GSP Presentation - SPE Offshore Europe

advertisement

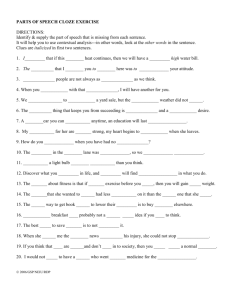

GSP Presentation Company Overview • • • • • • • • • • • • • Established in 2004 Member of Upetrom Group Experienced management team with a long history and track record in a variety of segments of the oil & gas industry Strong operating platform built for growth Controls a high quality fleet of diversified onshore and offshore assets enabling the group to offer turnkey solutions Strategically located in a fast growing region Strong customer base with a dominant market position in the Black Sea and growing market position in the North Sea, Azov Sea, Marmara Sea and South East Mediteranean markets Solid contract coverage for both vessels and rigs Member of the International Association of Drilling Contractors (IADC), International Maritime Contractors Association (IMCA), International Pipe Line and Offshore Contractors Association (IPLOCA), International Well Control Forum (IWCF) HSEQ Management System is certified as being in full compliance with ISO 9001, ISO 14001, BS OHSAS 18001 and ISM Code requirements. FPAL has audited our HSE MS - scored 9.1 from a maximum score of 9.4 More than 1,500 employees HQ in Constanta Romania, subsidiary offices in Moscow, Rotterdam, Aberdeen, Dubai, Mexico, Tunis, Oslo, Valetta, Limassol, Tripoli Deloitte has been GSP’s auditor since 2004 Short History In 2004, following the privatization of National Oil Company, Petrom, GSP employed 90% of the personnel of its Offshore Drilling Branch, Petromar - the entire offshore drilling, maintenance and maritime crew members and the onshore technical assistance & engineering personnel, and took over six offshore drilling rigs, five offshore support vessels and a crane barge. Today, a significant part of GSP`s top and middle management gathers offshore engineering specialists who developed their careers within Petromar or IFLGS Bucharest (the operational base of the Drilling and Special Geological Operations Enterprise). The above mentioned companies were established in the 1970s and have a long history in the offshore drilling industry, both being branches of the National oil company, Petrom. 2 www.gspoffshore.com Key Customers STROYGAZMONTAZH 3 www.gspoffshore.com Company Profile Grup Servicii Petroliere (GSP) headquarters are located in Constanta Harbor, Romania. GSP provides a wide range of integrated services in the following business areas: • • • • • • • • • 4 Offshore Drilling Offshore Construction Support Vessels Well Services / P&A / Decommissioning Hydro-technical Construction Engineering Subsea Installation Offshore Windmill Construction & Installation Training www.gspoffshore.com Our Business 5 DRILLING ACTIVITIES OFFSHORE CONSTRUCTION • • • • • • • • • • • • Engineering and Design of Offshore Installations Directional and Horizontal Drilling Maintenance and Repairs Offshore and Onshore Wells Design Rig Moving Operations Ordinary and Continuous Coring Engineering and Technical Consultancy Side Tracking and Re-entries Fishing Jobs Drilling Fluids Engineering Conductor Hammering Wells Production Stimulation • Onshore Fabrication and Assembly Yards (Berth 34 Constanta, Midia North Constanta, Agigea South Constanta) • Midia Pipeyard and Machine Shop • Onshore Heavy Lift Equipment up to 550 t • • • • • • Load-out, Sea fastening and Transportation On Site Installation, Wind turbine erection Subsea Pipe Line, Umbilical and Cable Laying Saturation diving and ROV operation Commissioning and Operation Manpower www.gspoffshore.com Our Business 6 SHIPPING TRAINING • AHTS, AHT and PSV vessels • Offshore Personnel Carrier and offshore MEDEVAC vessel • Construction Vessels • DP2 Flex-Lay / J-Lay Pipelay Vessel • Ocean transport Submersible Barge • Top Flat Barge (incl.250 and 550 t cranes) • Top Flat Sliding Barge • Marine Floating Crane 100 t • Barge Shearleg Crane 1800 t • Derrick Lay Barge • • • • • • • • • • • • Training in well control Training in operating the driller’s cabin controls (Cyber Chair) Safe operation of onshore and offshore cranes Training in HSE On-the-job training Drilling Superintendent module training Safe operation of DP/non-DP operated vessels Safe operation of ROV Anchor handling and Dynamic Positioning Heavy lift operations Survival at sea Fire fighting www.gspoffshore.com Our Business 7 HYDROTECHNICAL CONSTRUCTION WORKS WELL INTERVENTION SERVICES • Water capture for creating domestic usage water networks or industrial usage water networks • Dam construction for production of electric energy • Protection against flooding by regulation of watercourses • Drainage and shore protection • Development of water transportation by dredging works and channel construction • Development of nautical recreation and sport areas • Breakwater construction for harbor protection • Quays, harbor platforms, maintenance dredging of harbors • Environmental water works • Rehabilitation of shoreline areas • Preservation of beach areas • • • • Engineering and Design of Workover Workover Operation Fishing Jobs Subsea well intervention • High-pressure/high-temperature wells • Horizontal and extended-reach intervention • Large well-bores and high-capacity production wells • Multi-lateral well intervention • Training of personnel • Manpower www.gspoffshore.com www.gspoffshore.com GSP Construction and Workshop Facilities: • GSP Central Production Facility, Berth 34 • GSP North Production Facility, Midia • GSP South Production Facility & Shipyard, Agigea GSP