring technical events and

training direct to interstate and overseas

members via live webinars.

We have been able to implement these

systems due to an increase in our

member base and revenue from training

and events. This increase in income,

combined with the remarkable generosity

of a $10,000 donation from one of our

members [who has requested anonymity],

has enabled us to invest monies back

into the organisation. To our kind benefactor: Thank-you for contributing so

generously to improve our Society for

the benefit of all our members.

INDUSTRY PROGRAMS

WORKING GROUP

AUSTRALIAN AUTOMOTIVE TALENT: A NEW ERA.

Martha Oplopiadis - Industry Programs & Allied

Societies Chair, SAE-A

With the announcements that Ford,

Holden and Toyota will wind up their

automotive manufacturing activities

in Australia by 2017, the future looks

very uncertain – and potentially

bleak – for thousands of automotive

industry employees.

Job losses at all major employers

have already commenced.

Development projects are coming

to an end, and many design, development and validation engineers

are actively seeking work, or trying

to figure out what the next phase of

their career will look like.

benefit to people currently, or soon to

be, out of work.

The review is a good start, but it

needs to be followed up with a

program that provides action, focussing on connecting automotive talent

with employers in complementary

industries.

The SAE-A represents automotive

industry members and has created

a new committee, the Industry

“To place engineers

into roles that add value

to the employer and

where the automotive

professional can utilise

their skills, knowledge and

experience.”

The final report from the Productivity

Commission, released in August

2014 estimates job losses of up to

40,000 across the industry.

Currently, a number of overseas

companies are taking advantage of

the closing of Australia’s automotive

industry, and are actively recruiting

in Australia. Attractive packages are

available for relocation – and there

are an enormous number of jobs

available in the USA and Europe.

Whilst these opportunities are of

great benefit to the individual engineers whose personal situations

enable them to take advantage of

such offers, a mass exodus of highly

trained, highly skilled individuals is a

great loss to the nation as a whole.

The Government recently conducted

an economic review to identify

growth sectors and industries that

could benefit from the skills of

Australia’s automotive professionals,

so that automotive engineers could

target these industries when seeking

employment opportunities. Sadly,

such reports provide little tangible

Programs Working Group, to assist

in addressing these issues. The

work of the IPWG will be fundamental to empowering engineers

and professionals to make their next

career decisions and will add long

term benefits to Australian industry

through the retention of a highly

skilled workforce.

The committee is chaired by Martha

Oplopiadis, Engineering Manager

at GM Holden and SAE-A board

member, and has the following remit:

•

•

To place engineers into roles that

add value to the employer and

where the automotive professional can utilise their skills,

knowledge and experience.

To retain the skills and knowledge of Automotive Professionals

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

3

FROM THE SAE-A

•

•

•

in Australia through a program

that identifies relevant employment opportunities and connects

professionals with potential new

employers.

Be the conduit connecting engineering talent with new growth

industries.

Develop strategies to educate

potential employers as to how

engineers can benefit their

organisations.

Promote engineering talent and

the value that engineers add

to small and multinational business, particularly through their

highly developed skills in problem

solving, risk management, attention to detail, and analysis.

The Industry Programs Working

Group, deeply aware that time is

running short for many people,

is working with urgency on these

issues. Preliminary discussions with

numerous industry groups have been

held, and an initial pool of industry

bodies interested in automotive engineering talent has been identified.

In early October 2014, the committee

will be running its first workshop to

gather data from potential industry

groups. Understanding the gaps in

their employee skill-sets, and how

automotive talent could assist them

in achieving their company strategies

will be the objective of this workshop.

Following the workshop, that data will

be analysed to allow skills-mapping

to be undertaken, to assist in identifying overlaps.

SAE-A SOFTWARE AND IT

UPDATE

Natalie Roberts - Executive Director, SAE-A

SAE-A is in the process of implementing a range of new systems

to improve member experience

and increase the engagement of

members in activities, including:

conferences, technical seminars, our

new Vehicle Technology Engineer

Workshops and training events.

renewal and will incorporate a range

of new features:

•

•

•

•

In moving to the new systems, we

will be increasing the efficiency of

the national office, which will mean

our new-found time can be used to

develop and offer even more services

to our member base!

•

The new website and membership

software will be supported by a fully

upgraded IT infrastructure in the

national office that will offer a more

stable platform and provide staff

remote access to files and email for

when they are on the road.

So, What’s changing?

IT: Website, membership software

and IT infrastructure.

We are creating a new website that

will be your membership portal

and community engagement hub –

allowing you to take control of your

membership details and become

more involved with your Society from

the one location.

The new website and systems will be

online prior to the 2015 membership

Online Access to Events.

SAE-A has invested in a range of

products that enable live and pre-recorded webinars to be broadcast to

members and non-members – in fact,

we are able to broadcast our events

NEW IT EQUIPMENT

MEMBER PORTAL

OFFICE SERVER

MEMBER DATABASE

If you would like to become involved

and contribute to the research and

communication efforts of the IPWG,

contact the national office for details.

SAE-A WEBSITE

ADMIN

EXECUTIVE

Member Login & Profile Control

Events & Training

News & Industry Updates

CONTACT

Member Payments & Shop

Martha Oplopiadis

Industry Programs & Allied

Societies Chair, SAE-A

PH: (03) 9676 9568

EM: info@sae-a.com.au

WEB: www.saea.com.au

4

VEHICLE TECHNOLOGY ENGINEER

Member login to update personal

details and make membership

renewal payments directly online.

Event registration.

Training registration.

News blogs from the international

mobility community through RSS

feeds.

Shop online for books and SAE-A

branded memorabilia such as the

new SAE-A coffee mug.

EVENTS &

TRAINING

FINANCE

NEW MEMBER SOFTWARE

Email Newsletter Service

Event & Training Registration

AUSTRALASIA

October 2014

Automated Processes

Cloud Member Database

FROM THE SAE-A

live to 250 attendees concurrently!

The November VTE workshop will be

the first to take advantage of our new

technology, you can register online

here to attend this event:

www.stickytickets.com/sae-a

Being able to remotely access events

will make it much easier for our interstate and international members to

become directly involved. During live

sessions, there is the ability for the

on-line participants to engage with

presenters via instant messaging and

voice.

The changes that are underway will

set the foundations for the continued

growth of our organisation for the

coming years.

