Attachment

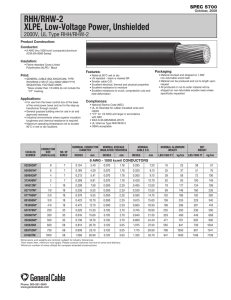

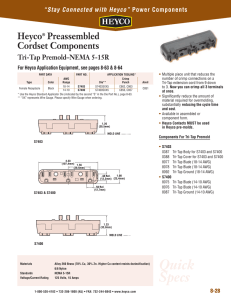

advertisement

Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 1 of 23 NEW YORK CITY TRANSIT AUTHORITY WIRE AND CABLE SPECIFICATIONS SPECIFICATION FOR IRRADIATED CROSSLINKED POLYOLEFIN INSULATED WIRE & CABLE 1. GENERAL 1.1 Spec. TGN, "General Provisions and Definitions" of the New York City Transit Authority Wire and Cable Specifications is a part of this specification. 1.2 When there is a difference between the requirements of the Military Specifications or other organizations named herein and those specified within this Specification the requirements of this Specification shall apply. 2.1 CONDUCTOR: All conductors shall be soft annealed tinned copper conforming to the ASTM-B33 and tables "A" and "B" herein. 2.2 INSULATION: The insulation system shall have an operating temperature of 110°C (125°C where specified), rated for 600 V or 2000 V (AC or DC), consist of a thermosetting, flame retardant, oil and grease resistant compound that is also moisture and abrasion resistant and irradiated crosslinked Polyolefin Insulation in accordance with tables "A" and "B" herein. The insulation shall be tight fitting over the stranded conductors, but easily removed with either automatic or manual mechanical stripping - tools, and shall conform to Insulated Cable Engineers Association (ICEA) Standard S-95-658-1999 / NEMA WC-70, Tables 3-1, 3-4, and 3-7 for Type X-2 (XLPE). Insulation thickness at any point shall not be less than 90% of the minimum average wall thickness as shown in tables "A" and "B" herein when measured in accordance with Section 3 of ICEA Standard T-27-581-2000 / NEMA WC-53. 2.2.1 INSULATION COLOR CODING: Color coding shall be as specified in the order or contract specifications. The colors shall be durable, easily distinguishable, and shall have no deleterious effect on the finished product. The following abbreviations shall be used to identify insulation color: BK WH RD BL GR - Black White Red Blue Green 0 1 2 3 4 OR YE GRY BR PU - Orange Yellow Gray Brown Purple 5 6 7 8 9 The numbers that are associated with the colors above are the last digit of the wire or cable's stock number, which indicates the insulation color of that wire or cable. Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 2 of 23 3. TEST REQUIREMENTS: Test No. Property or Test 1 Original Physical Properties: 2 3 Requirement Tensile Strength, Min. PSI 1800 Elongation at Rupture Min. Percent 250 Aging Requirements: After air oven for 7 days at 158 °C + 2 °C, Test Method ICEA S-95-658-1999 / NEMA WC-70, Section 6.4 and ICEA T-27-581-2000 / NEMA WC-53, Section 4.11 ICEA S-95-658-1999 / NEMA WC-70, Section 6.5 and ICEA T-27-581-2000 / NEMA WC-53, Section 4.11 Tensile Strength, Min. Percentage of Original Value 90% Elongation, Min. Percentage of Original Value 50% Tension Set: Test Specimen Stretched Until 2" Gauge Marks are 4" Apart: Maximum 30% ICEA T-27-581-2000 / NEMA WC-53, Section 4.11 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 3 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 4 Requirement Voltage tests: The insulated conductors 6 AWG or larger shall withstand the Tank Test Voltages AC or DC given in (Table 3- 4) ICEA S-95658-1999 / NEMA WC-70, for 5 minutes after a 6 hour immersion in non-distilled water. Insulated conductors 8 AWG or smaller shall withstand either the tank test requirements above or an impulse dielectric test using an impulse test voltage of 18KV. Test apparatus in this case shall be a Slaughter Co., Series Pulse Ionization Tester, or Spark Test Voltage specified in ICEA