Production Facilities The location provides fast river /canal connection with Western Europe and directly with Rotterdam port, through the Rhine-Main canal. GSP North Production Facility, Midia Rotterdam 20 Km Constanta Constanta GSP Central Production Facility, Berth 34 7 Km GSP South Production Facility & Shipyard, Agigea Google Earth® 9 Google Earth® www.gspoffshore.com GSP Central Production Facility - Berth 34, Constanta Harbor • Multipurpose workshop for industrial buildings • The workshop is endowed with a ten tons gantry • A heavy duty open concrete platform completes the production area • Berth facilities allow execution of various types of offshore construction as well as vessel and offshore drilling rig overhaul projects GSP HEADQUARTERS QUAY GSP TRAINING CENTER WORKSHOP 10 total area – 15,100 sqm. www.gspoffshore.com GSP Central Production Facility - Berth 34, Constanta Harbor • Offshore Prefabrication and Construction • Tubular and Valves Checking and Repairs • Jack-up rig Overhaul and Upgrading • Hydraulic Equipment Checking and Repairs • Barge Conversion • Electrical Equipment Checking, Measurement, Rewind and Repairs • Complete Drilling Package Outfitting for jack-ups and Drillships • Engines Maintenance and Repairs • Offshore Oilfield equipment Repairs • Cranes and Lifting Equipment Checking and Repairs • NDT • Refrigeration Plant Maintenance and Repair Work • Steelwork • Carpentry GSP HEADQUARTERS WORKSHOP 11 total area – 15,100 sqm www.gspoffshore.com GSP Central Production Facility - Berth 34, Constanta Harbor • • • • concrete & asphalt pavement maximum allowed load total berth length quay water depth 8, 300 sqm 30 tons / sqm 100 m 12 m New construction & assembly hall – 4,500 sqm: • production area - 2 000 sqm (fully heated) • one gantry - 10 tons • offshore welding school (fully heated) • storage areas - 300 sqm • workshops • boiler room, locker rooms, lavatories 12 Main office – 3,970 sqm: • reception • meeting rooms • offices • boiler room • design rooms • IT rooms total area – 15,100 sqm Working on GSP Saturn Rig Upgrade Project www.gspoffshore.com GSP Central Production Facility - Berth 34, Constanta Harbor 13 www.gspoffshore.com GSP Training Center - Berth 34, Constanta Harbor gsptrainingcenter.com GSP Training Centre is the first step in the GSP’s endeavor to build a complete set of facilities capable to offer a comprehensive training package, including the following: • Introductory to Well Control • Well Control – Surface BOP / Driller & Supervisor level • Electronic Drilling System • Top Drive System • Non-Destructive Testing • Welding Courses 14 total area – 2,196.5 sq m www.gspoffshore.com GSP Training Center - Berth 34, Constanta Harbor gsptrainingcenter.com Simulator room: Equipped with the DrillSIM-6000 capable to offer full Well Control training and training in Cyber Base operating controls. GSP Training Center employs as well the Drill SIM 20 mobile compact drilling simulator. The two simulators are high level technological products, offering comprehensive training solutions for the oil and gas industry. • • • • • 15 2,196.5 square meters total area 120 seats in four training halls 20 seats in conference room 14 design offices 50 seats in cafeteria total area – 2,196.5 sqm www.gspoffshore.com GSP Training Center - Berth 34, Constanta Harbor gsptrainingcenter.com Simulator room II: Equipped with a remote operated vehicle (ROV) simulator. The ROV Triton XLX Simulator is designed and manufactured by Perry Slingsby, UK in 2010, in collaboration with VMAX Simulation Technologies US. ROV Triton XLX Simulator is installed in a specially designed room of 71,98 sq m. The ROV simulator comprises: • ROV Pilot and Assistant controls; • Input / Output devices identical with the real ROV devices, including Media Wall monitors; • Instructor’s desk for monitoring, logging, scenario creation and troubleshooting problems input, parameters and variables for the virtual environment. 16 www.gspoffshore.com GSP Training Center - Berth 34, Constanta Harbor gsptrainingcenter.com – future capabilities Offshore Vessel Simulator System (Forward Bridge view) Offshore Crane Simulator 17 Offshore Vessel Simulator System (Aft Bridge view) Neptune Full Mission Engine Room Simulator www.gspoffshore.com GSP North Production Facility - Midia Base Midia Base is a unique industrial facility / harbor in Romania, integrating all required services to support our offshore drilling activity. These facilities are also available to provide: • Well intervention services in the Black Sea • Construction of modules for the petrochemical industry in Eastern Europe and the Middle East 18 total area – 373,766 sqm www.gspoffshore.com GSP North Production Facility - Midia Base • Offshore prefabrication and construction • Pipe coating, pipe storage • Jack-up rigs overhaul • Hydraulic and equipment storage, checking and repair • Land rig overhaul with the support of Upetrom 1 Mai • Electrical equipment storage, checking, measurement, rewind and repairs • Offshore oilfield equipment storage and repairs • Engines storage, maintenance and repairs • NDT • Refrigeration plant maintenance and repair works • Steel works • Carpentry • Cranes and lifting equipment • Tubulars and valves storage, checking and repairs 19 total area – 373,766 sqm www.gspoffshore.com GSP North Production Facility - Midia Base • • • • crushed stone pavement area maximum allowable load concrete pavement maximum allowable load 310,000 sqm 15 tons / sqm 45,000 sqm. 