So many new systems. How

has this been possible?

Despite the downturn in the automotive engineering industry, SAE-A

has experienced substantial growth

in 2014 through the introduction of

new services, such as our professional development courses and

our expansion across all mobility

sectors including aerospace, heavy

commercial vehicles, caravans

& campervans and the offroad

industry. As mentioned in my From

The Executive Director column [pg

3], the increase in income from

Meet Paul Muscat

Meet Paul Muscat, our new

Event and Training Co-ordinator.

Paul has more than 17 years

experience as an Aircraft

Maintenance Engineer from the

commercial aviation heavy maintenance sector, specialising in

composites and structures. Paul

has brought to the role substantial knowledge, enthusiasm,

leadership and project management skills.

The SAE-A works to serve the needs of its members and

to promote the relevance of mobility related technologies to governments, industry and the community. Paul

joins the SAE-A with the vision to advance the mobility

engineering industry in Australasia through professional

engineering-related training and events; promoting

the transfer of technical knowledge and skills, encouraging research and development, and involving industry

and members in the maintenance and development of

Australasian and global technical standards.

For more information on SAE-A’s technical training and

events, contact Paul: PaulMuscat@sae-a.com.au

these streams, combined with the

remarkable generosity of a $10,000

donation from one of our members,

has enabled us to invest monies back

into the organisation.

“SAE-A has experienced

substantial growth in 2014

through the introduction

of new services ... and

our expansion across all

mobility sectors”

The generosity and commitment

of people in our industry and their

dedication to making a positive

contribution to our professional

community by way of their time or

money continues to inspire me.

SAE-A Mugs For Sale

In a recent E-Newsletter, the SAE-A proposed a

mini-competition to supply a quote to feature on the side

of a corporate labelled coffee mug; a mug used primarily

as a gift for event organisers and presenters.

SAE-A would like to thank all participating members for

the fantastic quotes submitted. After a thorough discussion and rigorous selection process the winning quote

has been chosen.

The winning phrase; “A mug-full of mobility engineering

excellence”, is a light-hearted way to remind the holders

of the mug about the Society’s purpose and direction. The

mugs are now available for purchase at $10 + postage.

Contact Rose De Amicis on (03) 9676 9568 to order.

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

5

FROM THE SAE-A

Quick Facts:

MEMBER

INTERVIEW

Owen Johnstone - BE (Hons), MBA

About Owen Johnstone:

Owen’s interest in all things mechanical was sparked in his

early teens, in the small Hunter Valley town of Aberdeen. At

the age of 15 he inherited the family’s well-worn 1938 Austin Big Seven utility

(body by Holden) which he proceeded to rebuild. Staying true to the Austin

connection, Owen joined the British Motor Corporation as an engineering

trainee in 1964. Soon after graduation, Owen moved to BMC’s Vehicle

Proving Department as Instrumentation Engineer, designing and building

test instrumentation, and testing vehicles to the newly-introduced Australian

Design Rules. This started a career-long passion for vehicle safety and

efficiency, and within a few years he was involved in on-scene crash investigations for the NSW Traffic Accident Research Unit.

Owen has had significant roles in the NSW Department of Motor Transport,

the NRMA, and now as an investigator with the NSW Office of Transport

Safety Investigations. He has represented industry, government and

consumers on a wide range of government, industry and Australian

Standards committees, chaired the NSW Division of SAE-A, and served a

term as an SAE-A Director. Owen is an enthusiastic supporter and advocate

of Formula SAE-A, rarely missing the opportunity to assist as a volunteer at

each year’s event.

What is the most memorable place

you’ve worked at?

The NSW Traffic Accident Research

Unit, where I had the opportunity to

work as a member of a multi-disciplinary team conducting on-scene crash

investigations. We worked in teams

comprising of a Mechanical Engineer,

a Traffic Engineer and a Behavioural

Scientist, with the support of a

Research Medical Officer. We were

notified as soon as an ambulance

was called, and generally arrived

on-scene within minutes of emergency services so we were trained to

give assistance where needed. Being

able to collect fresh evidence and

interview witnesses within minutes of

the incident made the investigation

process very efficient and the use of

a multi-disciplinary team provided a

valuable range of expertise.

6

VEHICLE TECHNOLOGY ENGINEER

What has been the most rewarding

part of your career?

As chair of a Standards Committee,

to bring together the disparate and

often divergent interests of industry,

aftermarket and academic representatives and achieve agreement on a

standard for windscreen repairs.

Family:

Wife of 45 years, two sons, one

daughter, two daughters-in-law,

two grandchildren.

Currently Reading:

‘Archaeology of the Dreamtime’

by Josephine Flood.

‘Human Evolution’ by Robin

Dunbar.

Favourite Motto:

A n i nvestment i n knowledge pays the best interest

Benjamin Franklin

Favourite Sporting Team:

The Waratahs, until the last

Bledisloe Cup game. Perhaps

now the Sydney Swans.

Tea or Coffee?

A well-brewed flat white or

Ceylon Orange Pekoe tea.

memory and a cassette tape drive to

digitise vehicle locations by vehicle

type and postcode throughout NSW,

and determine where inspection

facilities should be located to most

efficiently serve the community.

Who has been your most inspirational figure through your working

life?

Sir Alec Issigonis, whose creative

design of the Mini pioneered modern

front wheel drive and efficient space

utilization.

What was one of the greatest

projects you have undertaken?

A three-year federally funded project

on vehicle inspection technology.

We covered everything from inspection equipment through inspection

facility design and layout, to the strategic location of inspection facilities

throughout NSW.

Back in 1978, before the advent of

desktop PCs, we were able to use a

programmable calculator with 4kb of

AUSTRALASIA

October 2014

Sir Alec Issingonis, remembered

chiefly for the groundbreaking and

influential development of the Mini.

FROM THE SAE-A

Which book do you feel is a ‘must

have’ for all engineers?

‘Unsafe At Any Speed’

by Ralph Nader. In

1965 Nader wrote

“A great problem of

contemporary life is

how to control the

power of economic

interests which ignore the harmful

effects of their applied science

and technology.” Unfortunately this

problem remains today.

What should get taught more in

university?