S-95658-1999 / NEMA WC-70, Table 3-4 5 Test Method ICEA S-95-658-1999 / NEMA WC–70, Section 6.10 and ICEA T-27-581-2000 / NEMA WC-53, Section 2.2 Insulation Resistance: A) For Reels Impulse or Spark Tested, the center 20 foot section of 25 foot lengths shall be immersed in a 5% salt water solution at a bath temperature of less than 25 °C for a period of 24 hours. ICEA S-95-658-1999 / NEMA WC-70, Section 6.10.2 and ICEA T-27-581-2000 / NEMA WC-53, Section 2.3 B) For Reels Tank Tested, Insulation Resistance Test to be run on complete Reels. Minimum IRK Constant Minimum IR 10,000 Not less than calculated by formula IR = IRK log D TCF d Where: IR = Insulation resistance IRK = Insulation resistance constant TCF = Temp. Correction factor D = Diameter over insulation in inches d = Diameter over conductor in inches Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 4 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 6 Test Method Moisture Absorption: Gravimetric Method at 70 degrees + 2 °C for 7 days. Maximum mg per square inch Electrical Method Increase in Capacitance maximum percent 1 - 14 days 7 - 14 days Stability Factor after 14 days maximum Alternate to Stability Factor, maximum 1 - 14 days Initial S.I.C. (1 day) maximum 7 Requirement ICEA T-27-581-2000 / NEMA WC-53, Section 4.6 8 3 1.5 ICEA S-95-658-1999 / NEMA WC-70, Section 6.9 and ICEA T-27-581-2000 / NEMA WC-53, Section 2.6 1 0.5 ICEA S-95-658-1999 / NEMA WC-70, Section 6.9 and ICEA T-27-581-2000 / NEMA WC-53, Section 2.6 6.0 Cold Bend: The insulation shall not exhibit cracks upon visual examination and shall thereafter withstand the voltage test (Test No. 4). The temperature shall be -55 °C + 2 °C See Table I for Mandrel diameters and tensioning weights. Bending Speeds shall be 15 RPM for sizes 3 AWG and smaller, 2 RPM for 2 AWG and larger. No cracks and pass voltage Test 4 ICEA S-95-658-1999 / NEMA WC-70, Section 6.7.1 and ICEA T-27-581-2000 / NEMA WC-53, Section 4.2 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 5 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 8 Requirement Test Method Heat Resistance: (see sample size below) The insulated cable shall be conditioned for 96 hours at 175 °C+ 2 °C. The wire shall then withstand the voltage test Test No. 4). The insulation shrinkage shall not exceed 1/32 inch at either end on gauges 18-12 AWG; 1/8 inch on gauge 10 - 4/0; 3/16 inch on gauges 250 kcmil and larger. < 1/32" (18-12 AWG) < 1/8" (10-4/0 AWG) < 3/16" (250 kcmil and larger) Sample size: A 24 inch sample length of completed wire shall be obtained at random from production with the insulation and conductor cut flush and straight at the sample ends The insulation shrinkage measurement shall be made after sample cools for at least one hour at room temperature. The sample shall be wrapped around a metal mandrel, as specified in Table II. The insulation shall show no cracks when examined visually on mandrel, after cooling to room temperature. No cracks As detailed in the property or test Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 6 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 9 Heat Distortion: Requirement Test to 150 °C + 2 °C, the maximum distortion shall be: 4/0 AWG and smaller in percent Larger than 4/0 AWG in percent 10 ICEA T-27-581-2000 / NEMA WC-53, Section 4.3 Load Weight for AWG 18-16 shall be 300 gm 20 10 Temperature Cycling Test: Two (2) eight foot size 2/0 AWG, 2000V, or larger samples of the insulated Cable shall be conditioned for 2 hours at 150 °C, then temperature cycled for at least 100 cycles between 90 °C and -13 °C. Each cycle shall take between one to two hours. 