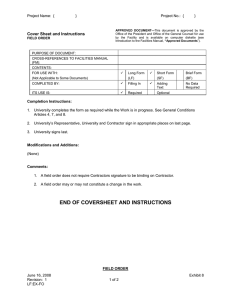

RFP 5671 Exhibit 3

advertisement