There needs to be a greater

emphasis on the application of

engineering knowledge in the real

world. Too many academics spend

too little time in the world of industry

and commerce, and students are

finding it increasingly difficult to gain

appropriate industrial experience in

their student years. This is one area

where Formula SAE-A has played an

important role.

What are some of your hobbies or

pastimes?

Reading (almost anything), repairing

labour-saving appliances, and

enjoying the bushland and wildlife

behind our house. The many others

on my list will have to wait for my

retirement.

Tell us about the best car you’ve

ever owned or driven.

The best car for me is the one that

best serves my needs at the time.

In recent years it was probably my

2003 Peugeot HDi Wagon, because

of its combination of safety and

convenience features, excellent fuel

efficiency, effortless highway cruising

and Tardis-like interior.

CONTACT

Owen’s ‘well worn’ 1938 Austin Big

Seven utility, inherited at age 15.

Owen Johnstone

NSW Office of Transport Safety

Investigations

PH: 0400 440 386

EM: owen.johnstone@bigpond.com

WEB: otsi.nsw.gov.au

NEW MEMBERS

The SAE-A welcomes the following individuals to the Society.

Fellow:

Jon Edsell

Member:

Ross Deves

Sarah Roberts

Associate Member:

Cameron Palmer

Craig Richards

Associate Member-T:

Adam Elbouch

Daniel Marshall

Student Member:

Jamie Allender

Osman Allouch

Elliott Altmann

Terrill Anthony

George Athanasakos

Henry Beevor

Ryan Belworthy

Jordan Benton

Jason Biviano

Gage Boon

Luke Brand

Simon Brown

James Bryant

Lyulph Car

Nathan Cassar

Joshua Chadwick

Julian Cook

George Cottew

Thomas Cotton

Andrew Crutch

Eugene Cullity

Kooper de Lacy

Daniel de Mel

Douglas de Souza

Brenton Deane

Emily Dinsdale

Christopher Dobell

Robert Dyck

Kushan Elabadage

Emmanuel Fazio

Adam Fin

Adam Flower

Hayden Freeth

Jason Fu

Gurpreet Garcha

MatthewGay

Benjamin Geayley

Sukhminder Ghataura

Isaac Grigor

Phillip Hamilton

Jack Han

Lawrence Han

Alex Harris

Hannah Harrison

Harrison Hart

Daniel Haysom

Jing Liu

Michael Healy

Thomas Hegarty

Oliver Herbst

Mizuno Hiroshi

Tonoharu Hosaka

Thomas Hotchkin

Zein Jaber

Lloyd Jeffrey

Jeremiah Jez

Yamaguchi Junpei

Asanka Kekulawala

James Kendall

Daniel Kent

Jason Kumar

Andy Lam

Donald Lam

Alexander Lam

Anna Le Huynh

Samara Love

Angus Malcolm

Benjamin Martin

Sam Martinella

Laearna Maxfield

Stuart McAdam

Bradley McCarthy

Luke McClelland

Liam McPhan

Harold Mighell

Brook Mitchell

Alexis Molinaro

Samuel Mulkearns

Yan Mei Ng

Christopher Nguyen

Edward Palmer

Steven Parker

Josh Parkin

Joel Patniotis

Huy Phan

Craig Piggott

Daniel Pugh

Ben Richards

Nattawin Ruckwatin

Elizabeth Russell

Steven Ryan

Hitender Saini

VEHICLE TECHNOLOGY ENGINEER

Peter Sefont

Sam Snowdon

Nicola Staltari

Josh Stephens

Jarrod Stilp

Dominic Stulen

Kato Takeshi

Ashneel Thakur

Peter Thang

Rhiannon Tibbey-Tiedeman

Marukawa Tsubasa

Nathaniel Van Vugt

William Wallace

Yiduo Wang

Jack Ward

Adam Waterhouse

Hamish Waters

Toby White

Peter Whitley

Edward Williams

Jamie Wilson

Sudeera Withanage

Jade Yeung

Nishio Yushi

James Zeitz

Tawanda Zhungu

AUSTRALASIA

www.saea.com.au

7

EVENTS & TRAINING

VEHICLE TECHNOLOGY ENGINEER

WORKSHOP

A REVIEW OF THE FIRST VTE WORKSHOP

EXPLORING ENGINES AND FUELS.

Dr Kai Morganti - Director, SAE-A

T h e o p e n i n g S A E - A Ve h i c l e

Te c h n o l o g y E n g i n e e r ( V T E )

Workshop was held recently at

Swinburne University of Technology

in Melbourne. The workshop

attracted a large number of delegates

from a diverse range of backgrounds,

including the OEMs, academia, policymakers, transport and industrial

consultants, along with the automotive aftermarket and refining

“The workshop attracted a

large number of delegates

from a diverse range of

backgrounds ... allowing

participants to engage

with other experts from

across the wider fields of

mobility”

industries. This diversity contributed

to several very interesting and topical

panel discussion sessions, whilst

also allowing participants to engage

with other experts from across the

wider fields of mobility.

The workshop commenced with

Natalie Roberts reviewing the current

and future utilisation of energy within

the transport sector, together with the

likely drivers of change in the coming

decades. Garry Whitfield, from BP

8

VEHICLE TECHNOLOGY ENGINEER

Australia, then provided a unique

insight into the operations within a

modern oil refinery. Garry addressed

not only the production and properties of conventional transport fuels,

but also several areas not well understood outside of the oil & energy

industry. Examples of these included

the techniques used to balance

a refinery with market demand,

quality control and in-service vehicle

operability considerations relating

to gasoline, diesel and LPG fuel

production.

engine downsizing and reducing

CO 2 emissions – without compromising outright performance or driver

satisfaction.

Matt Turner (Robert Bosch Australia)

then spoke about one of the key

enablers of these downsized/turbocharged engines – Gasoline direct

injection (GDi). This was followed

by Cameron Anderson’s (Toyota

Motor Corporation) presentation on

Toyota’s unique implementation of

GDi technology in conjunction with

a PFI system in the 86 GT vehicle.

This included an interactive display

featuring the Toyota 86 GT vehicle

and its FA20 boxer engine – both

of which were co-developed with

Subaru.

In the penultimate presentation,

Thomas Rogers (RMIT University)

examined natural gas jets using

high-speed imaging techniques.