30 tons / sqm Construction & assembly hall – 7,500 sqm: • production area – 3,500 sqm • storage areas – 3,350 sqm • workshops • offshore welding school • automatic line for tubular drilling equipment check & repair • drilling school (similar offshore rig equipment) • offices • boiler room, locker rooms, lavatories 20 Offices - 900 sqm: • meeting rooms • mess rooms • office rooms • locker rooms • lavatories total area – 373,766 sqm total berth length 1,100 m quay water depth 7 m www.gspoffshore.com GSP North Production Facility - Midia Base Development Phases Phase I Existing Operation Base Phase II Phase III Final Development Phase 21 www.gspoffshore.com GSP South Production Facility & Shipyard, Agigea GSP Shipyard located in Constanta Sud – Agigea Port offers the necessary infrastructure to support offshore construction with a complex steelwork facility endowed with an extensive fleet of heavy lift cranes. The Constanta South – Agigea Port facility includes a multipurpose workshop and a heavy duty open platform, as well as the necessary infrastructure and utilities • • • • • • crushed stone pavement area maximum allowable load pile reinforced area maximum allowable load concrete pavement maximum allowable load 34 000 sqm 30 tons / sqm 2,400 sqm 200 tons / sqm 9,400 sqm 30 tons / sqm total berth length quay water depth 1,037 m 7m working on GSP Bigfoot 1 Project 22 total area – 70,265 sqm www.gspoffshore.com GSP South Production Facility & Shipyard, Agigea New built construction & assembly hall - 3,000 sqm: • production area 2,250 sqm • two 40 ton gantries • storage areas • workshops • offices • mess room • boiler room, locker rooms, lavatories 23 New built yard quarter - 900 sqm: • meeting rooms • mess rooms • office rooms • locker rooms • lavatories working on the Jacket for Akcakoca Project total area – 70,265 sqm www.gspoffshore.com GSP South Production Facility & Shipyard, Agigea Pictures Overall picture - 01.2010 Working on the jacket for Akçakoca Project - 03.2010 24 Working on GSP Bigfoot 1 Project - 02.2010 Working on the topside for Akçakoca Project - 03.2010 www.gspoffshore.com GSP Fleet Jack up rigs Vessels 25 GSP Saturn: GSP Jupiter: GSP Orizont: GSP Atlas: GSP Prometeu: GSP Fortuna: GSP Britannia: Built in 1988, rebuilt in 2009, cantilever type, ABS class Built in 1987, rebuilt in 2007, cantilever type, ABS class Built in 1982, rebuilt in 2010, cantilever type, GL class Built in 1985, rebuilt in 2007, cantilever type, GL class Built in 1984, upgraded in 2003, ABS class Built in 1984, upgraded in 2011, cantilever type, ABS class Built in 1968, rebuilt in 1984, upgraded in 2011, cantilever type, ABS class GSP King: GSP Queen: GSP Vega: GSP Alcor: GSP Antares: GSP Orion: GSP Licorn: GSP Perseu: GSP Phoenix: GSP Lyra: AHTS offshore support vessel, built in 2005, Singapore, ABS class AHTS offshore support vessel, 8000HP. Built in 2005 Singapore, ABS class AHTS offshore tug/supply vessel built in 1983. 12800HP, DnV class AHTS offshore vessel, built in 2010, ABS Class AHTS offshore vessel, built in 1985, DNV Class Offshore supply vessel built in 1983. Major upgrade 2009. DnV class Tug and supply vessel built in 1995. BV class Tug and supply vessel built in 1994. BV class Passenger and supply vessel, built in 1995. BV class High speed passenger and MEDEVAC vessel www.gspoffshore.com GSP Fleet Construction Vessels: Offshore heavy lift cranes: ROVs: SAT Diving System Onshore heavy lift cranes: GSP Falcon: GSP Bigfoot 1: GSP Bigfoot 2: DP2 Flex-Lay / J-Lay Pipelay Vessel DP2 Derrick / Pipe Lay Barge Semi-submersible, Heavy lift, Transportation Barge GSP Neptun: GSP Granit: 1800T floating shearleg crane, built in 1998, upgraded in 2010 100 tons floating crane GSP ROV Triton XLR Perry Slingsby GSP ROV Triton XLX Perry Slingsby GSP ROV Mohican Inspection Class ROV GSP ROV Navajo GSP Sat 1 12 man saturation diving system, operating water depth 300 m. Liebherr LG 1550: Liebherr LR 1300: Liebherr LR 1280: Liebherr LR 1200: Liebherr LR 1250: Liebherr LTM 1070: Onshore crane with 550 tons lifting capacity 4 crawler cranes with 300 tons lifting capacity Crawler crane with 280 tons lifting capacity Crawler crane with 200 tons lifting capacity Crawler crane with 250 tons lifting capacity All terrain mobile crane with a 50 metres length telescopic boom and 70 tons lifting capacity Hydraulic rough terrain crane with 30 tons lifting capacity TAKRAF crane type with 27 tons lifting capacity TEREX A 300: MDK 504: 26 All our assets are compliant with: • MODU Code requirements • ISM (International Safety Management Code) • ISPS (International Ship and Port Facility Security Code) • SOLAS (Safety Of Life At Sea) • MARPOL (Maritime Pollution) • IMO (International Maritime Organization) • COLREG (Collision Regulations) • Load Line Conventions • International Conventions of Tonnage measurements of ships www.gspoffshore.com GSP Fleet – Rigs 27 GSP Saturn GSP Jupiter GSP Orizont GSP Atlas Rig Type Four legs, self elevating unit, cantilever Design Sonnat Offshore Company Builder Galatzi Shipyard, Romania Year built 1988, rebuilt in 2009 Class ABS Flag Panama Accommodation for 100 Helideck 80 x 80 ft, rated for PUMA SA 330 B / BELL 212–412 helicopter Max Drill depth 30,000 ft Max Water Depth 300 ft (91 m) Rig Type Four legs, self e levating unit, cantilever Design Sonnat Offshore Company Builder Galatzi Shipyard, Romania Year built 1987, rebuilt in 2007 Class ABS Flag Malta Accommodation for 95+2 Hospital Helideck 80 x 80 ft, rated for