11 Test Method No cracks As detailed in the property or test Flammability Tests: Vertical Flame test for wire 18-2 AWG. Application of flame shall be 5 times with 15 second rest periods 3 seconds maximum burn after each flame application ICEA S-95-658-1999 / NEMA WC-70, Section 6.8.2 (Type A) Insulated cable, 1 AWG or larger, shall be tested to the IEEE Standard 383-2003 (70,000 BTU/HR flame) Propagation maximum 36 inches above flame source No Propagation after 15 minutes of the 20 minute test IEEE 383-2003 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 7 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 12 Test Method No insulation cracks ASTM D470-2005, Section 71 Ozone Resistance: Exposure shall be to to ozone concentration of 0.03% (300 ppm) by volume at 90 °C + 20 °C for 24 hours. 13 Requirement Corrosivity Test: Test specimen shall be 0.4 grams of the insulation cut into small pieces. Test period is 16 hours at 175 °C + 2 °C. Maximum removal of copper film in any part of the mirror ASTM D 2671 Copper Mirror 5 percent of area Duplicate test (two separate mirrors) shall be run. Specimen must pass both tests. 14 Hot Oil Resistance: Insulated cable (8 AWG or smaller) are pre-measured and then immersed for 100 hours in hot oil bath of ASTM No. 2 or IRM 902 described in ASTM D471 oil heated to 150 °C + 2 °C. Maximum swell in percent. The insulation shall show no cracks, ruptures or splits. For 6 AWG or larger cable, insulation die cut specimen may be used. ICEA S-95-658-1999 / NEMA WC-70, Section 6.5.3 40 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 8 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 15 Pass voltage test No.4 As detailed in the property or test Typical 220 ppm per milligram Mine Safety Apparatus #91636 or Drager 6728181 Short term detector tubes Acid Gas Detection: A 1 milligram sample shall be heated to combustion in a closed quartz tube. The resulting gases are drawn through the detector using an air sampling pump. 17 Test Method Relative Humidity: After a 120 hour exposure of a 25 foot sample coil ( Use 2/ 0 AWG, 2000 volt or larger and 12 AWG 600 volt construction) to 40 °C, 95 percent relative humidity in a humidity cabinet, the wire shall satisfactorily pass test No. 4 (Voltage Test) for dielectric properties 16 Requirement Smoke Generation: Using an NBS Smoke Density Chamber, place a #12 AWG, 45 Mil. insulated wire as a 5 foot specimen lightly wrapped around on open frame metal fixture to form 10 turns of wire with even spacing. Test specimen exposed to both the flaming and non-flaming conditions. Exposure is continued for 20 minutes or until minimum light transmission is reached, whichever occurs first. Federal Railroad Administration 49CFR Part 238, ASTM E 662-06 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 9 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test Requirement Measure Specific Optical Density In Flaming and NonFlaming Modes. Flaming Mode Test Method 1.5 minutes Ds < 100 4 minutes Ds < 200 Non-Flame Mode 10 minutes Ds < 100 18 Abrasion Resistance: Insulated cable samples shall be cut from un-aged samples. Samples smaller than 10 AWG are checked with G.E. Repeated Scrape Abrasion Tester (single blade) The samples (10 AWG and larger) are laid flat and parallel on a horizontal reciprocating table beneath steel plungers. Each plunger is equipped with three carborundum alloy tool blanks. Pressure applied to each plunger is based on Table III values. Tool is a 6E. Carbolloy Blank Order No. 1330, Group II-370. Table motion is 30 cycles per minute. Failure is indicated on a cycle counter when electrical contact is made between the cutting edge