This presentation revealed several

critical phenomena that could ultimately influence the suitability of this

This highly interesting presentation

was complemented by Phil Fleming’s

(AS Harrison & Co.) review of fuel

additives. Phil explained the different

types of gasoline and diesel additives, and how these relate to engine

performance, fuel transport and

storage, and climatic factors. Kai

Morganti then discussed the all-important octane number property. This

included an overview of both the test

method and how this property relates

to the practical anti-knock quality of

fuels in modern engines.

Rob Sharples and Jamie Slaymaker

(Ford Motor Company) discussed

Ford’s new generation of EcoBoost

engines. This comprehensive

presentation revealed how turbocharging can be used to extend the

engine’s efficient operating range

well beyond that of a naturally aspirated engine. This a key enabler of

AUSTRALASIA

October 2014

TOP: Garry Whitfield of BP Australia

addressing the effect of varying

cetane fuels on engine combustion

characteristics.

BOTTOM: Toyota’s display of their

86 GT and its FA20 Boxer engine.

EVENTS & TRAINING

fuel in some reciprocating engine

applications.

The workshop then closed with Kai

Morganti providing an overview

of several promising combustion

modes and engine technologies that

Kai Morganti presenting on the

octane number property and

later, combustion and engine

technologies.

could become widespread in the

coming decades. This presentation

focused on the likely implications of

these technologies on vehicle fuel

consumption, exhaust after-treatment

requirements and fuel formulations.

With the first workshop now

complete, our attention shifts towards

the next VTE Workshop. The second

workshop addresses fuel quality

standards, engine lubricants, diesel

engine combustion imaging, hybrid

vehicles and exhaust after-treatment

systems. This event will take place

on Thursday 6th November, again at

Swinburne University of Technology.

A full program will be made available

shortly.

The SAE-A would like to thank

each of our presenters and participants from the workshop, together

with our very knowledgeable event

chair, Professor Harry Watson. We

would also like to thank our event

supporters, Robert Bosch Australia

and Swinburne University of

Technology, particularly Dr. Ambarish

Kulkarni and his staff.

CONTACT

Dr Kai Morganti

Director, SAE-A

EM: kai.j.morganti@gmail.com

VOLVO TECHNICAL INNOVATIONS EVENING

Tim Car - SAE-A Senior Vice President

On the 17th of July the SAE-A

held an event to showcase the

safety and technology features

found on the new Volvo FH

prime mover now available in

Australia.

The event was held at the CMV

Truck and Bus Technical Training

Centre which was first opened

in 2003 to fast track CMV

technicians through their apprenticeship focusing on Volvo Truck

product. Scott Simpson (Product

Manager for Volvo Trucks) and

Paul Munro (Product Trainer for

Volvo Trucks) were on hand to deliver

the safety and technology presentations, as well as demonstrate

features on the Volvo FH16 700

prime mover on display.

The new Volvo FH and FH16 has

been re-designed from the ground

up carrying over only the engine,

transmission and rear axles from the

previous FH (Classic) model truck.

New cabin, electronics, suspension

and driver support systems have

set a new benchmark in the trucking

industry.

Safety features such as Adaptive

Cruise Control with Emergency

Braking Support and Stretch Brake

(on rigid chassis models), Lane

Change Support, Lane Keeping

Support, Driver Alert Support,

Electronic Stability Program were

demonstrated showing Volvo’s

commitment to driver safety as well

as to other road users.

Technology in the form of Volvo’s

Telematics Gateway providing

features such as I-See that learns

the topography of the road and uses

this information next time the truck

is on the same road to save

fuel, Volvo Action Service

that automatically downloads

truck position and engine fault

codes to a service centre at

the push of a button on the

dash if the truck ever breaks

down, Features Online which

monitors brake and clutch wear

as well as air filter and battery

condition to a service centre

with the ability to upload new

software to the truck remotely,

Work Remote which allows the

driver to adjust engine idle for

PTO use, suspension heights and

ancillary equipment from out of the

cab, and Dynafleet which monitors

key operating parameters and ranks

driver performance within a customer’s truck fleet from anywhere in the

world, which prompted an extremely

interesting Q&A session at the end of

the evening.

SAE-A would especially like to

thank Volvo Group Australia and

CMV Truck & Bus for presenting and

hosting the evening.

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

9

EVENTS & TRAINING

Discover the

very latest in

automotive parts,

accessories, tools

and equipment

16-18 APRIL

2015

MELBOURNE

EXHIBITION

CENTRE

FREE TRADE REGISTRATION! aftermarketexpo.com.au

An initiative of

Major Sponsor

Co-located with

The Society of

Automotive Engineers

Australasia requests

the pleasure of your

company at the

JOIN US TO CELEBRATE SUCCESS

• Professional Engineering Award

• Young Engineer Award

• Student Project Award – Undergraduate

• Student Project Award – Postgraduate

Date: 29 October 2014

Pre Dinner Refreshments at 6.30pm | Dinner at 7.00pm

Leonda by the Yarra | 2 Wallen Road Hawthorn Victoria

Black Tie | RSVP 14 October 2014 | Enquiries 03 6234 7844

Book your tickets online at www.saea.com.au

10

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

October 2014

EVENTS & TRAINING

FORMULA SAE-A

2014 FORMULA SAE-A

TEAM LIST

THE DECEMBER COMPETITION DRAWS CLOSER.

TEAMS ARE LOCKED IN AND READY TO GO.

E17

Swinburne University of

Technology

VIC

Paul Muscat - Events and Training, SAE-A

E20

University of Western

Australia

WA

E46

Queensland University of

Technology

QLD

E88

RMIT University

VIC

3

The University of

Newcastle

7

Edith Cowan University

WA

8

University of Adelaide

SA

10

University of Wollongong

NSW

11

Sophia University

Japan

12

RMIT University

VIC

13

University of Canterbury

NZ

14

Curtin University

WA

19

Dankook University

Sth

Korea

21

Tokyo Denki University

Japan

22

The University of Sydney

NSW

23

Tokai University

Japan

24

Chandigarh Engineering

College

India

25

The University of Waikato

34

James Cook University

QLD

41

University of Queensland

QLD

44

University of Tasmania

TAS

47

University of Auckland

NZ

63

University of New South

Wales

Impact attenuator data

requirements

66

Monash University

Design report, specification

sheet & video

84

Warsaw University of

Technology

101

The University of

Melbourne

The clock is ticking; it’s now less

than three months to go before the

2014 Formula SAE-A competition

kicks off. We are seeing teams

launch their vehicles, display them at

University open days and on social

media for supporters and competitors to admire. Check out University

of Canterbury‘s ‘wee teaser’, making

a statement under its moon light

debut. Some teams have already

been competing - however, not on

the track, but in the name of fun and

charity carrying out team ALS ice

bucket challenges. We encourage

teams to post their updates on the

Formula SAE-A Facebook site.