PUMA SA 330 B / BELL 212–412 helicopter Max Drill depth 30,000 ft Max Water Depth 300 ft (91 m) Rig Type Four legs, self elevating unit, cantilever Design Sonnat Offshore Company Builder Galatzi Shipyard, Romania Year built 1982, rebuilt in 2007 Class Germanischer Lloyd Flag Malta Accommodation for 95+2 Hospital Helideck 80 x 80 ft, rated for PUMA SA 330 B / BELL 212–412 helicopter Max Drill depth 30,000 ft Max Water Depth 300 ft (91 m) Rig Type Four legs, self elevating unit, cantilever Design Sonnat Offshore Company Builder Galatzi Shipyard, Romania Year built 1985, rebuilt in 2007 Class Germanischer Lloyd Flag Malta Accommodation 90+2 Hospital Helideck 80 x 80 ft, rated for PUMA SA 330 B / BELL 212–412 helicopter Max Drill depth 25,000 ft Max Water Depth 300 ft (91 m) www.gspoffshore.com GSP Fleet – Rigs GSP Prometeu Rig Type Four legs, self elevating unit Design Sonnat Offshore Company Builder Galatzi Shipyard, Romania Year built 1984, upgraded in 2003 Class ABS Flag Malta Accommodation 90 + 2 Hospital Helideck 80 x 80 ft, rated for PUMA SA 330 B/BELL 212–412 Max Drill depth 20,000 ft Max Water Depth 300 ft (91 m) 28 GSP Fortuna Rig Type Three legs, self elevating unit, cantilever Design Friede & Goldman Builder Astilleros Corientes ARG. Year built 1984, upgraded in 2011 Class ABS Flag Vanuatu Accommodation 88 Helideck70 ft diameter, rated for Sikorsky S-61 helicopter Max Drill depth 25,000 ft Max Water Depth 300 ft (91 m) GSP Britannia Rig Type Four legs, self elevating unit, cantilever Design Breit Engineering Inc. Builder Norsmec Redcar UK Year built 1968, rebuild in 1984, upgraded in 2011 Class ABS Flag Vanuatu Accommodation 104 Helideck 75 x 75 ft, rated for Sikorsky S-61 helicopter Max Drill depth 20,000 ft Max Water Depth 200 ft (61 m) www.gspoffshore.com GSP Fleet – AHTS Vessels GSP King GSP Queen GSP Alcor GSP Vega AHTS Offshore Support Vessel, class ABS, towing, fire fighting and antipollution vessel Class 1, DPS-2, main engines 2 X 4,000 KW @750 rpm, Wartsila 8L32 Built in 2005 by Jaya Shipbuilding & Engineering , Singapore. AHTS Offshore Support Vessel, class ABS, towing, fire fighting and antipollution vessel Class 1, 8,000 HP, DPS-2, effective power 2 X 2,925 kW Built in 2005 by Jaya Shipbuilding & Engineering Singapore. Duties: offshore drilling rig towing and positioning, rescue, supply transport for offshore activities. Duties: offshore drilling rig towing and positioning, rescue missions, supply transport for offshore. AHTS Offshore Support Vessel, class ABS, class notation A1E Offshore Support Vessel, Fire Fighting Class 1 + AMS + DPS-1, offshore support, towing, fire fighting and antipollution vessel. Main generators 3 x 350 kW @ 1,500 rpm / 415 V / 3Ph / 50 Hz Caterpillar C18. Built in 2009 at Fujian, China. Duties: offshore drilling rig towing and positioning, anchor handling, rescue missions, supply transport for offshore activities. AHTS Offshore Tug/Supply Vessel, class DnV., DP1 firefighting, antipollution, rescue vessel with 150 persons capacity Class 1A1 ICE-C Tug Supply Vessel E0 DYNPOS AUT, designed and built in 1983 by Bolsoenes Verft, Norway. Main engines 4 x MAK Diesel 3,200 BHP, total 12,800 HP Duties: offshore drilling rig towing and positioning, rescue, supply transport for offshore activities. GSP Antares AHTS Offshore Tug/Supply Vessel, class DNV., class notation + 1A1 Tug/Supply Vessel – SF FiFi I+II – Oil Rec Dyn. Pos. autr. – LFL, EO. Designed and built - Ulstein Yard/Norway, 1985. Propulsion: 4 x Winchmann Diesel type AXAG, each 4500 BHP. 170 tons continuous bollard pull. Duties: offshore drilling rig towing and positioning, multifunction Safety Service Vessel – full rescue class, certificated for 300 persons, supply transport for offshore activities. 29 www.gspoffshore.com GSP Fleet – Survey & PSV ,Crew & MEDEVAC Vessels GSP Phoenix GSP Orion GSP Licorn GSP Perseu Passenger and supply vessel, Built 1995 Effective power 2,800kW,class BV. Length 73.33 m, width 13.63 m, maximum passenger 99 persons. Supply vessel, Oil Recovery Ship, class BV, built in 1983. Major upgrade in 2009. Main propulsion system, Rolls Royce Bergen DE 5,160HP. Tug and supply vessel, class BV Built 1995 Effective power 2 x 1,814 kW, length 60.79 m, width 13.59 m, maximum 38 persons. Tug and supply vessel, class BV Built 1994 Effective motor power 2 x 1,814 kW, length 60.92 m, width 13.59 m, minimum crew 13. Duties personnel and supply transport for offshore drilling and production rigs. Duties Offshore support including Oil Spill Recovery (OSR) capability under EMSA coordination, covering the EU border at the Black Sea. Duties supply transport, assistance during towing and positioning of offshore drilling rigs and support for drilling and production rigs. Duties supply transport, assistance during towing and positioning of offshore drilling rigs, assistance and support for drilling and production rigs. GSP Lyra Special Offshore Vessel (Crew and MEDEVAC) Built 1988 by Baatutrustning AS-Rubbestadneset Yard, Norway, upgraded in 1991, Class IRS, 45t net tonnage. Passengers & crew capacity 101 persons (96 passengers, 5 crew). Duties personnel transportation service for offshore installation projects, as well as for shallow water offshore rigs crew transport and MEDEVAC missions. 