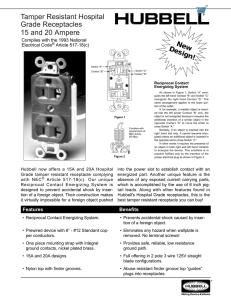

HUBBELL® Safety Product Guide

advertisement