Formula

SAE-Australasia

Formula

provides

a great community,

11

–

14

December

allowing friendships

& networking

2014

opportunities locally & internationally.

Calder Park Raceway

Melbourne

Down at the business

Victoria end: Formula

CA

LD

ER

FR

EE

W

CA

LD

ER

CFA

RLE

DEEW

RA

F

YR

E

AY

EW

AY

SAE-A project co-ordinators had a

site visit of Calder Park Raceway on

Tuesday 2nd September 2014. We

looked at all aspects of the facility

including, but not limited to, team

parking, pit bay access, catering,

amenities, electrical safety, event

placement and spectator viewing. We

are pleased to announce that every

team will have a dedicated underWELDING

cover bay with power and lighting.

Pit lane is spacious allowing efficient

movement of teams and vehicles.

BOSCH WORKSHOP

Under team news: University of

Technology Sydney will not be

attending this year’s competition,

however, research and development

is underway with an all new UTSM15

E

E

TIC

TIC

Electric Vehicle

ACto be

AC ready for next

PR

$ PR

year.

We have now putTILT

out our call for

volunteers

for Friday 12th, Saturday

FSAEA

13th or PADDOCK

Sunday 14th December

2014.

SCRUTINEERING

More details, including benefits of

involvement and requirements are

available on the SAE-A website.

TH

OM

PS

ON

SR

OA

D

NOT TO SCALE

CA

LD

ER

FR

EE

W

AY

UPCOMING IMPORTANT

DATES

E

TIC

AC

PR

ALL VEHICLES

12/09/14

26/09/14

Structural equivalency form SES

17/10/14

Cost report - digital copy

24/10/14

Cost report - hard copy

ELECTRIC VEHICLES

Electrical systems officer &

advisor form

26/08/14

ESF & FMEA - hard copy

NOT TO SCALE

PARKING

ESF & FMEA - digital copy

ADMINISTRATION

FIRST AID

NSW

NZ

NSW

VIC

Poland

VIC

CONTACT

Paul Muscat

Events and Training, SAE-A

EM: PaulMuscat@sae-a.com.au

PH: (03) 9676 9568

WEB: www.sae-a.com.au

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

11

EVENTS & TRAINING

YOUNG ENGINEERS: BAE SYSTEMS

FACILITY TOUR

Gavin Kroon - Young Engineers Chair, SAE-A

construction of two Canberra Class

Landing Helicopter Dock ships, that

will enable the Australian Defence

Force to combine sea, air and ground

forces for humanitarian aid, policing

On the 8th of July, BAE Systems, an

aerospace, maritime and defence

company, welcomed the SAE-A

Young Engineers Division to their

Williamstown production facility. After

receiving an overview on the current

projects at BAE, the 15 young

engineers enjoyed a tour of the

impressive ship-building production

facility led by Engineering Manager

James Hall, and graduate engineers

Dean Wright, Andrew McAuley and

Michael Blake.

operations, special recovery operations and conflicts.

The event finished with a Q&A

session on engineering opportunities

and career advice, with the young

engineers receiving some great feedback and tips from the BAE team.

The YE team will continue to deliver

high quality and interesting events

for young engineering professionals

and students, helping them in their

careers and opening their eyes to the

opportunities around them.

BAE showed off one of their

major engineering projects; the

International Management Systems P/L trading as

ENGINEERING CONSULTANTS

NSW

NSW

Ali Akbarian

Ian Carpenter

Stuart Larkham

Mobility Engineering

Kreative Enterprises P/L

Phone: (02) 9482 4572

Email: ali@mobilityengineering.com.au

Address: Asquith, New South Wales

Web: www.mobilityengineering.com

Phone: (02) 4577 3633

Email: kreativeent@bigpond.com

Address: Windsor, New South Wales

Web:

www.kreativeengineering.com.au

Signatory

Automotive Engineering

Customer Focus:

Commercial

Customer Focus:

Private and Commercial

Specialisation:

LV, HV, MC, ICV, Imports, SR1, SR2

Specialisation:

LV, ICV, Imports

NSW

International Management Systems P/L trading as

VIC

NSW

Phone: (02) 6761 3636

Email: stuart@signatory.com.au

Address: Tamworth, New South Wales

Web: www.importcars4u.com.au

Customer Focus:

Private and Commercial

Specialisation:

LV, HV, MC, ICV, Imports

VIC

Talk Torque

Automotive

Vaughan Larkham

Rowan Carter

William Malkoutzis

Signatory

Automotive Engineering

Cartech

Talk-Torque Automotive

Phone: 0419 313 113

Email: info@cartech.com.au

Address: Richmond & Hawthorn, Victoria

Web:www.cartech.com.au

Phone: 0409 439 315

Email: talktorq@bigpond.net.au

Address: Eltham North, Victoria

Phone: (02) 6761 3636

Email: vaughan@signatory.com.au

Address: Tamworth, New South Wales

Web: www.importcars4u.com.au

Customer Focus:

Private and Commercial

Customer Focus:

Private and Commercial

Specialisation:

LV, HV, MC, ICV, Imports, SR1, SR2,

Expert Witness, Legal Reports, Accident

Investigation

Specialisation:

LV, HV, MC, ICV, Imports

KEY: LV - Light Vehicles with GVM up to 4.5 tonnes

ICV - Individually Constructed Vehicles

Customer Focus:

Private and Commercial

Specialisation:

LV, ICV, Imports, SR1, Expert Witness/

Consultant

HV - Heavy Vehicle with GVM over 4.5 tonnes

MC - Motorcycles Imports - Imported Vehicles

SR1 & SR2 - Street rod inspection certificate applicable to the Street Rod Club Permit Scheme (CPS) only

Interested in advertising your Engineering Signatory or Expert Witness business? Contact the SAE-A for more information. Info@sae-a.com.au

12

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

October 2014

Crown Promenade Hotel, Melbourne Australia

meeting regional challenges

with global technology

six reasons to attend this event

conference themes

1

Future Transportation:

Technology and Policy

• Gaseous and alcohol fuels

2

Plenary and technical sessions from

key international experts, including

gaseous fuels research

• Noise, vibration and harshness

3

See future F1 hybrid technology that

will be adopted in future road cars

• CO2 reduction and improved air quality

4

APAC will take place during

Automotive Week, culminating in the

first Formula One Grand Prix of the

season

5

Meet at the Supplier Showcase on

11 and 12 March 2015

6

International and Australian Full

Registrations includes a ticket to

The Cars of Tomorrow Conference

Thursday 12 March 2015

• Formula 1: Improving the breed

for passenger cars

• Regional variants in global platforms

• Light-weighting and mass-production

• Meeting regional needs in

communication & information

• Building the engineers of the future

• Experiment or simulate for vehicle

development?