30 www.gspoffshore.com GSP Fleet – Construction Vessels GSP Falcon GSP Bigfoot 1 GSP Bigfoot 2 DP2 Flex-Lay / J-Lay Pipelay Vessel Class DNV 1A1, ICE-1B, HELDK, DYNPOS ATUR. Built in 1976, major upgrade and conversion into offshore construction vessel in 1994, rigid pipe lay system installed in 1996. Main power system: 2 x AEG, 7,000 HP; propulsion: 7 thrusters (5 x 1,305 kW, 1 x 1,200 KW, 1 x 1,540 kW). DP2 Derrick/Pipe Lay Barge Class ABS +A1 Barge, E; UWILD,CRC Built in 2010 in GSP Shipyard, upgraded in 2011, Heavylift 400 MT offshore mast crane, 60 MT pipe handling crane, Length (excluding stinger) 135.00 m, 6 x 2,200 kW Rolls Royce Azimuth Thrusters, Kongsberg DP System, 200 MT pipelaying capacity, 6 x 50 MT Pipe Repair Davits, A&R Winch capacity of 200 MT, three sections 90 m Stinger, helideck for Sikorsky S-61N & S-92, accommodation for 240 POB. Semi-submersible, Heavy lift, Transportation Barge Class Lloyd’s Register, class notation +100A1 submersible pontoon, maximum operating depth 12.26 meters to bottom of keel, deck strengthened up to 15,000 kg / m2. Length 122.45 m Built 1977 in Japan Rebuilt in GSP’s North Production Facility – Midia Base. Duties: Installation of rigid pipelines, flexible flowlines and umbilicals; flexible lay capacity 1,600 tons, and rigid lay of 4 to 14 inch pipe welded, tested and coated conventional horizontal firing line and overboarded via radius controllers and straightener and J-Lay ramp located at stern of ship. 31 Duties Pipelay, heavy lift works. The pipelay system is based on the single joint S-lay principle. The barge is capable of installing 6” to 60” diameter pipelines. Duties dry heavy marine transportation – offshore drilling rigs, offshore production structures and modules such as jackets, topsides, other heavy floating and non-floating cargoes, using the float on / float off method, other offshore installation works. www.gspoffshore.com GSP Fleet – Crane Barges GSP Neptun GSP Granit 1,800 tons floating crane, Built in 1998, upgraded in 2010 Lifting speed / load 1.8 m / min., lifting speed / unload 3.6 m / min., lifting height 76.00 m. Length (LOA) 83 m, width 36 m, gross tonnage 6,557t. Accommodation: 9 persons. 100 tons floating crane, Built in 1973 Length 40,66 m Width 20.02 m Effective motor power 2 x 331 kW, Accommodation: Crew only – 16 Duties offshore construction – platform installation, rebuilding and removal. 32 www.gspoffshore.com GSP Fleet –Trenching Equipment 33 GSP Ocean Trencher & GSP Ocean Ranger GSP Jetting Jack Capable of simultaneous or post-lay burial in up to 30 m of water and with modifications to 100 m water depth. Tracked vehicles with interchangeable tooling. Capable of trenching up to a 3 m trench and can operate from the beach, through the intertidal zone and to the rated depth. The product is fed into the forward bell mouth and runs over the vehicle and into the depressor aft of the chain cutter. A hydraulically operated lockable depressor guides the cable to the bottom of the trench. The 3.3 m chain cutter or jetter sword fitted is fed directly from a surface hydraulic power pack. A separate hydraulic power pack feeds the vehicle valve tanks or auxiliary functions. This water pressure driven cable trencher is designed to bury cables to a depth of 0.6 to 1 m. The Jetting Jack can also be towed which allows all pressurized water to be utilized for burying cable. The frame is fabricated with stainless steel AISI316L SPECIFICATIONS: • Length: 13.4 m (cutter fitted) • Width: 3 m • Height: 2 m • Weight: 3.5 t • Max. Operating Depth: 50 m • Burial Depth: 0.6 to 1 m to top of product • Cutting Capacity: Sand / Clay • Minimum Ground Pressure: 10 Kpa www.gspoffshore.com GSP Fleet – ROV & Sat Diving The ROVs (Remotely operated vehicle) GSP owns and operates incorporate latest generation robotic technologies being able to operate in the safest manner in the toughest weather conditions and challenging environment. GSP operates four ROVs: Perry Slingsby Triton XLR, Medium Duty Work Class ROV, 3,000 msw, 125 HP Perry Slingsby Triton XLX, Heavy Duty Work Class ROV, 3,000 msw, 150 HP Mohican Inspection Class ROV system, 2,000 msw, incorporating an enhanced propulsion system which allows it to continue working in high current conditions Navajo compact size and weight portable ROV system, 300 msw GSP’s diving services have the reputation for both excellence and highly trained and passionate personnel and most advanced technologies and equipment. GSP operates a modularized saturation diving system designed to be installed on various construction and support vessels, depending on project requirements. The 12 man saturation diving system was designed and built by LexMar Engineering, and is IMCA and ABS compliant. It allows divers to undertake subsea surveys, light construction works, inspections, maintenance and repair up to 300 meters water depth. 34 www.gspoffshore.com www.gspoffshore.com GSP Activities • Offshore Construction • Offshore Drilling • Logistic Support • Onshore Windmill Installation DLS Project – Black Sea, Russian Federation Ultimate Client: Gazprom, Russian Federation The Dzhubga – Lazarevskoye – Sochi gas pipeline is part of the Program for Construction of Olympic Facilities and Development of Sochi as a Mountain-Climatic Resort, approved by the Government of the Russian Federation. The gas pipeline is designed to provide a reliable energy supply to Sochi and other areas, including delivery of gas to the Olympic facilities which are under construction; it gives a powerful impulse to the implementation of gas supply in both private and public households of Sochi and the Tuapse District, particularly facilitating the power supply on the Black Sea coast of the Caucasus. The total length of the gas pipeline is 177 kilometers, including the 159.5 kilometer offshore section. The pipeline route runs on the Black Sea bottom following the coastline (approximately 4.5 kilometers away from the coast) to the Kudepsta gas distribution station near Sochi. The 24 inches gas pipeline will have an annual throughput capacity of approx. 