Handout Format - National Association of State Facilities

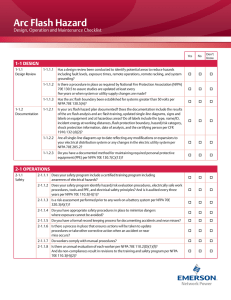

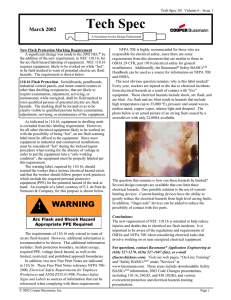

advertisement

Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 - 8:30am-9:45am, Clark, Lower Level Presented by: Joe Schommer, Senior Accounts Manager, RESA Power Jake Jacobson, Facilities Program Manager, Facilities Construction & Management, Utah Administrative Services The world of electrical hazards, protection and accident prevention can be a confusing place. Hundreds of deaths and thousands of injuries can be avoided each year by following the NFPA 70E: Standard for Electrical Safety in the Workplace. Be prepared by arming yourself with the knowledge of the types of electrical hazards and the effects of electrical shock from a 20-year electrical maintenance industry veteran. This session will identify the need for electrical safety as well as electrical maintenance and safety programs. Attendees will learn about arc flash hazard risk assessment, personal protective equipment (PPE) and shock and arc flash approach boundaries. Reduce your liability concerns while establishing a culture of safe work practices among employees after attending this session. ABOUT THE SPEAKERS JOE SCHOMMER has been involved in the electrical maintenance and testing industry for over 20 years. Starting as a field service technician and progressing through the disciplines, Joe has experienced the importance of maintenance and acceptance testing and how these practices improve reliability and ultimately safety within your electrical distribution system. Joe brings practical application experience for improving the safety of your facility by adhering to NETA and the NFPA 70E guidelines, merging electrical safety with electrical maintenance. JAKE JACOBSON is a Facilities Operations and Maintenance Program Manager for the State of Utah Division of Facilities Construction and Management. He has been in this position for 13 years and worked his way through the organization in several different roles. The Division Operates and maintains properties throughout Utah, Jake's role is to administer this program and insure the safety of the tenants and the 130 plus employees employed by DFCM throughout the state His back ground prior to working for the State was as an Electrical and Mechanical Contractor working in a variety of different areas Including commercial and Industrial processing. He has been a Master Electrician in the State of Utah for 26 years and has been involved with a variety of types and needs for Electrical work. Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 1 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Parts of 70E have been around since 1979/1981. OSHA actually adopted new regulations on safe electrical work practices in 1990 based on 70E. However, the reason we’re just now talking about 70E is because the NEC (National Electrical Code) and OSHA (Occupational Safety and Health Administration) have both started referring to it in their documents, and citations are now being written on 70E. In September 1999 a major U.S. corporation experienced an electrical accident that resulted in serious burn injuries to an electrical apprentice employee. OSHA (Occupational Safety and Health Administration) investigated the accident and issued a number of citations. The employer challenged the citations and the disagreement ended up before the Occupational Safety and Health Review Commission. Tuesday, June 14, 2016 ♦ 8:30am – 9:45am As a part of the citation OSHA contended that the employer violated a federal regulation because it did not provide or require that its electricians wear appropriate flame‐resistant or retardant personal protection, specifically, flame‐resistant coveralls and insulated gloves. OSHA also contended that the employer violated a regulation when I did not provide or require that its electricians wear appropriate face protection. 2 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? In the settlement the employer agreed to develop hazard analyses in accordance with the personal protective equipment provisions contained in NFPA (National Fire Protection Association) 70E. OSHA agreed that given the present state of its standards and regulations, the hazard analyses would achieve compliance with their requirements. OSHA has not adopted NFPA 70E, and does not mandate 70E compliance, yet you can be cited for non‐compliance!! Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Before attempting to address the questions concerning compliance, it is important to understand what is the “General Duty Clause” ‐ In 29 CFR 1910.2(g) a National Consensus Standard is defined as a standard that is developed by the same persons it affects and then is adopted by a nationally recognized organization. Some examples of organizations that publish national consensus standards include: NFPA, ASTM and ANSI Section 5.(a)(1) within the ACT: Occupational Safety and Health Act of 1970 5. Duties (a) Each employer (1) Shall furnish to each of his employees and place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees; 3 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Section 5(a)(1) has become known as “The General Duty Clause”. It is a catch all for citations if OSHA identifies unsafe conditions to which a regulation does not exist. In practice, OSHA, court precedent, and the review commission have established that if the following elements are present, a “general duty clause” citation may be issued. Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 1) The employers failed to keep the workplace free of a hazard to which employees of that Employer were exposed. 2) The hazard was recognized. (Examples might include: through your safety personnel, employees, organization, trade organization or industry customs). 3) The hazard was causing or was likely to cause death or serious physical harm. 4) There was a feasible and useful method to correct the hazard. 