• Future Transportation: Technology

and Policy.

APAC18 provides an opportunity to

extend your global network and make

new introductions for future business

and technical development

To sign up for more information, visit www.apac18.com.au

For further information contact:

This event is being hosted by the Society of Automotive Engineers – Australasia

Conference Managers

Leishman Associates

E: paula@leishman-associates.com.au

T: 61 3 6234 7844

E: info@sae-a.com.au

W: sae-a.com.au

T: 61 3 9676 9568

INDUSTRY NEWS

Defence Aerospace Updates: Australian

C-17 and KC-30 Fleet increases & First

Australian F-35 off production line.

Australian Defence Minister, Senator David

Johnson, has hinted towards a possible increase

in Airbus KC-30/A330 and Boeing C-17 numbers.

The Airbus multi-role tanker transport and

Boeing’s strategic transport aircraft have a total

flight range that Johnson says “allows us to go Airbus KC-30

anywhere in our region and far and away beyond

that”. The two aircraft have had great success

in performing nonstop training missions across

both Australia and North America. Several

different training missions across the Pacific

from Darwin to Dallas-Fort Worth have been

completed. The announcement has been made

Boeing C-17

despite some questions about KC-30’s aerial

refuelling ability and small software issues.

Already, these aircraft have been deployed in aid

of the Malaysian Airlines flight MH17 recovery

mission in Ukraine due to their substantial

endurance.

Australian Auto

Aftermarket Expo

The nation’s most comprehensive

exhibition of vehicle repair and

servicing equipment, replacement

parts, tools and accessories will

return to Melbourne in 2015. Industry

experts will update business on

the latest technologies available

and the new trends in workshop

management.

This industry run exhibition will be

held during the 16 th-18 th of April

2015 at the Melbourne Exhibition

Centre. Australia’s first F-35A Joint Strike Fighter has F/A 18E

rolled off the production line in Fort Worth, Texas.

This is first of the Fifth Generation Air Superiority

jets to join the current Australian Fleet of F/A 18

Hornet’s. Two RAAF pilots will be travelling to

Luke Air Force Base, Arizona, where they will

begin the extensive training required for flying

the F-35’s.

F-35A

MotorWorld

Melbourne

Pilots of the F-35A will experience an unobstructed 360 degree view around

the aircraft from within the cockpit. A variety of sensors and cameras situated

in crucial points around the aircraft relay images to the pilot’s helmet, allowing

them to see ‘through’ the aircraft and monitor the surrounding airspace.

Despite the delays and increased cost of the F-35A, the Australian

Government has assured that the increase in stealth capabilities, sensor

fusion and other capabilities that make the F-35 the gold standard of tactical

aviation, is a worthy investment that will ensure Australia has the air superiority to protect its borders.

Aircraft Specifications

C-17

KC-30

F-35A

F/A-18E/F

(in service)

Wing Span (m)

51.9

60.3

10.7

13.62

Length Overall (m)

53

58.8

15.67

18.31

Max Payload (t)

77.5

108

6.8

15.4

Range (Nautical Miles / km)

2,420 / 4,482

8,000 / 14,816

1,200 / 2,222

1,800 / 3,334

Cruise Speed (km/h)

830

860

2,222

1,915

Date of Release/First Flight

17/01/1995

1/06/2011

15/12/2006

29/11/1995

Manufacturer

Boeing

Airbus Military

Lockheed

Martin

McDonnel

Douglas

14

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

October 2014

MotorWorld Melbourne is an automotive showcase event hosted by

Definitive Events. It is being held for

the first time at Sandown Raceway

from November 25-29 2015. The

event aims to deliver an interactive

automotive festival, engaging with

buyers across all market segments,

from car lovers and enthusiasts

to the trade and family. Definitive

Events aims to attract over 100,000

visitors over the 5 day event.

New release vehicles will be showcased on the Raceway, on both street

and dirt courses. Managing Director,

of Definitive Events, Rod Lockwood

added “MotorWorld Melbourne will

showcase the very latest car and

motorbike releases, permit test

drives, and deliver buyer information on the latest technology, newest

products services and entertain and

engage with exciting experiences.”

INDUSTRY NEWS

SALT WATER POWERED SUPERCAR THE FUTURE OF FLOW CELLS?

The Quant e-Sportlimousine is

a research prototype supercar

released at the recent Geneva Motor

Show and powered by salt water. To

be more specific, it’s powered by a

flow cell using electrolytic fluids usually metallic salts in aqueous

solution – as its energy storage

medium; a fluid more complex

than common sea water. Despite

the marketing spin, the technology

behind the 2.8 second, 680 kW

supercar is highly innovative and

interesting.

for use during lull in wind speeds.

Research and development group,

nanoFLOWCELL AG, founded

Flow cells are chemical batteries, in late 2013 and based in Vaduz,

combining aspects of an electro- Liechtenstein, have developed a flow

chemical accumulator cell with

cell system specifically for the Quant

those of a fuel cell. In the compact

supercar. The nanoFLOWCELL

cell, a “cold burning” takes place, system continuously sends elecduring which oxidation and reduc- trical energy to the central storage

tion processes occur in parallel. The

unit. Storing the energy in two large

electrolytic fluids are pumped from “supercap” capacitors. This energy

storage tanks through the cell. This

is used to power four three-phase

forms a kind of battery cell with a 170kW electric induction motors. The

cross-flow of electrolyte liquid. One

process is illustrated in figure 1.

advantage of this system in general

is that the larger the storage tanks for

the electrolyte fluid are, the greater

the energy capacity. Simultaneously,

the concentration of the electrolytic

solution determines the quantity of

energy that it transports.