3.8 billion cubic meters. GSP, as contractor for the offshore works, installed the submarine pipelines (159.5 km), including welding, non-destructive testing, inspection, pipe transport, installation of five shore approaches, pipeline tie-ins, ROV operations, surveys, trenching and pipeline hydrotesting. 36 www.gspoffshore.com Akcakoca Oil Field Project – Black Sea, Turkey Client: TPAO, Turkey The Akcakoca site is located in a water depth of 95 metres, approximately 14 km from shore. The Akcakoca gas project included fabrication, transport, installation and hook-up of a 4-leg jacket over the two predrilled wells, AKC-3 and AKC-4, and drilling three new directional wells, using GSP’s self contained modular drilling rig GSP 31, which will also be used for completing and maintaining all wells. The four leg cross-braced jacket supports a two level trussed deck, also fabricated, installed and hooked-up by GSP. GSP Bigfoot 1 installed subsea pipelines of 12’’ and 7 kilometers and made tie-ins to the existing offshore pipeline system via a piggable wye connection, for transporting the produced gas from the Akcakoca platform to the Cayagzi gas processing plant located onshore near Akcakoca town. GSP carried out all fabrication, construction, installation, drilling and pipelay for the project. 37 www.gspoffshore.com Galata Project – Black Sea, Bulgaria Client: Melrose Resources, England In early 2009, Melrose Resources commenced a development program to convert the Galata field offshore Bulgaria to a gas storage facility. GSP was awarded the contract for engineering, procurement, fabrication, transportation, offshore installation and testing of the pipelines 8.5 km x 6” from Galata Platform to Wellhead Kavarna 2, and 14.5 km x 10” from Galata Platform to Wellhead Kaliakra 2, with associated piggyback liquid lines. Pipeline installation was performed by GSP Bigfoot 1 in water depths ranging from 36 to 80 meters. 38 www.gspoffshore.com Pipeline Installation between Q4-C and Q8-A platform, North Sea Client: Wintershall Noordzee B.V. GSP has been awarded its first North Sea project for Wintershall Noordzee B.V. for the installation of 30.6 km pipeline, 10” OD between Q4-C and Q8-A platform locations. GSP Falcon, the DNV class pipelay vessel installed the subsea pipeline in the Dutch sector of the North Sea. The newly installed pipeline reroutes production from the existing Q4-C platform and connects it subsea to the existing 10 inch pipeline in the Q8 field, which runs to the gas treatment facilities at the Q8Terminal. The project was completed in September 2012. 39 www.gspoffshore.com Pipeline installation project, between the LEMAN 53/02 a-14A b well and the existing 49/27A platform facilities Client: Perenco UK Ltd. The operations under the contract with Perenco, “Installation and trenching of 9.5 km pipeline 8” OD and umbilical” involved all Engineering, Procurement, Installation, and Pre-Commissioning required to lay the 9.5 km 8” diameter offshore gas pipeline and umbilical between the LEMAN 53/02 a – 14A well and the existing 49/27A platform facilities. Grup Servicii Petroliere (GSP Offshore) has been awarded the new contract in the North Sea and the works were carried out by GSP Falcon, the DNV class pipelay vessel. The offshore operations were completed in January, 2013. 40 www.gspoffshore.com Hunter Pipeline Replacement Project Client: E.ON E&P UK LIMITED The Hunter field is located in Block 44/23A of the UKCS southern North Sea, at water depth of approximately 34 m to 38 m. The original Hunter pipeline which comprises approximately 8 km of 8” flexible pipe which ties in directly to flanges on the Hunter flowbase and the Murdioch K wellhead manifold failed during a pressure test, being disconnected and isolated both ends. GSP, the general contractor, replaced the pipeline with rigid carbon steel line routed parallel to the existing pipe, the project’s scope of work comprising the installation of the 8 km of 8” pipeline between Hunter well head and Murdock K well, trenching and backfilling, survey, project management and engineering. The offshore operations commenced in March 2013, in the Hunter field, located in UK Southern North Sea. The pipelay operations were performed by GSP Falcon, the DNV Class construction vessel. 41 www.gspoffshore.com Galata East 3 Gas Field Development Client: Melrose resources, England Melrose Resources SARL continues the development of its projects for Galata field, offshore Bulgaria. The new project includes the Engineering, Procurement, Fabrication and Installation works for 1.7 km 10” pipeline with two 1” piggyback lines between Galata East 3 and Kaliakra well. GSP Offshore is the general contractor of the project scheduled to be carried out in two phases: phase one – the installation of the 1.7 x 10” pipeline with 2 X 1” piggyback lines and testing, and phase two – the subsea works for the pipeline connection to Galata East and Kaliakra Christmas Trees (removal of existing spool and installation of manifold, installation of spools, tie in of the piggyback lines and completion pressure test) GSP mobilizes for the development of the Galata