of scrapper and the bared conductor. Minimum of 5000 strokes AAR Specification RP-585 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 10 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 19 Test Method Crush Resistance: Insulated cable samples are placed between two (2) parallel flat places and compressed until electrical contact is detected across conductor to the plate. Samples are 12 AWG, 19 strands, 30 mil. insulation. Minimum lbs. 20 Requirement Underwriter Laboratories Standard 44 Paragraph 50 UL Standard 1581 Section 620 2000 lbs. Cut-through Penetration: Samples of insulated cable are preconditioned at 125 °C for one hour. While at 125 °C a weighted chisel (at 90 °C) cutting edge is applied perpendicular to long axis of sample. Radius of chisel edge should be 0.005" Detection of cut-through penetration is monitored with a 12 volt lamp circuit connected in series with plunger and conductor. Samples shall be the smallest gauge with the listed wall thickness. Length of test minimum "Weighted Chisel"; 500 gm. 0.030 wall 1,000 gm. 0.045 wall 1,200 gm. 0.055 wall 1,500 gm. 0.065 wall 1,800 gm. 0.075 wall 2,000 gm. 0.105 wall 10 minutes As detailed in the property or test Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 11 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 21 22 Strippability: The insulation shall be tight fitting over the stranded conductors but shall strip freely in at least a two inch length using either automatic or manual mechanical stripping tools without damage to the conductor or the insulation Test Method As detailed in the property or test Hot Creep or Cross-Linking verification: (The procedures as described in ICEA T-28-562 - 2003 shall be followed.) After Conditioning at 200 + 2 °C Elongation, Max. % Set, Max. % 23 Requirement 100 5 ICEA T-27-581-2000 / NEMA WC-53, Section 4.9 and ICEA T-28-562 - 2003 Oil Immersion Aging: ASTM No. 2 or IRM 902 described in ASTM D471 at 121 °C, 18 hrs. a. Tensile Strength, Min % of b. Elongation "Original" AAR RP-585 60% 60% Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 12 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 24 Requirement Test Method Notch Propagation: Notch samples around the whole wire and cable circumference to the depth shown in Table IV. Place notch so that it touches and is paralleled with the axis of the mandrel. Wrap the notched Samples around the mandrel for 3 complete turns on each side of the notch. Place the wrapped samples (on mandrel) in the environmental temperature chamber and soak for four hours at -25 °C + 5 °C to 90 °C + 5 °C. After each temperature soak, the sample shall be returned to room temperature and than subjected to the voltage test No. 4. See Table IV for notch depth and mandrel diameter. No separation of the insulation As detailed in the the property or test Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 13 of 23 3. TEST REQUIREMENTS: (Cont'd.) Test No. Property or Test 25 Requirement Test Method Flexibility: (For 2KV cables only) At a Temperature of 20° 25°C, one end of a test specimen of suitable length, with an excess not to exceed 2 feet beyond the mandrel after the 3 turns have been wrapped, shall be secured to the mandrel & the other end to the specified load weight. The mandrel shall be mounted in a fixture so the weighted end of the test specimen is freely suspended. Rotate the mandrel at 2 RPM until at least 3 full turns of the test specimen have been wrapped around the mandrel. The flexibility shall be such as to permit these turns to fit tightly against the mandrel and the adjacent turns of the test specimen to be in actual contact with each