This flow cell technology boasts a

5-times greater energy density (600

Wh/kg) over conventional flow cells,

providing an estimated range of

400-600 km for the flagship vehicle.

Recently, this flow-cell system

received approval from German certification group TÜV Süd to operate on

public roads in Germany and Europe.

But with vehicle approval regulations

yet to be completed for this concept,

and with a predicted pricetag of

around $1.7 million, we may not see

this car in Australia for a while yet.

The energy transfer within a flow

cell is roughly the same as that in a

lead-acid car battery: charge passes

between metal plates acting as positively and negatively charged poles

via an ionisable liquid.

Redox flow batteries were patented

in 1976 for NASA and the American

space programme as part of a drive

to advance energy storage technology for space flight. The 1976

patents have long since expired and

the flow cell systems are in regular

use today for terrestrial applications

like storing solar energy for domestic

residences, or storing wind energy

Figure 1. The Quant e-Sportlimousine’s electric powertrain.

Source: www.nanoflowcell.com

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

15

EMISSIONS SIMULATION

TRANSPORT

EMISSIONS SIMULATION

PΔP: A SIMULATION TOOL FOR VEHICLE EMISSIONS AND FUEL

CONSUMPTION SOFTWARE WITH A HIGH RESOLUTION IN TIME AND SPACE.

Dr Robin Smit

Senior Research Fellow (Hon),

University of Queensland

Road transport is a major source of air pollution

and greenhouse gas emissions around the world.

Comprehensive measurement of transport emissions in

urban networks is not feasible due to the large number

of vehicles that operate on our roads, large spatial and

temporal variability and the many factors that influence

emission levels. Modelling tools are therefore commonly

used to estimate fuel consumption and air emissions.

Models are also required to make projections into the

future. Vehicle emission prediction software is well

developed in Europe and the US. However, they do not

adequately reflect Australian conditions in terms of fleet

mix, vehicle technology, fuel quality and climate.

16

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

July 2014

This article provides an overview of a new Australian

vehicle emission software and its applications. The

software predicts second-by-second fuel consumption, air pollution and greenhouse gas emissions with

a high resolution in time and space. It uses engine

power and the change in engine power as the main

model variables and includes all relevant vehicle

classes. It links well with output from microscopic

transport models.

A free “light” version of the software is available on

request.

EMISSIONS SIMULATION

A hierarchy of vehicle emission

models exists reflecting different

levels of complexity and different

types of application. These

include ‘average-speed’ models

(e.g. COPERT, MOBILE), where

emission rates (g/veh.km) are a

function of mean travelling speed,

‘traffic-situation’ models (e.g.

HBEFA, ARTEMIS), where emission factors (g/veh.km) correspond

to particular traffic situations (e.g.

‘stop-and-go-driving’, ‘freeflow’) and

‘modal’ models (e.g. PHEM, CMEM,

MOVES), where emission factors

(g/s or g/driving mode) correspond

to specific engine or vehicle operating conditions. Whereas average

speed and traffic situation models are

designed to operate at the national

or city network level, modal models

are designed for local assessments.

Vehicle emission prediction software

is well-developed in Europe and the

US. However, they do not adequately

reflect Australian conditions in terms

of fleet mix, vehicle technology, fuel

quality and climate. Large errors

of up to a factor of 20 (Smit and

McBroom, 2009), have been reported

when overseas models are directly

applied to Australian conditions

without calibration. Therefore two

software packages were recently

developed for Australian conditions

using comprehensive empirical

data from major Australian emission

testing programs. COPERT Australia

has been designed to estimate

motor vehicle emissions at regional

and national level (Ntziachristos et

al., 2013), whereas a power based

model (PΔP) was developed for

more localised assessments. This

short paper will focus on PΔP and its

applications.

Tool Design.

The PΔP model uses engine power

(P, kW) and the change in engine

power (ΔP, kW) to simulate fuel

consumption and CO2 and NOX emissions for 73 vehicle classes (Smit,

2013a). The vehicle classification

is shown in Table 1. ADR emission

standard is used as a proxy for ‘emission control technology level’. ADRs

refer to “Australian Design Rules”,

which are the emission standards

adopted in Australia. The input to

the model is speed-time data (1 Hz)

and information on road grade, wind

speed, vehicle loading and use of air

conditioning (on/off). This information is used to compute the required

(change in) engine power for each

second of driving.

real-world Australian driving cycles

(Composite Urban Emissions Drive

Cycle for Petrol or Diesel vehicles; CUEDC-P and CUEDC-D)

that were developed from on-road

driving pattern data in Australian

cities. In addition to these real-world

cycles, test data from the DT80 test

cycle are used. The DT80 test is the

Australian Transport Council’s in-ser-

“Vehicle emission

prediction software is

well-developed in Europe

and the US. However, they

do not adequately reflect

Australian conditions in

terms of fleet mix, vehicle

technology, fuel quality

and climate”

The model was developed using

empirical data from a verified

Australian emissions database with

about 2,500 second-by-second

emission tests (1 Hz) and about

12,500 individual aggregated ‘bag’

measurements.

Each modal test contains

approximately 30 minutes of laboratory-grade second-by-second

emissions and speed data based on

Main Category

vice missions test that is conducted

to assess emissions performance of

on-road diesel vehicles1. The DT80

test simulates worst-case driving

conditions (e.g. full open throttle

acceleration, high cruise speeds) in

order to capture worst-case emission

levels. This is useful information as

it ensures that emissions data are

available over the full range of operating conditions, including extreme

accelerations.

Emission Control

Standard

Sub Category

Fuel Type

Passenger Car

Small (< 2.0 L);

Medium (2.0 - 3.0 L);

Large (≥ 3.0 L)

Petrol, Diesel

Uncontrolled;

ADR27;ADR37/00-01;

ADR79/00-05

SUV

Compact (≤ 4.0 l);

Large (> 4.0 l)

Petrol, Diesel

Similar to “Passenger

Car” but also including

ADR36 (SUV-L) and

ADR30 (SUV-Diesel)

Petrol, Diesel

Uncontrolled;

ADR36 (P); ADR30

(D); ADR37/00-01;

ADR79/00-05

Light

Commercial

Vehicle

GVM ≤ 3.5 t

Heavy Duty

Truck

Medium;

Heavy;

Articulated

Diesel

Bus

Light Bus (≤ 8.5 t);

Heavy Bus (> 8.5 t)

Diesel

Uncontrolled;

ADR30; ADR70;

ADR80/00; ADR80/02-05

Table 1. Vehicle Classification.