East 3 gas field the pipelay barge GSP Bigfoot 1, GSP AHTSs, GSP SAT 1 diving system and heavy duty as well as survey ROVs. 42 www.gspoffshore.com Drilling Projects Since its establishment, Grup Servicii Petroliere has been a leader in offshore drilling operations. Projects carried out by GSP include: Development of Cantarel in field in Mexico for Pemex E&P with GSP Atlas and GSP Orizont. Exploration program of Wintershall in Noth Sea – NL block F-17. Offshore exploration drilling campaign on the Bulgarian continental shelf between 2004 and 2005, for Melrose Resources; Offshore horizontal sidetracking and directional drilling in Salman and Esfandihar fields in the Persian Gulf between 2004 and 2005 for PEDCO Iran; Offshore drilling campaign on the Turkish continental shelf in 2006 and exploration in 2012 for TPAO; Vertical and directional exploration and production drilling, well completion, production tests with two MODUs in the Black Sea, GSP Jupiter and GSP Saturn, in various offshore fields between 2006 and 2007 for OMV-Petrom; Exploration drilling operations in Doina field, Black Sea, the well completion and the production tests at the beginning of 2008, for Midia Resources (a subsidiary of Sterling); 43 www.gspoffshore.com Drilling Projects GSP is involved in offshore drilling projects in the North Sea, the Black Sea, the Mediterranean Sea, The Arabian Gulf, the Gulf of Mexico and seasonally the Arctic continental shelf of the Russian Federation. GSP customers range from small independent to major oil & gas company (national and private): Petrom / OMV Kavala Oil Wintershall Pemex GazpromNeft Turkish Petroleum A.O. Cooper Energy Repsol YPF Midia Resources PEDCO Toreador Resources IOOC Melrose Resources/ Petroceltic Petreco/ Cameron Madison Oil 44 www.gspoffshore.com Logistic support for deepwater drilling operations Client: ExxonMobil GSP Offshore was awarded two contracts for onshore logistic support services for the deepwater drilling in the Black Sea. The service offer includes onshore project cargo & heavy lift, general & steel cargoes, assembly and packaging of industrial cargoes, offshore vessels port assistance and services, warehousing, open storage, bulk storage, loading and offloading, manpower, security services and client support facilities engineering / fabrication / administration / procurement / interface document controlling, 3rd party services: customs clearance, dangerous goods transportation measures; fuel bunkering: fuel supply and call-out as required. GSP provides specialized services of inspection, repair and storage of the tubular material & oilfield equipment. The first logistic support contract comprised services for the deepwater drilling campaign carried out between August 2011 and July 2012. The second contract has secured the port facility and services for the campaign scheduled to be carried out between April 2013 and July 2015. GSP provides on contractual basis services mobilizing the GSP Shipyard facility in Midia Port, the berths 10 and 11, the Full Service Tubular Material & Oilfield Equipment Inspection, Repair and Storage facility and offshore support services with AHTS. 45 www.gspoffshore.com Onshore Windmill Accomplished Projects Client: Martifer 5 wind turbines were installed within the first onshore windmill installation project performed by GSP Offshore on the Babadag location. The first project of the kind mobilized a six men team and an LG 1550 crane with lattice boom. Martifer, the developer of the wind park in Babadag area, has a 260 hectares concession and a project designed for the development of a 48 MW wind farm. The five wind turbines installed by GSP Offshore were made up of four column sections having different lengths and weights raging between 30 and 40 tons each. On top of the column of each wind turbine was installed an 82 tons drive train including the gearbox and the generator as well as the wind blades. The work site is located 90 kilometers away from the operational base and headquarters of the heavy equipment division of GSP Shipyard, in Midia Port. 46 www.gspoffshore.com Onshore Windmill Accomplished Projects Client : Iberdrola Renovables 22 installed wind turbines within the onshore windmill installation project performed by GSP Offshore on the Mihai Viteazu location for Iberdrola Renovables. The installation of the 22 wind turbines was carried out between the 1st of November 2011 and the 12th of January 2012, with an average of 2 wind turbines per week, within the onshore wind farm project at Mihai Viteazu. The wind turbines are Gamesa G 87 type, with a 2 MW rated power each, an 80 meters hub/tower height and 83 tons generator. The operations were carried out by one GSP's operational team and the LG 1550 heavy lift mobile crane. The 22 wind turbines are erected and ready for commissioning. The beneficiary, Iberdrola Renewables, owner of the I, II, III, and IV Mihai Viteazu wind farms, scheduled the connection to the grid for April 2012. The project: Iberdrola Renovables S.A. acquired the projects in 2010. It's expected that Iberdrola will connect a total of 1’500 MW of wind power to the grid in the south-east of Romania. The development and engineering work on these projects are expected to be undertaken between 2011 and 2017. 