4 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Insert video 5 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 6 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 7 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 8 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 9 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 10 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 11 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 12 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am A greater proportion of injuries occurred six or more hours into shift (32%) Percent Percent Of Workforce Hours into shift Years of experience 13 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Electrical Shock Electrocution Internal and external burns Arc Flash Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Electrocution is the FOURTH highest cause of industrial fatalities The National Safety council estimates 1000 fatalities each year are due to electrocution, more than half of them while servicing energized systems of less than 600 volts Flash Boundary WARNING LABEL Provides Boundary information Potentially severe external burns Arc Blast Pressure and sound waves Shrapnel (in excess of 700 MPH) Over 30,000 non‐fatal electrical shock accidents occur each year Restricted Limited Most of the deaths and injuries that occurred could have been avoided Limited Restricted 14 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Nominal System Voltage (Phase to Phase) 50 V ‐150 V 151 V – 750 V 751V ‐ 15kV 15.1kV‐ 36kV 36.1kV‐ 46kV From a Moveable Conductor 3 m (10 ft 0 in.) 3 m (10 ft 0 in.) 3 m (10 ft 0 in.) 3 m (10 ft 0 in.) 3 m (10 ft 0 in.) From a Fixed Conductor 1 m (3 ft. 6 in.) 1 m (3 ft. 6 in.) 1.5 m (5 ft. 0 in.) 1.8 m (6 ft. 0 in.) 2.5 m (8 ft. 0 in.) Limited Approach Boundary Distance (L) Unqualified individual(s) shall be advised by the qualified person of the electrical hazard and warned to stay outside the limited approach boundary An approach limit at a distance from an exposed energized electrical conductor or circuit part within which a shock hazard exists. To cross the Limited Approach Boundary and enter the limited space a person should meet the following criteria: 1. Be “Qualified” to perform the job/task. 2. Be able to identify the hazards and associated risks with the tasks to be performed. Tuesday, June 14, 2016 ♦ 8:30am – 9:45am An Approach limit at a distance from an exposed live part within which there is increased risk of shock due of electrical arc‐over Nominal System Voltage (Phase to Phase) Includes Inadvertent Movement Adder 50 V-150V 151 V 750 V 751 V 15kV 15.1kV 36kV 36.1 kV 46kV Avoid Contact .3 m (1 ft. 0 in.) .7 m (2 ft. 2 in.) .8 m (2 ft. 7 in.) .8 m (2 ft. 9 in.) 15 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? An approach limit at a distance from an exposed energized electrical conductor or circuit part, within which there is an increased risk of shock due to electrical arc over combined with inadvertent movement, for personnel working in close proximity to the energized electrical conductor or circuit part. To cross the Restricted Approach Boundary and enter the restricted space, qualified persons should meet the following criteria: 1. Have an energized electrical work permit authorized by management. 2. Use personal protective equipment (PPE) that is rated for the voltage and energy level involved. 3. Minimize the likelihood of bodily contact with exposed energized conductors and circuit parts from inadvertent movement. 4. Use insulated tools. 35,000 °F Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Molten Metal Pressure Waves Sound Waves Shrapnel Copper Vapor: Solid to Vapor Expands by 67,000 times Hot Air-Rapid Expansion Intense Light One of the hottest things on earth Size of arc is independent of voltage Amount of short circuit current available determines size of arc Responsible for about 75% of all industrial electrical injuries Arcs on low voltage systems can be just as dangerous as arcs on medium & high voltage systems 16 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am To work within the Trained and knowledgeable in the construction and operation of equipment or specific work method Flash Boundary Warning Label provides boundary information. Able to recognize and avoid electrical hazards Restricted Distinguish exposed energized parts from other parts Determine nominal voltage May be qualified with respect to certain equipment and methods but unqualified for others. Limited You must be trained to: Determine approach distances Determine degree and extent of hazard and PPE required. 17 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am >740 mph 1000° C 480 Volt System 6‐Cycle Arcing Fault (0.1 sec) IR 165 db 15000° C Visible UV Shrapnel 2000 psf 50 cal/cm2 18 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am 19 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am NFPA 70E – 2015 Standard for Electrical Safety in the Workplace Sets the requirements for Safe Work Practices Establishes the requirements for: ● ● ● ● ● Shock Hazards Boundaries Arc Flash Boundaries Incident Energy Methods of calculations for Arc Flash Personal Protective Equipment (PPE) 20 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Based on Maintained Equipment!! (70E-130.5) ● Determines Trip Time for Each Protective Device based on Arcing Fault Current ● Calculates Incident Energy at Working Distance ● Calculates Arc Flash Boundary ● Determines Required PPE ● Is Used to Generate Warning Labels Part of the Electrical Safety Program should include: Article 110 General Requirements for Electrical Safety‐Related Work Practices. – 110.1 Electrical Safety Program • (B) Maintenance. The electrical safety program shall include elements that consider condition of maintenance of electrical equipment and systems. Article 205 General Maintenance Requirements. – 205.3 General Maintenance Requirements • Electrical equipment shall be maintained in accordance with manufacturers’ instructions or industry consensus standards to reduce the risk associated with failure. The equipment owner or the owner’s designated representative shall be responsible for maintenance of the electrical equipment and documentation. Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Informational Note: Common industry practice is to apply test or calibration decals to equipment to indicate the test or calibration date and overall condition of equipment that has been tested and maintained in the field. These decals provide the employee immediate indication of last maintenance date and if the tested device or system was found acceptable on the date of test. This local information can assist the employee in the assessment of overall electrical equipment maintenance status. 21 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Infrared Inspection Tuesday, June 14, 2016 ♦ 8:30am – 9:45am MCB LVB 22 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? LVB Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Switch Disconnects 23 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Liquid Filled Transformer Tuesday, June 14, 2016 ♦ 8:30am – 9:45am DRY TYPE TRANSFORMERS Arc Flash Situation: ● 20,000‐amp short‐circuit ● 480 volts ● 3‐inch arch gap ● The worker is 18 inches from the arc ● With a 5 cycle clearing time for a 3‐phase arc, incident energy is 3.79 cal/cm2 – Category 2 24 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Due to a sticky mechanism, with a 30 cycle clearing time Incident energy is 38.64 cal/cm2 – Category 4 The worker could be seriously injured because he/she was under protected Most common cause of opening delay Improper lubrication of circuit breakers Maintenance is extremely important to an electrical safety program Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Arc Rating of FR Clothing and Equipment must match the Arc Flash Exposure Level Arc Flash Exposure 80 cal/cm2 Arc Rating of Clothing (2 FR Layers) Arc Rating 21cal/cm2 25 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am WHY NOT WEAR CONVENTIONAL WORK CLOTHES? Everyday fabrics can ignite, burn and melt when exposed to an Electric Arc Cotton, wool, silk are flammable but don’t melt Polyester, Nylon, Polypropylene MELT AND BURN When Conventional Clothing Ignites… Clothed areas can be Burned more severely Than exposed skin If everyday fabric does ignite and burn. It can significantly increase the extent of a worker’s burn injury. 26 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Items NOT to be Worn: • Conductive jewelry and clothing such as: • Watchbands, bracelets, rings, metal earrings, necklaces, metallized aprons • Clothes with conductive threads • Metal headgear • Metal framed safety glasses ASTM Arc Rated Clothing Labeling: Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Step 1: Conduct Arc Flash Risk Assessment Step 2: Reduce Hazards Where Possible ● ● ● ● ● ● Manufacturer & manufacturer tracking code Care Instructions Fabric fiber content Garment size Meets ASTM F1506 Fire Retardant Standards Lists ATPV (Arc Thermal Performance Value) in calories per square centimeter Step 3: Assess and Categorize PPE Needs Step 4: Select PPE to Match Arc Flash Risk Assessment The Arc Hazard is identified, quantified and matched to PPE 27 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Not all injuries will be prevented Injuries can be minimized Quality of life can be preserved Tuesday, June 14, 2016 ♦ 8:30am – 9:45am NFPA 70E Definition Electrically Safe Work Condition. A state in which the conductor or circuit part to be worked on or near has been disconnected from energized parts, locked/tagged in accordance with established standards, tested to ensure the absence of voltage, and grounded if determined necessary. The need for PPE is still present during lock‐out, tag‐out, testing and grounding. 28 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? The Arc Flash Risk Assessment needs to be addressed to reduce injuries And fatalities in the workplace NFPA 70E is an effective approach for addressing the Arc Flash Risk Assessment PPE labeling can clarify the protection level of FR daily wear used with Arc Flash suits PPE labeling can indicate approaches to reduce the probability of 2nd degree burn injury Workforce involvement and Education are key to launching an FR daily wear & PPE Program for the Arc Flash Risk Assessment Tuesday, June 14, 2016 ♦ 8:30am – 9:45am Still Confused? Here’s the bottom line: Many OSHA regulations are written in general terms leaving the details up to the employer on how to comply. The employer is expected to use consensus standards to help in the selection of the best method to achieve compliance with the OSHA regulations. NFPA 70E is not a Federal regulation, it is a “how to comply” consensus standard for specific OSHA regulations. Compliance with 70E will assure compliance with some OSHA electrical regulations. 29 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? If you do nothing YOU RISK: In the event of an injury or death due to an electrical accident, if OSHA determines that compliance with 70E would have prevented or lessened the injury, OSHA may site the employer under the “general duty clause” for not using 70E to protect the employee(s). In a 2003 “Standards Interpretation” letter OSHA stated 70E can be used as evidence of whether the employer acted reasonably. • Fatality/Injury • Treatment cost • Fines • Litigation • Insurance • Perform OSHA mandated analysis Tuesday, June 14, 2016 ♦ 8:30am – 9:45am If you wear improper PPE YOU RISK: • • • • • • • Inadequate or excessive PPE Fatality/Injury Treatment cost Fines Litigation Insurance Perform OSHA mandated analysis 30 Arc Flash, The NFPA 70E Standard and Your Electrical Maintenance. ARE YOU PREPARED? Tuesday, June 14, 2016 ♦ 8:30am – 9:45am WHEN PERFORMING THE ANALYSIS: • Should be performed by a registered professional Engineering Firm “Safety starts with Awareness” • Issue the analysis report with results • Professional should make recommendations “Awareness starts with YOU!” • Training 31