other. See Table V for mandrel sizes and load weights. No separation between adjacent turns wrapped around mandrel. AAR RP-585 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 14 of 23 4. Marking Requirements: All wire and cable shall be surface printed, in a legible and durable manner, at intervals no greater than 12 inches apart throughout the entire length of the wire or cable, with the following information: (a) (b) (c) (d) (e) (f) (g) (h) Number of Conductors; Size of Conductor, AWG or Cir. Mils.; Voltage Rating; Manufacturer's Name; Product Name (Ie: Polyrad XT, Exar, Exane); NYCT Commodity Number (TX); Date of Manufacture; Sequential Footage Marker; (on cables 0.375 inches in diameter and larger) 5. Separator: A NYCT approved separator may be used if necessary. 6. Dimensions: The finished cable shall be uniform in diameter throughout its length and the overall dimensions shall not exceed the values given in the tables of this specification. 7. Procedure For Qualification: A. The manufacturer shall have a documented Quality Assurance program that is acceptable to NYCT as to assure the delivery of a quality product to NYCT within the terms of this specification. B. NYCT reserves the right to inspect the manufacturer’s facility to assess their Quality Assurance program. The manufacturer must be prepared to prove, to the satisfaction of NYCT, their quality control procedures and the necessary facilities, skill, experience and financial resources to perform and deliver the product in a satisfactory and timely manner. C. For initial qualification, the manufacturer shall produce 500 ft. samples of a # 12AWG / 600 volt and a # 12AWG / 2000 volt wires and perform all Class A tests and all Class B tests except test numbers 10 & 25. The manufacturer shall also produce a 500 ft. sample of #2/0 AWG - 2000V cable and perform all Class A tests except test numbers 1,2,3,5 & 21 and only Class B test numbers 10,15,18 & 25. Class A and Class B tests must be performed by an independent testing laboratory approved by NYCT. The manufacturer shall arrange and incur all costs associated with performing these tests. NYCT may elect to witness some or all tests performed. The tests shall be performed on a portion of the wire and cable. All reports covering Class A and Class B tests shall be notarized and submitted in triplicate, together with the remaining length of wire and cable. The remaining length of cables shall be shipped at no cost to NYCT for additional testing as deemed necessary by NYCT. D. Class A tests are required for every lot of up to 100,000 feet of AWG size 8 and smaller and 25,000 feet of AWG size 6 or larger. For subsequent orders, the manufacturer must perform Class A tests by either an independent laboratory or in the manufacturer’s facility, and include copies of the Class B tests that were performed for the latest qualification. Class B tests shall be performed at a frequency of at least once per year. If no order has been processed during the year, then Class B tests shall be run on the following order. E. All reports covering Class A and Class B tests shall be notarized and submitted in triplicate, together with two (2) foot lengths of the sampled test product for review and approval by NYCT, before any delivery of such product. The notarized test reports shall also contain a certified statement by the manufacturer that the sampled product(s) supplied has been manufactured with the same formulation used for qualification. F. If there is a change of formulation, the manufacturer shall repeat Class A and Class B tests as proof of the design performance characteristics, as specified under section C above. Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 15 of 23 8. Class A Tests Test Tinned Single End Original Physical Properties Test No. ASTM-B-33 1 Aging Requirements 2 Tension Test 3 Wall Thickness Tables A and B Dimensions Tables A and B Voltage Withstand 4 Insulation Resistance 5 Cold Bend 7 Heat Resistance 8 Heat Distortion 9 Flammability 11 Hot Oil Resistance 14 Stripability 21 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 16 of 23 9. Class B Tests Test Moisture Absorption Test No. 6 Temperature Cycling (Size 2/0 AWG or Larger) 10 Ozone Resistance 12 Corrosivity 13 Relative Humidity 15 Acid Gas Detection 16 Smoke Generation 17 Abrasion Resistance 18 Crush Resistance 19 Cut-Through Penetration 20 Hot Creep or Cross-Link Verification 22 Oil Immersion Aging 23 Notch Propagation 24 Flexibility (For 2KV cables only) 25 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 17 of 23 Test 7: Cold Bend: Conductor Size AWG or kcmil 18 16 14 12 10 8 6 5 4 3 2 1 1/0 2/0 3/0 Table I Dia. of Mandrel (in.) 600V 2000V Minimum Tensioning Wgt. Pounds 1/4 5/16 1/4 5/16 1/4 5/16 1/2 1/2 5/8 5/8 3/4 3/4 5 x cable diameter 3 3 5 8 10 12 15 20 25 25 5 x cable diameter 5 x cable diameter 25 25 25 25 4/0 No. of Turns 6 6 6 6 6 6 6 6 5 4 1/2 Turn (180° U Bend) 1/2 Turn (180° U Bend) 25 1/2 Turn (180° U Bend) 250-500 8 x cable diameter 25 1/2 Turn (180° U Bend) over 500 10 x cable diameter 25 1/2 Turn (180° U Bend) Test 8: Heat Resistance: Conductor Size AWG or kcmil 18 - 16 AWG 4 - 12 10 - 3 2 - 4/0 250 - 500 kcmil over 500 kcmil Table II Dia of Mandrel (in.) 600V 2000V 1/4" 1/4" 3/8" 3/8" 3 x cable diameter 3x cable diameter 8 x cable diameter 10 x cable diameter No. of Turns 6 6 4 1/2 turn (180° U Bend) 1/2 turn (180° U Bend) 1/2 turn (180° U Bend) Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 18 of 23 Test 18: Abrasion Resistance Table III 600 V 18 AWG 16 AWG 14 AWG 12 AWG 10 AWG - 6 AWG 5 AWG - 3 AWG 2 AWG - 4/0 250 kcmil and Larger Test 24: Notch Propagation: Conductor Size Size AWG or kcmil 800 gms. 800 gms. 1000 gms. 1000 gms. 2 lbs. 3 lbs. 5 lbs. 10 lbs. 2000 V 1000 gms. 1000 gms. 1500 gms. 1500 gms. 3 lbs. 4 lbs. 8 lbs. 16 lbs. Table IV Diameter of Mandrel 600V/2000V Depth of Notch (Mils) 600V / 2000V 18 16 14 12 10 8 6 4 3 2 1 1/0 2/0 3/0 4/0 250 - 500 500 and Larger 3 x cable diameter 10/15 10/15 10/15 10/15 10/15 15/18 15/18 15/18 15/18 15/18 15/18 22 22 22 22 35 35 Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 19 of 23 Test 25: Flexibility (For 2KV cables only) Table V Size Mandrel (Inches) Max. Load Weight (Pounds) 8 AWG 5 AWG 3 AWG 2/0 AWG 4/0 AWG 313 kcmil 444 kcmil 535 kcmil 597 kcmil 5/8 " 3/4 " 1" 3" 3" 3" 4 1/2 " 5" 5" 8 lbs. 10 lbs. 10 lbs. 12 lbs. 17 lbs. 24 lbs. 26 lbs. 35 lbs. 40 lbs. Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 20 of 23 INDEX CLASS 20 TABLE GROUP DESCRIPTION A 88 Single conductor wire Insulated with irradiated Crosslinked Polyolefin Insulation, rated for 0-600 volts circuit voltage. B 90 Single conductor wire Insulated with irradiated Crosslinked Polyolefin Insulation, rated for 601 to 2000 volts circuit voltage. Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 21 of 23 TABLE A SINGLE CONDUCTOR WIRE WITH IRRADIATED CROSSLINKED POLYOLEFIN INSULATION RATED CIRCUIT VOLTAGE 0 - 600 VOLTS Class 20 Group 88 (1) Stock No. 20-88-1500 To 1509 20-88-1700 To 1709 20-88-1900 To 1909 20-88-2100 To 2109 20-88-2300 To 2309 20-88-2500 To 2509 20-88-2700 To 2709 20-88-2900 To 2909 20-88-3100 To 3109 20-88-3300 To 3309 (2) Size AWG or Cir. Mils. (3) Number of Strands (4) Strand Diameter (Inches) (5) Maximum Length of Lay (Inches) (6) Nominal Diameter Over Conductor (Inches) (7) Maximum Direct Current Conductor Resistance OHMS per 1,000 ft. of Cable at 25 °C (8) Maximum Cable Diameter (Inches) (9) Insulation Color (10) Insulation Thickness Minimum Average (Mils) 18 19 0.010 0.70 0.052 6.21 0.120 * 30 Car Wiring DCE 16 19 0.0113 1.0 0.062 4.82 0.132 * 30 " " 14 19 0.0142 1.2 0.074 3.05 0.144 * 30 " " 12 19 0.0179 1.5 0.094 1.93 0.164 * 30 " " 10 27 0.0201 1.8 0.128 1.05 0.198 * 30 " " 8 37 0.0201 2.0 0.147 0.76 0.267 * 45 " " 6 61 0.0201 3.0 0.200 0.473 0.310 * 45 " " 4 105 + 1 % 0.0201 3.5 0.260 0.275 0.366 * 45 " " 3 125 + 1 % 0.0201 4.0 0.288 0.231 0.394 * 45 " " 2 150 + 1 % 0.0201 4.5 0.325 0.193 0.435 * 45 " " * = See insulation color coding 2.2.1 (11) App. (12) Using Dept. Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 22 of 23 TABLE B SINGLE CONDUCTOR WIRE WITH IRRADIATED CROSSLINKED POLYOLEFIN INSULATION RATED CIRCUIT VOLTAGE 601 - 2000 VOLTS Class 20 Group 90 (1) Stock No. 20-90-1600 To 1609 20-90-1800 To 1809 20-90-2000 To 2009 20-90-2200 To 2209 20-90-2400 To 2409 20-90-2600 To 2609 20-90-2800 To 2809 20-90-3000 To 3009 20-90-3200 To 3209 20-90-3400 To 3400 20-90-3600 To 3609 (2) Size AWG or Cir. Mils. (3) Number of Strands (4) Strand Diameter (Inches) (5) Maximum Length of Lay (Inches) (6) Nominal Diameter Over Conductor (Inches) (7) Maximum Direct Current Conductor Resistance OHMS per 1,000 ft. of Cable at 25 °C (8) Maximum Cable Diameter (Inches) (9) Insulation Color (10) Insulation Thickness Minimum Average (Mils) 18 19 0.010 0.70 0.052 6.21 0.152 * 45 Car Wiring DCE 16 19 0.0113 1.0 0.062 4.82 0.162 * 45 " " 14 19 0.0142 1.2 0.074 3.05 0.174 * 45 " " 12 19 0.0179 1.5 0.090 1.93 0.194 * 45 " " 10 27 0.0201 1.8 0.125 1.05 0.228 * 45 " " 8 37 0.0201 2.0 0.145 0.765 0.275 * 55 " " 6 61 0.0201 3.0 0.190 0.473 0.367 * 55 " " 6 84 0.0179 3.0 0.190 0.473 0.367 * 55 " " 4 105 + 1 % 0.0201 3.5 0.256 0.275 0.386 * 55 " " 3 125+ 1 % 0.0201 4.0 0.288 0.231 0.412 * 55 " " 2 150 + 1 % 0.0201 4.5 0.325 0.193 0.455 * 55 " " * = See insulation color coding 2.2.1 (11) App. (12) Using Dept. Spec. TX Issue No. 3 Date: April 18, 2008 Sheet 23 of 23 TABLE B (Cont'd.) SINGLE CONDUCTOR WIRE WITH IRRADIATED CROSSLINKED POLYOLEFIN INSULATION RATED CIRCUIT VOLTAGE 601 - 2000 VOLTS Class 20 Group 90 (1) Stock No. (2) Size AWG or Cir. Mils. (3) Number of Strands (4) Strand Diameter (Inches) (5) Maximum Length of Lay (Inches) (6) Nominal Diameter Over Conductor (Inches) 20-90-3800 1 225 + 1 % 0.0201 5.0 0.390 To 3809 20-90-4000 1/0 275 + 1 % 0.0201 5.5 0.430 To 4009 20-90-4200 2/0 325 + 1 % 0.0201 6.0 0.470 To 4209 20-90-4400 3/0 450 + 1 % 0.0201 7.0 0.550 To 4409 20-90-4600 4/0 550 + 1 % 0.0201 8.0 0.600 To 4609 20-90-4800 262,600 650 + 1 % 0.0201 8.0 0.655 To 4809 20-90-5000 313,100 775 + 1 % 0.0201 9.0 0.730 To 5009 20-90-5200 373,700 925 + 1 % 0.0201 9.0 0.780 To 5209 20-90-5400 444,400 1100 + 1 % 0.0201 10.0 0.860 To 5409 # 20-90-5600 535,000 1325 + 1 % 0.0201 11.5 0.920 To 5609 20-90-5800 535,000 1325 + 1 % 0.0201 11.5 0.920 To 5809 # = The insulation system of these cables shall have an operating temperature of 125°C. * = See insulation color coding 2.2.1 (7) Maximum Direct Current Conductor Resistance OHMS per 1,000 ft. of Cable at 25 °C (8) Maximum Cable Diameter (Inches) (9) Insulation Color (10) Insulation Thickness Minimum Average (Mils) (11) App. (12) Using Dept. 0.130 0.540 * 65 Car Wiring DCE 0.107 0.585 * 65 " " 0.091 0.640 * 65 " " 0.066 0.715 * 65 " " 0.054 0.790 * 65 " " 0.0456 0.905 * 105 " " 0.038 0.970 * 105 " " 0.032 1.030 * 105 " " 0.027 1.105 * 105 " " 0.022 1.165 * 105 " " 0.022 1.165 * 105 " "