47 www.gspoffshore.com GSP’s past activities in the Black Sea 48 www.gspoffshore.com GSP’s future activities in the Black Sea 49 www.gspoffshore.com www.gspoffshore.com GSP Investment Policy • Current / Ongoing Investments • Planned Investments • Future Potential Investments Investment Policy Since 2004, GSP has invested almost one billion USD in the acquisition and modernization of its vessels and drilling rigs, including extensive upgrades of GSP Jupiter and GSP Saturn rigs and conversion of GSP Bigfoot 1 and GSP Bigfoot 3. GSP puts strong emphasis on its workforce and will continue to invest in the training and education of its employees to ensure the highest quality of operations. GSP has a long term investment plan including the continuous modernization of the equipment onboard of the drilling rigs. GSP is the dedicated investment vehicle for the group’s non transportation offshore assets All investments made must meet GSP’s long term strategic objectives and return requirements GSP JUPITER pre and post upgrade December 2006 51 December 2007 GSP SATURN pre and post upgrade September 2008 June 2009 www.gspoffshore.com Planned Investments GSP CJ54-X135-A The CJ54-X135-A is intended for use in water depths of up to: • 106.7 m (350 ft) in harsh environment conditions • 137.2 m (450 ft) in moderate environment conditions Modifications to suit the client's requirements are possible. 52 Length hull: Breadth hull: Accommodation 76.0 m 76.0 m 150 persons Classification DNV / ABS, Self-elvating drilling unit, IMO MODU code, latest edition SNAME T&R 5-5A Main power Emergency power 6 diesel driving 1,534 kW generators 1 diesel driving 910 kW generator Drilling depth: Mud pumps: Rotary table: Draw works: Derrick: BOP: Diverter: Kill and choke manifold: Top drive: 30,000 ft 4 x 2,200 HP 49.5 inch 4,600 HP 210 ft, 40 x 45 ft base, 2,500 kips hookload 18 3/4 inch 15,000 psi 49.5 inch, 2000 psi 15,000 psi 1,134 metric ton Mooring winches: Cranes 4 single winches 3 electro-hydraulic driven Helideck Helicopter: Dimensions: EH101 22.8 m diameter Cantilever GustoMSC X-Y www.gspoffshore.com Planned Investments GSP Tbn Ultra-Deepwater Drillship 53 Design Global Marine / Hughes Dimensions (MD) 19 ft. x 116 ft. x 51 ft. Draft at Loadline 35 ft. Quarters capacity 160 persons Maximum Water Depth 7,800 ft. Maximum Drilling Depth 30,000 ft. Derrick 170 ft. x 61.3 ft. x 41.7 ft. Drawworks National-Oilwell 2040, 5,000 hp Rotary table National Oilwell C-495 Top Drive Varco TDS-1000 AC Mud Pumps 3 x National Oilwell 14-P-220, 2,200 hp 1 x National Oilwell 12-P-160, 1,600 DP System Triple redundant dynamic positioning system Main Power Four EMD MD 16E9B diesel engines Emergency Power One Detroit diesel 16V-149 emergency generator Marine Drilling Risers Stewart & Stevenson SSQR-F 2,000,000 lbs. Riser Tensioners 10 x Shaffer single riser tensioner 200,000 lbs. Diverter System Stewart & Stevenson complete shut off 21-1/4 in. Deck Cranes Two Seatrax 7228 cranes www.gspoffshore.com Planned Investments GSP Venus self propelled dynamically positioned drillship GSP Caspian drilling barge 54 Length overall Breadth moulded Depth at side Scantling draught Operational draft Speed Accommodation Power Main thrusters Retractable thrusters Bow thruster 208.0 m 35.0 m 18.2 m 12.5 m 9.0m 14 knots 200 persons 6 x 7400 kW 3 x 5500 kW 3 x 3200 kW 1 x 2500 kW Length Breadth moulded Depth at side Scantling draught Operational draught for deepwater Operational draught for shallow water Displacement at operational deep draught Deadweight at operational deep draught Displacement at shallow draught Deadweight at shallow draught 140 m 48 m 15 m 10.6 m 10.0 m 1.8 m Approx. Approx. Approx. Approx. 68,900 t 56,500 t 16,500 t 12,800 t www.gspoffshore.com Planned Investments GSP Titan Multi Purpose Offshore Construction Multi Laying Vessel Subsea Installation GSP DSV ROV Survey & Offshore Construction Diving Support Vessel 55 Length overall Length BP Breadth Depth to 1st deck Depth to 2nd deck Complement Type of Main Engines: Service Speed Class Notation: 175.20 m 163.40 m 32.00 m 14.40 m 10.80 m 240 POB WARTSILA 8L32 17.5 Knots +1A1, ICE-1A, SF, SPS, DYNPOSAUTRO,CRANE, HELDK-SHF, CLEANDESIGN, BIS, E0,NAUT-OSV(A), COMF V(3)C(3), DK(+), FIFI II Length overall Length BP Breadth mld. Depth to main deck Design draught, moulded Complement Type of Main Engines: Service Speed Class Notation: 123.00 m 109.30 m 24.00 m 10.50 m 6.50 m 110 POB+18(SAT) WARTSILA 8L26 13.5 Knots DNV, +1A1, Diving Support Vessel, COMF-V(3)C(3), HELDK-SH, DK(+), E0, DYNPOS AUTRO, DSV-SAT, SF, ESV-DP[HIL],CLEAN, BIS, SPS www.gspoffshore.com Planned Investments A fleet of self supporting barges to do complete Pipelay Projects in the Caspian Sea • Pipelay Complex consist of three standard barges • Accommodation barge, consist of two standard barges • Trenching barge, consist of two standard barges • Pipe supply barge, one short barge (5 off) Pipelay Complex Length 137.6m, Width 49.4m 3000m2 deck space 1500t Deadweight @ 1.4m draft 2200t Deadweight @ 1.5m draft 19000t Deadweight @ freeboard draft (4m) Arthropod 600 56 Offshore Support barge Length 137.6m Width 32.7m 2600m2 deck space 1000t Deadweight @ 1.5m draft 12000t Deadweight @ freeboard draft (4m) Shallow Water Pipe Supply Barges Length 99.2m, Width 16m, Depth 7.2m 450t Deadweight @ 1.5m draft 4100t Deadweight @ freeboard draft (4m) 5 barges in the fleet Trenching Barge Length 137.6m Width 32.7m 2600m2 deck space 1000t Deadweight @ 1.5m draft 12000t Deadweight @ freeboard draft (4m) The ‘Arthropod 600’ is capable of trenching pipelines from 12” to 50” OD at a maximum burial depth of 3.5 m (bottom of trench). www.gspoffshore.com Thank you! www.gspoffshore.com 08 August 2013