1

The test is specified in Rule 147A of Schedule 1 of the National Transport Commission

(Road Transport Legislation Vehicle Standards) Amendment Regulations (No. 1).

VEHICLE TECHNOLOGY ENGINEER

AUSTRALASIA

www.saea.com.au

17

EMISSIONS SIMULATION

All modal emissions test data have

been subjected to a verification and

correction protocol (Smit, 2013b).

This includes time re-alignment, verification of emission traces (analyser

drift, clipping) and computation and

verification of test statistics (e.g.

Brake Specific Fuel Consumption

(BSFC) and mean thermal efficiency). For each vehicle class, one

representative vehicle is selected for

model development.

First, a mathematical relationship

between engine power and emission

measurements during the actual tests

is developed. Engine power (kW) is

computed for each second of driving

using dynamometer load algorithms

in combination with algorithms to

simulate internal vehicle losses due

to drive train and tyre rolling resistances. The vehicle emission rate

(et, g/s) is then fitted to the following

equation:

instantaneous emissions value, e.g.

due to the use of a timer to delay

command enrichment or oxygen

storage in the catalytic converter.

Total driving cycle emissions for the

vehicles selected for model development must match average values

of similar vehicles in the empirical

database. A calibration factor φ is

therefore incorporated in the software. It is computed as the emission

ratio of the vehicle used in model

development to the average value

for all tested vehicles of the same

vehicle class. Vehicle emission rates

in the simulation tool (et*, g/s) are

then computed as:

On-Road Power Algorithms

Prolres = ( τ0 + τ1 vt + τ4 vt4 ) g M vt

Pair = 0.5 ρ Cd A Δvt3

Pinert = ( Mveh Λ + Mload ) vt at

et =

{

α

vt = 0

β0 + β1 Pt + β2 ΔPt+ β3 Pt2

+ β4 ΔPt2 + β5 Pt ΔPt + ε where ε ~ ARMA(p, q)

Pgrade = g M vt G

vt > 0

(eq. 1)

Pt represents engine power (kW) at

time t and is a function of operational

variables

(vehicle speed, acceleration) and vehicle characteristics

(vehicle mass). For idling conditions

(speed = 0 km/h) a constant average

value (g/s) is used. For non-stationary driving conditions (moving

vehicle) a multivariate time-series

regression model has been fitted

using the generalised least-squares

method, where β 0, …, β 5 represent the regression coefficients.

An autoregressive model is used to

account for autocorrelation effects on

the residuals. The variable ΔPt quantifies the change in power over the

last three seconds of driving and is

computed as:

ΔPt = Pt - Pt-2

Ptransm = fac P* ( ( 1/η ) - 1)

for P* ≥ 0

Input variables:

vt

= Vehicle speed (m/s)

va

= Air speed (m/s)

Δvt

= vt - va (m/s)

G

= Road gradient (%)

ω

= Auxiliaries on/off factor (value is 1 or 0)

Mload

= Mass of the payload and/or

passengers and luggage (kg)

Internal/derived variables:

at

= Acceleration (m/s2)

g

= Gravitational constant (9.81 m/s2)

η

= Transmission efficiency (-)

ρ

= Air density (kg/m3)

Λ

= Rotating mass factor (function of vehicle speed) (-)

Vehicle parameters:

(eq. 2)

VEHICLE TECHNOLOGY ENGINEER

for P* < 0

Paux = ω κ Prated

ΔPt aims to include “history effects”

into the model. This is important

because vehicle operating history

can play a significant role in an

18

Ptransm = fac P* ( η - 1)

A

= Frontal area (m2)

Cd

= Aerodynamic drag coefficient (-)

fac

= Technology correction factor (-)

M

= Vehicle mass including Load (kg)

Mveh

= Tare mass (kg)

P*

= Total power to overcome the driving resistances without

transmission losses (W)

Prated

= Rated engine power (W)

τ0, 1, 4

= Rolling resistance Coefficients (function of vehicle loading)

κ

Ratio of rated engine power to power demand for auxiliaries

= (airco, compressor) (-)

Table 2. On-Road Power

Algorithms in PΔP.

AUSTRALASIA

July 2014

et* = φ et (eq. 3)

The next step is to include algorithms

that predict second-by-second

on-road engine power demand for

each vehicle. A motor vehicle requires

engine power to overcome all resistive

forces while driving and to run its

accessories (e.g. air conditioning).

On-road power algorithms in PΔP

are adopted from Rexeis et al. (2005)

with some modifications, and account

for tyre rolling resistance (P rolres),

aerodynamic drag (P air ), inertial

drag (Pinert), gravitational resistance

(Pgrade), drive train resistance (Ptransm)

and power required to run auxiliaries

(Paux), as is shown in Table 2.

The power components are predicted

for each second of driving and require

input on speed, acceleration, road

grade, wind speed, vehicle mass

(including loading) and use of air

conditioning. These algorithms also

require vehicle specific information

such as aerodynamic drag coefficient,

frontal area and rolling resistance

coefficients. This vehicle specific

information was collected for all

vehicles and hard coded into the

software.

The simulation will check for the

occurrence of unrealistically high

engine power during the simulation.

This could occur, for instance, when

a light-duty vehicle driving cycle

is used for an articulated truck. In

this case the truck cannot deliver

the acceleration rates required to

follow the speed-time input data and

the rated power of the truck will be

exceeded.

Model validation and model verification showed that the performance

results for the PΔP modeling software results are good with average

R2 values of 0.65 and 0.93 for NOX

and CO2/Fuel Consumption, respectively (Smit, 2013a). These results

compare well and are generally

similar or better as compared with

reported results from other models

(e.g. Atjay et al., 2005; Silva et al.,

2006). The validation showed that the

PΔP emission algorithms are robust

PUTTING THE MOST ADVANCED

TECHNOLOGY WITHIN EASY